Flux-cored wire for welding different materials, method for laser welding of different materials, and method for MIG welding of different materials

A dissimilar material, laser welding technology, used in laser welding equipment, welding/welding/cutting items, welding media, etc., can solve problems such as the decrease of peel strength of joints, improve peel strength, improve tensile shear strength and , the effect of improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

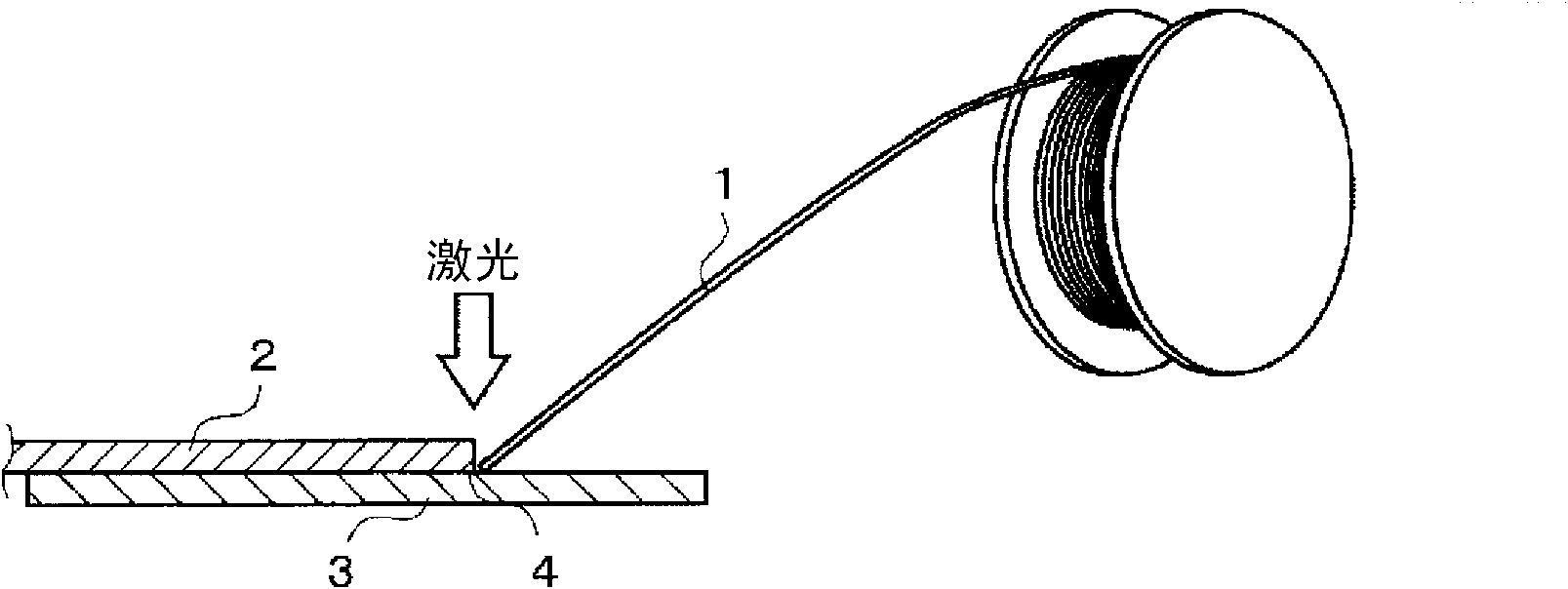

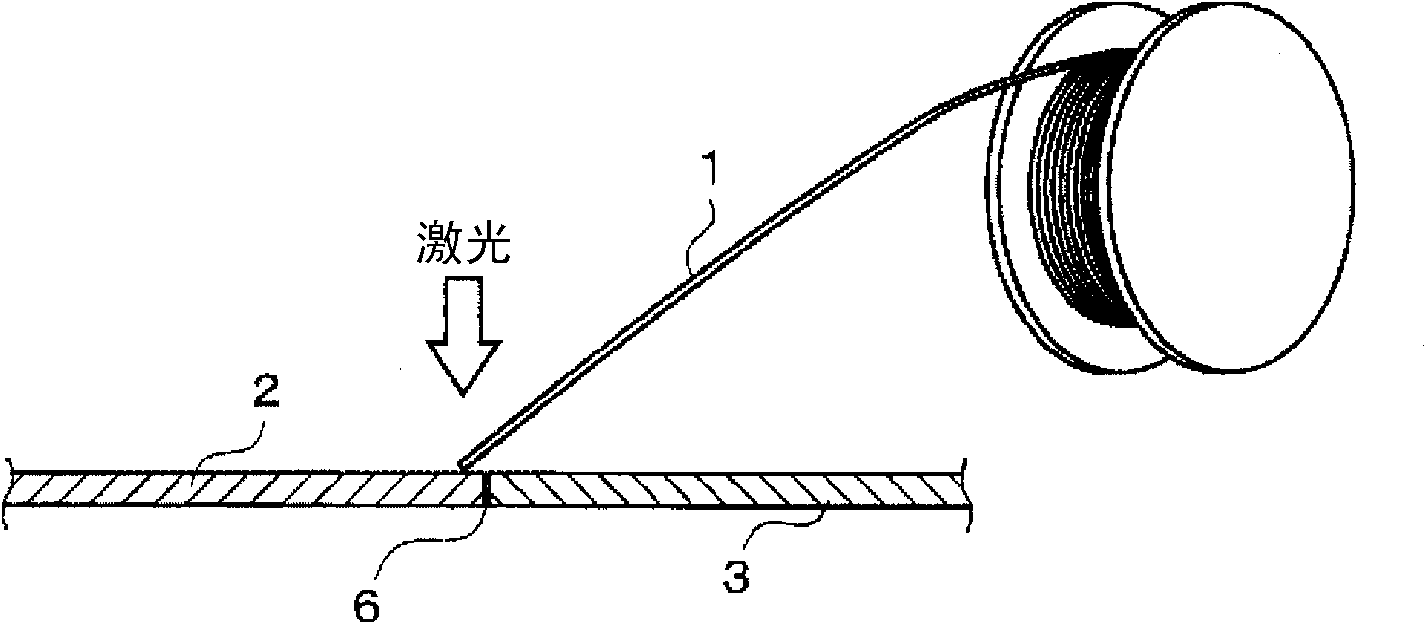

[0058] Hereinafter, an example showing the effect of the flux-filled wire for laser welding of dissimilar materials according to the present invention will be specifically described by comparing it with a comparative example. As the aluminum alloy material 2 , a plate material having a plate thickness of 1.0 mm (for example, a width of 100 mm and a length of 300 mm) formed of an AA6022 alloy (JIS A6000 series alloy) was used. Furthermore, hot-dip galvanizing was performed on a 980 MPa-class cold-rolled steel sheet having a plate thickness of 1.2 mm (for example, a width of 100 mm and a length of 300 mm) to obtain a galvanized steel material 3 . Moreover, as the total test material of the welding object, what use is to keep the aluminum alloy material 2 and the galvanized steel material 3 as the plate is separated from the end of the plate by an appropriate length (for the aluminum alloy material 2, it is 10mm away from the end of the plate; For galvanized steel material 3, it ...

