Patents

Literature

101results about How to "High tensile shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and preparation method of adhesive thereof

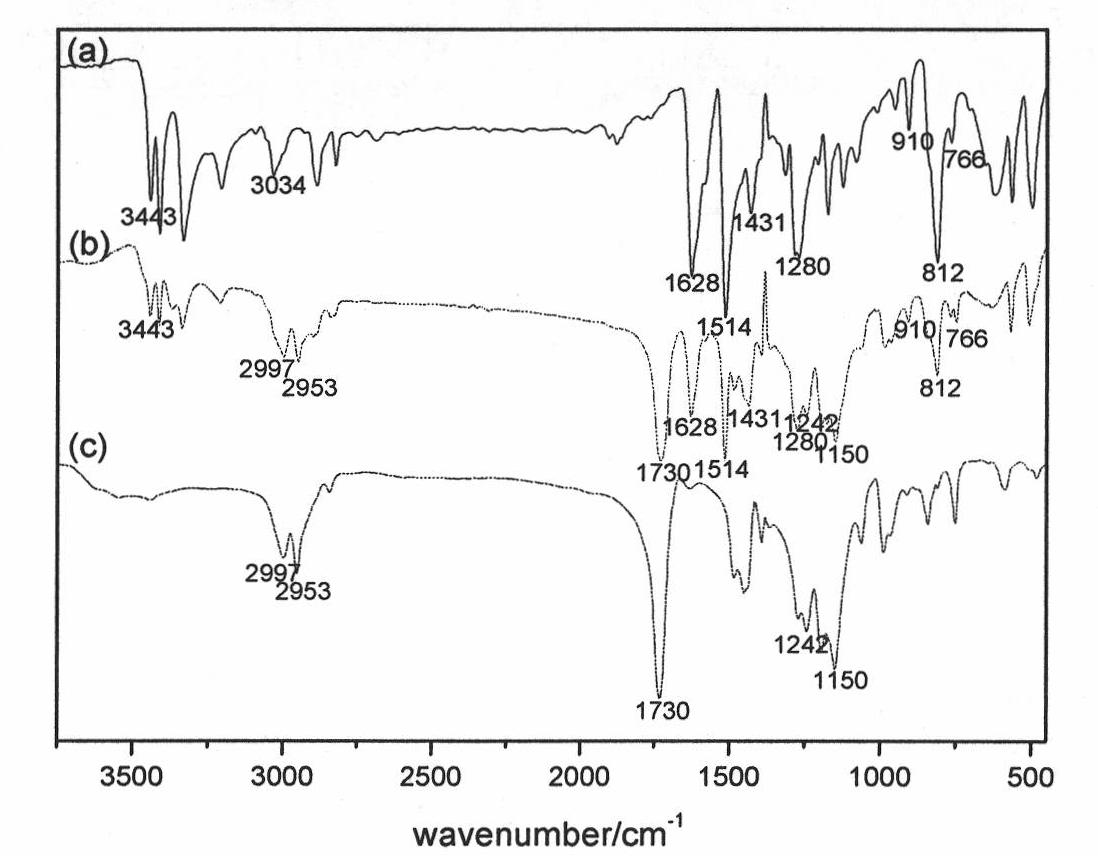

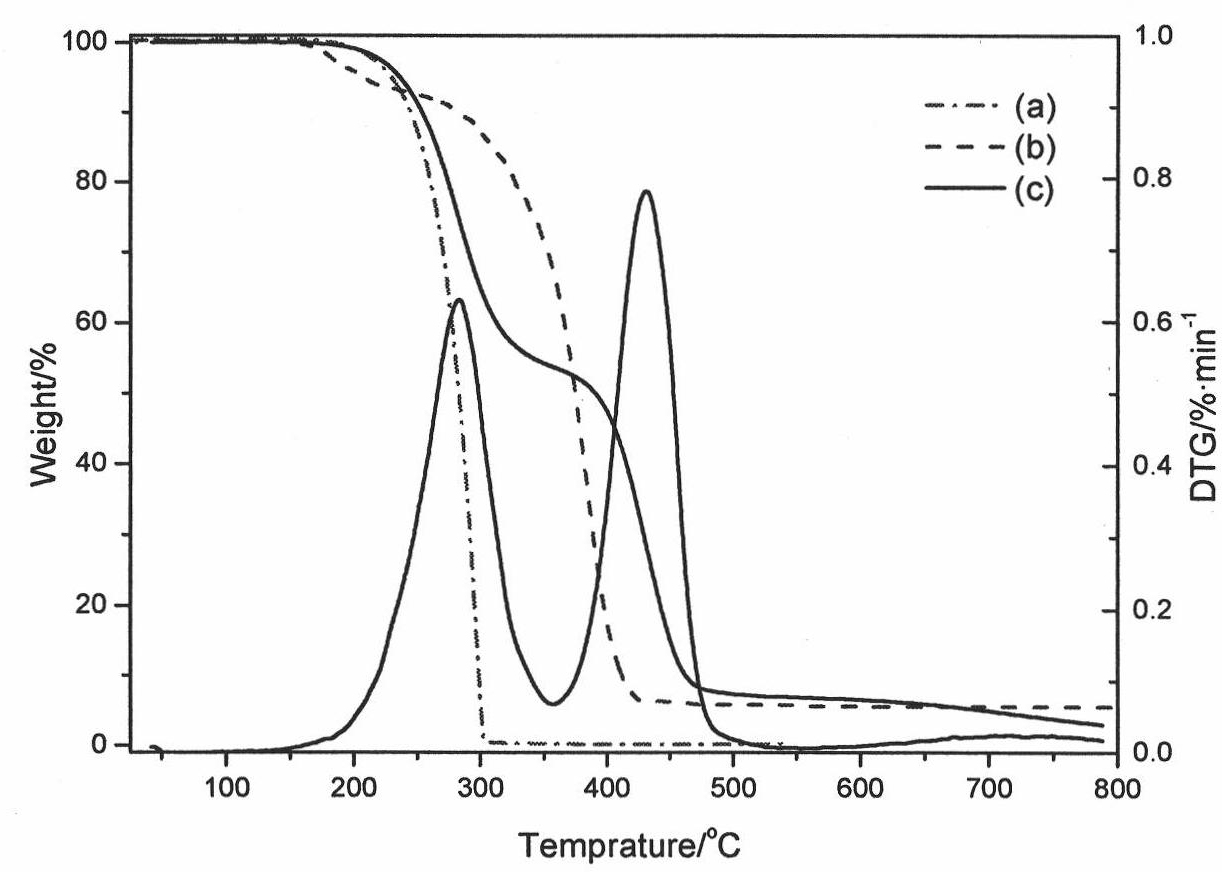

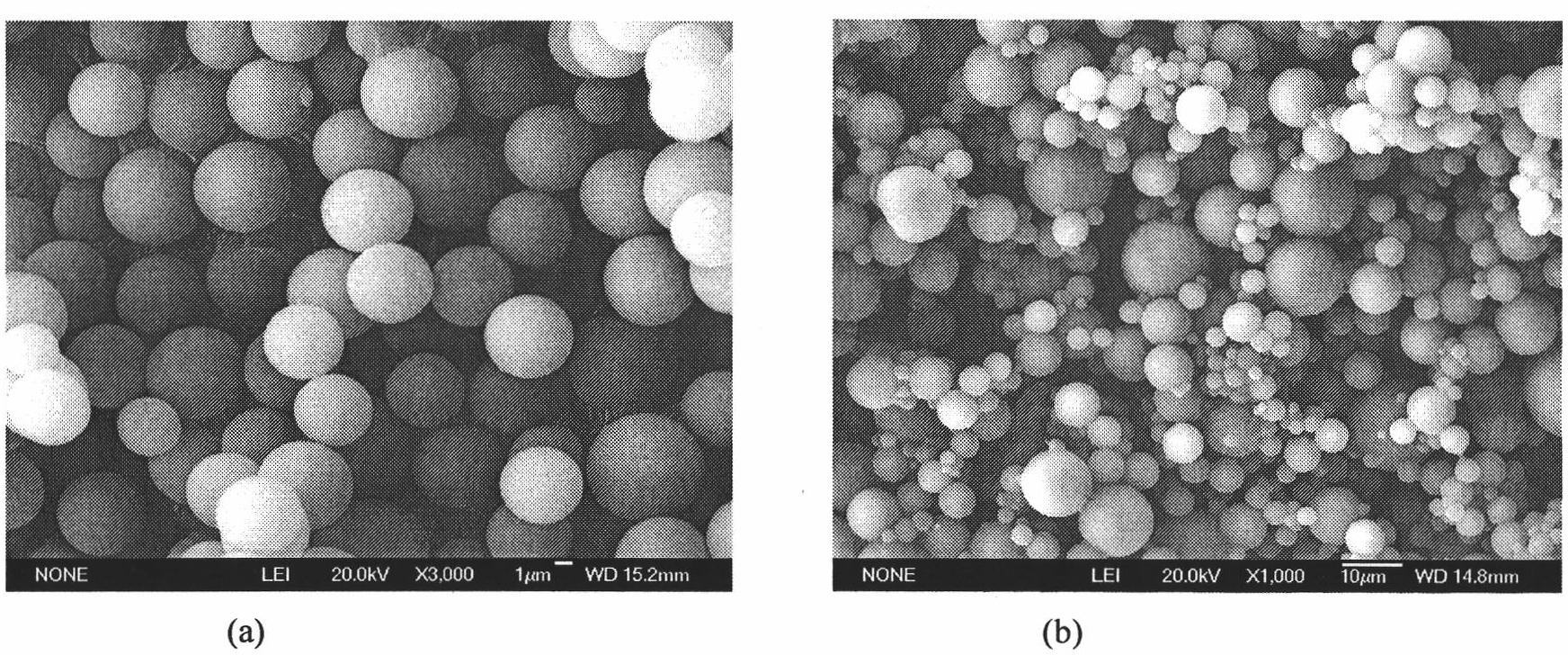

InactiveCN102423673AHigh core contentFlat surfaceMicroballoon preparationMicrocapsule preparationEpoxyMicrosphere

The invention relates to a latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and a preparation method of an adhesive thereof. The latent microcapsule curing agent is technically characterized in that the high-activity medium temperature curing agent is taken as a core material, thermoplastic high polymer microspheres are taken as a wall material, the solvent evaporation technology is adopted for preparing the latent microcapsule curing agent with better curing performance and latent performance, and the latent microcapsule curing agent can be applied to an epoxy resin system for preparing the single-component medium temperature curing epoxy resin adhesive. Microcapsules prepared by the method are high in capsule core content, smooth in surfaces, narrow in particle size distribution and good in compatibility with matrix epoxy resin and can be better dispersed in the epoxy resin; and the prepared single component adhesive can realize curing at the medium temperature, the storage period at room temperature is longer and the tensile shear strength performance can be further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

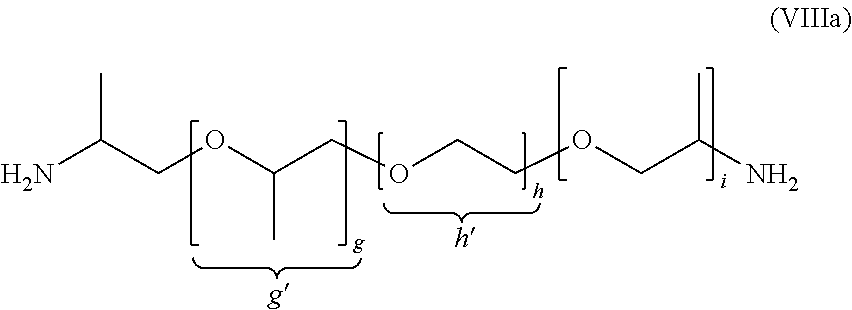

Amino group terminated impact strength modifier and use thereof in epoxy resin compositions

ActiveUS20130037213A1Efficiency and flexibilityHigh tensile shear strengthPolyureas/polyurethane adhesivesLaminationEpoxyUltimate tensile strength

The present disclosure relates to impact strength modifiers, the derivative products thereof, and the use thereof in producing two-component epoxy resin compositions. The disclosure in particular relates to amino group terminated impact strength modifiers prepared by reacting a polyurethane prepolymer having isocyanate groups, a primary diamine, and optionally at least one Michael acceptor. The two-component epoxy resin compositions thus formulated are characterized by a great increase in impact strength while retaining an acceptable tensile shear strength. The impact strength modifiers according to the disclosure and the epoxy resin compositions comprising same are in particular suitable for vehicle manufacturing.

