A hot extrusion die permeation-plating compound surface strengthening method

A technology of hot extrusion die and composite surface, applied in arc ion plating CrAlN coating composite strengthening design and process realization, hot extrusion die plating compound surface strengthening, gas nitriding layer, hot extrusion die surface strengthening application fields , which can solve the problems that the first two processes cannot be combined and applied, and achieve the effect of better strengthening effect, satisfying wear resistance and increasing coating thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] This embodiment provides a kind of process method of preparing the permeation-plating composite layer on the surface of the aluminum profile hot extrusion die and the sample block made of H13 material. It should be noted that the permeation-plating composite layer prepared by the method of the present invention can be used in Any type of hot extrusion die and workpiece made of H13 material is not limited to this embodiment.

[0048] The concrete preparation process of this embodiment is:

[0049] 1) The hot extrusion die and sample block made of H13 material with hardness HRC=43 after quenching at 1070°C + tempering at 530°C for three times (H13 material composition: 4Cr5MoV1Si, mold size: φ260×80mm, sample block size : φ30×10mm) as a sample, after surface degreasing and polishing, immerse in acetone for ultrasonic cleaning, and alcohol dehydration.

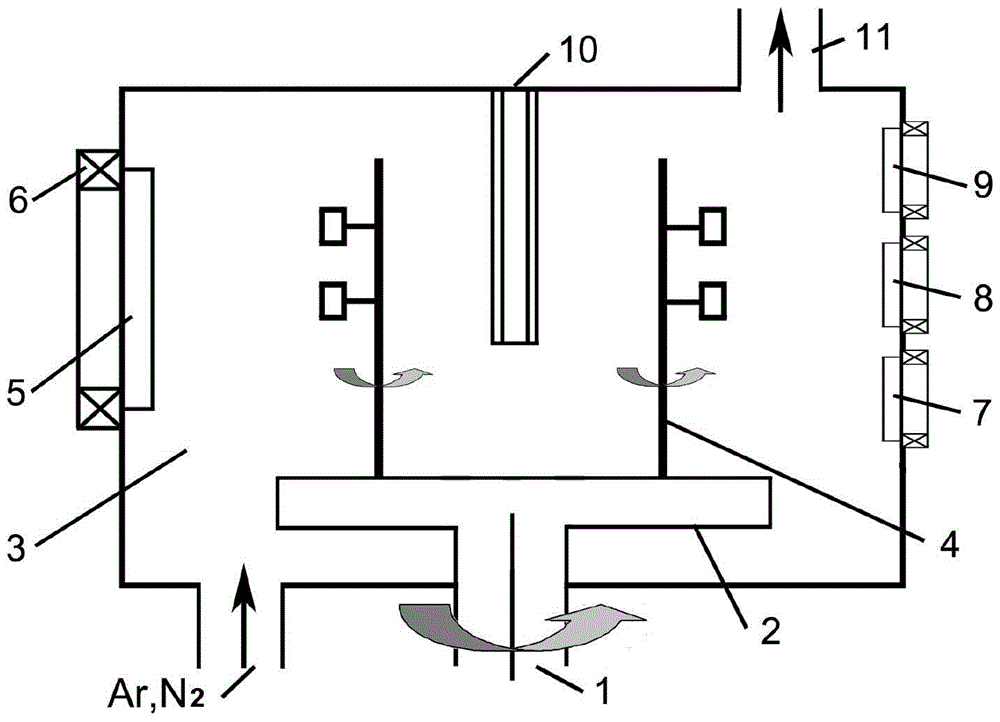

[0050] 2) Put the pretreated sample into the gas nitriding furnace for nitriding treatment. The nitriding equipment inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| anti-oxidation temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com