Ballastless track CA (cement and asphalt) mortar layer damage repair resin material and preparation method thereof

A ballastless track and resin material technology is applied in the field of engineering materials for high-speed railway tracks, which can solve the problems of unfavorable repair of CA mortar layer damage, affecting the penetration process of pulp material, and large shrinkage rate of cured products, achieving fast curing, High bond strength, good fluidity and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 A resin material for repairing damage to the CA mortar layer of a ballastless track, which is made of the following raw material ratios: 100 kg of epoxy resin, 30 kg of furfural, 20 kg of acetone, 0.2 kg of saturated ammonia water, 6 kg of toughening agent, accelerator Agent 2kg, coupling agent 1.2kg, surfactant 1kg, compound amine curing agent 40kg, the viscosity of the epoxy resin is 28mPa·s, the accelerator is DMP-30, and the coupling agent is KH- 550, the toughening agent is polysulfide rubber, the surfactant is oleic acid, and the complex amine curing agent is SK-302.

[0022] A method for preparing a resin material for repairing damage to a ballastless track CA mortar layer, the preparation method comprising the following steps:

[0023] A, take furfural, acetone, saturated ammonia water, put furfural and acetone in the reaction kettle, add saturated ammonia water, stir for 10min, generate furfurylidene acetone resin;

[0024] B, take the epoxy resin, a...

Embodiment 2

[0029] Example 2 A resin material for repairing damage to the CA mortar layer of a ballastless track, which is made of the following raw material ratios: 100 kg of epoxy resin, 35 kg of furfural, 23 kg of acetone, 0.25 kg of saturated ammonia, 8 kg of toughening agent, and 1.5kg of epoxy resin, 1.2kg of coupling agent, 1kg of surfactant, 35kg of compound amine curing agent, the viscosity of the epoxy resin is 20mPa·s, the accelerator is DMP-30, and the coupling agent is KH -550, the toughening agent is polysulfide rubber, the surfactant is oleic acid, and the complex amine curing agent is SK-302.

[0030] The preparation method is the same as in Example 1.

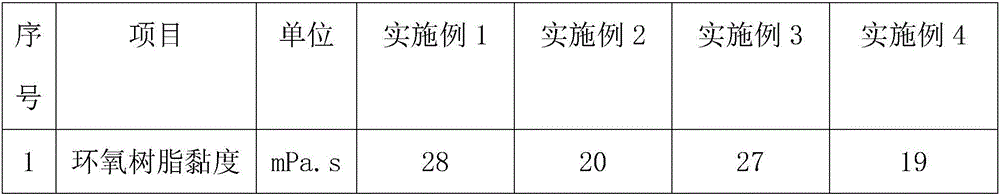

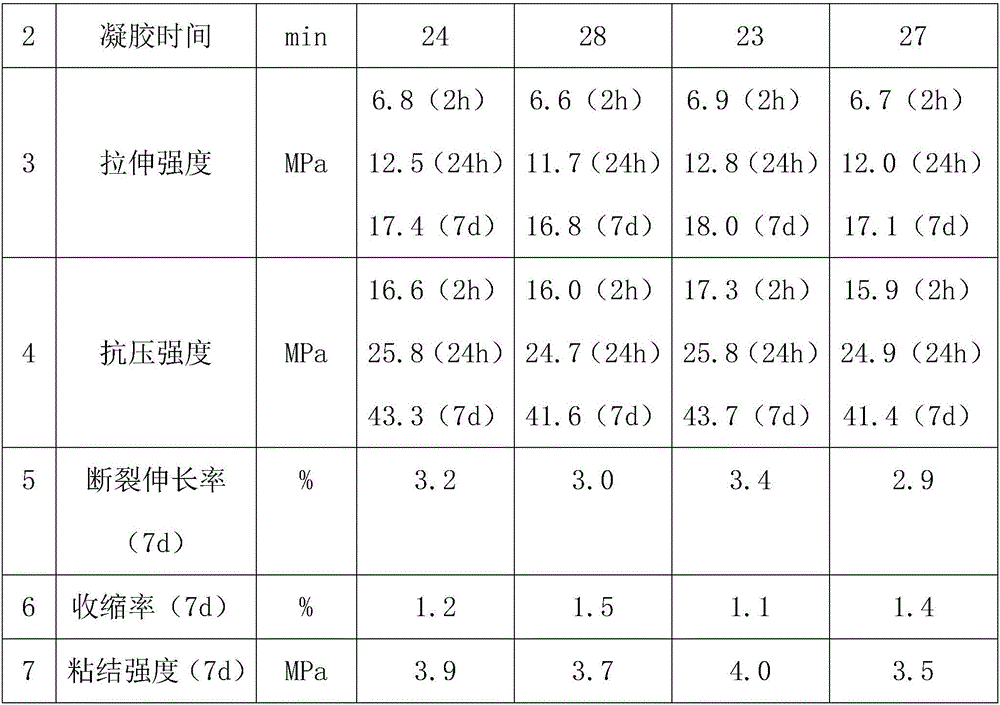

[0031] The resin material for repairing damage to the CA mortar layer of the ballastless track prepared in this example is injected into the cracks of the ballastless track, and the aging test results are shown in Attached Table 1.

Embodiment 3

[0032] Example 3 A resin material for repairing damage to the CA mortar layer of a ballastless track, which is made of the following raw material ratios: 100 kg of epoxy resin, 30 kg of furfural, 20 kg of acetone, 0.2 kg of saturated ammonia water, 4 kg of toughening agent, accelerator Agent 1.5kg, coupling agent 1.2kg, surfactant 1.3kg, complex amine curing agent 45kg, the viscosity of the epoxy resin is 27mPa·s, the accelerator is DMP-30, and the coupling agent is KH-550, the toughening agent is polysulfide rubber, the surfactant is oleic acid, and the complex amine curing agent is SK-302.

[0033] The preparation method is the same as in Example 1.

[0034] The resin material for repairing damage to the CA mortar layer of the ballastless track prepared in this example is injected into the cracks of the ballastless track, and the aging test results are shown in Attached Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com