Owner:SIKA TECH AG

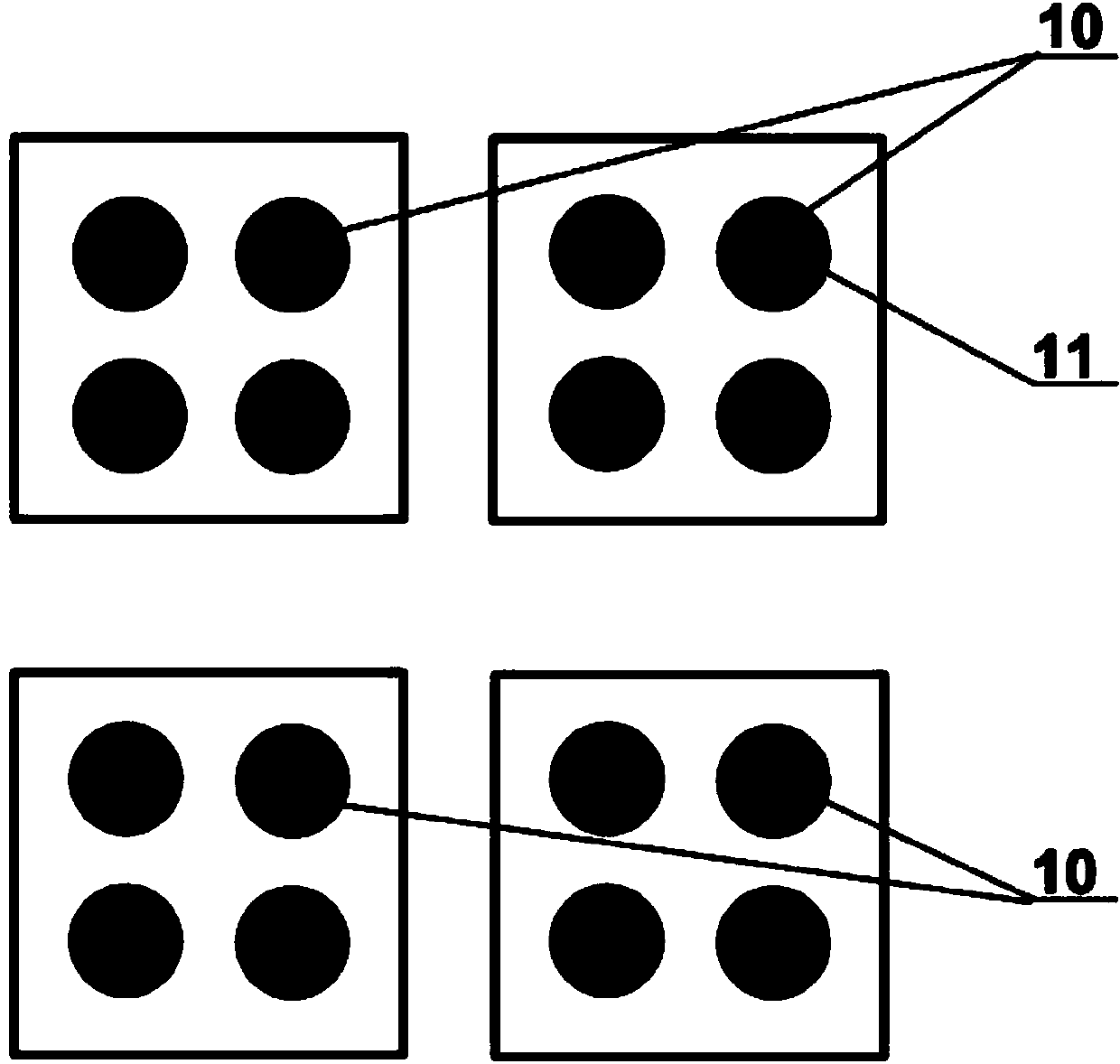

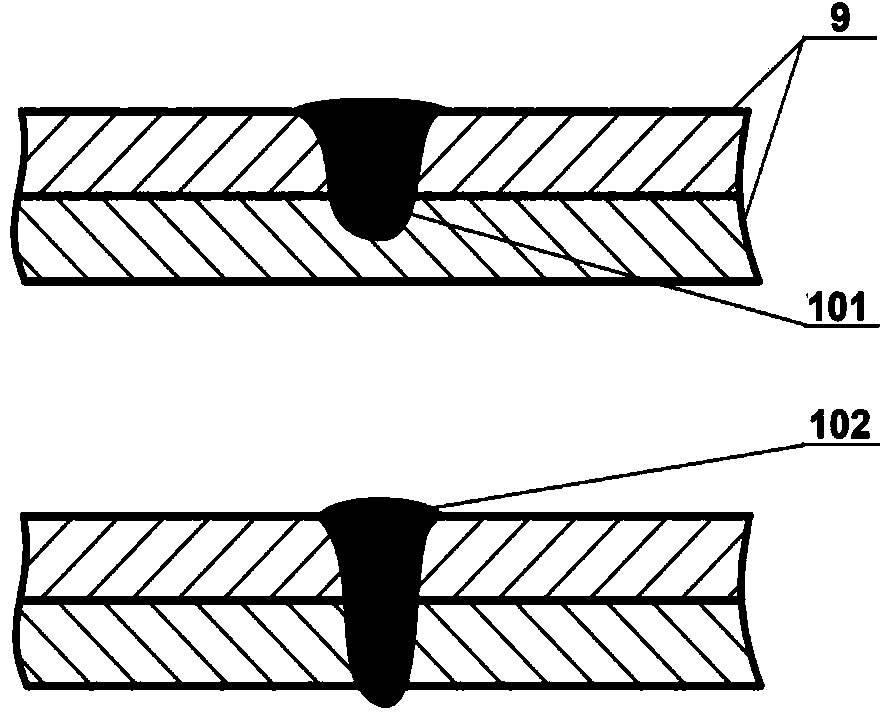

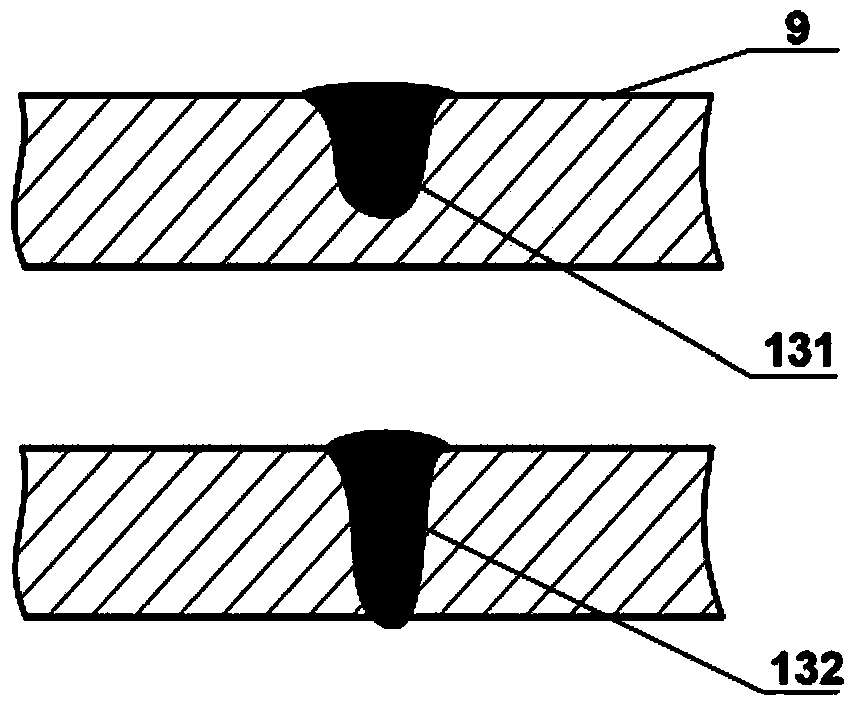

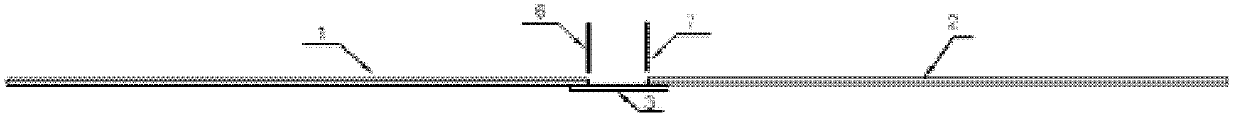

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

Cross-linkable materials based on organyl oxysilane-terminated polymers

ActiveUS20140155545A1Improve responseEasy to produceFilm/foil adhesivesPolyureas/polyurethane adhesivesAdhesiveAlkoxy group

Moisture curable adhesives of high tensile shear strength contain an alkoxysilyl-terminated polymer and an alkoxy-functional silicone resin.

Owner:WACKER CHEM GMBH

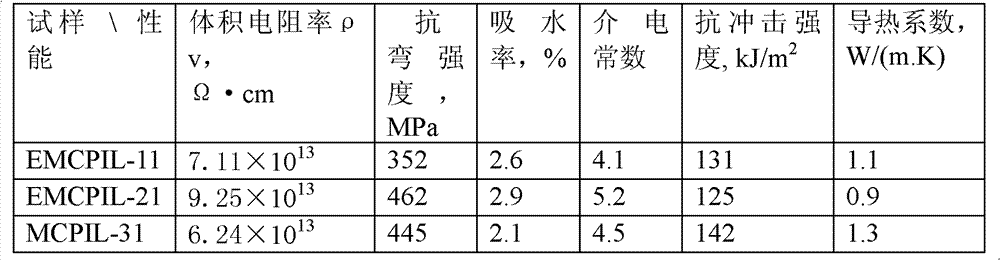

High-toughness high-heat-conduction epoxy-imine resin system and preparation method and application thereof

The invention relates to a high-toughness high-heat-conduction epoxy-imine resin system and a preparation method and application thereof. The high-toughness high-heat-conduction epoxy-imine resin system comprises epoxy resin, carboxyl-containing polyimide resin solution, firming agent, filler and organic solvent in a weight ratio of 100:100-200:30-50:30-50:150-250. The preparation method includes sequentially adding the epoxy resin, the carboxyl-containing polyimide resin solution, the firming agent, the filler and the organic solvent into a mixer, and mixing well to obtain the high-toughness high-heat-conduction epoxy-imine resin system. The high-toughness high-heat-conduction epoxy-imine resin system is applicable to preparation of glass cloth reinforced composite material. The high-toughness high-heat-conduction epoxy-imine resin system is moderate in viscosity and fine in usability. The preparation process is simple and convenient to operate. The glass cloth enhanced composite is high in impact resistance, fine in heat conductivity, high in heat resistance, and fine in electrical insulation.

Owner:DONGHUA UNIV +1

High-temperature resistant copper foil glue and preparation and application thereof

