A continuous forming method for low melting point metal

A technology of low melting point metal and forming method, applied in the field of metal forming, can solve the problems of difficult continuous forming and strong surface tension of low melting point metal, and achieve the effects of easy recovery, convenient extraction and continuous forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

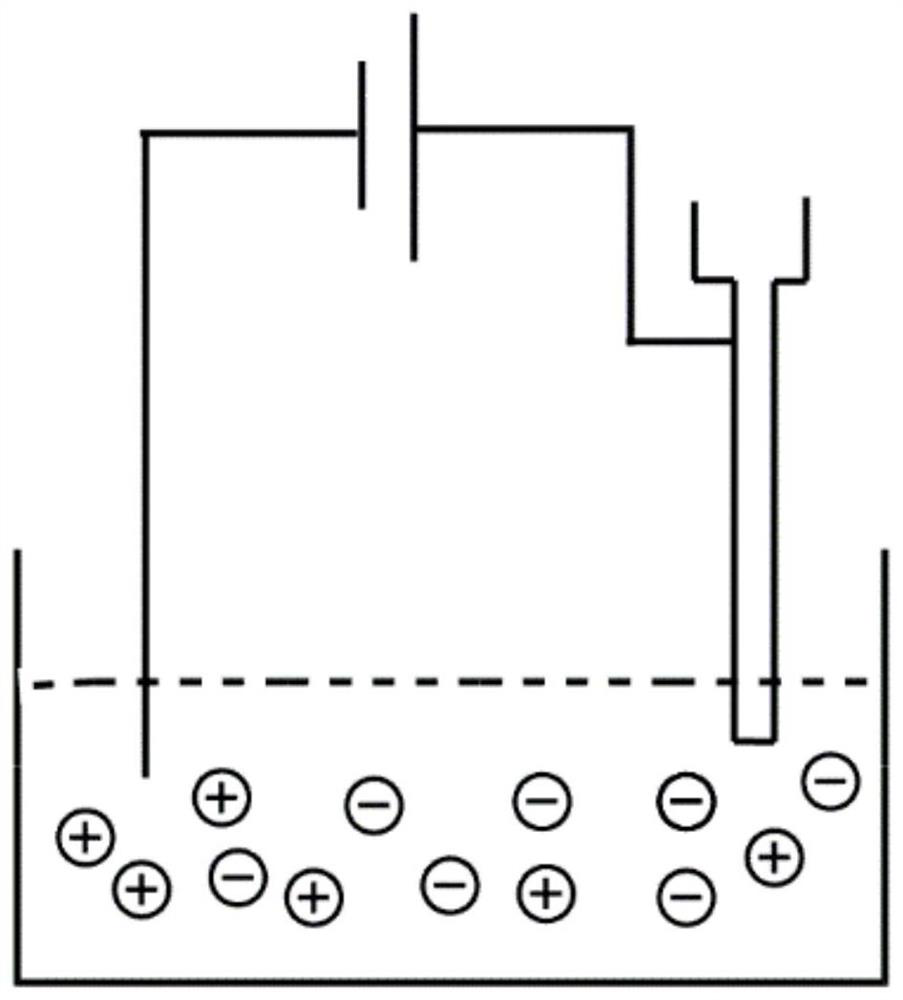

Method used

Image

Examples

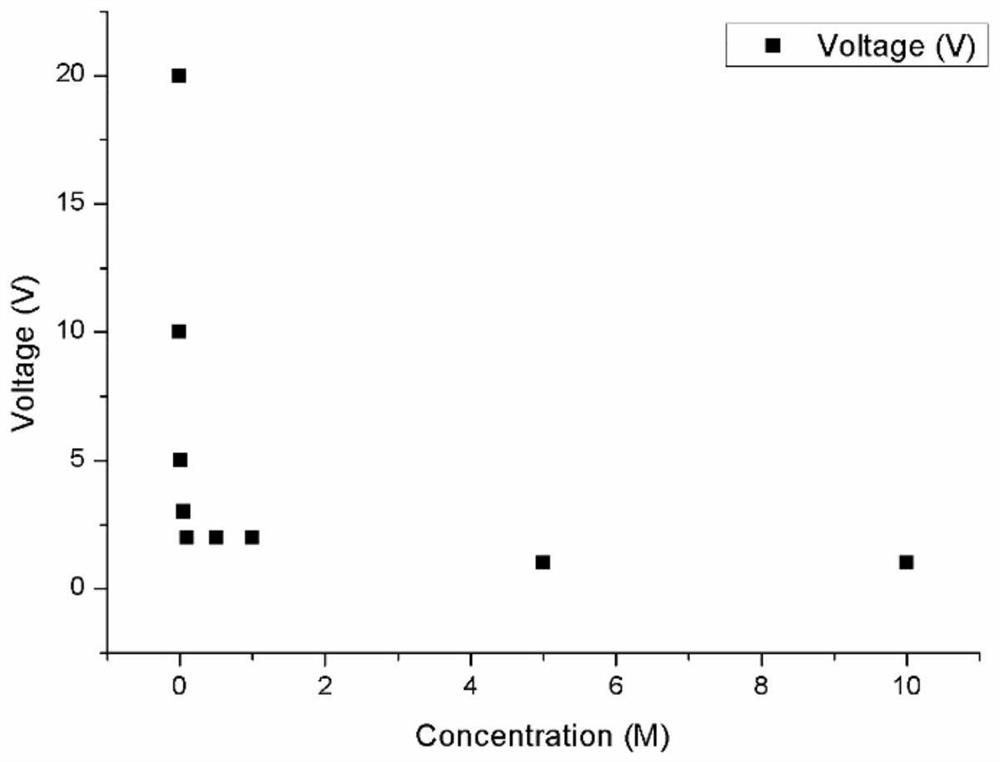

Embodiment 1

[0039] The forming method process of low melting point metal is as follows:

[0040] (1) Prepare 1mmol / L NH 4 Cl solution is used as conductive matrix liquid;

[0041] (2) Heating to melt the indium-based alloy into a liquid state;

[0042] (3) Turn on the power to make the NH prepared in step (1) 4 The Cl solution is energized, and the control voltage is 50V;

[0043] (4) Turn on the injection device, and uniformly inject the molten indium-based alloy obtained in step (2) into NH at an extrusion speed of 50 μL / min. 4In the Cl solution, the injection head of the injection device is controlled to move at a constant speed during the injection process, and the moving speed is controlled to be 25mm / s, so that in NH 4 Continuous indium-based alloy wires are formed in Cl solution.

