A kind of preparation method of high permeability amino silicone oil

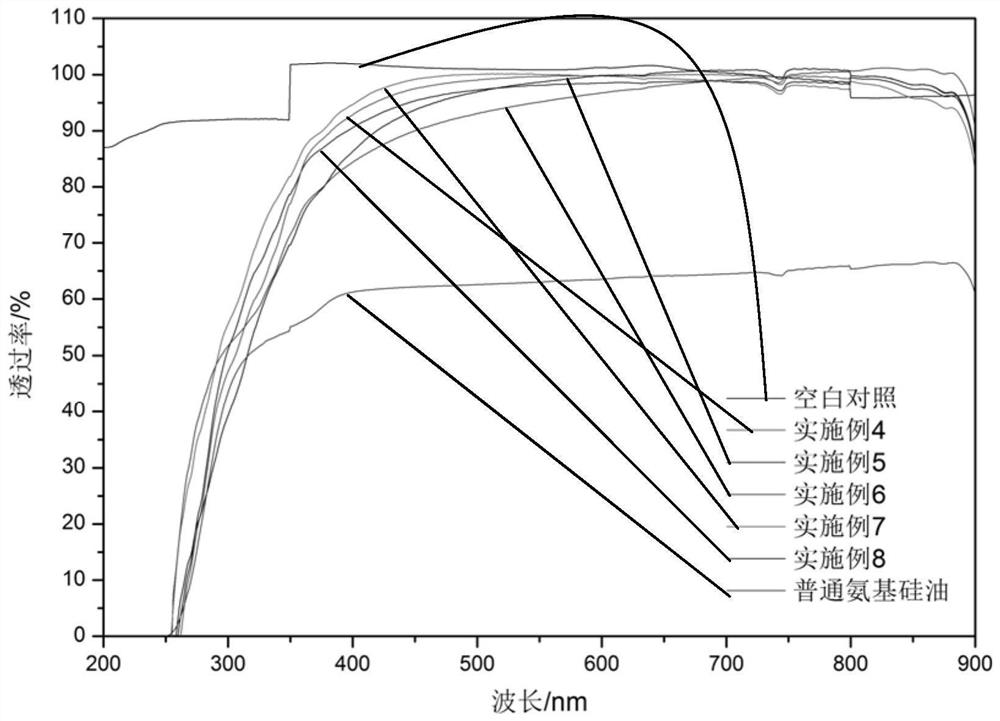

An amino silicone oil, high transmittance technology, applied in animal fibers, fiber treatment, textiles and papermaking, etc., can solve the problems of affecting the use effect, poor transparency, uneven distribution of amino groups, etc., to achieve excellent results, excellent stability The effect of uniform distribution of sex and amino groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a. Preparation of coupling agent hydrolyzate

[0026] Mix 20 parts of KH602 and 18 parts of water in a closed four-necked flask and stir at a constant speed for hydrolysis, the hydrolysis temperature is 10°C, and the hydrolysis time is 2 hours; then maintain at -0.09MPa for 1 hour to remove low-molecular compounds; the viscosity obtained after standing still is 300mPa·s (25°C) KH602 hydrolyzate mainly composed of silicon glycol.

Embodiment 2

[0028] a. Preparation of coupling agent hydrolyzate

[0029] Mix 18 parts of KH602 and 13.5 parts of water in a closed four-necked flask and stir at a constant speed for hydrolysis, the hydrolysis temperature is 15°C, and the hydrolysis time is 1h; then maintain at -0.09MPa for 1h to remove low-molecular compounds; the viscosity obtained after standing still is 200mPa·s (25°C) KH602 hydrolyzate mainly composed of silicon glycol.

Embodiment 3

[0031] a. Preparation of coupling agent hydrolyzate

[0032] Mix 17 parts of KH602 and 9 parts of water in a closed four-necked flask and stir at a constant speed for hydrolysis. The hydrolysis temperature is 12°C and the hydrolysis time is 1.5h; then maintain at -0.09MPa for 1h to remove low-molecular compounds; stand still to get the viscosity It is KH602 hydrolyzate mainly composed of silicon glycol at 100mPa·s (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com