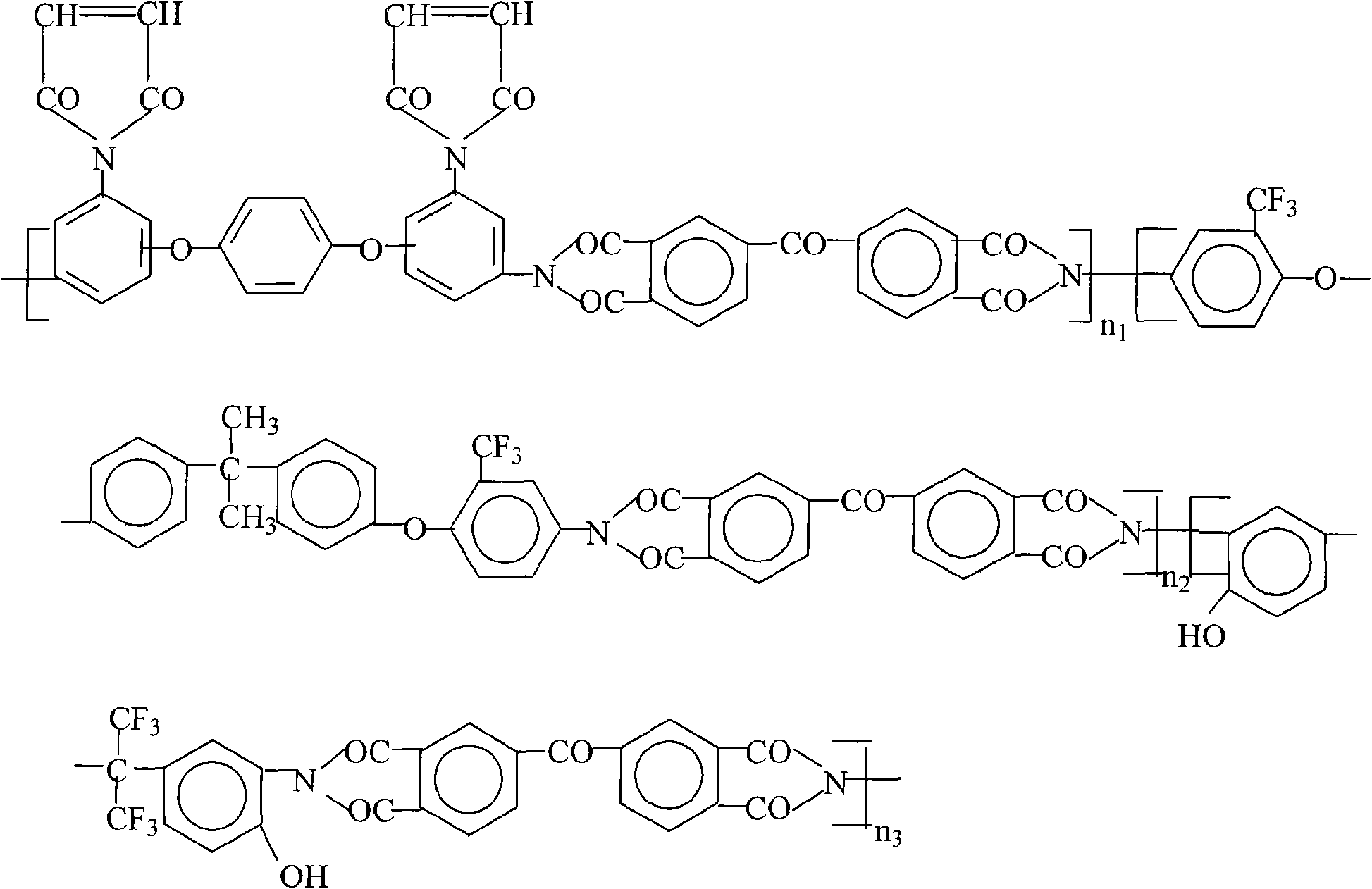

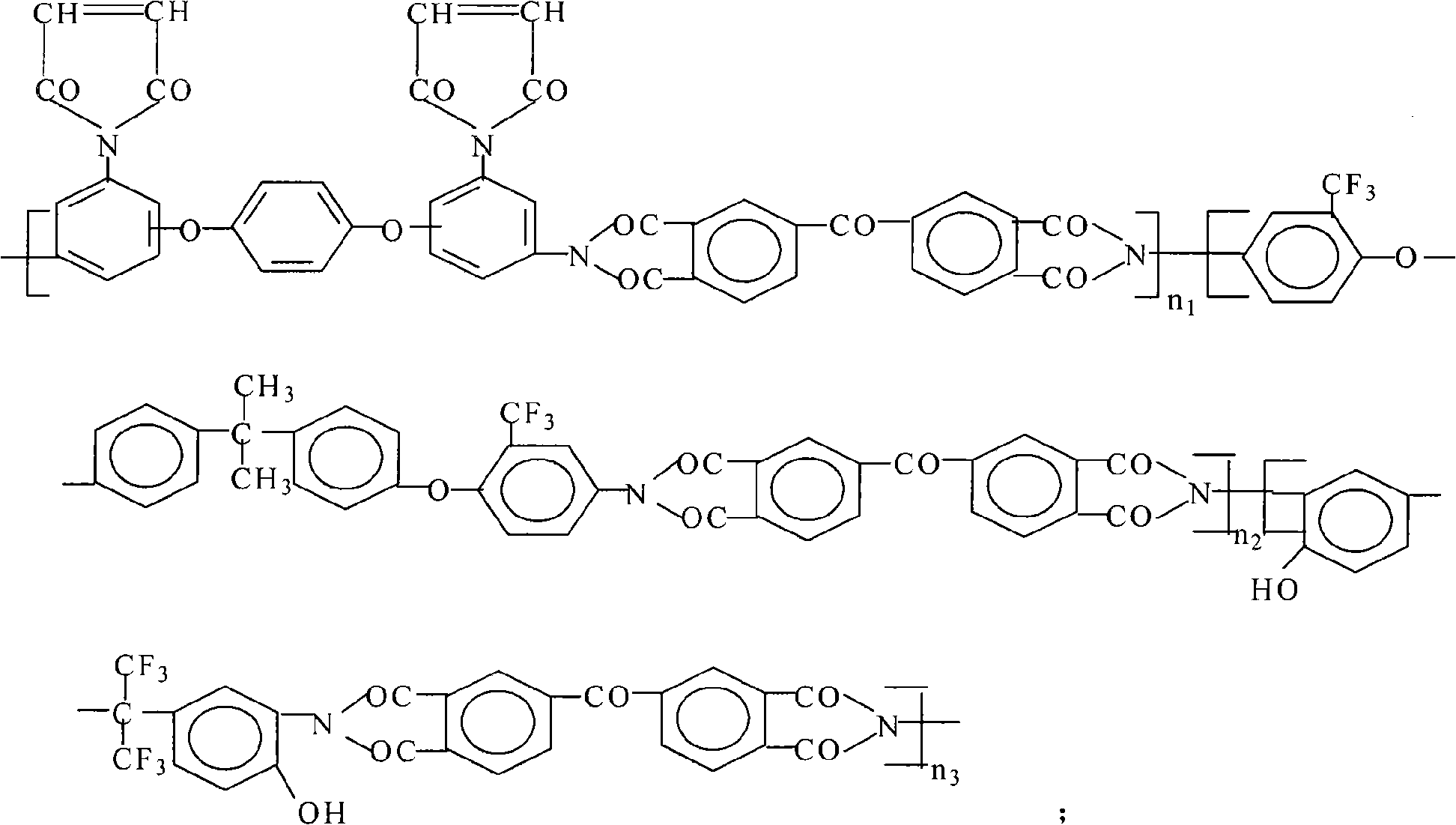

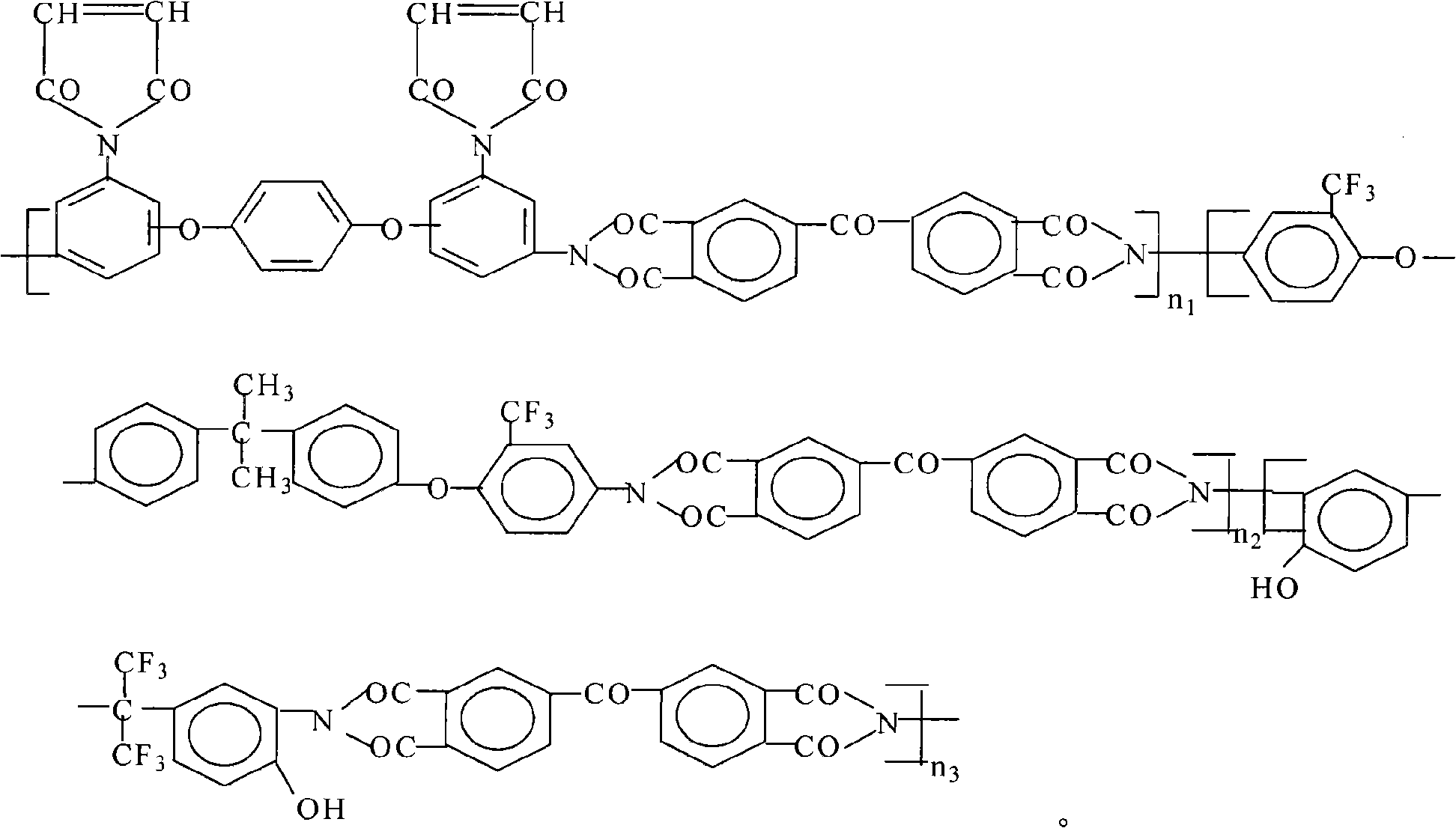

InactiveCN101717613AGood viscosity controllabilityGood workmanshipInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentOrganic solventPolyetherimide

The invention relates to high-temperature resistant copper foil glue containing the following components: 5-15wt percent of trifluoromethyl-contained maleimide resin, 10-30wt percent of polyfunctional ethoxyline resin, 10-40wt percent of bisphenol A epoxy resin, 5-15wt percent of ethylene-contained polyetherimide, 5-10wt percent of curing agent and 25-45wt percent of organic solvent; the preparation comprises the following steps of: adding the trifluoromethyl-contained maleimide resin and the ethylene-contained polyetherimide to the mixture of the polyfunctional ethoxyline resin and the bisphenol A epoxy resin, stirring while heating for reacting, and then cooling to 30-50 DEG C; adding the organic solvent and the curing agent; evenly stirring to obtain the high-temperature resistant copper foil glue the homogeneous phase of which is transparent and clear. The high-temperature resistant copper foil glue has Tonset temperature reaching up to 415 DEG C and excellent comprehensive performance, can be applied to the high-tech fields of electronics and microelectronics, automobiles, electrical machines, aerospace and the like; moreover, the invention has simple preparation process, low cost, convenient operation and available reaction raw materials, thereby being beneficial to realizing industrial production.

Owner:DONGHUA UNIV

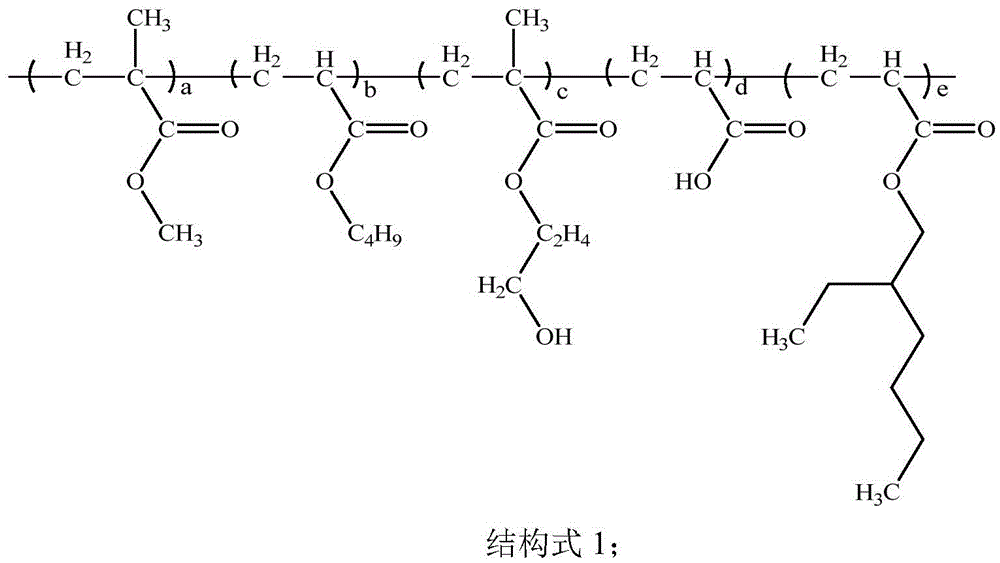

Acrylate structure adhesive and preparation method thereof

The invention discloses a novel acrylate structure adhesive and a preparation method thereof. The two-component acrylate structure adhesive comprises components A and B, wherein the volume ratio of the component A to the component B is (10-2):1; the component A comprises 55 to 75 parts of acrylate monomer, 0 to 25 parts of toughening agent, 10 to 35 parts of oligomer, 0.1 to 5 parts of reducing agent, 0.1 to 2 parts of stabilizer, and 0.1 to 10 parts of aids; and the component B comprises 15 to 50 parts of oxidant, 15 to 25 parts of toughening agent, 15 to 50 parts of plasticizer, and 0.1 to 10 parts of aids. Compared with the conventional acrylate adhesive (SGA), the novel acrylate structure adhesive prepared by the method has the advantages that under the condition of guaranteeing the same tensile shear strength, the elongation at break is over 30%, which is much higher than the 5% of elongation at break of common acrylate adhesives available in the market.

Owner:康达新材料(集团)股份有限公司

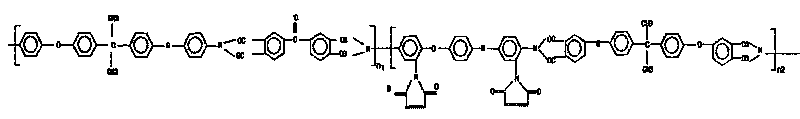

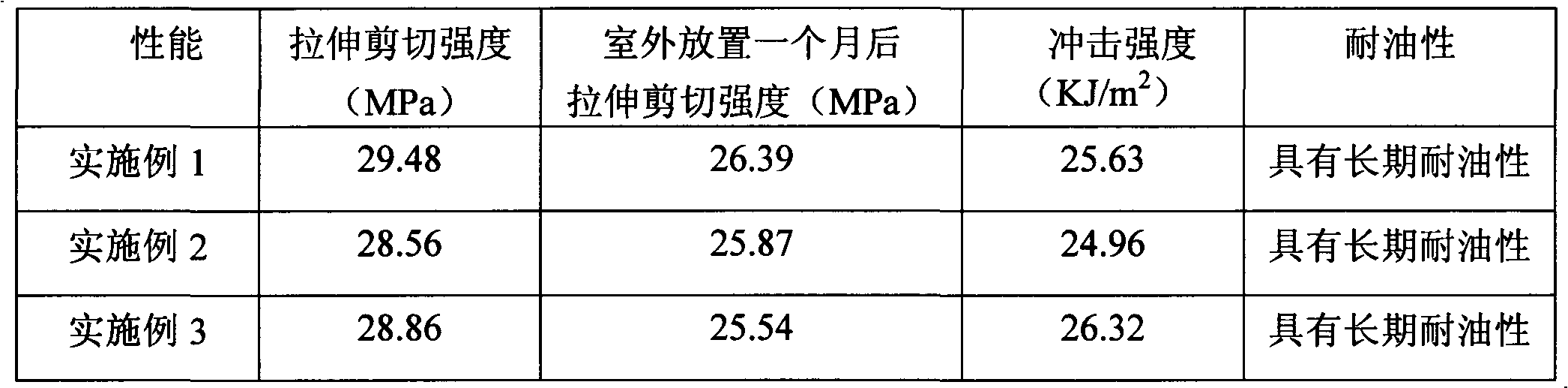

Polyimide-epoxy resin adhesive and preparation method and application thereof

InactiveCN101629062ASimple preparation processLow costEpoxy resin adhesivesMicroelectronicsChemistry

The invention relates to a polyimide-epoxy resin adhesive and a preparation method and an application thereof; the adhesive comprises the following components: maleimidopolyimide, polyfunctional epoxy resin, curing agent, promoter and organic solvent; the preparation method comprises the following steps: adding maleimidopolyimide powder and polyfunctional epoxy resin in a reaction rank to react for 1-2h, cooling, adding organic solvent, stirring the solution for dissolving, obtaining component A; mixing curing agent, promoter and organic solvent, stirring the solution for dissolving, obtaining component B; mixing the component A and component B, stirring evenly and obtaining the finished product. The adhesive has good adhesive property, the tensile shear strength is up to 30MPa; the preparation process is simple, the cost is low, the operation is simple, the reaction raw materials are accessible so that the method is applicable to industrialized production; and the adhesive can be used in high-tech fields such as electronics and microelectronics, flexible clad-copper laminates, flexible printed wiring boards, hard clad-copper laminates, automobiles, motors, aviation and aerospace and the like, and has broad application prospect.

