Polyimide-epoxy resin adhesive and preparation method and application thereof

A technology of epoxy resin and polyimide, which is applied in the direction of epoxy resin glue, adhesive type, adhesive, etc., can solve the problem of limited heat resistance improvement, limited reactive groups, unsaturated adhesive system Low double bond content and other issues, to achieve the effect of industrialized production, low cost, and convenient source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

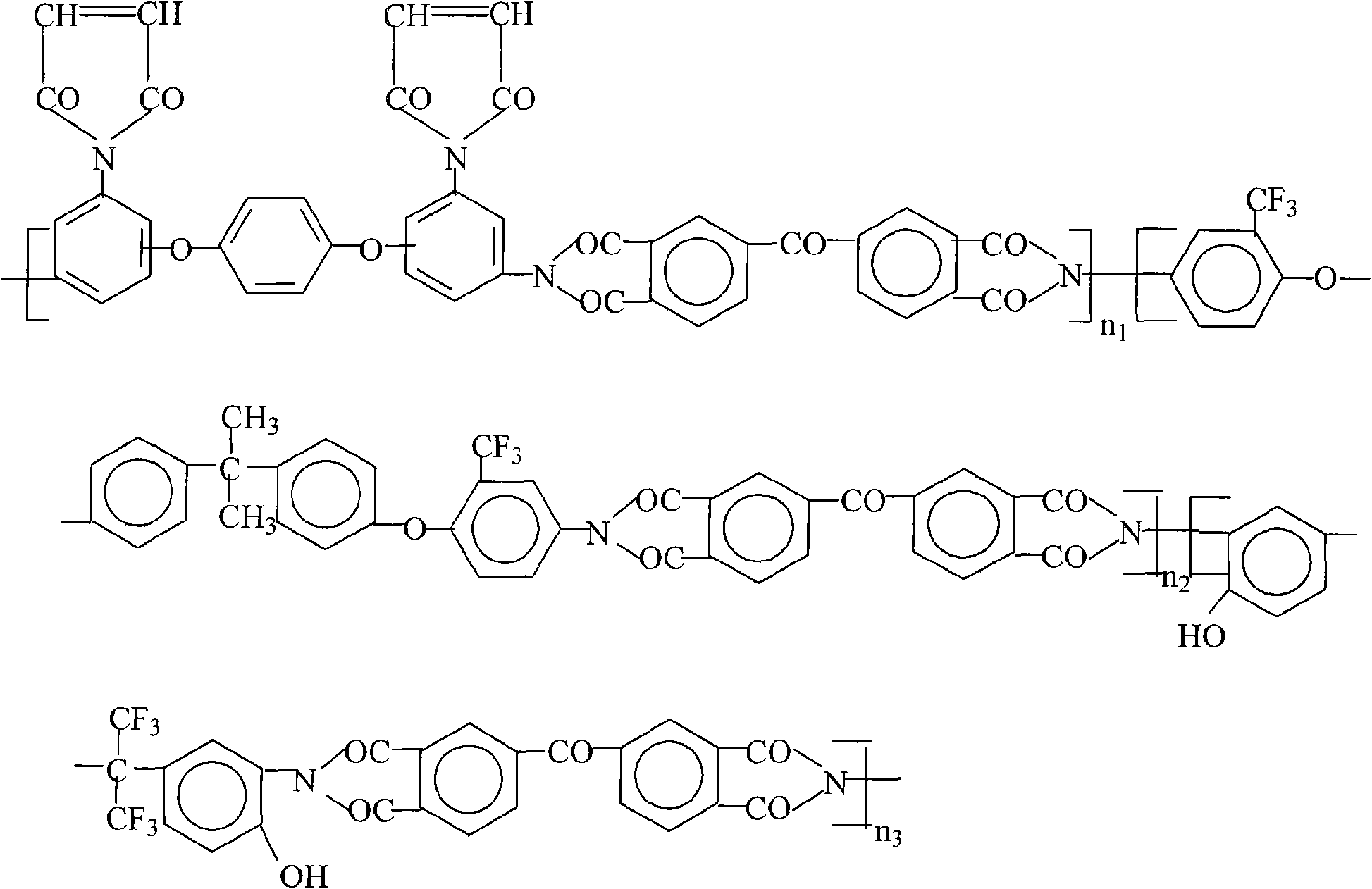

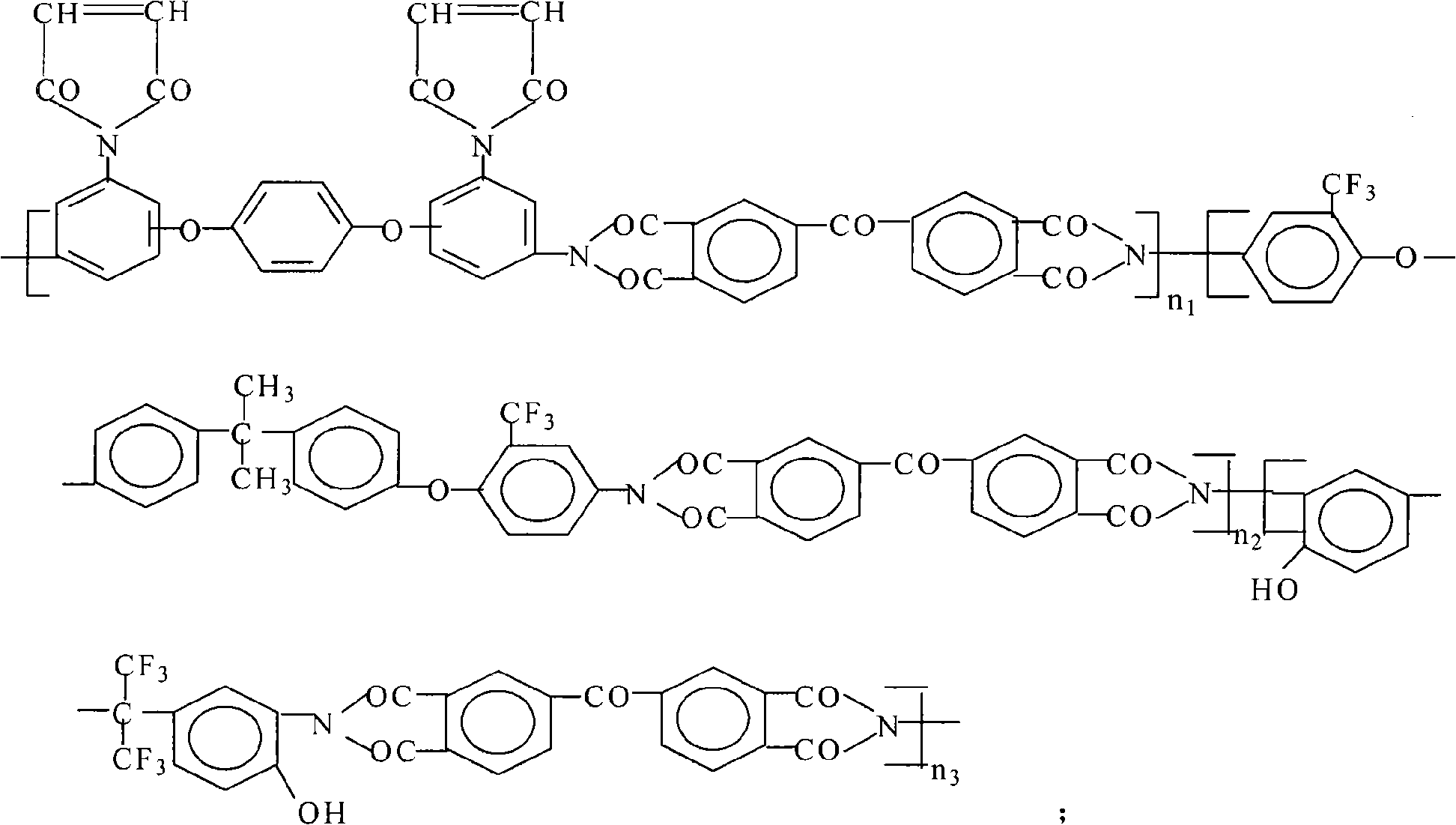

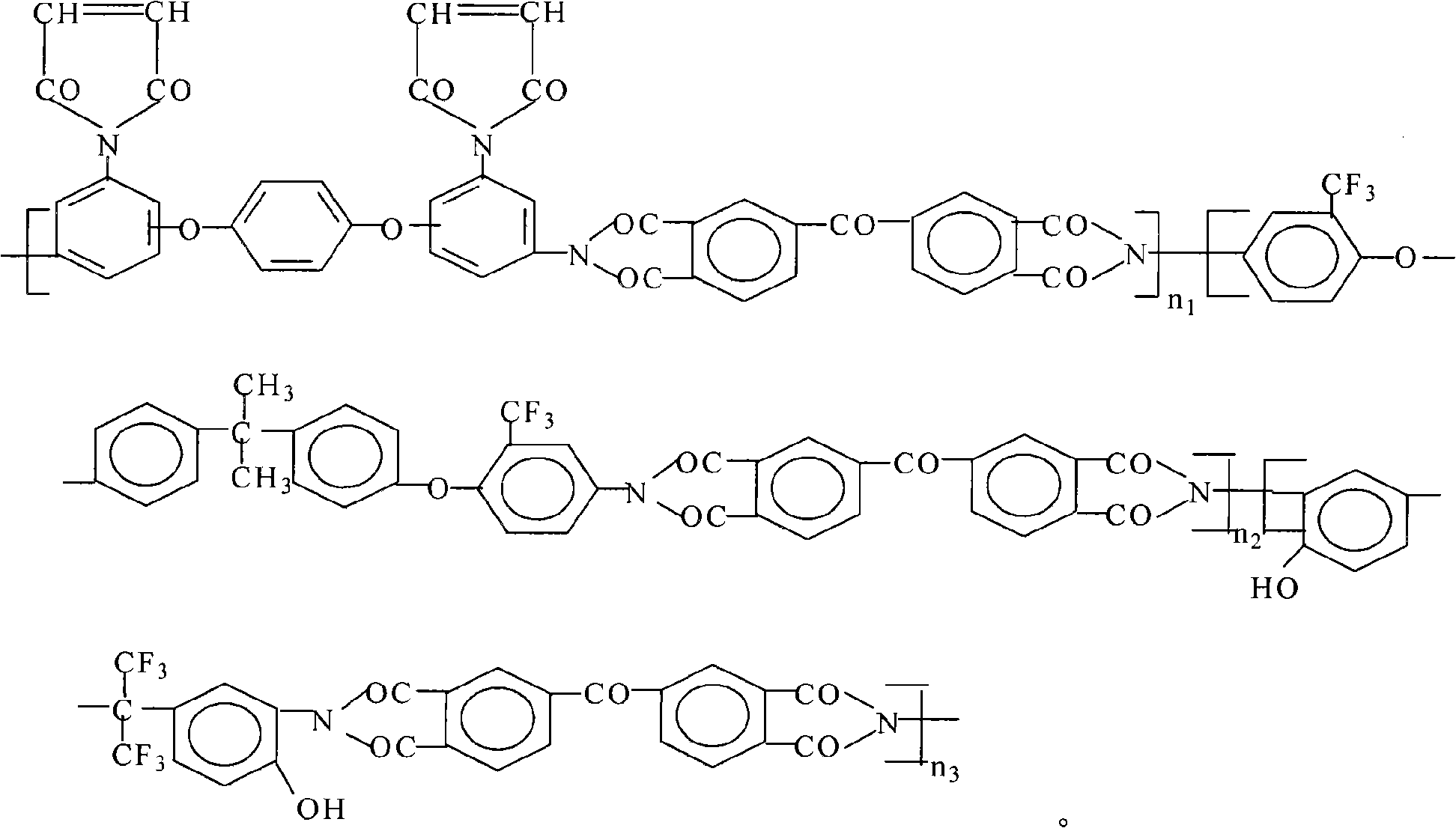

Method used

Image

Examples

Embodiment 1

[0031] 10.0 g of maleimide-based polyimide (MHPI) powder, 10.0 g of N,N,N',N'-tetraglycidyl-3,3'-dimethyl-4,4'-di Add aminodiphenylmethane and 60.0 grams of thermoplastic novolac epoxy resin into the reaction kettle, react at 80°C to 120°C for 1 to 2 hours, cool, add 