High-temperature resistant copper foil glue and preparation and application thereof

A technology of high temperature resistance and copper foil adhesive, which is applied in the field of organic polymer adhesives and its preparation and application, and can solve the problems of limited heat resistance improvement, limited reactive groups, and low content of adhesive systems , to achieve the effects of good viscosity controllability, industrialized production, and excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

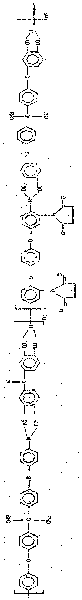

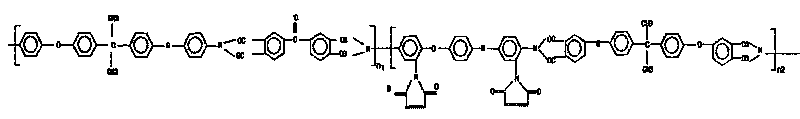

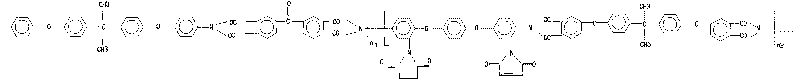

Method used

Image

Examples

Embodiment 1

[0035] Mix 5.0 g of activated vinyl polyetherimide (AEPEI) powder, 15.0 g of 1,3-bis(4-maleimido-2-trifluoromethylphenoxy)benzene, 10.0 g of N, N,N',N'-tetraglycidyl-3,3'-dimethyl-4,4'-diaminodiphenylmethane and 40.0 grams of ES-216 bisphenol A epoxy resin were added to the reaction kettle, After reacting at 90℃~120℃ for 30min-90min, cool to 40℃, add 25.0 grams of N,N-dimethylacetamide organic solvent, stir until completely dissolved, add 5.0 grams of dicyandiamide curing agent, stir evenly, A homogeneous transparent and clear high temperature resistant copper foil adhesive was obtained, which was recorded as CFA-1.

[0036] Take an appropriate amount of CFA-1 high temperature resistant copper foil adhesive and evenly apply it on the surface of thick copper test piece or phenolic hydroxyl polyimide film to prepare copper-adhesive-copper and copper-adhesive-phenolic hydroxyl polyimide film The sample is cured: heat from room temperature to 100 °C, hold for 1 h, continue to hea...

Embodiment 2

[0039] 15.0 g of activated vinyl polyetherimide (AEPEI) powder, 5.0 g of 2,2-bis[4-(4-maleimido-2-trifluoromethylphenoxy)phenyl] Propane, 20.0 g of N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether, 5.0 g of E-51 and 5.0 g of ES-216 bisphenol A epoxy resin were added to the reaction In the kettle, react at 90℃~120℃ for 30min-90min, cool to 40℃, add 35.0g N,N-dimethylformamide and 10.0g methylene chloride organic solvent, stir until completely dissolved, add 3.0g 4,4'-diaminodiphenylsulfone and 2.0 g of 1,4-bis(2,6-diamino-4-trifluoromethylphenoxy)benzene curing agent, stir well to obtain a homogeneous transparent and clear resistant High temperature copper foil adhesive, recorded as CFA-2.

[0040] Take an appropriate amount of CFA-2 high temperature resistant copper foil adhesive and evenly apply it on the surface of thick copper test piece or phenolic hydroxyl polyimide film to prepare copper-adhesive-copper and copper-adhesive-phenolic hydroxyl polyimide film The sample ...

Embodiment 3

[0043]8.0 g of activated vinyl polyetherimide (AEPEI) powder, 3.0 g of 4,4'-bis(4-maleimido-2-trifluoromethylphenoxy) biphenyl and 8.0 g of 1,3-Bis(4-maleimido-2-trifluoromethylphenoxy)benzene, 10.0 g N,N,N',N'-tetraglycidyl-3,3'-di Methyl-4,4'-diaminodiphenylmethane, 20.0 g N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether, 5.0 g E-44 and 6.0 g ES-216 bisphenol A epoxy resin was added to the reaction kettle, reacted at 90℃~120℃ for 30min-90min, cooled to 40℃, added 30.0g N,N-dimethylacetamide organic solvent, stirred until complete After dissolving, add 5.0 grams of 2-ethyl-4-methylimidazole and 5.0 grams of dicyandiamide curing agent, stir evenly, and obtain a homogeneous transparent and clear high temperature copper foil adhesive, which is recorded as CFA-3.

[0044] Take an appropriate amount of CFA-3 high temperature resistant copper foil adhesive and evenly apply it on the surface of thick copper test piece or phenolic hydroxyl polyimide film to prepare copper-adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com