Owner:DONGHUA UNIV

Cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal

InactiveCN103372710AContinuous moldingUniform shapeArc welding apparatusWelding/cutting media/materialsShielding gasAluminum metal

Disclosed is a cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal. Cold metal transition welding is adopted, argon is adopted as protecting gas, transition metal is a galvanized steel sheet, two types of welding wires are adopted, an aluminum-silicon welding wire is adopted on the aluminum side, and a magnalium zinc welding wire is adopted on the magnesium side. A welding gun is utilized to align to an aluminum edge and a magnesium edge, high-melting-point transition metal is clamped between magnesium and aluminum to stop mutual contact of liquid magnesium and liquid aluminum, so that melting-brazing welding connections between a magnesium melting welding joint and the transition metal (the galvanized steel sheet) as well as between an aluminum melting welding joint and the transition metal (the galvanized steel sheet) are realized, and connection of dissimilar metal between an aluminum alloy sheet and a magnesium alloy sheet is realized finally.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

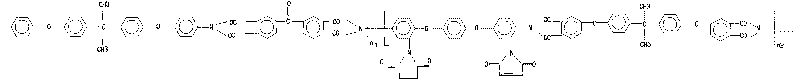

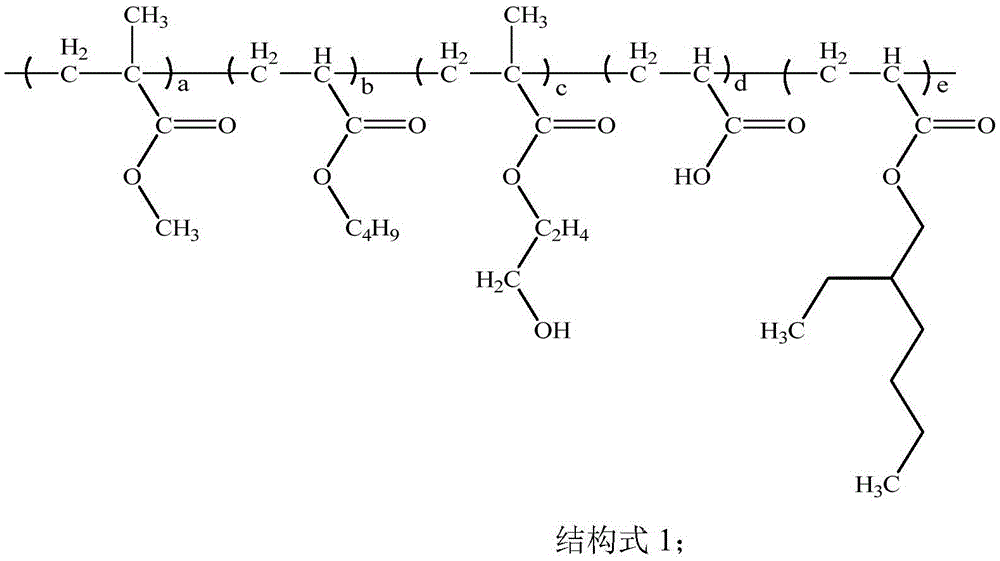

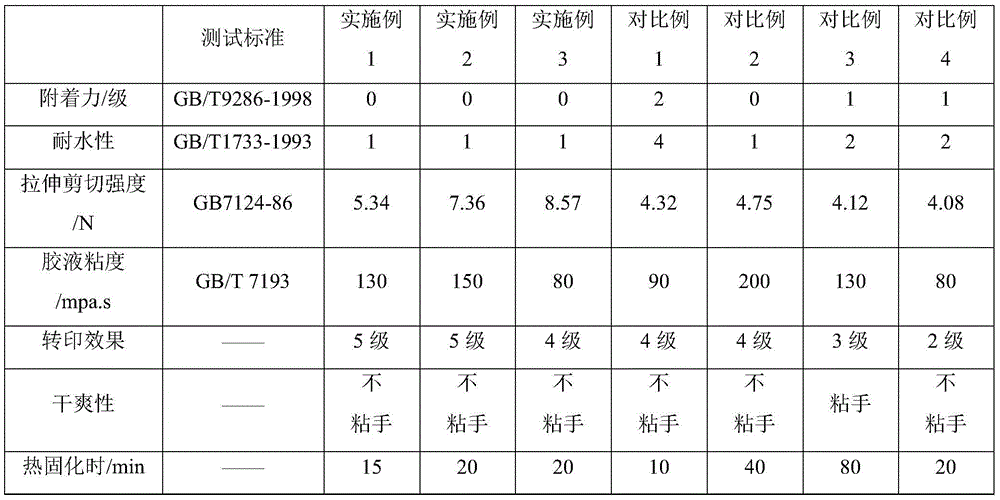

Ultraviolet light curing transfer printing glue and preparation method and application thereof

ActiveCN105602515AHigh glass transition temperatureHigh tensile shear strengthDuplicating/marking methodsPolyureas/polyurethane adhesivesIsooctyl acrylateUltraviolet lights

The invention discloses an ultraviolet light curing transfer printing glue composition for a transfer printing film. The ultraviolet light curing transfer printing glue composition comprises the following components in parts by weight: 20-40 parts of modified acrylate, 20-40 parts of epoxy resin, 10-30 parts of reactive diluent, 3-8 parts of photoinitiator, 5-15 parts of adhesion promoter, 2-5 parts of silane coupling agent and 0-1 part of auxiliary, and the modified acrylate is prepared by modifying pentapolymer prepared from methyl methacrylate (MMA), n-butyl acrylate ((i)n( / i)-BA), hydroxypropyl methacrylate (HMPA), acrylic acid (AA) and 2-ethylhexyl acrylate (EHA) through free radical copolymerization by using polyurethane containing isocyanato. The prepared ultraviolet light curing transfer printing glue has good adhesion to a glass base material, and is good in water resistance, high in tensile strength and excellent in transfer printing effect.

Owner:GUANGDONG UNIV OF TECH

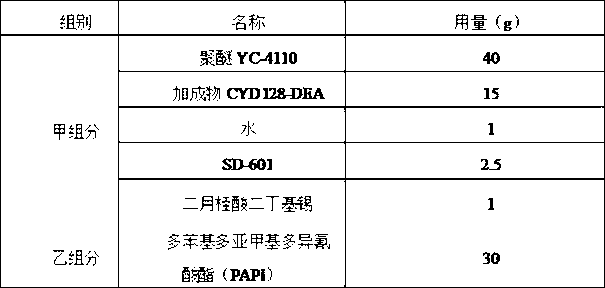

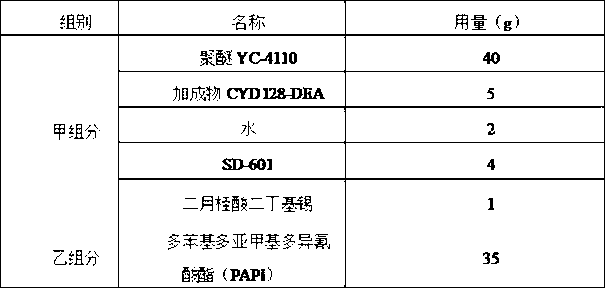

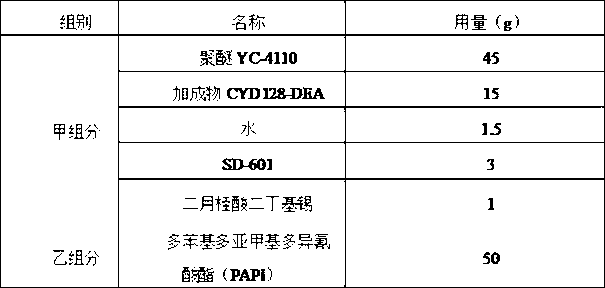

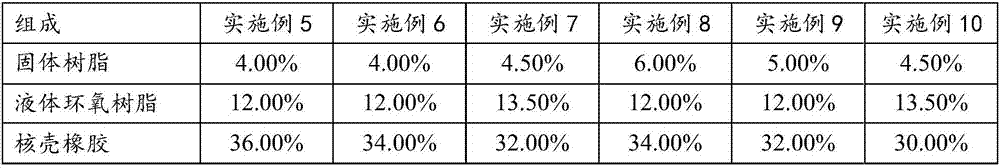

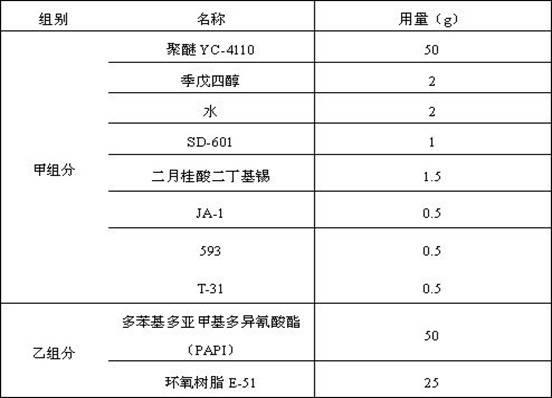

Epoxy modified polyurethane double-component grouting material for road engineering maintenance and preparation method thereof

InactiveCN102702473ASynthetic reaction conditions are mild and efficientIt has the function of self-catalysisEpoxyPolyol

The invention relates to an epoxy modified polyurethane double-component grouting material for road engineering maintenance and a preparation method thereof, wherein the grouting material comprises a component A and a component B; the component A comprises following components in part by weight: 700-800 parts of polyether glycol, 100-300 parts of epoxy resin addition product, 20-40 parts of foaming agent, 40-80 parts of foam stabilizer and 10-40 parts of catalyst; and the component B is polyphenyl polymethylene polyisocyanate. The preparation method comprises the step of mixing and stirring the component A and the component B according to the mass ratio of (0.8-1.5): 1 uniformly. The grouting material has the advantages that: when the material participates in foaming reaction and is cured, the compression strength and bonding force of the formed liquid cement are improved, and the maximum tensile shear strength can reach 4.3Mpa, so that the grouting material is better than the grounding material mixed by polyurethane and epoxy resin; and the grouting material reduces builder body damage and has a certain economic benefit.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Multicomponent crosslinkable compositions based on organyloxysilane-terminated polymers

ActiveUS20150203729A1Good tensile shear strengthHigh tensile shear strengthOther chemical processesFilm/foil adhesivesChemistryIsocyanate compound

Multicomponent crosslinkable compositions based on organyloxysilane-terminated polymers free of toxicologically objectionable catalysts and isocyanates exhibiting good tensile shear strength are useful for adhesive bonding and sealing of substrates.

Owner:WACKER CHEM GMBH

Adhesive for repairing wood structure of ancient buildings, and preparation method and application method of adhesive

InactiveCN109868106AGood adhesionLow densityAdhesive processesNon-macromolecular adhesive additivesEpoxyFiber

The invention discloses an adhesive for repairing a wood structure of ancient buildings, and a preparation method and application method of the adhesive. The adhesive for the wood structure of the ancient building is prepared from epoxy resin, a modified amine curing agent, tris(dimethylaminomethyl)phenol, plant fibers, hollow microbeads, other extender pigment and an active diluent. The preparation and use method of the adhesive comprises the following steps: mixing the epoxy resin, the plant fibers, the hollow microbeads, the active diluent and the like according to a certain ratio, then adding the modified amine and the tris(dimethylaminomethyl)phenol according to a certain ratio, and completing adhesion within 40 minutes. The adhesive has the characteristics that the curing speed is high, no toxic or harmful gas is released, the adhesive property is excellent, and the like, and has relatively high popularization value in the field of ancient buildings.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

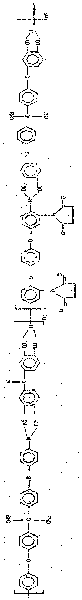

Polyimide-epoxy type electrical insulating paint and preparation method thereof

The invention relates to a polyimide-epoxy type electrical insulating paint and a preparation method thereof. The polyimide-epoxy type electrical insulating paint comprises the components: a maleimide polyimide resin solution, N, N, N', N', O-5-penta-glycidyl-4,4'-diamido-4''-hydroxyl triphenylmethane, N, N, N', N'-4-tetra-glycidyl-4,4'-diamido-diphenyl methane and 2-ethyl-4- methylimidazole which have the weight ratio of 100: (80-100): (80-100):(10-30). The preparation method comprises the steps of: evenly stirring and mixing all the components at the room temperature to obtain the paint. The polyimide-epoxy type electrical insulating paint is moderate in viscosity, good in using technological efficiency, excellent in adhesive property for metal base materials (such as iron, copper, aluminium alloy, glass and ceramics), simple in preparation technology and convenient in operation and reaction raw material source; and the preparation process can be completed in general equipment and is beneficial to realization of industrial production.

Owner:DONGHUA UNIV +1

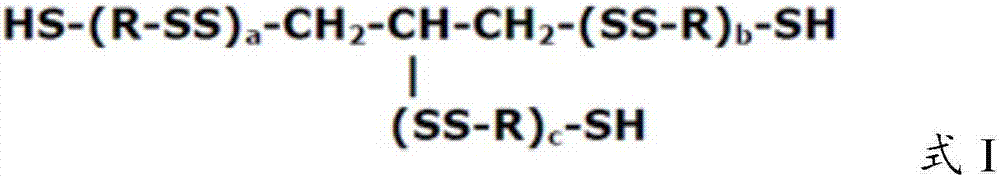

Anti-impact epoxy adhesive composition and preparation method thereof

ActiveCN107142054AImprove impact resistanceHigh tensile shear strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolysulfide rubberUltimate tensile strength

The invention provides an anti-impact epoxy adhesive composition. By adopting two different kinds of epoxy resin as raw materials and adding a composite toughening agent at least including a liquid rubber toughening agent with a core-shell structure, epoxy resin modified nitrile butadiene rubber, a ketoxime-capped reaction type polyurethane elastic prepolymer and an epoxy resin modified polysulfide rubber toughening agent, the obtained epoxy adhesive composition has good impact resistance in normal-temperature and low-temperature conditions; the steel-steel tensile shearing strength is also obviously improved.

Owner:HANGZHOU ZHIJIANG NEW MATERIAL CO LTD +1

Epoxy-polyurethane blending grouting material used for road engineering maintenance

The invention relates to an epoxy-polyurethane blending grouting material used for road engineering maintenance, which is formed by blending a component A and a component B, wherein the component A comprises polyurethane white material and modified polyamine at a mass ratio of 100:1-20:1; the component B comprises phenyl methylene polyisocyanate and bisphenol-A epoxy resin at a mass ratio of 20:1-1:1 in the; and the use amount of the modified polyamine is 0.5%-10% the mass of the bisphenol-A epoxy resin. According to the invention, the epoxy-polyurethane blending grouting material can foam and expand and has excellent bonding performance, so that the using durability of a road is expected to be improved. Compared with a waterborne epoxy resin grouting material, the epoxy-polyurethane blending grouting material has foam expansion performance, can extrude a flabby substrate densely and has a better strengthening effect; and the using amount of the grouting material is saved, and the cost is greatly reduced.

Owner:湖北省京珠高速公路管理处 +1

Cross-linkable masses based on organyl-oxysilane-terminated polyurethanes

ActiveUS20140311674A1Reduce hardnessReduce tensile shear strengthPolyureas/polyurethane adhesivesPretreated surfacesPolyurethane adhesivePolymer science

Adhesives having high tensile strength are prepared from moisture-curable alkoxysilyl-terminated polyurethanes.