no. 2 example

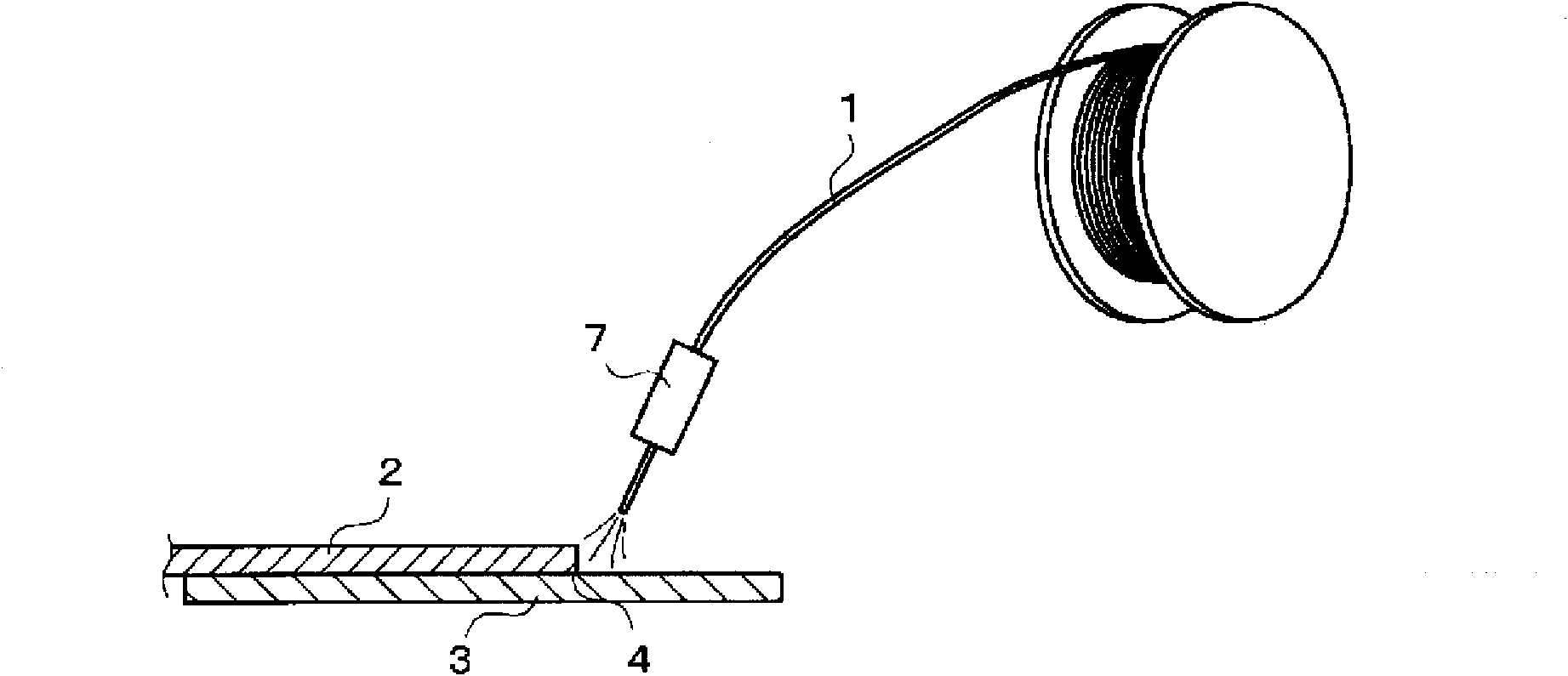

[0074] Next, an example of a dissimilar material MIG welding method using the filled flux wire for dissimilar material welding of the present invention will be specifically described by comparing it with a comparative example. As the aluminum alloy material 2 , a plate material having a plate thickness of 2.0 mm (for example, a width of 100 mm and a length of 300 mm) formed of an AA6022 alloy (JIS A6000 series alloy) was used. Furthermore, hot-dip galvanizing was performed on a 980 MPa-class cold-rolled steel sheet having a thickness of 1.4 mm (for example, a width of 100 mm and a length of 300 mm) to obtain a galvanized steel material 3 . Moreover, as the total test material of the welding object, what use is to keep the aluminum alloy material 2 and the galvanized steel material 3 as the plate is separated from the end of the plate by an appropriate length (for the aluminum alloy material 2, it is 10mm away from the end of the plate; For galvanized steel material 3, it is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com