A kind of near-infrared curing polyurethane acrylate adhesive

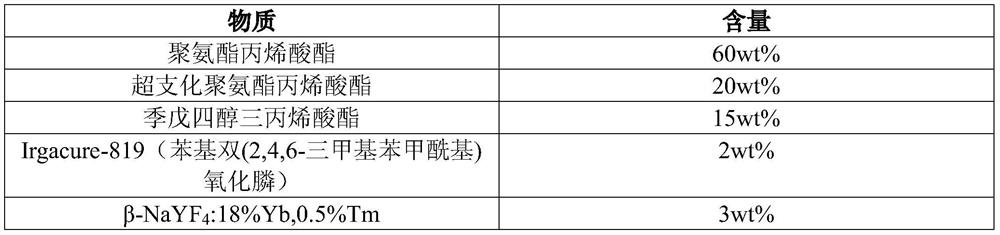

A polyurethane acrylate, hyperbranched polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low viscosity, difficult curing, limited UV curing depth, etc. The effect of viscosity, low viscosity and high depth of cure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 hyperbranched polyurethane acrylate

[0030] S1 Mix 55.55g of isophorone diisocyanate and 55.55g of N,N-dimethylacetamide solution, and when the solution is cooled to 0°C, slowly add 26.28g of diethanolamine and 26.28g of N,N-dimethylacetamide Solution, react at 0°C for 2 hours after dropping; slowly raise the temperature to 50°C, and measure the NCO content every 20 minutes. When the measured NCO content is close to the theoretical value of 6%, add excess amino silicone oil, and finally use The hyperbranched polyurethane with 2 terminal hydroxyl groups was obtained after sedimentation separation with anhydrous ether and vacuum drying. Hydroxyl value determined by acetic anhydride-pyridine titration.

[0031] S2 At 60°C, under nitrogen, add 55.55g of isophorone diisocyanate and 55.55g of N,N-dimethylacetamide solution, slowly drop 25g of polyethylene glycol 200 and 25g of N,N-dimethylacetamide solution, when the NCO value reaches 50% of...

Embodiment 2

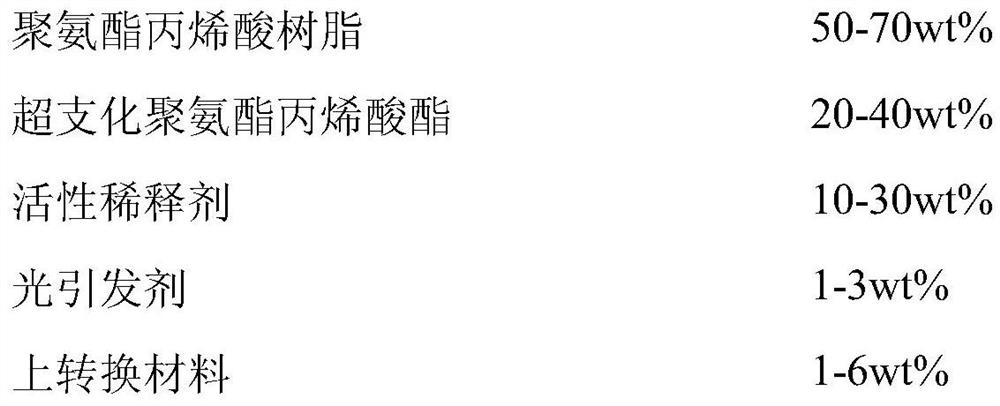

[0034] Embodiment 2 near-infrared curing polyurethane acrylate adhesive

[0035] Prepare according to the content of the substances in Table 1 and mix evenly under dark conditions to obtain Adhesive-1.

[0036] Table 1 Adhesive-1 formulation

[0037]

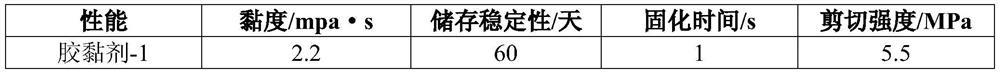

[0038] Coat the adhesive-1 on the organic plastic sheet, cover with another organic plastic sheet, control the thickness at 2mm, and irradiate it under near-infrared light.

Embodiment 3

[0039] Embodiment 3 near-infrared curing polyurethane acrylate adhesive

[0040] Prepare according to the content of the substances in Table 2 and mix evenly under dark conditions to obtain Adhesive-2.

[0041] Table 2 Adhesive-2 formulation

[0042] substance content urethane acrylate 50wt% hyperbranched urethane acrylate 30wt% trimethylolpropane triacrylate 10wt% Irgacure-784 (bis 2,6-difluoro-3-pyrrolephenyl titanocene) 3wt% β-NaYF4:18%Yb,0.5%Tm 6wt% carbon black 1wt%

[0043] Coat the adhesive-1 on the organic plastic sheet, cover with another organic plastic sheet, control the thickness at 2mm, and irradiate it under near-infrared light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com