Owner:WACKER CHEM GMBH

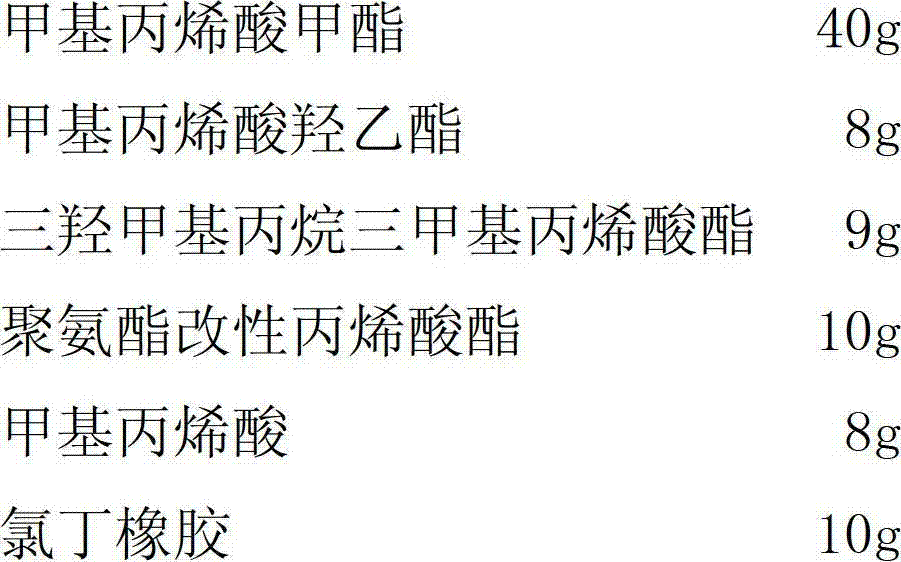

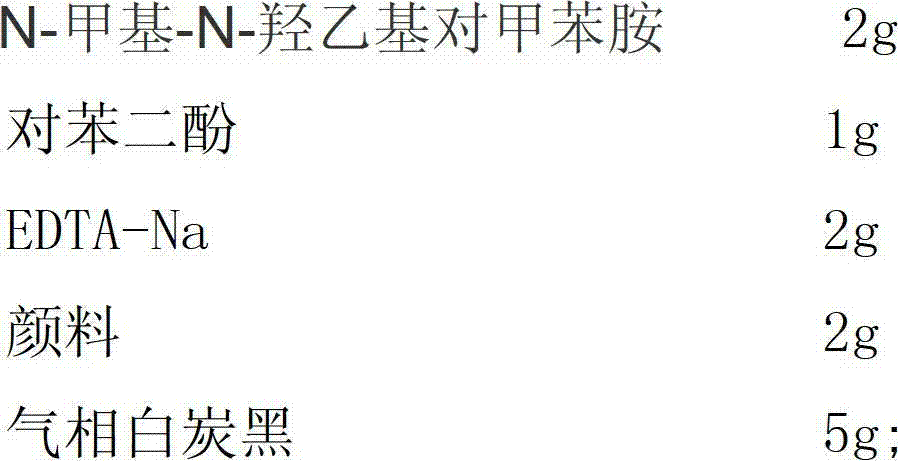

Tackiness agent for automobile tank

InactiveCN102329574AHigh tensile shear strengthImprove heat resistanceOrganic non-macromolecular adhesiveElastomer(Hydroxyethyl)methacrylate

The invention belongs to the field of resin adhesion, and in particular relates to a tackiness agent for an automobile tank. The tackiness agent is characterized by comprising components A and B, wherein the proportion of the components A and B is 1:1; the component A comprises the following compositions by weight percent: 2-5% of MAA (methyl acrylic acid), 35-45% of MMA (methyl methacrylate), 10-15% of hydroxyethyl methacrylate, 5-10% of ethylene glycol dimethacrylate, 15-22% of toughening resin, 0-30% of elastomer and 2-5% of initiator; and the component B comprises the following compositions by weight percent: 2-5% of MAA, 15-20% of hydroxyethyl methacrylate, 6-10% of organosilicon polymer, 35-45% of MMA, 15-22% of toughening resin, 0-30% of elastomer and 0.8-1.5% of accelerator. The tackiness agent provided by the invention has good mechanical property, storage stability, weather resistance, water tolerance and the like, can be quickly solidified at room temperature, has good fuel oil soaking resisting property, and is especially suitable for manufacturing of automobile tanks and products with similar applications.

Owner:SHANGHAI BANZAN MACROMOLECULE MATERIAL

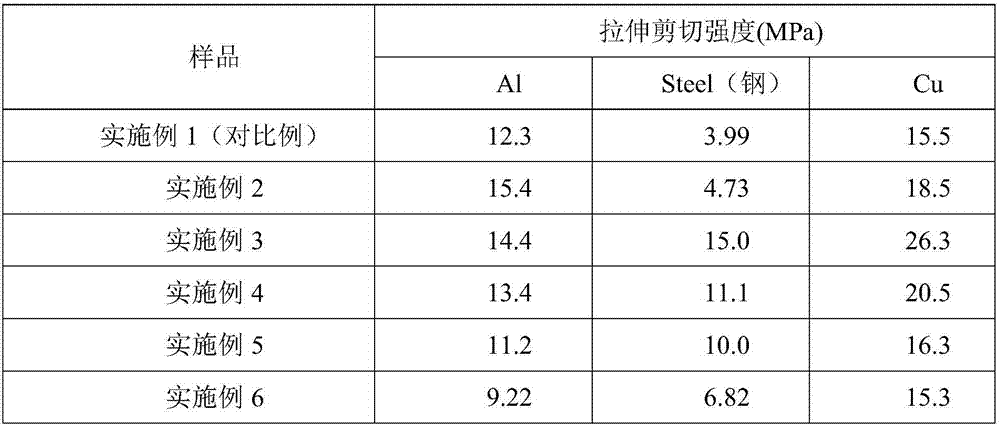

Epoxy-graphenemetal bonding agent and preparation method thereof

InactiveCN107236505AHigh tensile shear strengthNon-macromolecular adhesive additivesGrapheneChemistryTensile shear

The invention discloses an epoxy-graphenemetal bonding agent and a preparation method thereof and relates to the technical field of polymer based nanocomposites. The method comprises specific steps as follows: graphene and a silane coupling agent are dispersed in polyether amine with mechanical stirring and ultrasonic dispersing methods, then a mixture is added to an epoxy resin matrix to be stirred and mixed ultrasonically, and the epoxy-graphenemetal bonding agentis obtained finally. Compared with a pure epoxy resinmetal bonding agent, the epoxy-graphenemetal bonding agentprepared with the method has better performance, a tensile shear strengthperformance test indicates that bonding performance of the epoxy-graphenemetal bonding agent to an aluminum plate base material reaches 15.4 MPa, the bonding performance of the epoxy-graphenemetal bonding agent to a steel plate base material reaches 15.0 MPa, the bonding performance of the epoxy-graphenemetal bonding agent to a copper plate base material reaches 26.3 MPa, and the bonding performance of epoxy resin to a metal base material can be effectively improved.

Owner:SOUTH CHINA UNIV OF TECH

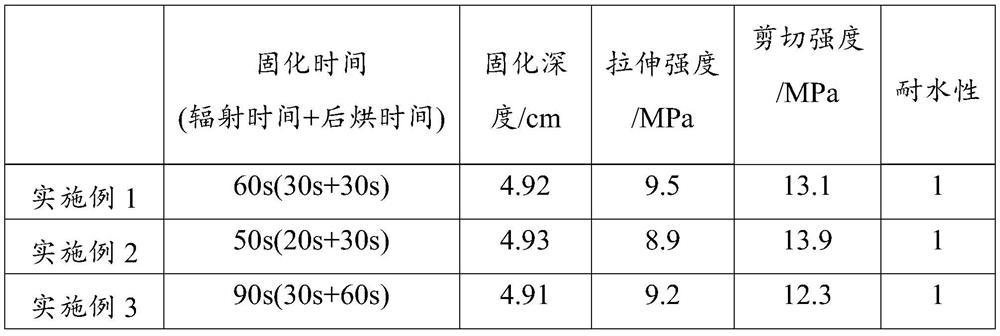

Light-cured adhesive as well as preparation method and application thereof

ActiveCN112080241AHigh functionalityMany branch pointsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention provides a light-cured adhesive and a preparation method and application thereof.The light-cured adhesive is prepared from sulfydryl-terminated hyperbranched polyester, urethane acrylate, epoxy resin, a reactive diluent, a silane coupling agent and a photobase generator. Compared with the prior art, sulfydryl-terminated hyperbranched polyester is adopted as a preparation raw material, and an active diluent is supplemented, so that the viscosity of the adhesive system can be further reduced, the uniform dispersion and migration of active components generated after illumination inthe system are facilitated, the concentration of active components at the bottom layer can be improved, and deep curing can be quickly realized after heating and drying. Sulfydryl-terminated hyperbranched polyester, urethane acrylate and epoxy resin are used as reaction monomers, and under the action of alkaline light initiation of a photobase generator, sulfydryl double bonds / epoxy can be subjected to a rapid click chemistry type deep photocuring reaction. The polyurethane acrylate and the silane coupling agent are introduced, so that the toughness, the adhesive force and the waterproof performance of the adhesive can be effectively improved.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

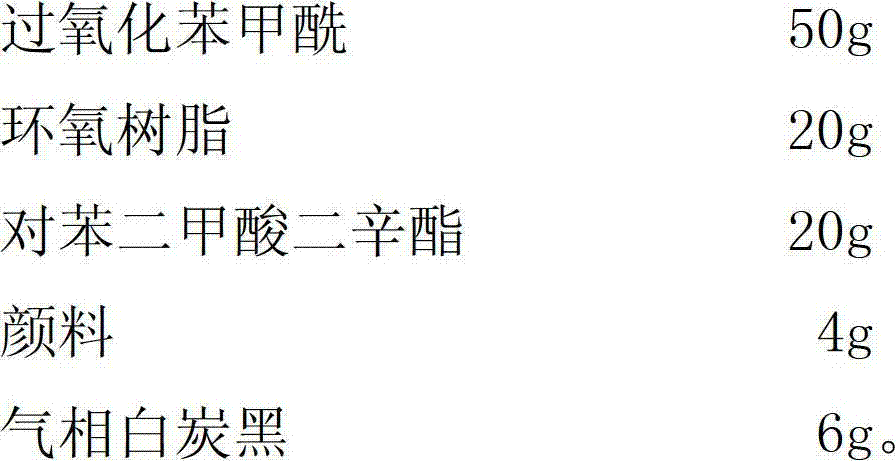

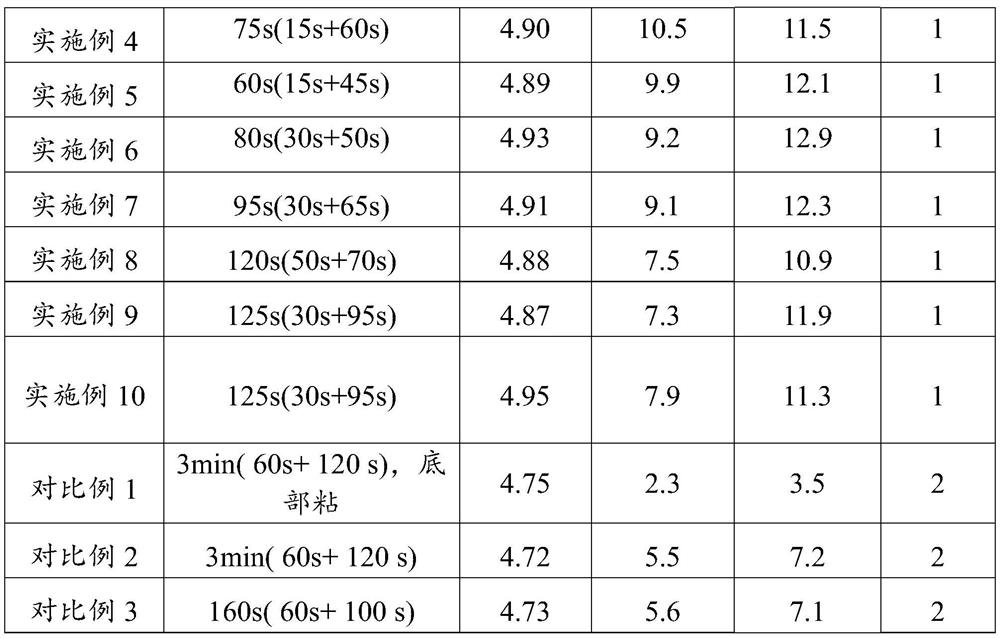

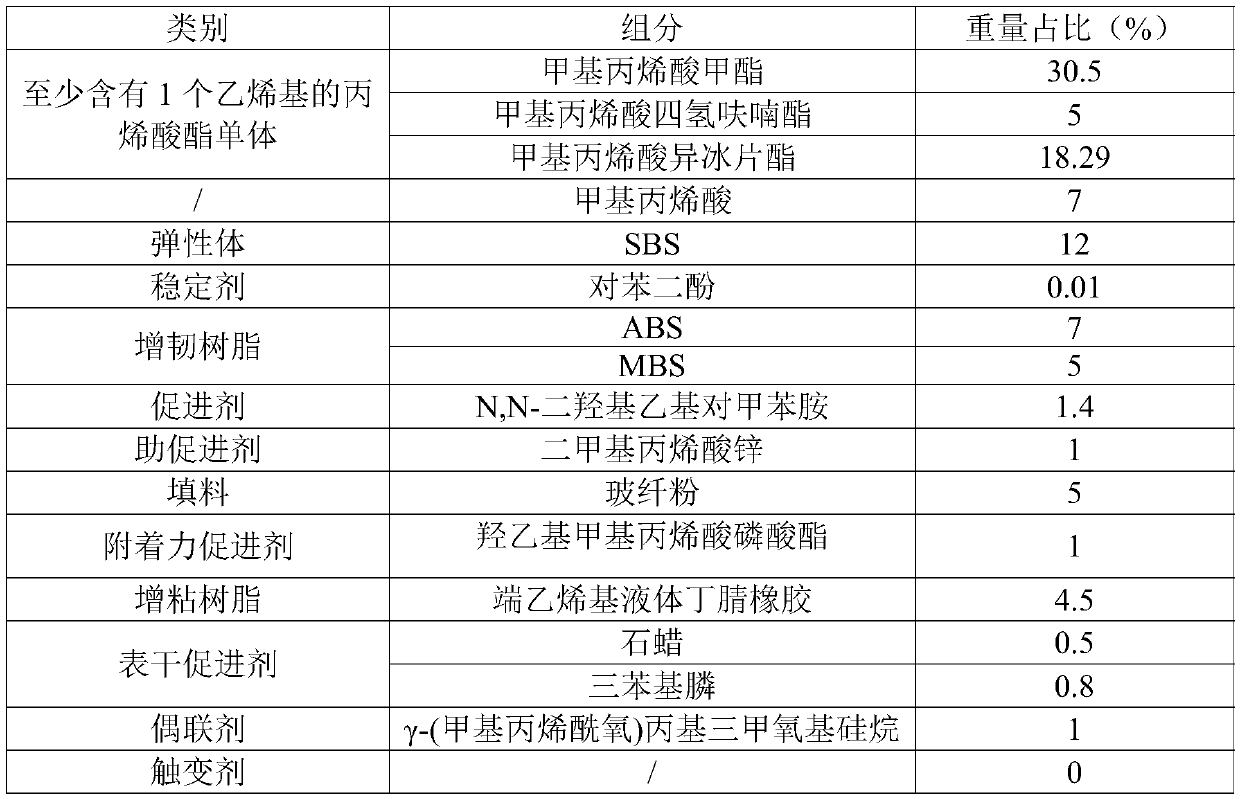

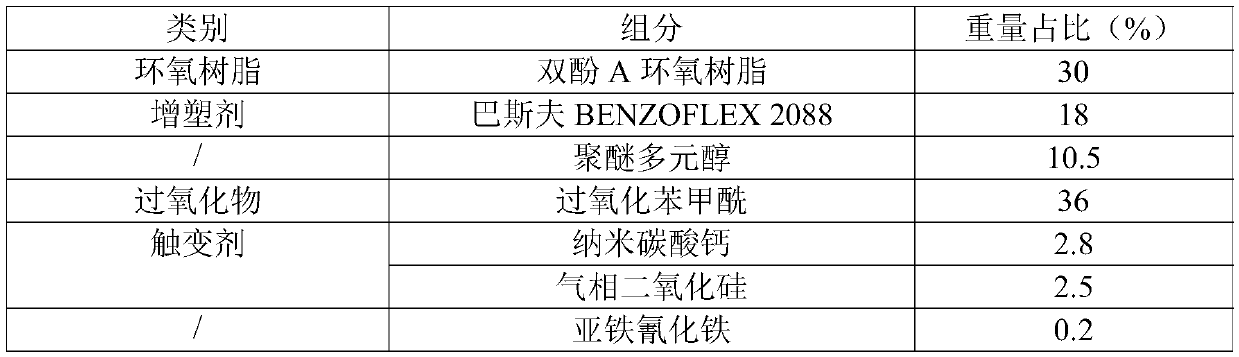

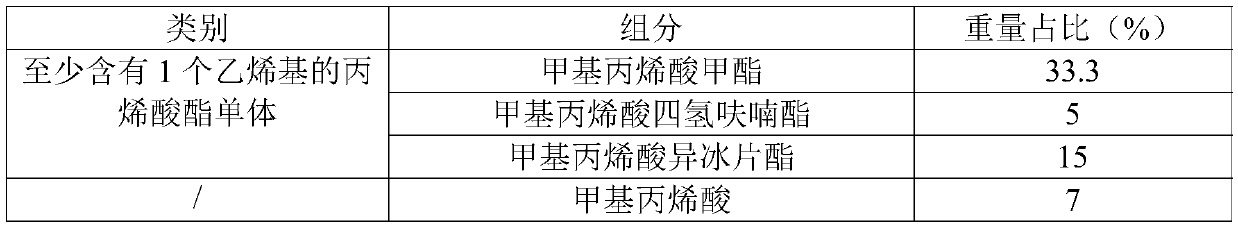

Acrylate adhesive

InactiveCN110240868AHigh tensile shear strengthGood effectNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePlasticizerCorrosion

The invention discloses an acrylate adhesive which is a two-component adhesive and comprises a reducing agent and an oxidizing agent, wherein the reducing agent comprises the following components in%age by weight: 30-70% of an acrylate monomer containing at least one vinyl group, 1-10% of methacrylic acid, 5-15% of an elastomer, 0-0.1% of a stabilizer, 5-20% of toughening resin, 0.1-2% of an accelerator, 0.1 to 2% of an activating accelerator, 0 to 10% of a filler, 0.5 to 3% of an adhesion promoter, 1 to 5% of tackifying resin, 0 to 2% of a surface drying promoter, 0.5 to 1.5% of a coupling agent and 0 to 2% of a thixotropic agent. The oxidizing agent comprises the following components in%age by weight: 20-40% of epoxy resin, 15-25% of a plasticizer, 10-15% of polyether polyol, 20-40% of a peroxide, 4%-6% of a thixotropic agent and 0.1%-0.3% of ferric ferrocyanide. The volume ratio of the reduce agent to the oxidizing agent is 10: 1. The acrylate adhesive has weak corrosion to copper, good bonding effect and good storage stability..

Owner:HUIZHOU DUV ELECTRONICS MATERIALS

Cross-linkable materials based on organyl oxysilane-terminated polymers

ActiveUS8907027B2Improve responseEasy to producePolyureas/polyurethane adhesivesCoatingsAdhesivePolymer chemistry

Moisture curable adhesives of high tensile shear strength contain an alkoxysilyl-terminated polymer and an alkoxy-functional silicone resin.

Owner:WACKER CHEM GMBH

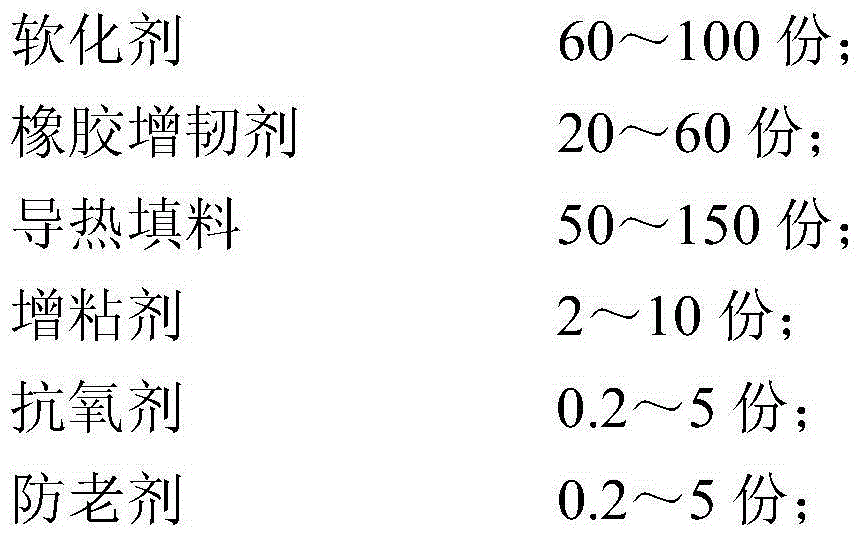

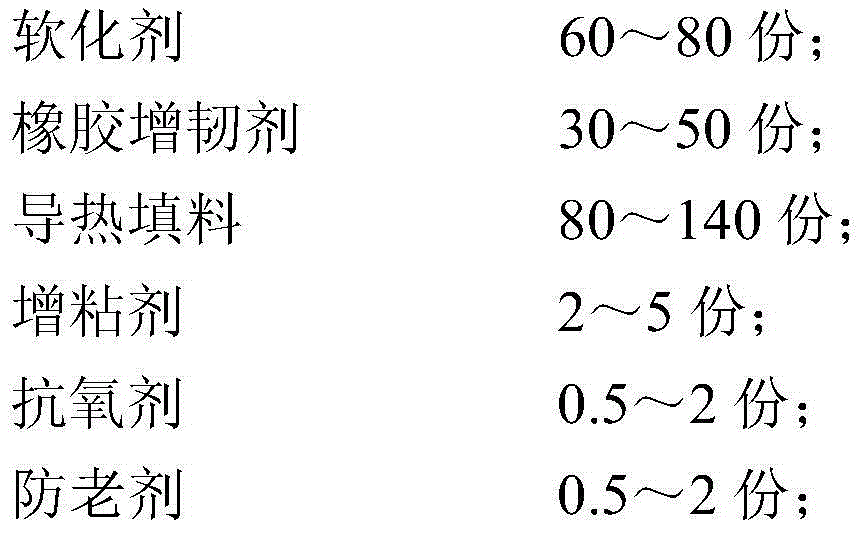

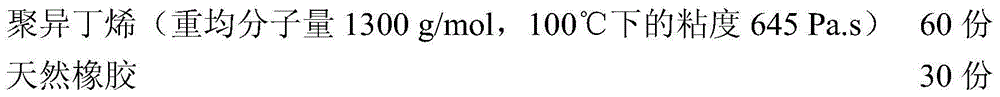

Heat conducting adhesive and preparation method and application thereof

ActiveCN104817985AAchieve a tight bondImprove performanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a macromolecular heat conducting composite material, in particular to a heat conducting adhesive and a preparation method and application thereof. The heat conducting adhesive is made of, by weight, 60-100 parts of softener, 20-60 parts of rubber flexibilizer, 50-150 parts of heat conducting filler, 2-10 parts of tackifier, 0.2-5 parts of antioxidant and 0.2-5 parts of antiager. The preparation method includes the steps: rolling the rubber flexibilizer, sequentially adding the softener, the heat conducting adhesive, the tackifier, the antioxidant and the antiager, and mixing for 1-2h at the temperature of 80-150 DEG C to obtain the heat conducting adhesive. The heat conducting adhesive has the advantages of freeness of curing, convenience in processing, excellent adhesion performance, high heat conductivity and the like. Close adhesion of devices can be realized only by application of a proper pressure at the normal temperature, and the heat conducting adhesive is cheap and environment friendly.

