A method for in-situ preparation of TICN coating on the surface of titanium alloy

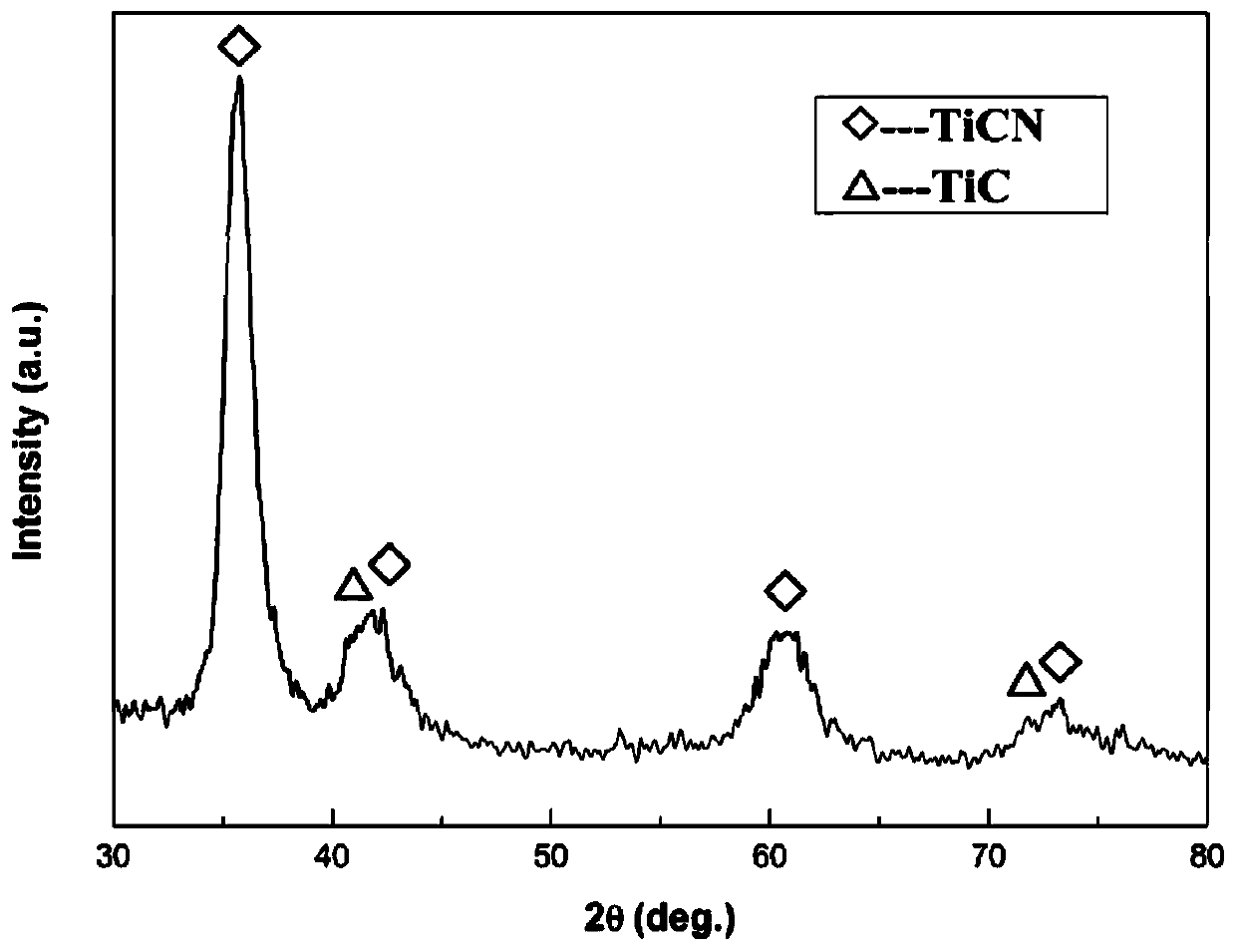

An in-situ preparation, titanium alloy technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low TiCN coating adhesion, poor corrosion resistance, slow coating growth, etc. The effect of good corrosion resistance, simplified preparation process and fast coating growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] Step 1. Mechanically clean the surface of the titanium alloy workpiece (Ti-6Al-4V) to be treated until the surface roughness of the titanium alloy workpiece is less than 3.2 μm, and then evenly apply a layer of Vaseline paste. The thickness of the Vaseline paste is controlled at 40 μm ;

