Preparation method of high temperature resistant single-component solventless epoxy adhesive

An epoxy adhesive, one-component technology, applied in the direction of adhesive types, epoxy resin adhesives, adhesives, etc., can solve the problems of inability to meet high temperature conditions, endanger human health, low bonding strength, etc., and achieve cost-effective Low, easy to operate, excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

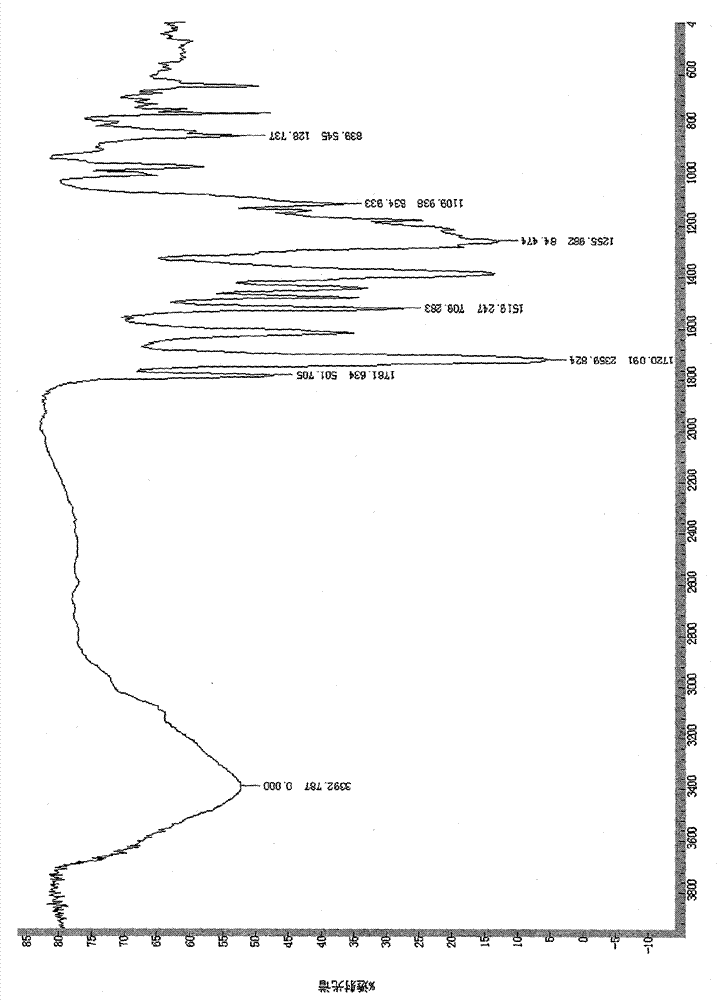

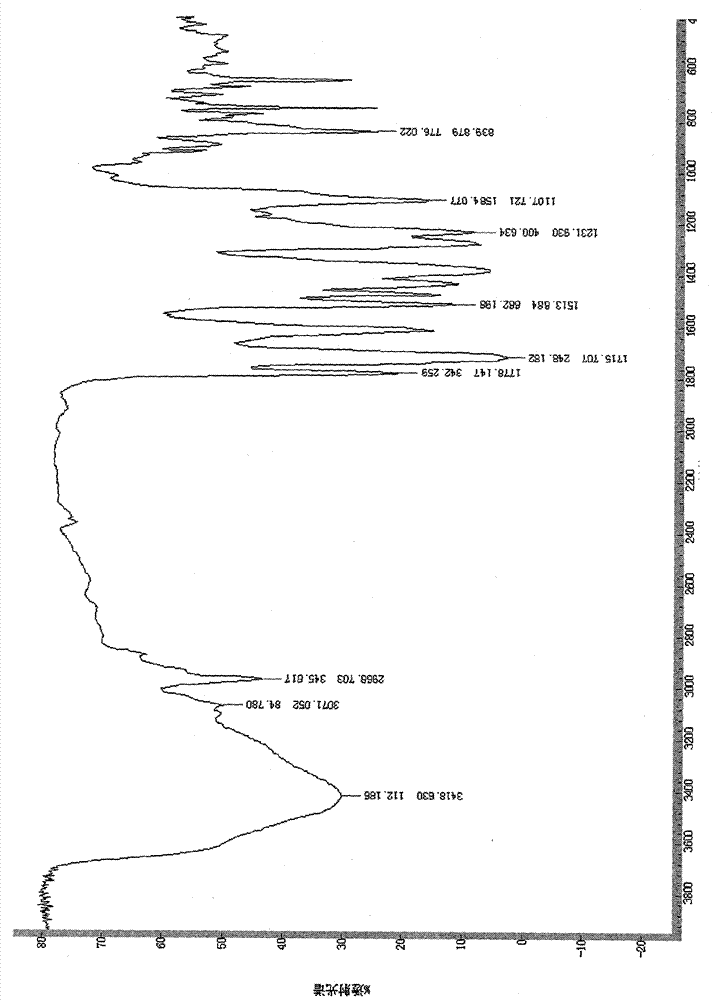

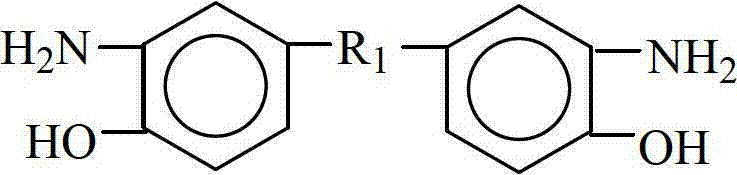

[0043] 36.6 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (BAHPFP), 414.4 grams (0.8 moles) of 2,2-bis[4-(4-aminophenoxy Base) phenyl] hexafluoropropane (BAPOPFP) and 3045 milliliters of N-methyl-2-pyrrolidone solvent are added in the reaction kettle, stirred at room temperature, after completely dissolving, add 310.0 grams (1.0 mole) 3,3 ', 4, 4'-tetracarboxylic acid diphenyl ether dianhydride (ODPA) powder, after stirring at room temperature to dissolve completely, continue to react for 4 hours, add 6090 milliliters of toluene entrainer and 0.05 mole of 4-methylbenzenesulfonic acid catalyst, heat up, After 6 hours of reflux and water separation reaction in the temperature range of 120°C to 150°C, the reaction solution was concentrated, cooled to room temperature, and the reaction solution was slowly added to a high-speed (5000r / min-10000r / min ) in the crushing kettle under stirring state, separate out solid powder, filter, wash 2-3 times with deioniz...

Embodiment 2