Owner:国科广化(南雄)新材料研究院有限公司 +1

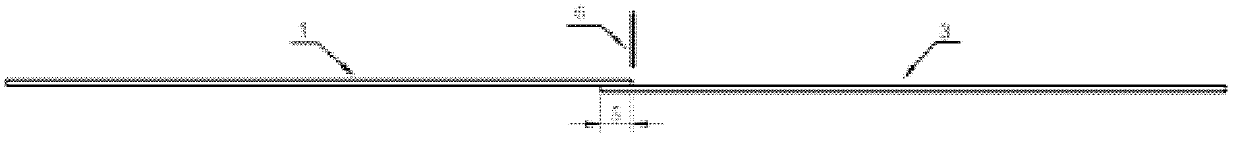

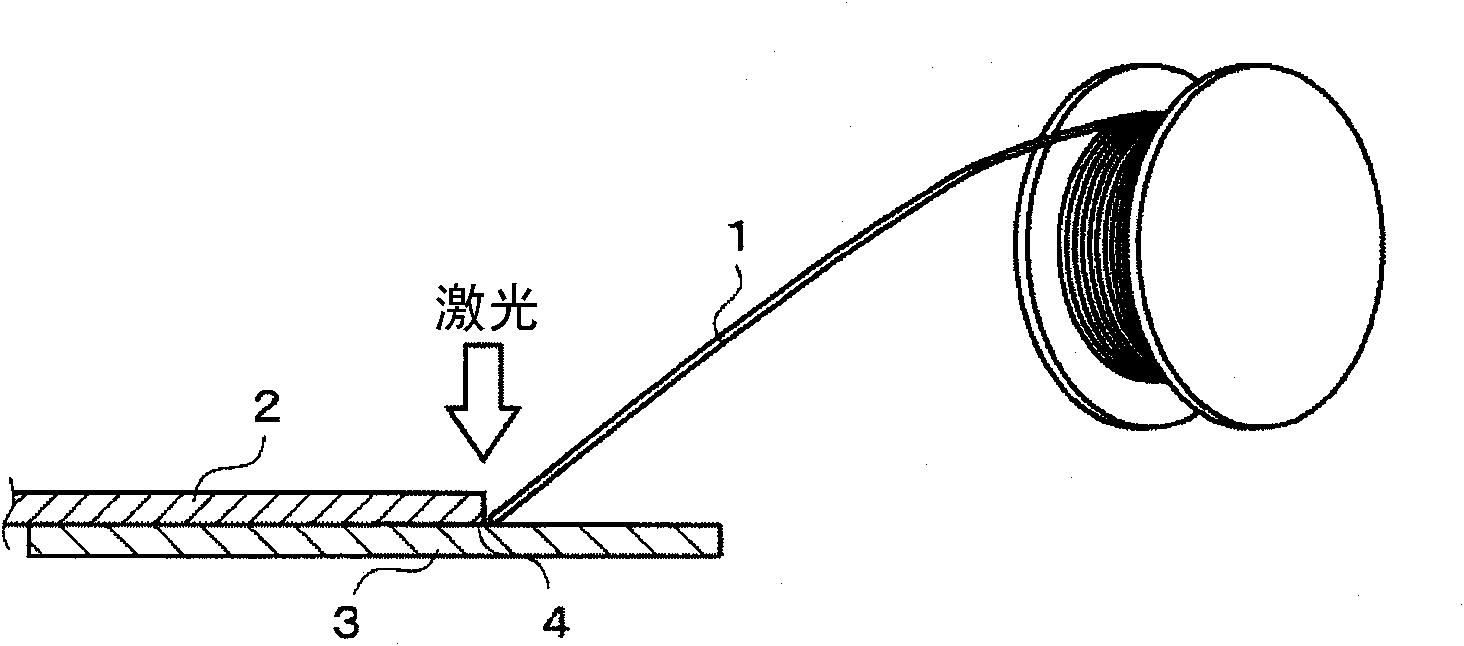

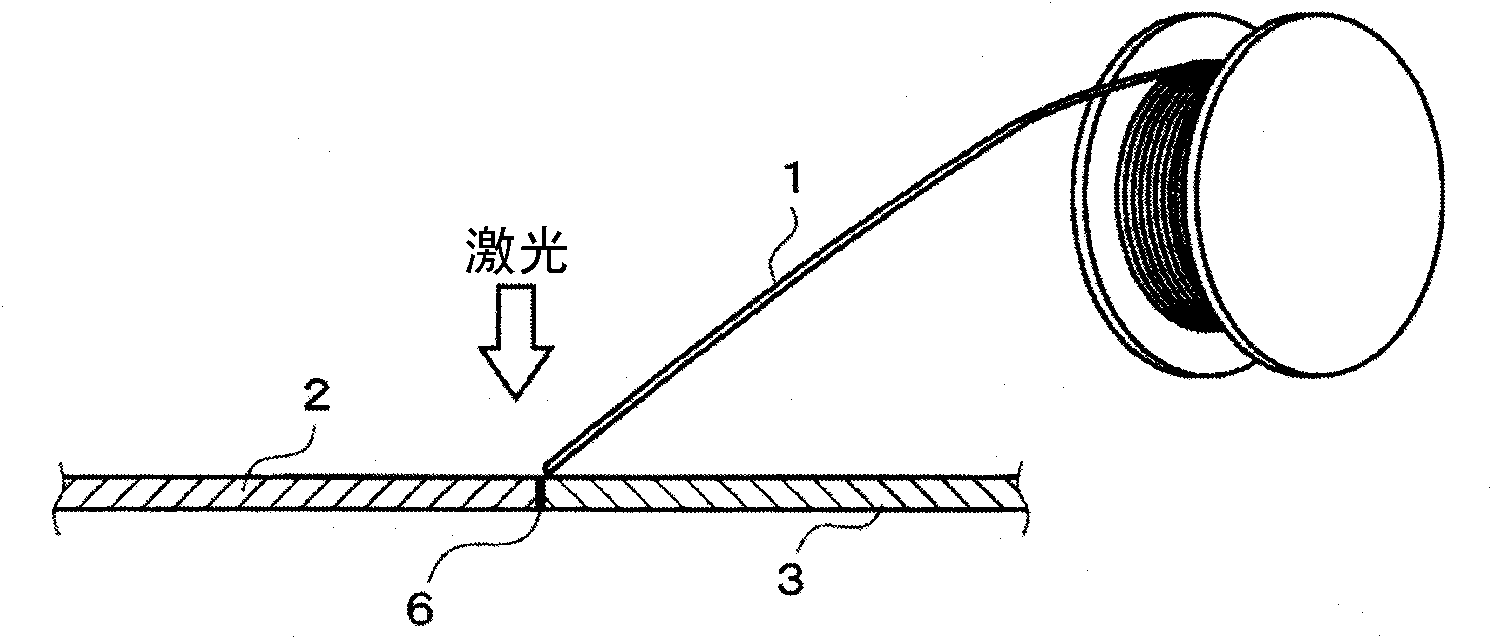

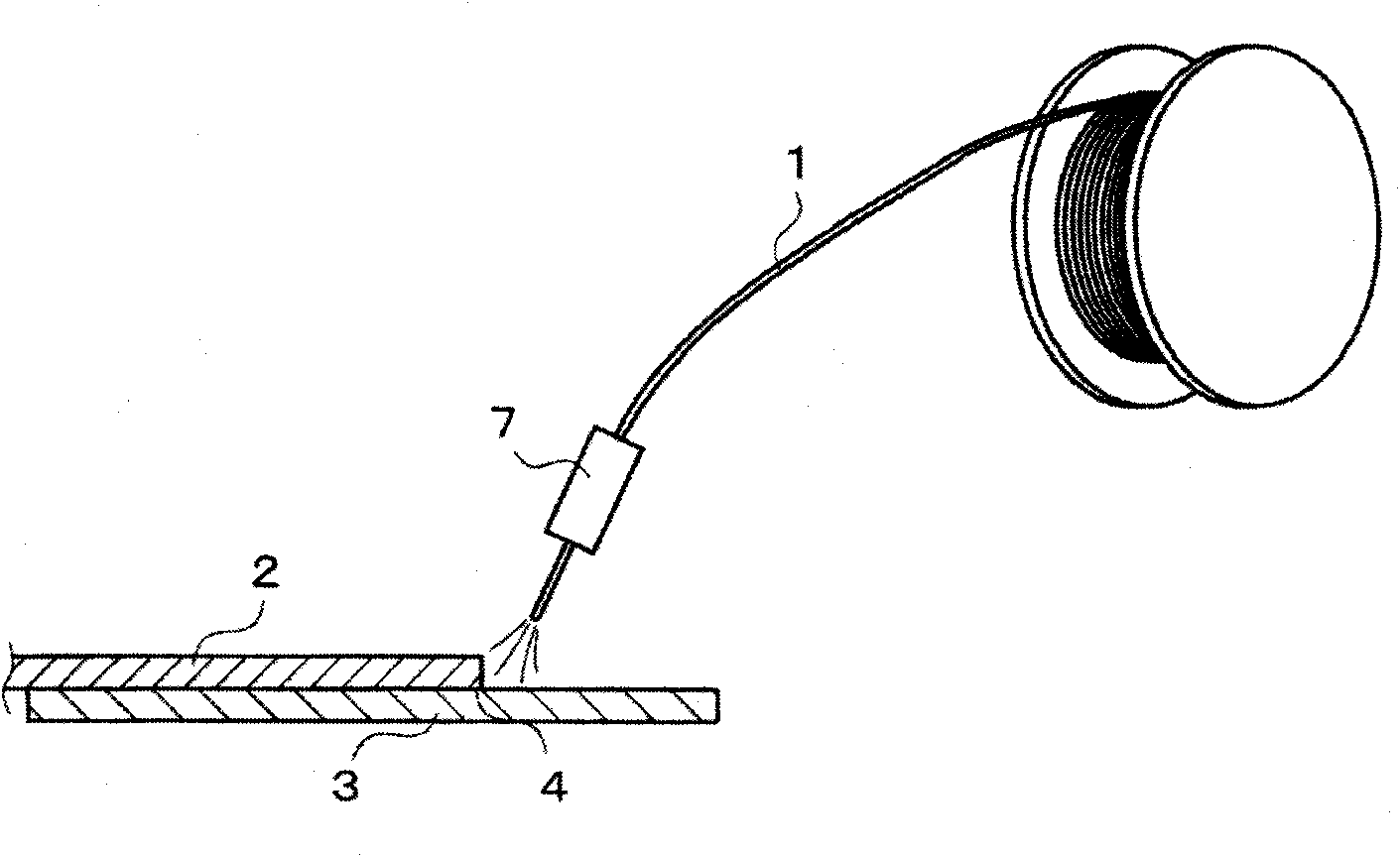

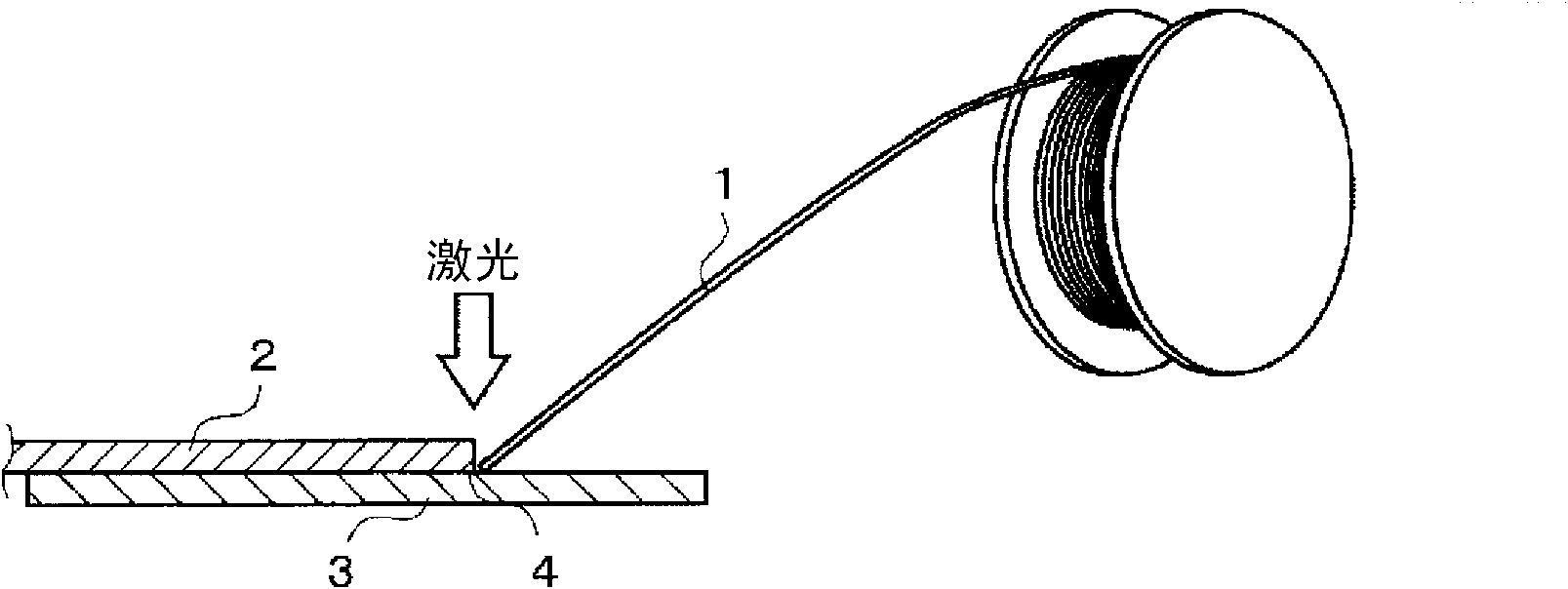

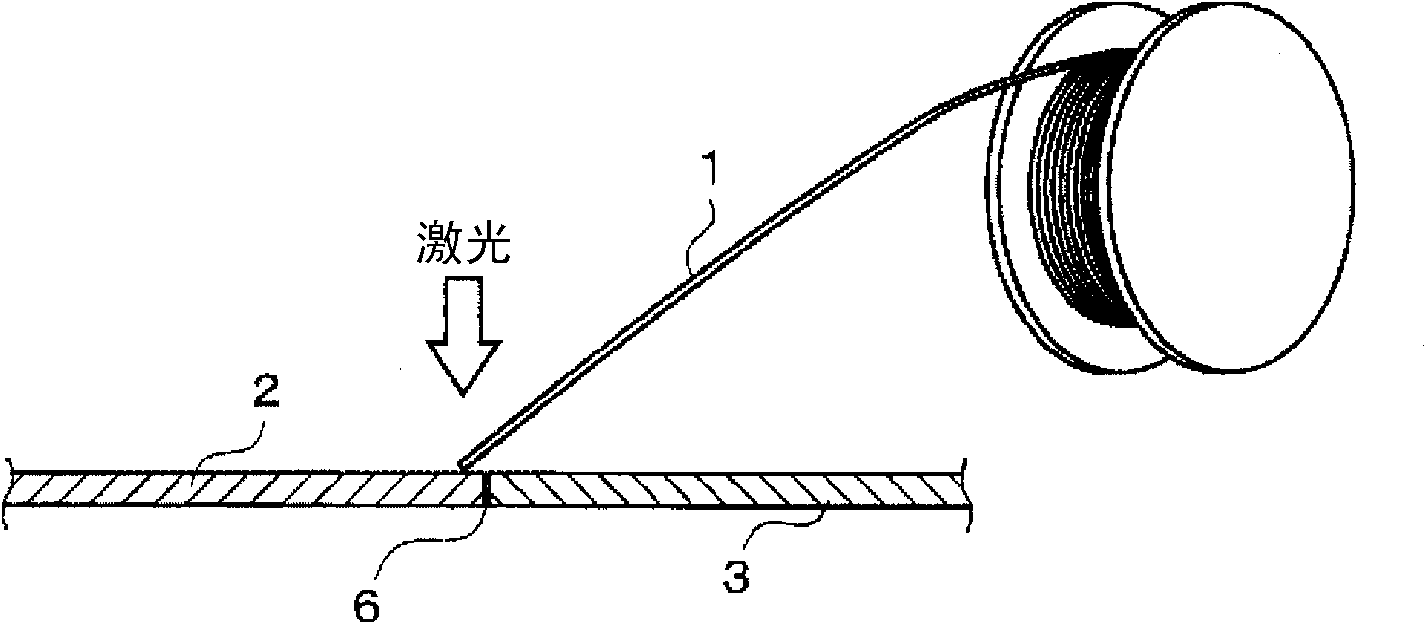

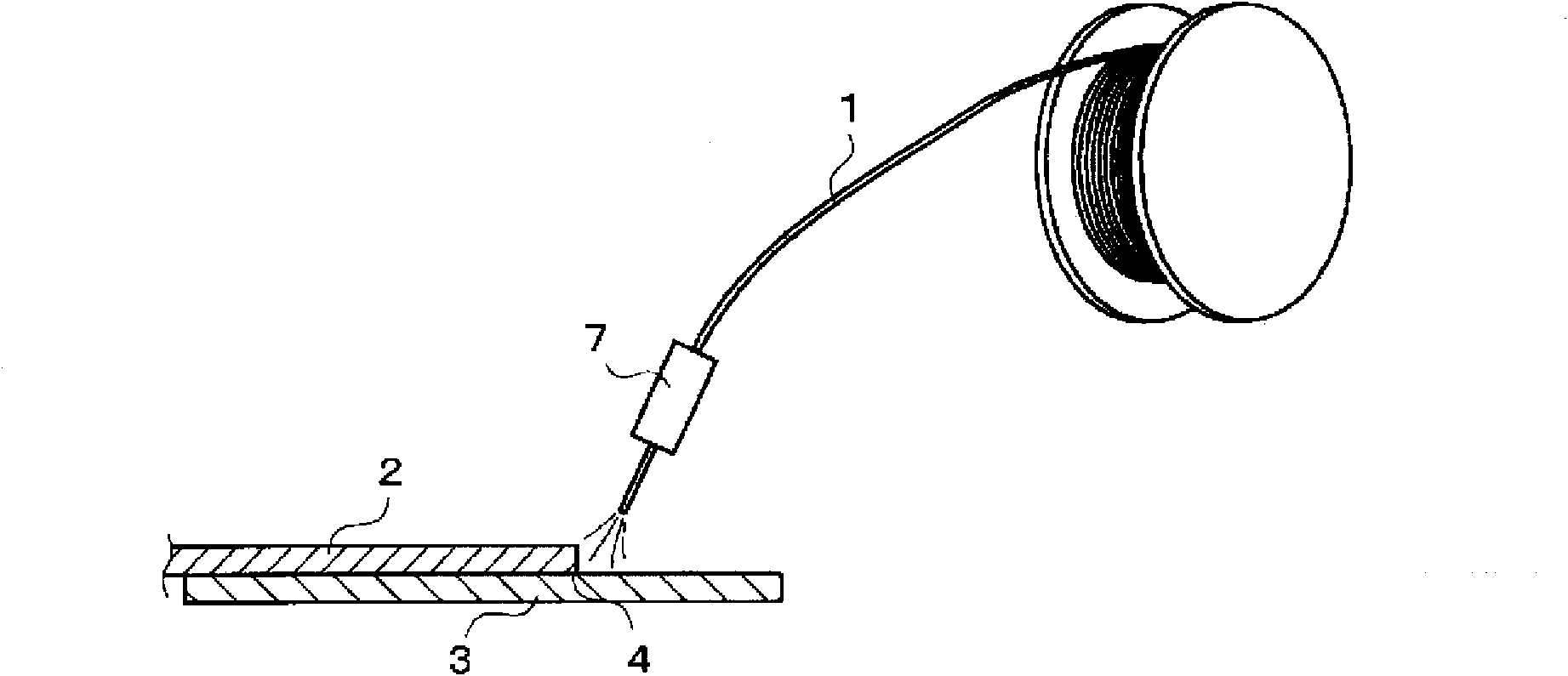

Flux-cored wire for welding different materials, method for laser welding of different materials and method for MIG welding of different materials

ActiveCN102430871AHigh tensile shear strengthHigh peel strengthArc welding apparatusVehicle componentsFluorideUltimate tensile strength

There are provided a flux-cored wire for welding different materials, a method for laser welding of different materials and a method for MIG welding of different materials which can improve tensile shear strength of a welded joint portion and peeling strength of a welded portion interface in welding aluminum or an aluminum alloy material and a steel material. The flux-cored wire has a cylindrical sheath comprising an aluminum alloy which contains Si in an amount of 1.5 to 2.5% by mass and Zr in an amount of 0.05 to 0.25% by mass, with the remainder being aluminum and inevitable impurities, and a flux filling inside this sheath and containing cesium fluoride in an amount of 20 to 60% by mass, and the packing fraction of the flux being 5 to 20% by mass of the total mass of the wire.

Owner:KOBE STEEL LTD

Flux-cored wire for welding different materials, method for laser welding of different materials, and method for MIG welding of different materials

ActiveCN102883852AHigh peel strengthIncreased tensile shear strength andArc welding apparatusWelding/cutting media/materialsArc weldingGalvanization

Disclosed is a flux-cored wire (1) for use in the laser welding or MIG welding of different materials that are aluminum or an aluminum alloy material (2) and a galvanized steel material (3). The flux-cored wire (1) comprises a cylindrical sheath constituted of an aluminum alloy containing 0.8-1.9 mass% Si, with the remainder being aluminum and incidental impurities, and a flux filled in the space within the sheath and containing 20-60 mass% cesium fluoride. The incidental impurities in the sheath include Mn, Mg, or Fe, and the contents of these impurities are at most 0.1 mass% each with respect to the total mass of the sheath. The percentage filling of the flux is 5-20 mass% with respect to the total mass of the wire.

