Low-shrinkage heat-conducting flame-retardant double-component condensed type organosilicone pouring sealant, and preparation method and application thereof

A silicone potting glue, two-component technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc. requirements, inability to export heat well, etc., to achieve the effects of fast deep curing, good mechanical properties, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

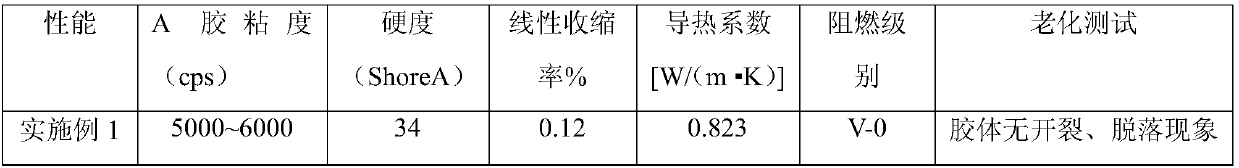

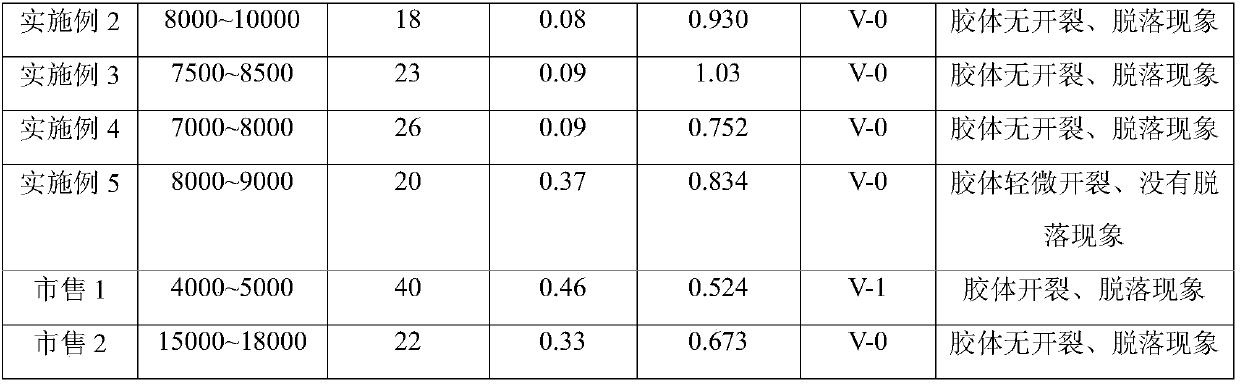

Examples

Embodiment 1

[0037](1) 100 parts by weight of viscosity is 107 glue of 500cps, 3 parts by weight of fumed silica, 80 parts by weight of aluminum oxide, 100 parts by weight of aluminum hydroxide, 3 parts by weight of hexamethyldisiloxane and 20 parts by weight of polyacetic acid Vinyl ester is added to the vacuum kneader, blended for 30-90 minutes, then heated up to 150°C, and reacted for 4 hours. After the reaction, stand to cool, and grind 1-3 times with a three-roll machine to obtain the base rubber;

[0038] (2) Add 100 parts by weight of base rubber obtained in step (1), 30 parts by weight of simethicone oil (viscosity 100cps), 0.3 parts by weight of carbon black, and 0.2 parts by weight of deionized water into the kettle, stir evenly, evacuate, and cool to normal temperature, component A can be prepared;

[0039] (3) 60 parts by weight of tetraethoxysilane, 30 parts by weight of vinyl triethoxysilane, 20 parts by weight of γ-glycidyl etheroxypropyl trimethoxysilane, 0.5 parts by weigh...

Embodiment 2

[0042] (1) 100 parts by weight of 107 glue with a viscosity of 5000cps, 10 parts by weight of precipitated silica, 45 parts by weight of alumina, 20 parts by weight of boron nitride, 40 parts by weight of aluminum hydroxide, 20 parts by weight of antimony oxide, 10 parts by weight of 3 parts by weight of hexamethyldisiloxane and 3 parts by weight of hollow glass microspheres were added to a vacuum kneader, blended for 30-90 minutes, then heated up to 150°C, and reacted for 4 hours. Roller grinding 1-3 times to obtain base rubber;

[0043] (2) 100 parts by weight of base rubber obtained in step (1), 80 parts by weight of methyl silicone oil (viscosity 50cps), 1 part by weight of carbon black, and 1 part by weight of deionized water are added to the kettle, stirred evenly, vacuumized, and cooled to At normal temperature, component A can be prepared;

[0044] (3) 150 parts by weight of tetraethoxysilane, 50 parts by weight of vinyltriethoxysilane, 25 parts by weight of γ-glycidy...

Embodiment 3

[0047] (1) 100 parts by weight of viscosity is 2500cps part 107 glue, 3 parts by weight of fumed silica, 5 parts by weight of precipitated silica, 35 parts by weight of boron nitride, 20 parts by weight of aluminum nitride, 20 parts by weight of zinc borate, Add 7 parts by weight of hexamethyldisiloxane and 10 parts by weight of polyvinyl acetate into a vacuum kneader, blend for 30-90 minutes, then raise the temperature to 150°C, and react for 4 hours. After the reaction is completed, let it stand for cooling. Use a three-roll machine to grind 1-3 times to obtain the base rubber;

[0048] (2) Add 100 parts by weight of the base glue obtained in step (1), 50 parts by weight of methyl silicone oil (viscosity 50cps), 0.5 parts by weight of carbon black, and 0.1 parts by weight of calcium glycerophosphate into the kettle, stir evenly, evacuate, and cool to At normal temperature, component A can be prepared;

[0049] (3) 120 parts by weight of tetraethoxysilane, 20 parts by weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com