Cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal

A technology of cold metal transition and dissimilar metals, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of reducing joint performance, easy oxidation of joints, and reduced efficiency, so as to reduce welding heat input, good weld shape, The effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

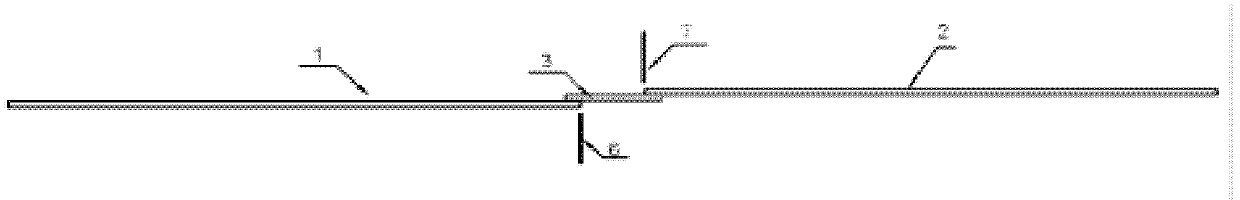

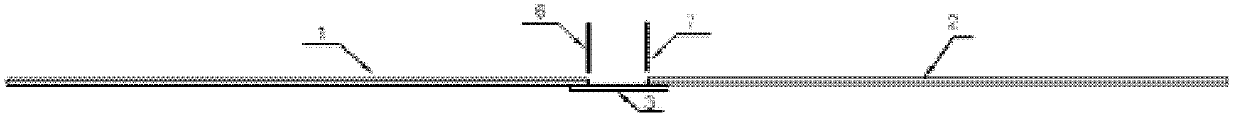

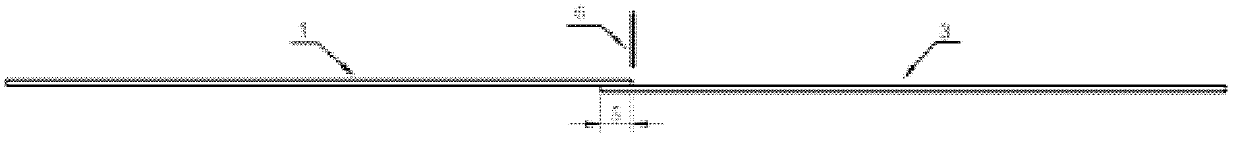

[0011] The present invention is magnesium, aluminum dissimilar metal cold metal transition fusion-brazing connection method, it is characterized in that a high-melting point metal galvanized steel plate is used as the transition metal layer, respectively melting aluminum alloy welding wire, aluminum alloy base material and magnesium alloy welding wire, magnesium The alloy base material is used to form two fusion-brazing joints on the interlayer metal respectively to obtain a magnesium-aluminum lap joint.

[0012] The galvanized steel plate is sandwiched between the magnesium alloy plate and the aluminum alloy plate, and the aluminum alloy plate and the galvanized steel plate are connected by the cold metal transition melting-brazing with the aluminum welding wire, and the magnesium welding wire is passed through the cold metal transition melting-brazing. The alloy plate is connected to the galvanized steel plate, thereby indirectly realizing the connection of the magnesium allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com