Owner:KOBE STEEL LTD

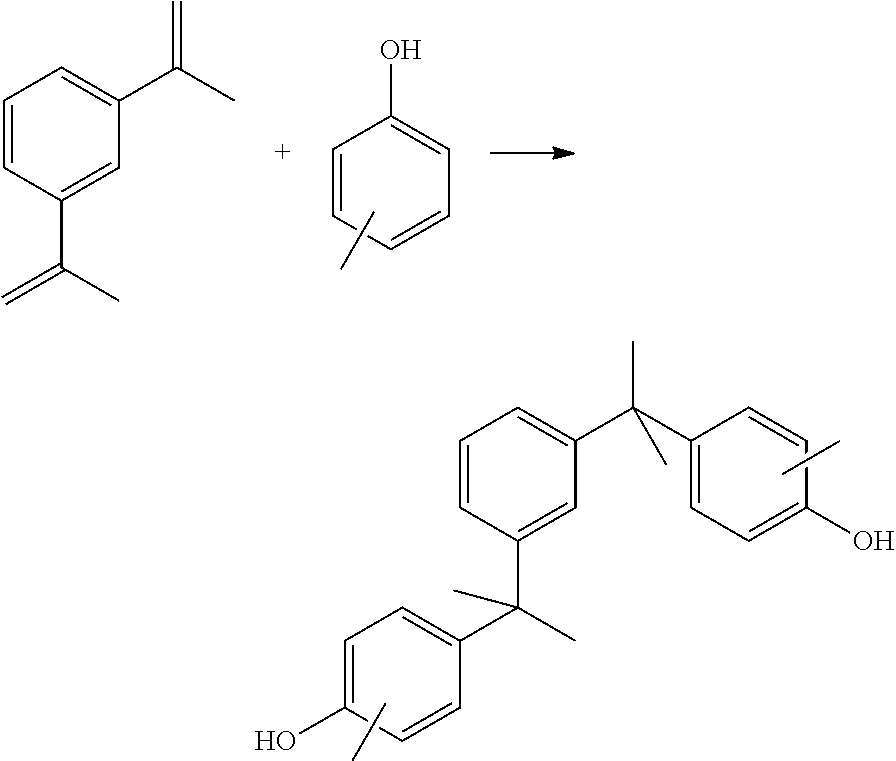

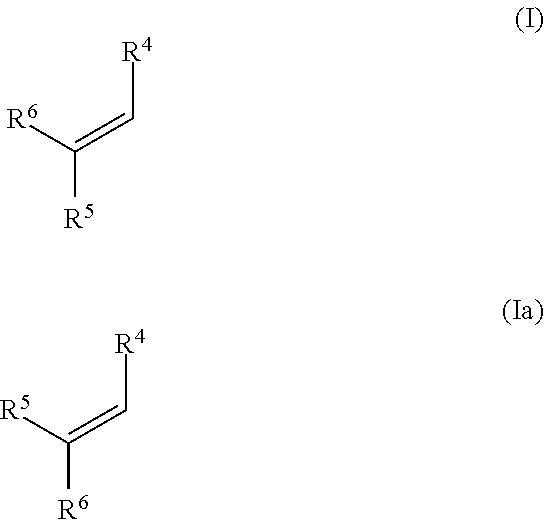

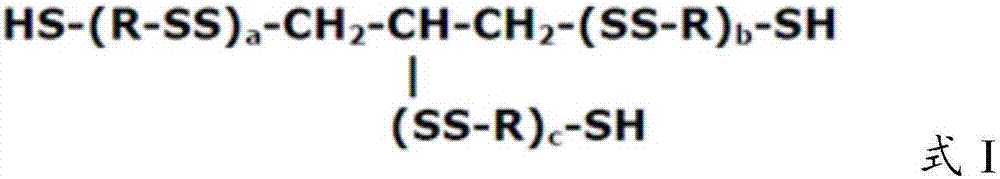

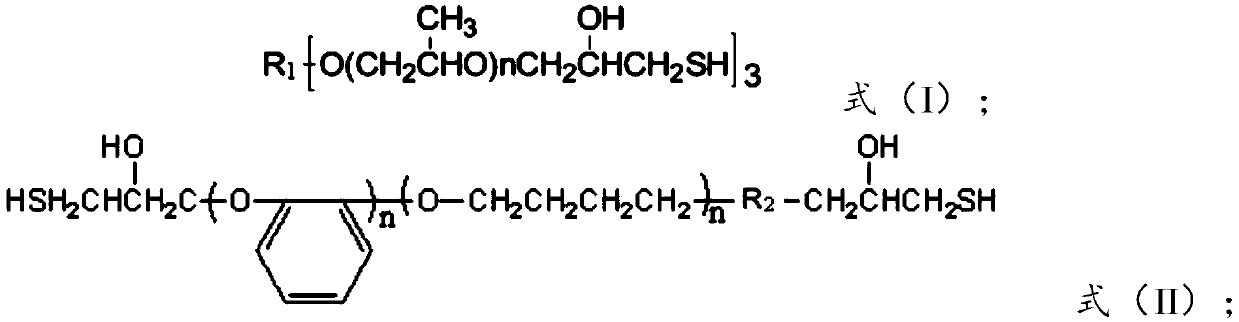

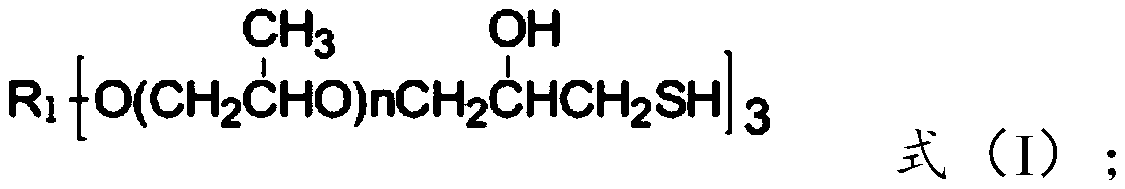

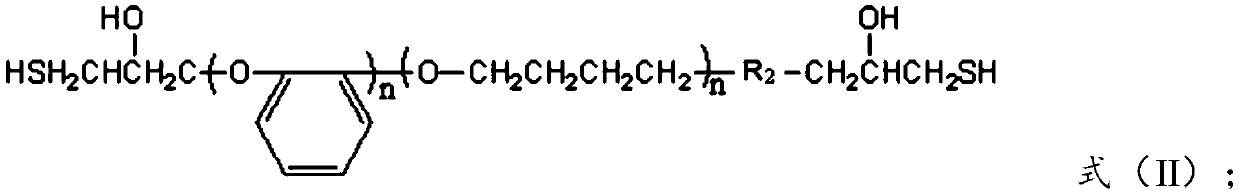

Epoxy resin adhesive and preparation method thereof

ActiveCN110343495AEasy to prepareThe preparation method is simple and controllableEpoxy resin adhesivesEpoxyThiol

The invention provides an epoxy resin adhesive. The epoxy resin adhesive is prepared from the following components in parts by weight: 1-15 parts of an amine curing agent, 30-60 parts of mercaptan, and 35-55 parts of epoxy resin; and the mercaptan has a structure shown in a formula (I) or a formula (II) (please see the specification for the formula (I) or the formula (II)), wherein R1 is trivalenthydrocarbyl of C1 to C6, and R2 is selected from a formula (please see the specification for the formula), and n is an integer from 1 to 5. Compared with the prior art, according to the epoxy resin adhesive, the components of the specific content are adopted, and good interaction is achieved, so that the epoxy resin adhesive has good room-temperature rapid curing performance, and is high in tensile and shear strength and good in oil and water resistance. Experimental results show that the gelation time of the epoxy resin adhesive at the room temperature is 6-13 min, the curing time is 10-19 min, the tensile and shear strength is 9.7-15.4 MPa, and the tensile and shear strength after oil soaking for half a year is 7.6-13.7 MPa.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Polyurethane foam gum with expandable graphite and diatomite to cooperatively enhance flame retarding

InactiveCN106065309AHigh oxygen indexImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiethyl phosphateWear resistant

The invention discloses polyurethane foam gum with expandable graphite and diatomite to cooperatively enhance flame retarding, which is prepared from, by weight, 150-160 parts of diphenyl methane diisocyanate, 100-105 parts of trihydroxy polyoxypropylene ether, 100-110 parts of castor oil, 5-6 parts of glycerol, 40-43 parts of diethyl phosphate, a proper amount of a 1 mol / L sodium hydroxide solution, 13-15 parts of diatomite, 5-6 parts of distilled water, 2-3 parts of triethanol amine, 3-4 parts of dibutyltin dilaurate, 3-4 parts of lauryl sodium sulfate, 5-6 parts of silicon oil, 3-4 parts of the expandable graphite, a proper amount of anhydrous ethanol, 0.8-1 part of cetyl trimethyl ammonium bromide, and a proper amount of deionized water. The foam gum is used for sealing switch cabinets and machine cabinets, is high in strength and is wear-resistant, can achieve on-site foaming and reduce production cost, has high total sealing performance, has simple and easy-to-control production process, and is safe and environment-friendly.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

Nano modified display shell position gum and preparing method thereof

ActiveCN101054503AGood stickinessGood flexibilityMineral oil hydrocarbon copolymer adhesivesFireworksEngineeringAdhesion strength

The invention relates to a nano-modified salute bomb location glue and method for preparing same. The glue uses SBS elastomer as the major material, addes with adhesion resin and nano-materials to reinforce the surface adhesive force and adhesion strength between the location glue and ignition pipe and the ball shells.

Owner:HUNAN SHENLI IND

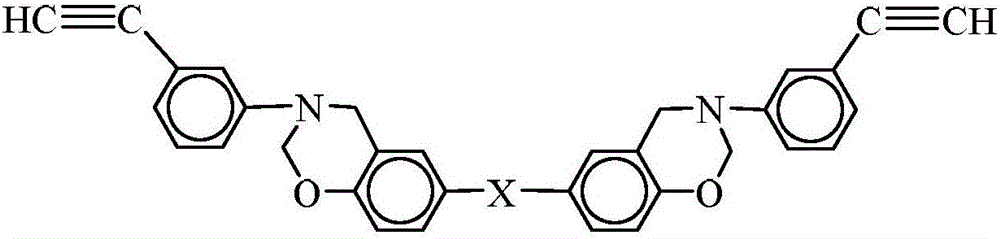

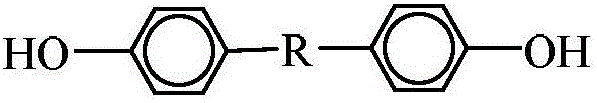

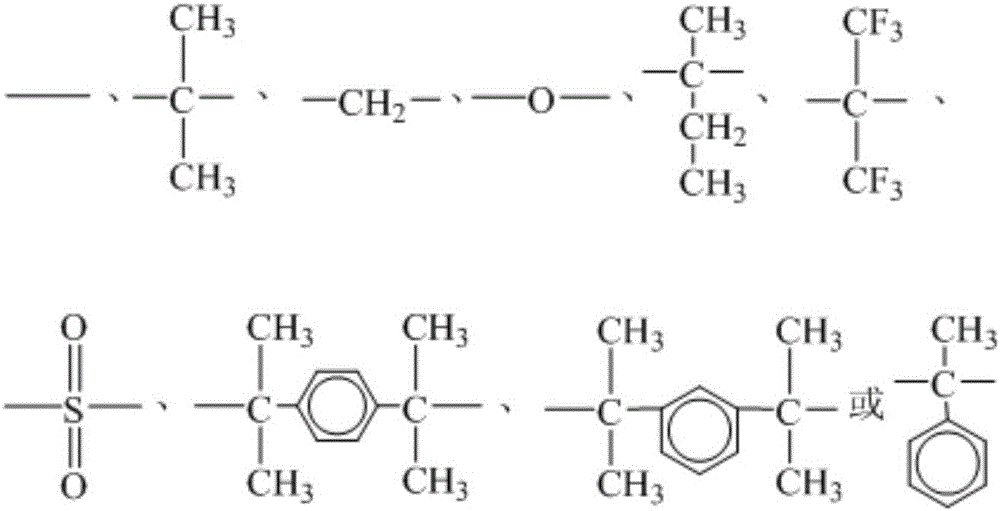

High-temperature-resistant benzoxazine resin adhesive and preparation method thereof

InactiveCN105838315AHigh temperature resistanceIncrease crosslink densityMacromolecular adhesive additivesDissolutionPhenol

The invention discloses a high-temperature-resistant benzoxazine resin adhesive and a preparation method thereof, relates to a benzoxazine resin adhesive and a preparation method thereof, and aims to solve the problems of poor resistance of an existing benzoxazine resin adhesive to high temperature and weak tensile shear strength at high temperature. The adhesive comprises acetylene-terminated benzoxazine resin, a toughening agent, an organic solvent, a coupling agent and an inorganic filler. The method comprises the following steps: 1, placing dihydric phenol, aminophenylacetylene and paraformaldehyde in a four-neck flask, performing heating reaction and cooling, adding trichloromethane for dissolution, performing extraction, performing washing to neutral with de-ionized water, and performing drying to obtain the acetylene-terminated benzoxazine resin; 2, uniformly mixing the acetylene-terminated benzoxazine resin, the toughening agent and the organic solvent to obtain a base adhesive; 3, sequentially adding the coupling agent and the inorganic filler into the base adhesive, and performing uniform mixing to obtain the high-temperature-resistant benzoxazine resin adhesive. The adhesive is resistant to high temperature, has strong tensile shear strength at high temperature, and is used in the field of adhesives.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Organic grouting material for road and preparation method of organic grouting material for road

The invention discloses an organic grouting material for a road and a preparation method of the organic grouting material for the road. The organic grouting material for the road is prepared by foaming black and white polyurethane materials, wherein an epoxy resin-diethanolamine affixture (EP-DEA affixture) is also added into the white polyurethane material, and the addition of the EP-DEA affixture accounts for 5-20wt% of the total mass of the black and white polyurethane materials. The EP-DEA affixture is prepared by using a method comprising the following steps of mixing EP and DEA, and uniformly dispersing in a reaction vessel by taking butanone as a solvent; heating to 70 DEG C, maintaining the temperature and reacting for 4h; and removing the superfluous solvent through reduced-pressure distillation to obtain a slightly-yellow oily liquid, namely the EP-DEA affixture. When the organic grouting material for the road, disclosed by the invention, is used for filling a gap of the road by grouting and solidifying, the adhesive property of solidification filler is better and the compression strength is more approximate to the use requirement on the premise that the grouting performance is not influenced, and therefore, the organic grouting material is an excellent improved product of a pure black / white polyurethane product, which is maximally used at present.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com