65.5 grams of N,N-dimethylacetamide organic solvent, at room temperature, Stir to dissolve and form a homogeneous transparent solution to obtain component A.

[0032] With 19.1 grams of 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane curing agent, 0.9 grams of 2-ethyl-4-methylimidazole accelerator and 34.5 grams of N,N-di Methylacetamide is mixed with an organic solvent, stirred and dissolved to obtain a homogeneous and transparent component B solution.

[0033] Mix components A and B and stir evenly to obtain a polyimide-epoxy resin adhesive, which is designated as PIEP-1.

[0034] Take an appropriate amount of PIEP-1 polyimide-epoxy resin adhesive, and apply it evenly on the standard steel test piece, stack...

Embodiment 2

[0037] 70.0 grams of maleimide-based polyimide (MHPI) powder and 10.0 grams of N, N, N', N'-tetraglycidyl-4,4'-diaminodiphenylmethane were added to the reactor, After reacting at 80°C to 120°C for 1 to 2 hours, cool down, add 45.5 g of chloroform and 20.0 g of N,N-dimethylformamide organic solvent, stir and dissolve at room temperature, and form a homogeneous transparent solution to obtain A components.

[0038] With 9.8 grams of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane curing agent, 0.2 gram of 1,8-diaza-bicyclo[5.4.0]undecene-7 accelerator and 44.5 gram of N,N-dimethylacetamide organic solvent mixed, stirred and dissolved to obtain a homogeneous and transparent component B solution.

[0039] Mix components A and B and stir evenly to obtain a polyimide-epoxy resin adhesive, which is designated as PIEP-2.

[0040] Take an appropriate amount of PIEP-2 polyimide-epoxy resin adhesive, and evenly spread it on a standard steel test piece, stack it, clamp it, and put it i...

Embodiment 3

[0043] Mix 24.0 grams of maleimide-based polyimide (MHPI) powder, 40.0 grams of thermoplastic novolac epoxy resin and 20.0 grams of N,N,N',N'-tetraglycidyl-4,4'-diamino Add diphenylmethane into the reaction kettle, react at 80°C to 120°C for 1 to 2 hours, cool, add 50.0 g of dichloromethane and 10.0 g of N-methyl-2-pyrrolidone organic solvent, and stir to dissolve at room temperature. Homogeneous clear solution, A component obtained.

[0044] 15.5 grams of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride curing agent, 0.5 grams of 1,8-diaza-bicyclo[5.4.0]undecene -7 Accelerator is mixed with 40.0 g of N-methyl-2-pyrrolidone organic solvent, stirred and dissolved to obtain a homogeneous and transparent component B solution.

[0045] Mix components A and B and stir evenly to obtain a polyimide-epoxy resin adhesive, which is designated as PIEP-3.

[0046] Take an appropriate amount of PIEP-3 polyimide-epoxy resin adhesive, and apply it evenly on the standard steel tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com