Embodiment 2

[0045] The forming method process of low melting point metal is as follows:

[0046] (1) Prepare 5mol / L NaCl solution as conductive matrix solution;

[0047] (2) Heating to melt the gallium-based alloy into a liquid state;

[0048] (3) Turn on the power to energize the NaCl solution prepared in step (1), and control the voltage to 1.5V;

[0049] (4) Turn on the injection device, and uniformly inject the molten gallium-based alloy obtained in step (2) into the NaCl solution at an extrusion speed of 600 μL / min, and control the injection head of the injection device to move at a constant speed during the injection process. The speed is controlled to be 50mm / s, so that a continuous gallium-based alloy metal wire is formed in the NaCl solution.

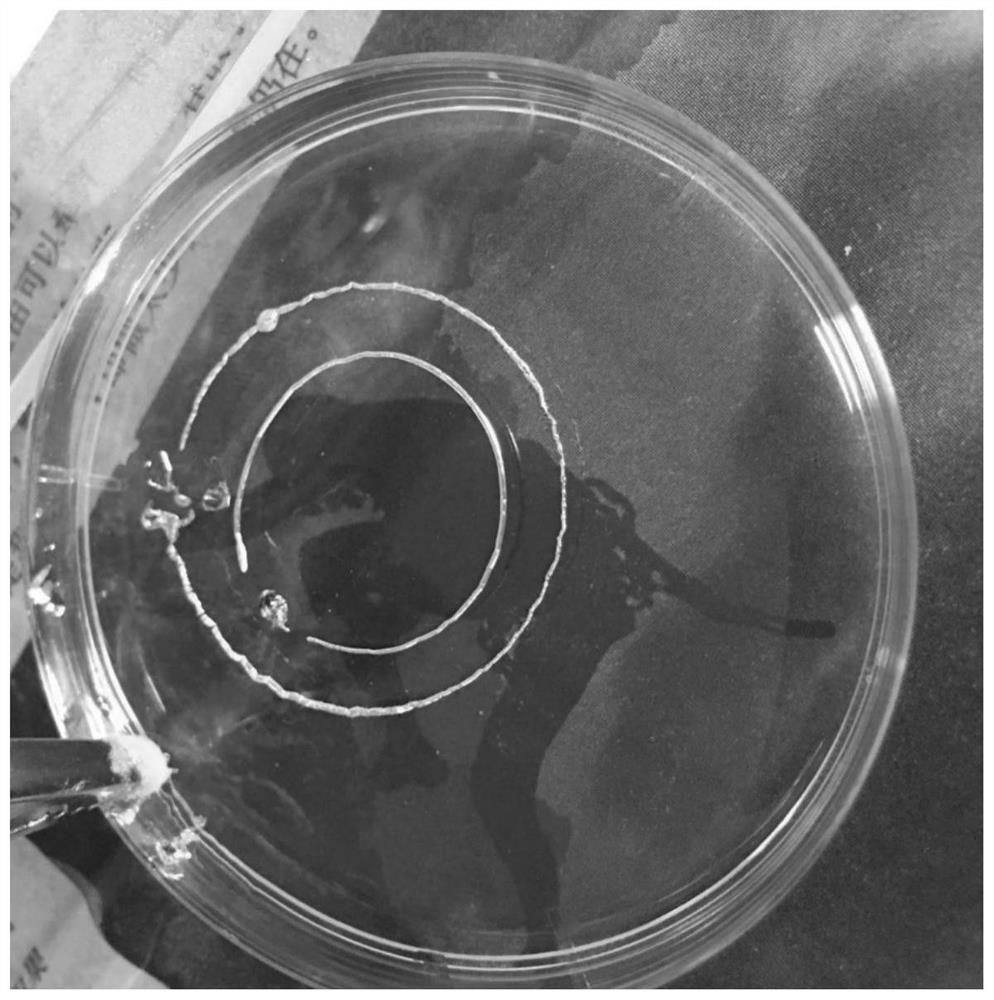

[0050] After forming, the gallium-based alloy metal wire taken out from the NaCl solution is as follows: figure 2 As shown, the obtained metal lines are continuous and uniform, and there is no black oxide layer on the surface.

Embodiment 3

[0052] The forming method process of low melting point metal is as follows:

[0053] (1) Prepare 10mol / L conductive gel solution as conductive matrix solution;

[0054] (2) Heating to melt the tin-based alloy into a liquid state;

[0055] (3) Turn on the power to energize the conductive gel solution prepared in step (1), and control the voltage to 20V;

[0056] (4) Turn on the injection device and uniformly inject the molten tin-based alloy obtained in step (2) into the conductive gel solution at an extrusion speed of 800 μL / min, and control the injection head of the injection device to move at a constant speed during the injection process , the moving speed is controlled to be 100mm / s, thereby forming continuous tin-based alloy metal wires in the conductive gel liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com