Furniture paint spraying method and lacquer furniture

A furniture spraying and furniture technology, applied in the field of painting, can solve the problem of low yield rate and achieve the effect of improving yield rate, promoting diffusion, and avoiding excessive viscosity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0036] In order to solve the problems of the prior art, the embodiment of the present invention provides a furniture painting method and painting furniture. The first furniture painting method provided by the embodiment of the present invention will be introduced below.

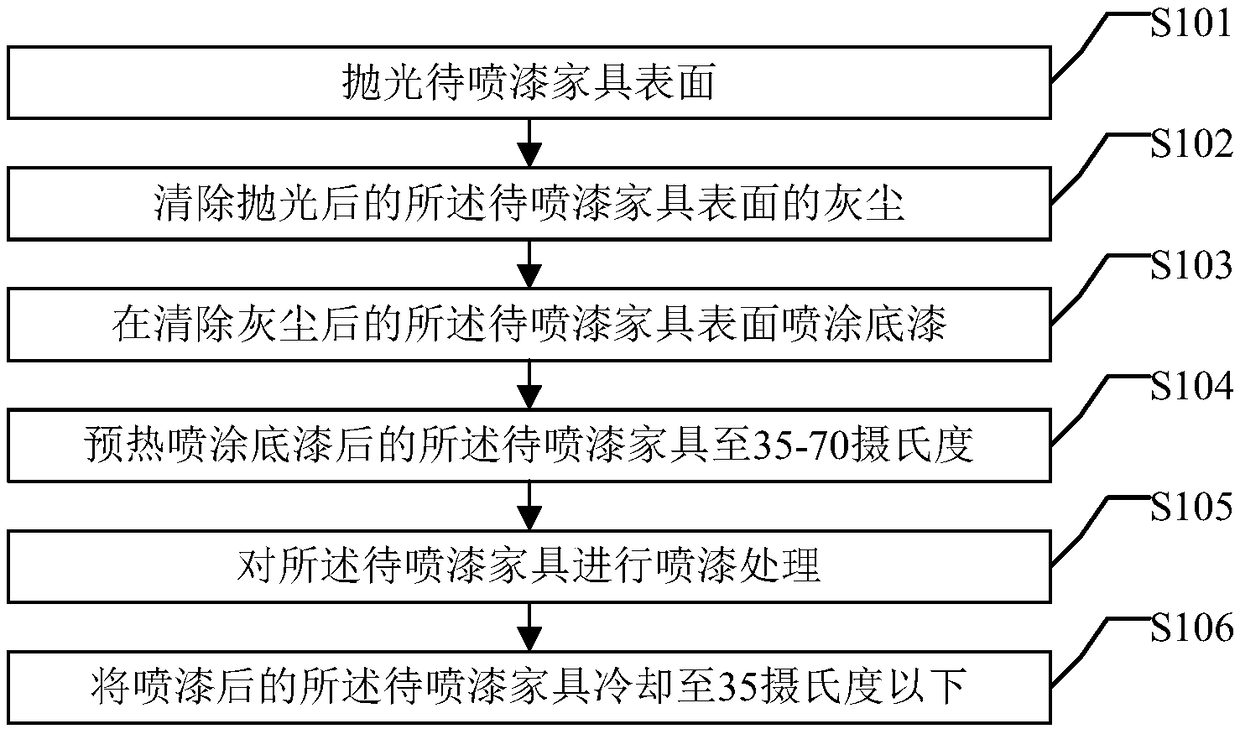

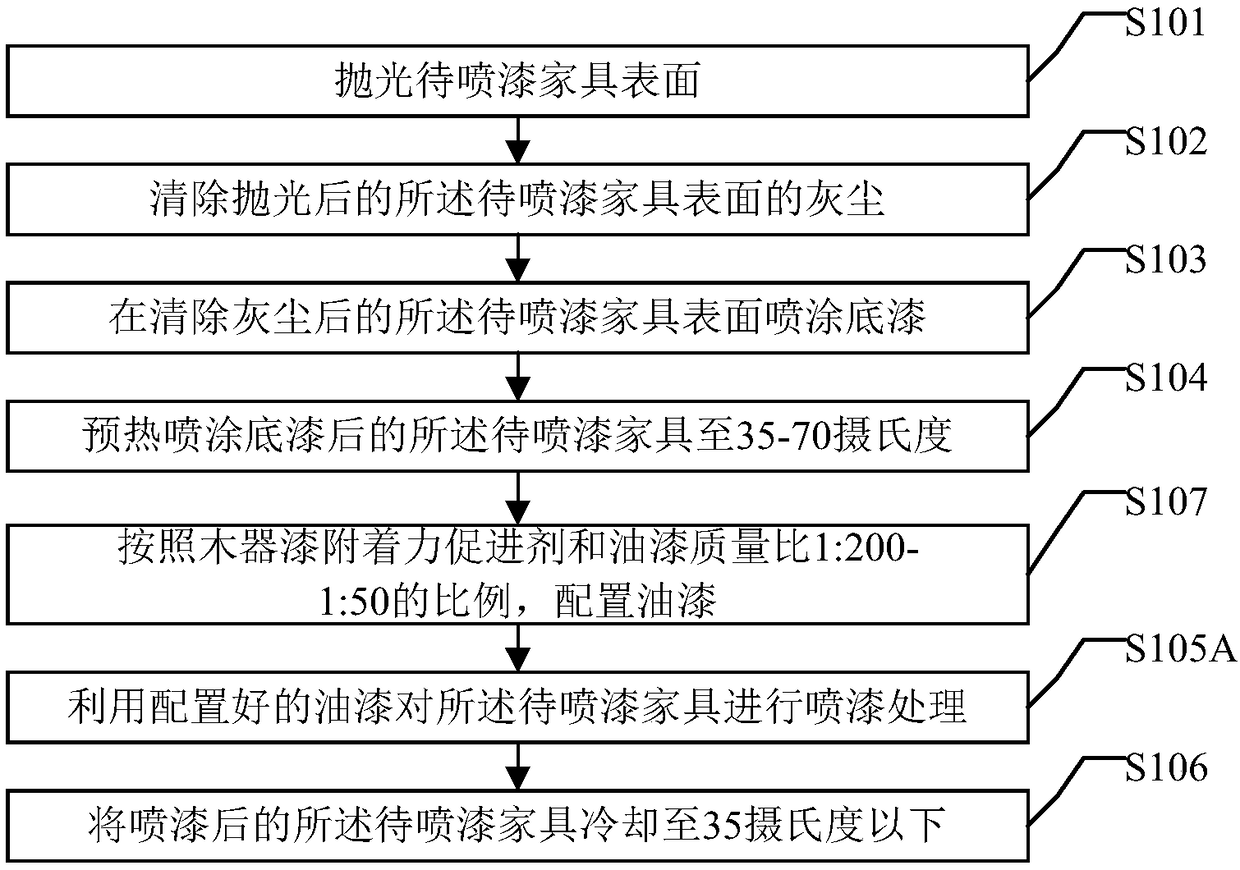

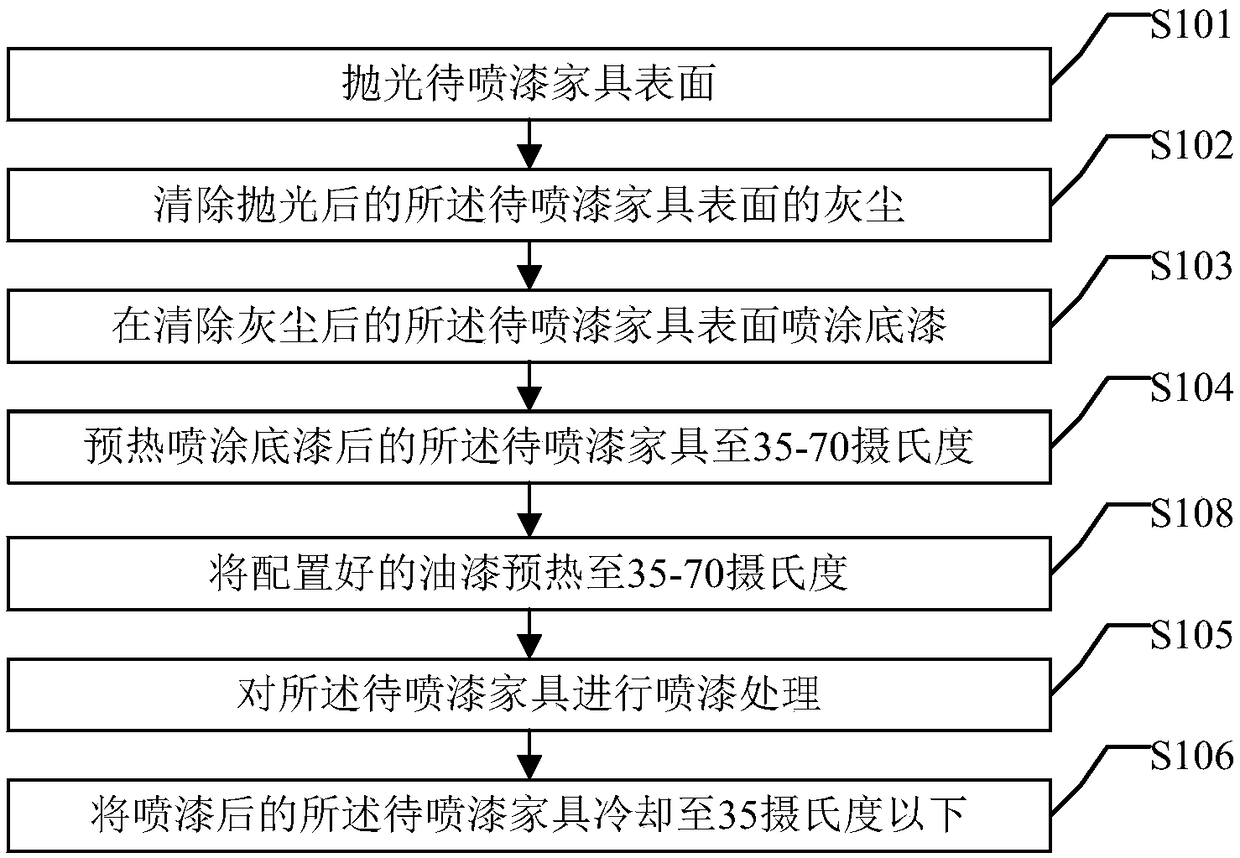

[0037] figure 1 The schematic flow sheet of a kind of furniture painting method that the embodiment of the present invention provides, as figure 1 As shown, the method includes:

[0038] S101: Polishing the surface of the furniture to be painted.

[0039] Specifically, No. 400-600 sandpaper can be used to perform rough polishing on the furnitur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com