Flux-cored wire for welding different materials, method for laser welding of different materials and method for MIG welding of different materials

A laser welding and dissimilar material technology, applied in laser welding equipment, welding/welding/cutting items, welding/cutting medium/material, etc. Cracks and other problems, to achieve the effect of improving peel strength, tensile shear strength and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

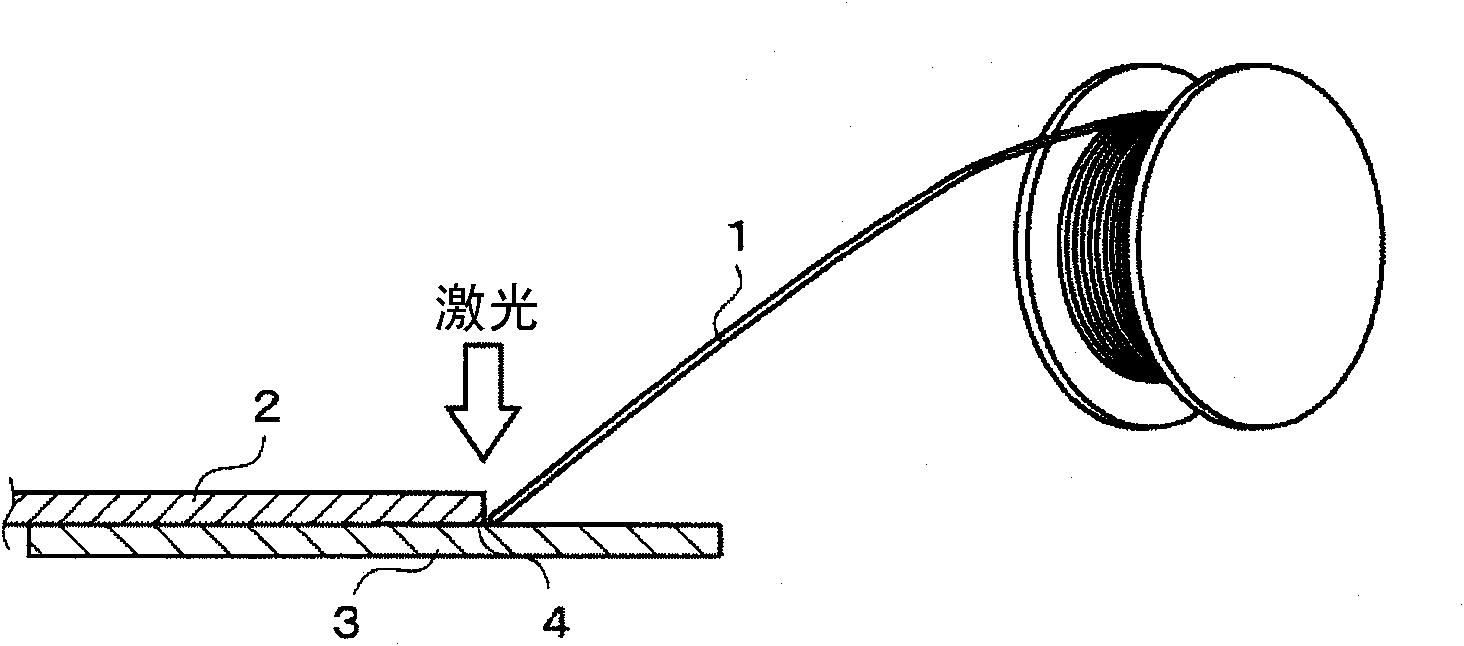

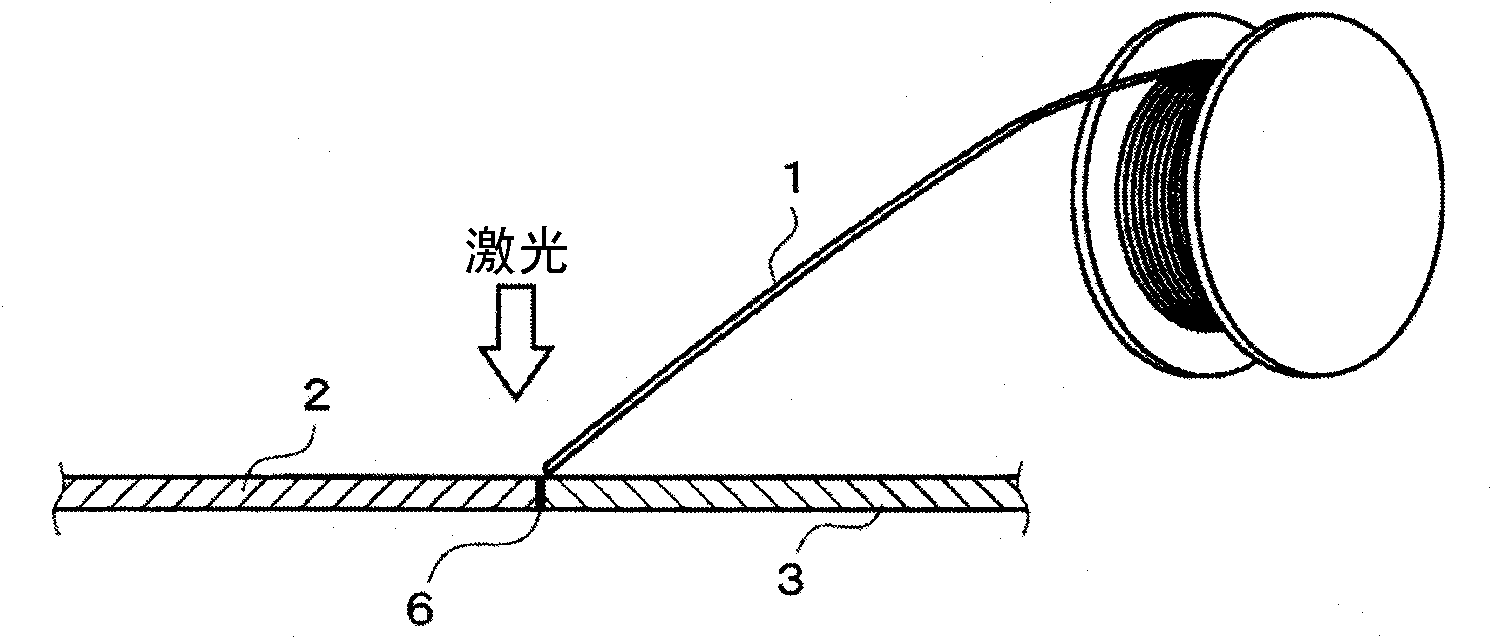

[0076] Hereinafter, an example showing the effect of the flux-cored wire for laser welding of different materials according to the present invention will be specifically described in comparison with a comparative example. As the aluminum alloy material 2 , a plate material having a plate thickness of 1.0 mm (for example, a width of 100 mm and a length of 300 mm) made of an AA6022 alloy (JIS A 6000 alloy) was used. In addition, as the steel material 3, a 980 MPa grade cold-rolled steel sheet with a thickness of 1.4 mm (for example, a width of 100 mm and a length of 300 mm) and two types of steel sheets obtained by hot-dip galvanizing the same steel sheet were used. In addition, as the test material to be welded, the aluminum alloy material 2 and the steel material 3 were used to maintain the plates as they were, and were separated from the end of each plate by an appropriate length (for the aluminum alloy material 2, it was 10 mm from the end of the plate, and for the The steel...

