A method for enhancing the surface of metal rolls by electrospark deposition combined with plasma cladding

A plasma cladding and electric spark deposition technology, applied in the field of metal rolls, can solve the problems of poor heat resistance of the quenching hardened layer, poor bonding between the coating and the substrate, and high maintenance costs, and achieve good heat resistance and wear resistance. Excellent wear and heat resistance, good anti-wear and anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In the specific implementation of the present invention, it is realized by the following steps:

[0016] (1) Preparation of iron-nickel alloy powder, the alloy powder is calculated by weight percentage: Ni31%, Cr28%, C1.5%, Mo4%, B2.8%, Si4%, W3% and the balance is Fe The powder is mixed together, and the particle size is 106-180mm;

[0017] (2) Use plasma cladding wear-resistant equipment to clad iron-nickel alloy powder layer on the surface of the roll, input power supply voltage: 380V±10%, rated input capacity: 30KVA, output voltage: 75V, working voltage: 10 ~ 30V, output Power 12-15KW, output current: 300~600A, scanning speed: 300~600mm / min, powder feeder airflow: 0.65~0.75m 3 / h, powder feeding rate is 250-300g / min, ion gas flow rate: 0.6~0.9m 3 / h, protective gas flow: 0.65 ~ 0.75m 3 / h, the diameter of the nozzle is 5mm, and the distance between the nozzle and the workpiece is 28-32mm;

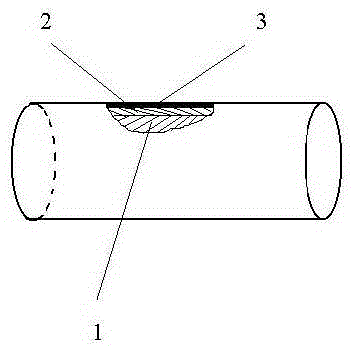

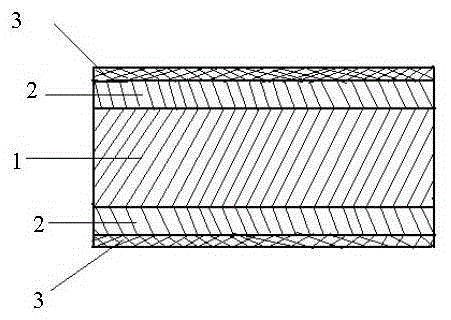

[0018] (3) The method of cladding the iron-nickel alloy powder layer 2 i...

Embodiment 2

[0021] In the specific implementation of the present invention, the iron-nickel alloy powder can also be calculated by weight percentage: Ni32%, Cr26%, C2%, Mo3%, B3%, Si3.5%, W4.5% and the remainder It is Fe powder, which is mixed together to form, and the others are the same as in Example 1.

Embodiment 3

[0023] In the specific implementation of the present invention, the iron-nickel alloy powder can also be calculated by weight percentage: Ni31%, Cr30%, C1%, Mo4.5%, B2.5%, Si5%, W2% and the balance It is Fe powder, which is mixed together to form, and the others are the same as in Example 1.

[0024] After experiments and tests of the present invention, a large number of nano-amorphous microcrystalline particles appear in the coating, and the coating density is high; the high temperature of 16000 ℃ in plasma cladding and 25000 ℃ in electric spark deposition causes the composite coating and the substrate to produce coating incompatibility. The metallurgical bond that will fall off; the surface hardness of the coating can reach 1707.6HV ~ 2084.1HV, while the hardness of the substrate is 352.1HV, the hardness of the coating can be increased by 4-6 times than that of the substrate; the wear resistance of the composite coating is higher than The wear resistance of the matrix can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com