Acrylate structure adhesive and preparation method thereof

An acrylate and acrylate technology, applied in the field of new acrylate structural adhesive and its preparation, can solve the problem of low toughness of the adhesive body, and achieve the effects of improving elongation at break and tensile shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

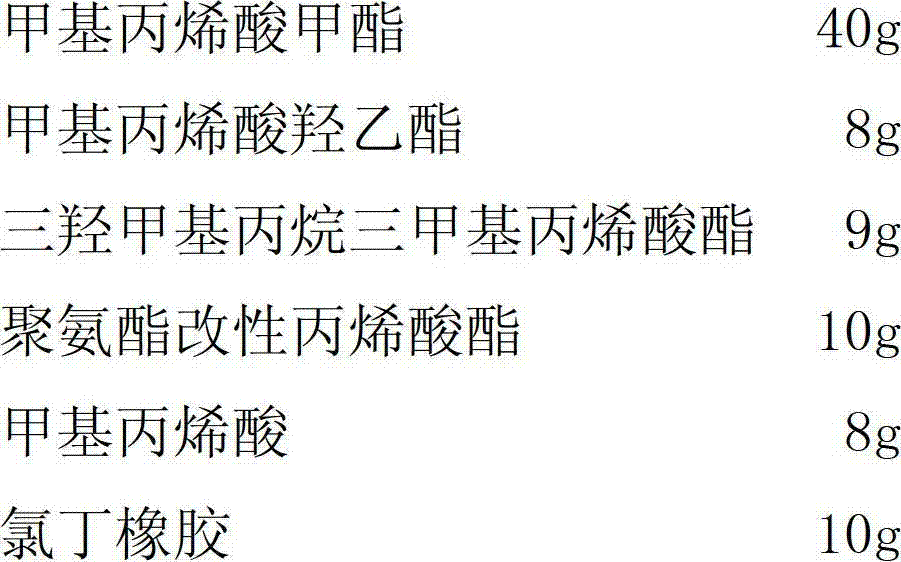

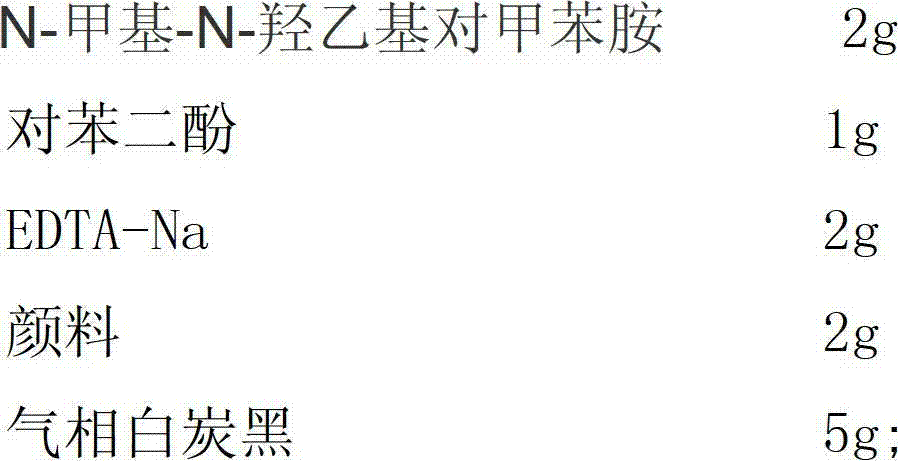

[0032] The formula of component A is as follows:

[0033]

[0034]

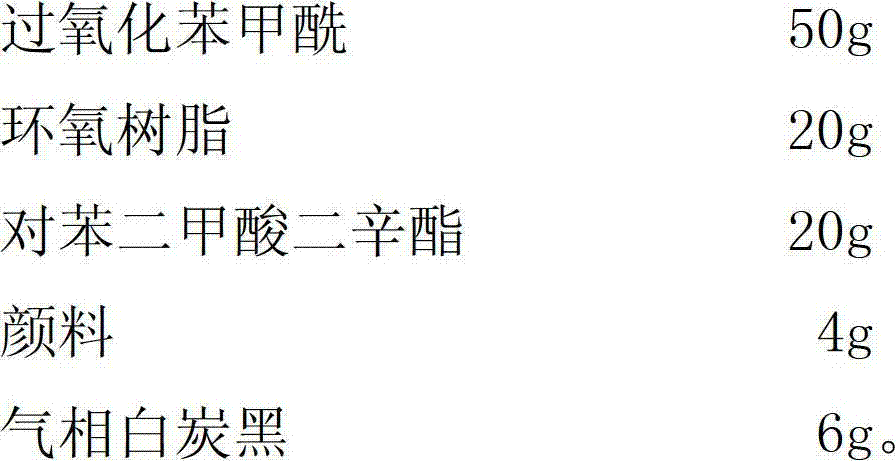

[0035] The formula of component B is as follows:

[0036]

[0037] The preparation method is as follows:

[0038] Mix and stir methyl methacrylate, hydroxyethyl methacrylate, trimethylolpropane trimethacrylate and methacrylic acid, add hydroquinone and EDTA-Na and stir, then add polyurethane modified acrylate, After the chloroprene rubber is dissolved evenly, add tertiary amine, pigment, gas phase white carbon black and other additives for vacuum defoaming to obtain component A.

[0039] Parameters of fumed silica CAB-O- The specific surface area of TS-720 is 100±20m2 / g, and the pigment is milori blue.

[0040] Mix benzoyl peroxide, epoxy resin, and dioctyl terephthalate evenly, then add pigments, gas-phase silica additives, and vacuum defoaming to obtain component B.

[0041] The epoxy resin used in this formula is D.E.R.330 epoxy resin, the parameters of fumed silica CAB-O- TS-720 specific...

Embodiment 2

[0044] The formula of component A is as follows:

[0045]

[0046]

[0047] The formula of component B is as follows:

[0048]

[0049] Mix and stir methyl methacrylate, hydroxypropyl methacrylate, laurate methacrylate and methacrylic acid, add p-hydroxyanisole and EDTA-Na and stir, then add polyurethane modified acrylate, epoxy modified After the non-toxic acrylate and nitrile rubber are dissolved evenly, add N-methyl-N-hydroxyethyl p-toluidine, pigments, gas phase white carbon black and other additives for vacuum defoaming to obtain component A.

[0050] Parameters of fumed silica CAB-O- The specific surface area of TS-720 is 100±20m2 / g, and the pigment is milori blue.

[0051] Mix benzoyl peroxide, epoxy resin, and dioctyl terephthalate evenly, and then add pigments, gas-phase silica additives, and vacuum defoaming to obtain component B.

[0052] The epoxy resin used in this formula is D.E.R.330 epoxy resin, the parameters of fumed silica CAB-O- TS-720 spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com