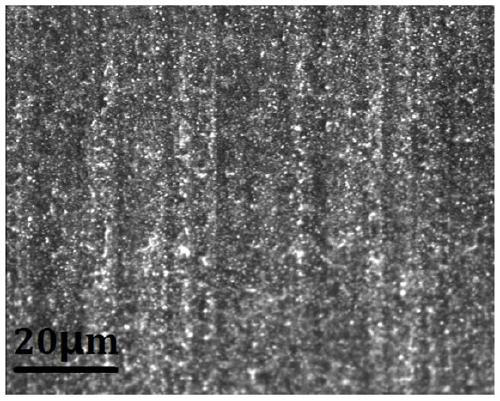

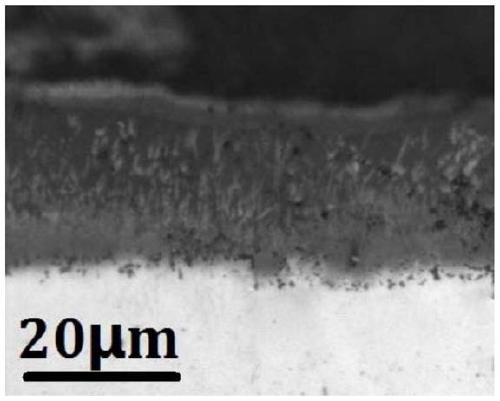

[0023] Step 2, the area where the titanium alloy workpiece described in step 1 is coated with vaseline paste is under the protection of nitrogen atmosphere, the pressure of nitrogen is 0.1MPa, placed in the laser action area of the pulsed YAG laser, the lens focal length of the pulsed YAG laser is selected 183mm , turn on the power supply of the pulsed YAG laser, and carry out laser irradiation on the area where the titanium alloy workpiece is coated with vaseline paste. During the laser irradiation process, the output pulse width of the pulsed YAG laser is controlled to be 200ns, and the frequency is 400kHz. It is 200mm / s, the ...

Embodiment 2

[0027] This embodiment includes the following steps:

[0028] Step 1. Mechanically clean the surface of the titanium alloy workpiece (Ti-6Al-4V) to be treated until the surface roughness of the titanium alloy workpiece is less than 3.2 μm, and then evenly apply a layer of Vaseline paste. The thickness of the Vaseline paste is controlled at 10 μm ;

[0029] Step 2, the area where the titanium alloy workpiece described in step 1 is coated with vaseline paste is under the protection of nitrogen atmosphere, the pressure of nitrogen is 0.2MPa, placed in the laser action area of the pulsed YAG laser, the focal length of the lens of the pulsed YAG laser is selected 183mm , turn on the power supply of the pulsed YAG laser, and carry out laser irradiation on the area where the titanium alloy workpiece is coated with vaseline paste. During the laser irradiation process, the output pulse width of the pulsed YAG laser is controlled to be 100ns, and the frequency is 1000kHz. 200mm / s, th...

Embodiment 3

[0032] This embodiment includes the following steps:

[0033] Step 1. Mechanically clean the surface of the titanium alloy workpiece (Ti-4Al-0.005B) to be treated until the surface roughness of the titanium alloy workpiece is less than 3.2 μm, and then evenly apply a layer of Vaseline paste. The thickness of the Vaseline paste is controlled at 160μm;

[0034] Step 2, the area where the titanium alloy workpiece described in step 1 is coated with vaseline paste is under the protection of nitrogen atmosphere, the pressure of nitrogen is 0.5MPa, placed in the laser action area of the pulsed YAG laser, the lens focal length of the pulsed YAG laser is selected 183mm , turn on the power supply of the pulsed YAG laser, and carry out laser irradiation on the area where the titanium alloy workpiece is coated with vaseline paste. During the laser irradiation process, the output pulse width of the pulsed YAG laser is controlled to be 20ns, and the frequency is 200kHz. It is 1600mm / s, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com