Epoxy resin-modified acrylic resin double-curing system needle adhesive and preparation method thereof

A technology of acrylic resin and epoxy resin, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of slow curing speed of single-component epoxy needle glue, complicated equipment, large heat loss, etc., and achieve The effect of simplifying production equipment, easy operation and reducing production cost of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

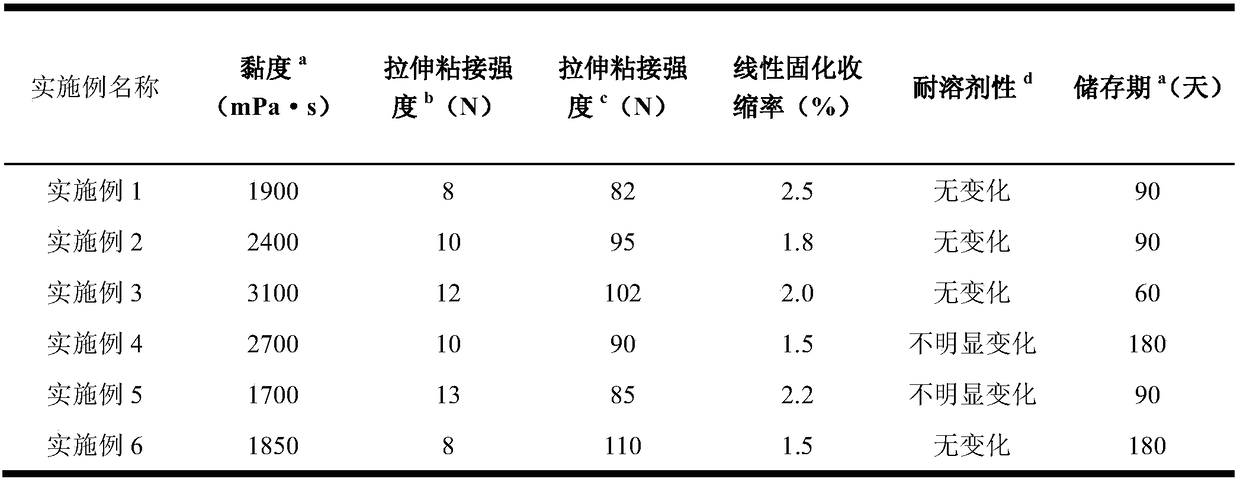

Examples

Embodiment 1

[0034] With 80 parts by weight of E-51, 5 parts by weight of polyurethane acrylate, 2 parts by weight of butyl glycidyl ether, 3 parts by weight of isobornyl acrylate, 6 parts by weight of propylene oxide modified dicyandiamide, 3.7 parts by weight Parts by weight of 4-hydroxybenzoyl hydrazide, 0.2 parts by weight of 2,4,6-trimethylbenzoyl diphenylphosphine oxide, 0.1 parts by weight of ethyl 4-dimethylaminobenzoate, mixed and protected from light Stir evenly to obtain a dual-cure system needle glue.

Embodiment 2

[0036] 40 parts by weight of E-44, 25 parts by weight of epoxy acrylate, 5 parts by weight of benzyl glycidyl ether, 5 parts by weight of o-cresyl glycidyl ether, 15 parts by weight of methacrylic acid-β-hydroxy Ethyl ester, 8 parts by weight of dicyandiamide, 1.5 parts by weight of photoinitiator 1-hydroxycyclohexyl phenyl ketone, and 0.5 parts by weight of triethanolamine were mixed in the dark and stirred evenly to obtain a dual-cure system needle glue.

Embodiment 3

[0038] 50 parts by weight of E-51, 15 parts by weight of polyester acrylate, 10 parts by weight of polypropylene glycol diglycidyl ether, 10 parts by weight of C12 fatty glycidyl ether, 2 parts by weight of 1,6-hexanediol Diacrylate, 5 parts by weight of modified imidazole, 4 parts by weight of modified dicyandiamide, 2 parts by weight of isophthalic acid hydrazide, 1.5 parts by weight of photoinitiator 2-hydroxyl-2-methyl-1 -Phenyl-1-propanone and 0.5 parts by weight of N,N-dimethylaminobenzamide were mixed in the dark and stirred evenly to obtain a dual-curing system needle glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com