no. 2 Embodiment

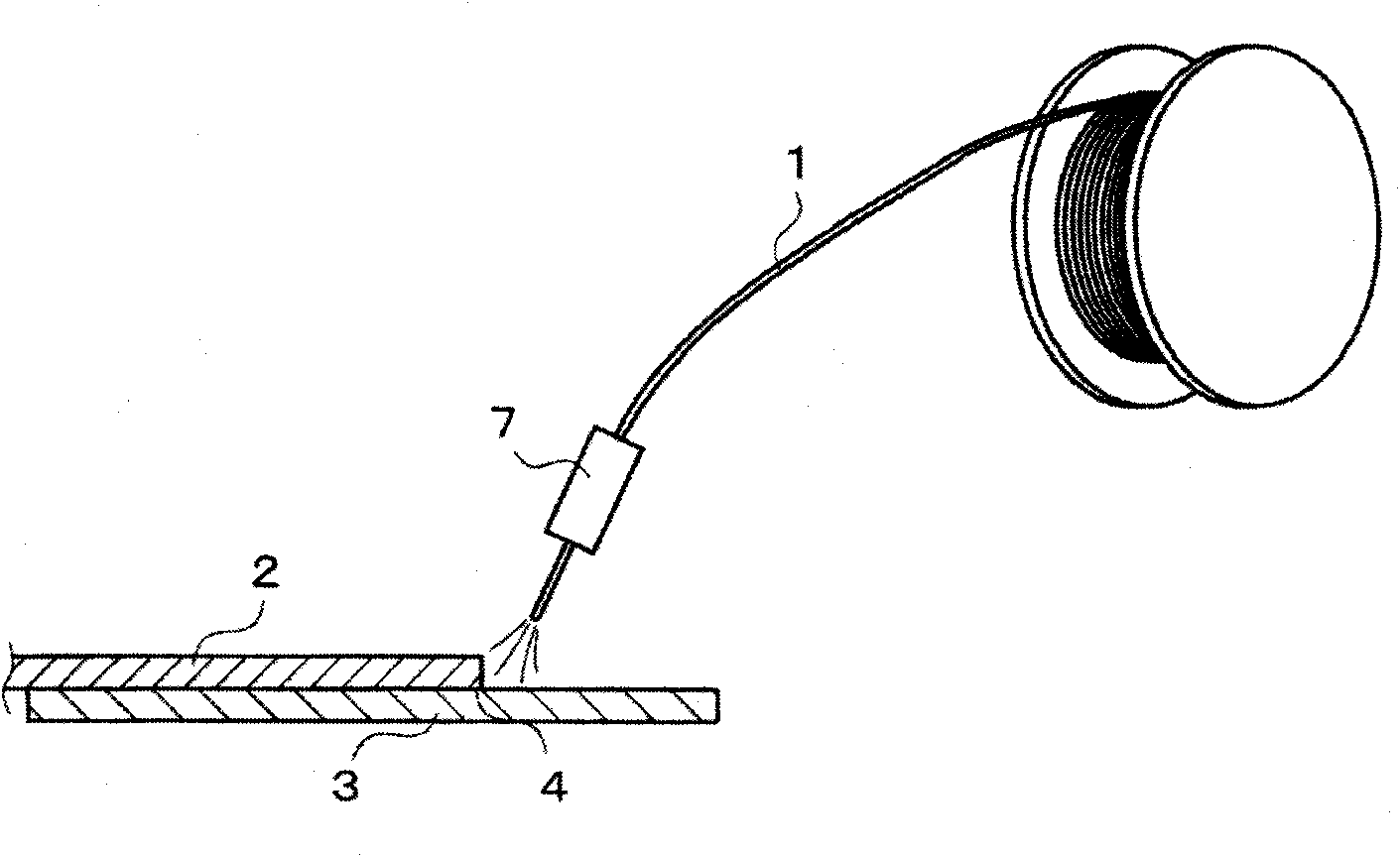

[0104] Hereinafter, an example of a different material MIG welding method using the different material welding flux-cored wire of the present invention will be specifically described in comparison with a comparative example. As the aluminum alloy material 2 , a plate material having a plate thickness of 2.0 mm (for example, 100 mm in width and 300 mm in length) made of AA6022 alloy (JIS A 6000 alloy) was used. In addition, a 980 MPa grade cold-rolled steel sheet having a thickness of 1.4 mm (for example, a width of 100 mm and a length of 300 mm) or a galvanized steel material obtained by hot-dip galvanizing the same steel sheet was used. In addition, as the test material to be welded, the aluminum alloy material 2 and the steel material 3 were used to maintain the plates as they were, and were separated from the end of each plate by an appropriate length (for the aluminum alloy material 2, it was 10 mm from the end of the plate, and for the The steel material 3 is a bent plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com