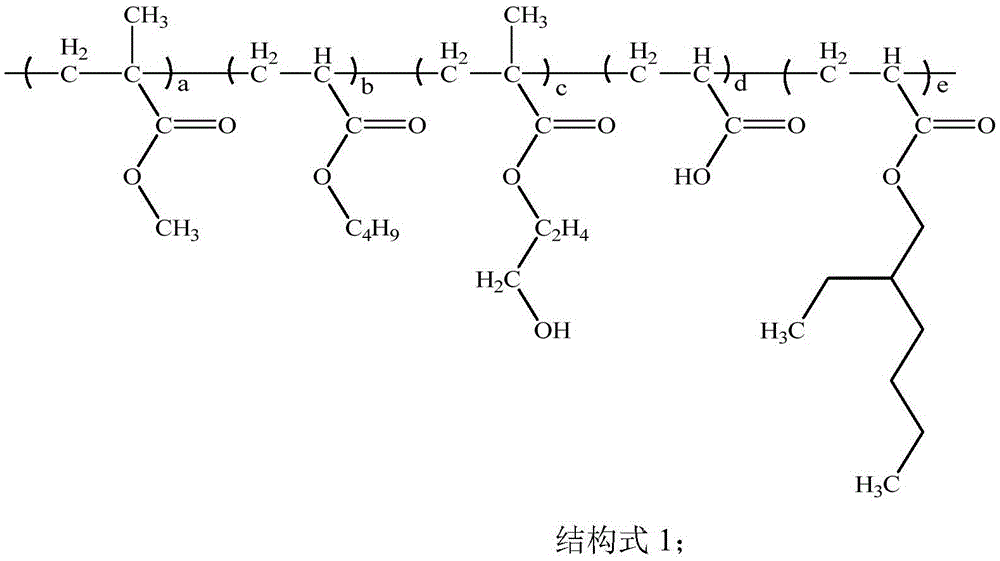

Ultraviolet light curing transfer printing glue and preparation method and application thereof

A technology of transfer glue and composition, which is applied in the direction of copying/marking methods, printing, adhesives, etc., can solve the problems of low bonding strength, insufficient heat resistance, poor chemical resistance, etc., and achieve tensile shear strength High, good light resistance, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

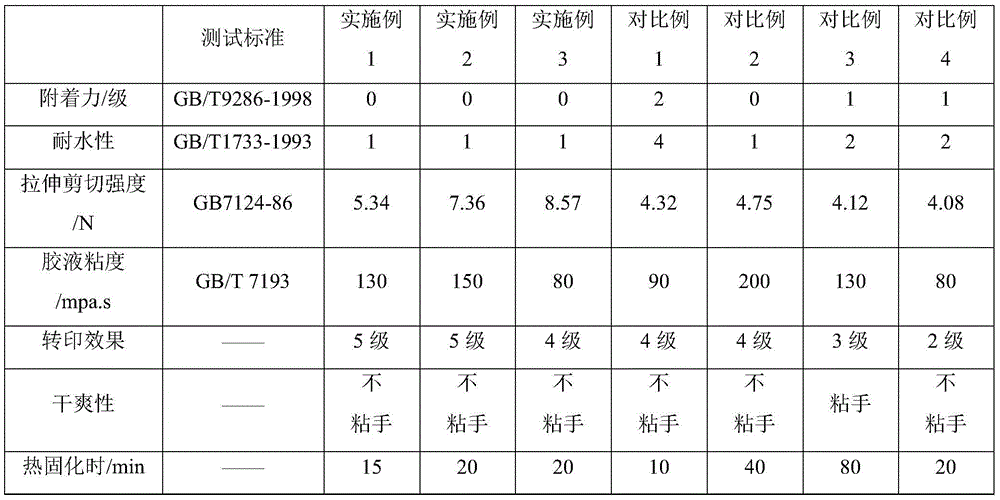

Examples

Embodiment 1

[0046]Add 30.8g of IPDI and 20mL of ethyl acetate to a four-neck flask with a condenser, thermometer, stirrer, and nitrogen conduit, and control the temperature at 45 to 50°C. Add 18.1g of HEMA, 0.3g of catalyst dibutyltin dilaurate (DBTDL), Mix 0.04g inhibitor 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO), MMA, n-BA, HMPA, AA and EHA with 20mL ethyl acetate, pour into the flask Add the mixed solution dropwise, raise the temperature to 65-70°C after the dropwise addition, and react for 1.5-2 hours to obtain isocyanate-containing polyurethane; mix 55gMMA, 20gn-BA, 20gHPMA, 5gAA, 10gHEA, 1gAIBN, 2g dodecane NDM and 50mL solvent were mixed uniformly to obtain a mixed solution, and the mixed solution was controlled to be added dropwise within two hours. After the dropwise addition of the mixed solution is completed, add 0.5g AIBN dropwise into the reaction vessel, control the system temperature at 72°C for 5h constant temperature reaction to obtain a five-component acrylate...

Embodiment 2

[0049] Add 24g TDI and 20mL ethyl acetate to a four-neck flask equipped with a condenser, thermometer, stirrer, and nitrogen conduit, control the temperature at 45-50°C, mix 16g HEA with 0.3g catalyst DBTDL, 0.04g polymerization inhibitor TEMPO, and 20mL acetic acid Ethyl ester, mix evenly, add the mixed solution into the flask dropwise, raise the temperature to 65-70°C after the dropwise addition, and react for 1.5-2 hours to obtain polyurethane containing isocyanate; mix 50gMMA, 18gn-BA, 20gHPMA, 5gAA , 9gEHA, 1.5gAIBN, 3gNDM and 50mL solvent were mixed evenly to obtain a mixed solution, and the mixed solution was controlled to be added dropwise within two hours. After the dropwise addition of the mixed solution is completed, add 0.5g AIBN dropwise into the reaction vessel, control the system temperature at 72°C for 5h constant temperature reaction to obtain a five-component acrylate copolymer with a number average molecular weight of 6000; Add the above mixed solution of is...

Embodiment 3

[0052] Add 25.9g of IPDI and 20mL of ethyl acetate to a four-neck flask equipped with a condenser, thermometer, stirrer, and nitrogen conduit 1, and control the temperature at 45-50°C. Mix 13.5g of HEA with 0.3g of catalyst DBTDL and 0.04g of polymerization inhibitor TEMPO , 20mL ethyl acetate, mix evenly, add the mixed solution dropwise into the flask, raise the temperature to 65-70°C after the dropwise addition, and react for 1.5-2h to obtain polyurethane containing isocyanate; mix 60gMMA, 22gBA, 21gHPMA, 5gAA, 11gEHA, 2gAIBN, 4gNDM and 50mL solvent were mixed evenly to obtain a mixed solution, and the mixed solution was controlled to be added dropwise within two hours. After the dropwise addition of the mixed solution is completed, add 0.5g AIBN dropwise into the reaction vessel, control the system temperature at 72°C for 5h constant temperature reaction to obtain a five-component acrylate copolymer with a number average molecular weight of 5300; drop into the five-component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com