Epoxy-graphenemetal bonding agent and preparation method thereof

A metal bonding, graphene technology, applied in the direction of graphene, adhesives, epoxy resin glue, etc., can solve problems such as low tensile shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

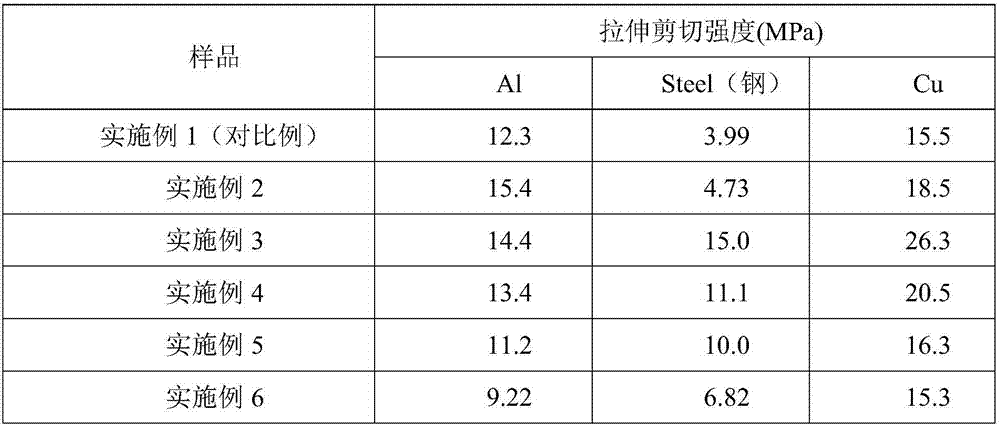

Examples

Embodiment 1

[0024] A preparation method of an epoxy metal adhesive, comprising: 60 parts of epoxy resin (E51) and 40 parts of polyetheramine (D400) in terms of components by weight.

[0025] The above-mentioned epoxy metal adhesive is prepared by the following steps:

[0026] (1) take epoxy resin and polyetheramine by weight;

[0027] (2) Put epoxy resin and polyetheramine into a container and mix, heat at 60°C, and mechanically stir at 15,000r / min for 20 minutes to obtain an epoxy metal adhesive.

[0028] (3) According to the GB / T 21526-2008 standard, use a glass rod to coat the obtained epoxy metal adhesive on a clean aluminum sheet, steel sheet, or copper sheet, and the coating thickness can cover the aluminum sheet, steel sheet, or copper sheet The surface is enough, then press tightly to discharge the excess adhesive, so that the upper and lower aluminum sheets or steel sheets or copper sheets are completely bonded, and finally put them in an oven for curing. The curing conditions a...

Embodiment 2

[0030] An epoxy-graphene metal adhesive, calculated by weight components: 60 parts of epoxy resin E51, 39 parts of polyetheramine D400, 0.5 parts of graphene, 0.5 parts of silane coupling agent KH550.

[0031] Above-mentioned epoxy-graphene metal adhesive is prepared by the following steps:

[0032] (1) take epoxy resin, polyether amine, graphene and silane coupling agent according to above weight parts;

[0033] (2) Add epoxy resin, polyether amine, graphene and silane coupling agent into the container, first mix mechanically, then ultrasonically oscillate, heat at 60°C, and mechanically stir at 15000r / min for 30 minutes to obtain epoxy-graphite Alkene Metal Adhesives.

[0034] (3) According to the GB / T 21526-2008 standard, use a glass rod to coat the obtained epoxy-graphene metal adhesive on a clean aluminum sheet or steel sheet or copper sheet, and the coating thickness can cover the aluminum sheet or steel sheet Or the surface of the copper sheet, and then press tightly ...

Embodiment 3

[0036] An epoxy-graphene metal adhesive, calculated by weight components: 59.5 parts of epoxy resin E51, 38 parts of polyetheramine D400, 1 part of graphene, 1.5 parts of silane coupling agent KH550.

[0037] Above-mentioned epoxy-graphene metal adhesive is prepared by the following steps:

[0038] (1) take epoxy resin, polyether amine, graphene and silane coupling agent according to above weight parts;

[0039] (2) Add epoxy resin, polyether amine, graphene and silane coupling agent into the container, first mix mechanically, then ultrasonically oscillate, heat at 60°C, and mechanically stir at 15000r / min for 30 minutes to obtain epoxy-graphite Alkene Metal Adhesives.

[0040](3) According to the GB / T 21526-2008 standard, use a glass rod to coat the obtained epoxy metal adhesive on a clean aluminum sheet, steel sheet, or copper sheet, and the coating thickness can cover the aluminum sheet, steel sheet, or copper sheet The surface is enough, then press tightly to discharge t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com