[0049] Add 100.0 grams of ES216 epoxy resin, 8.0 grams of white thermoplastic polyimide HPI-1 powder, and 0.1 grams of 2-ethyl-4-methylimidazole into the reaction bottle, and heat up to a temperature of 100°C-120°C The reaction was carried out for 1-2 hours to obtain a viscous imine toughened modified epoxy resin system. Add 80.0 grams of 3,4-epoxycyclohexanecarboxylic acid-3',4'-epoxycyclohexane methyl ester reactive diluent, 10.0 grams of Dicyandiamide latent curing agent, stir evenly to obtain high temperature resistant one-component solvent-free epoxy adhesive.

[0050] Take an appropriate amount of the adhesive obtained above, and evenly spread it on a standard steel test piece. Cool to room temperature.

[0051] The adhesive system has good viscosity controllability, can be adjusted in a wide range, has good manufacturability, and has excellent bonding performance to metal substrates (such as steel, etc.). The specific test results are as follows:

[0052] Steel-steel...

Embodiment 3

[0055] 25.8 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl)propane (BAHPP), 123.0 grams (0.3 moles) of 2,2-bis[4-(4-aminophenoxy) Phenyl] propane (BAPOPP) and 2728 milliliters of N, N-dimethylacetamide solvent are added in the reaction kettle, stirred at room temperature, after completely dissolving, add 124.0 grams (0.4 mol) 3,3',4,4'- Tetracarboxylic diphenyl ether dianhydride (ODPA) powder, after stirring and dissolving completely at room temperature, continue to react for 2 hours, add 275 milliliters of xylene entrainer and 0.08 mole of 4-methylbenzenesulfonic acid catalyst, heat up, at 120 After reflux and water separation reaction in the temperature range of ℃~150℃ for 12 hours, concentrate the reaction solution, cool to room temperature, slowly add the reaction solution to a high-speed (5000r / min-10000r / min) stirring solution containing 2728 ml of ethanol precipitant In the crushing still under state, separate out solid powder, filter, wash 2-3 times with deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com