Tackiness agent for automobile tank

A technology for automotive fuel tanks and adhesives, applied in the field of adhesive resins, can solve the problems of hindering the application range, insufficient strength, short storage time, etc., achieve good resistance to fuel immersion, and improve the effect of tensile shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] See the table below for each component and content (mass fraction %) of the adhesive used for the automobile fuel tank:

[0022] raw material name

[0023] Hydroxyethyl methacrylate

[0024] Stir the toughening resin, MAA, etc. at room temperature for 50-70 hours to dissolve in MMA according to the formula components to form a basic glue; then divide the basic glue into two parts, add corresponding raw materials according to the formula components, and use aluminum The tubes are packed and the back cover is made into components A and B of the adhesive used for automobile fuel tanks.

Embodiment 2

[0026] See the table below for each component and content (mass fraction %) of the adhesive used for the automobile fuel tank:

[0027] raw material name

[0028] Stir the toughening resin, MAA, etc. at room temperature for 50-70 hours to dissolve in MMA according to the formula components to form a basic glue; then divide the basic glue into two parts, add corresponding raw materials according to the formula components, and use aluminum The tubes are packed and the back cover is made into components A and B of the adhesive used for automobile fuel tanks.

Embodiment 3

[0030] See the table below for each component and content (mass fraction %) of the adhesive used for the automobile fuel tank:

[0031] raw material name

Component A

Component B

MMA

45

45

MBS

22

22

MAA

5

5

[0032] Cumene Hydroperoxide

5

Chlorosulfonated polyethylene

7

2.7

10

15

Ethylene glycol diester methacrylate

6

9

1.3

[0033] Stir the toughening resin, MAA, etc. at room temperature for 50-70 hours to dissolve in MMA according to the formula components to form a basic glue; then divide the basic glue into two parts, add corresponding raw materials according to the formula components, and use aluminum The tubes are packed and the back cover is made into components A and B of the adhesive used for automobile fuel tanks.

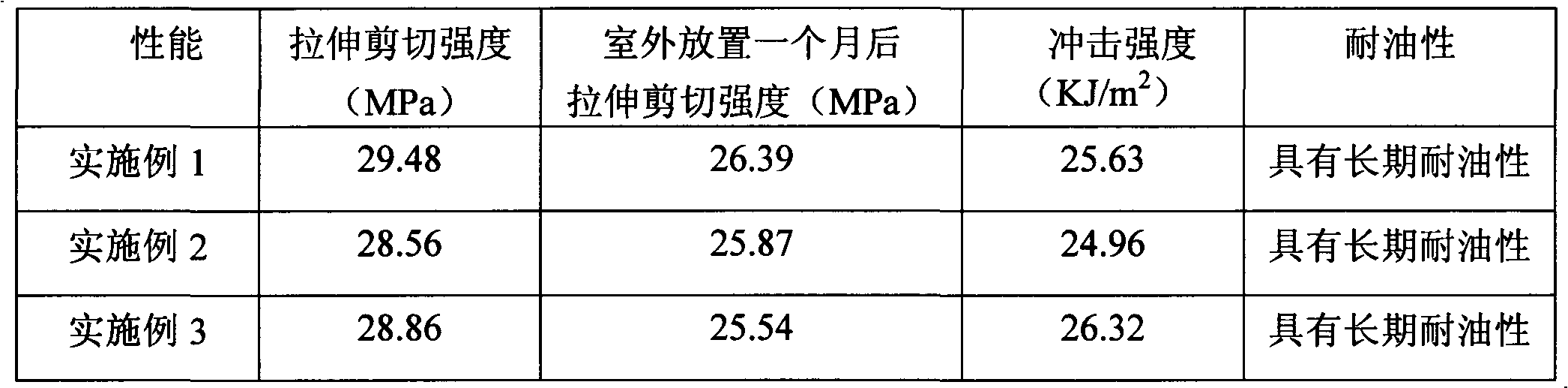

[0034] The perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com