Active phthalimide epoxy solvent-free dripping impregnating varnish and preparation method thereof

A phthalimide epoxy type and phthalimide technology, which is applied in the field of solvent-free dripping paint and its preparation, can solve the problems of undisclosed composition or chemical structure, inability to repeat tests or verify performance, and achieve paint film The effect of continuous compaction, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

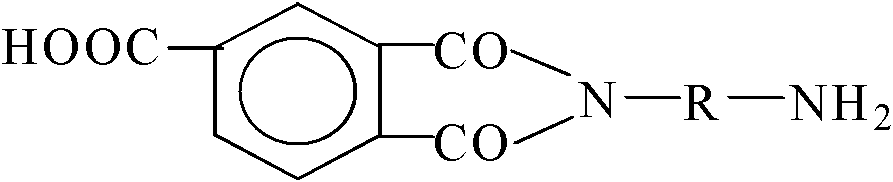

Method used

Image

Examples

Embodiment 1

[0051] Under a nitrogen atmosphere, a strong electrode of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane dibasic primary amine and 1120 grams of N,N-dimethylformamide was mixed with 366.3 grams (1.0 mole). Add 192.0 g (1.0 mol) of trimellitic anhydride powder after stirring and dissolving at room temperature, stir and react at room temperature for 2 hours, add 448 g of toluene, heat to reflux state, azeotropically divide water and stir After reacting for 3 hours, separate toluene, add 2240 g of ethanol, stir at high speed, precipitate solid powder, filter and dry to obtain 538.7 g of active phthalimide with a yield of 99.7%.

[0052] Get 150.0 grams of above-mentioned reactive phthalimides, 150.0 grams of N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane (YAG80, epoxy value 0.81) and 200.0 grams of bis Epoxy resin of phenol A diglycidyl ether (E-51, epoxy value 0.51), active toughening agent of 10.0 grams of amino-terminated polyetherimide and 15.0 grams of carboxyl-t...

Embodiment 2

[0062] Under a nitrogen atmosphere, 180.0 grams (0.9 moles) of 4,4'-diaminodiphenyl ether and 21.6 grams (0.1 moles) of 3,3'-diamino-4,4'-dihydroxybiphenyl dibasic primary amines And 1180 grams of N, the strong polar aprotic organic solvent of N-dimethylacetamide is added in the reaction kettle, after stirring and dissolving at room temperature, add the trimellitic anhydride powder of 192.0 grams (1.0 mole), after stirring and reacting at room temperature for 2 hours, add 472 grams of toluene, heated to reflux state, azeotropic water separation and stirring reaction for 3 hours, then separated toluene, added 2360 grams of ethanol, stirred at a high speed, precipitated solid powder, filtered, dried to obtain 374.8 grams of active phthalimide , the yield was 99.8%.

[0063] Get 100.0 grams of the above active phthalimide, 100.0 grams of N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane (YAG80, epoxy value 0.81), 150.0 grams of N , N, O-triglycidyl-4-aminophenol (APG-90, ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com