Production equipment and production method of ultra-high molecular weight polyethylene composite film

A technology of ultra-high molecular weight and production equipment, which is applied in the direction of final product manufacturing, other household appliances, flat products, etc., and can solve the problem of the reduction of ultra-high molecular weight polyethylene molecular weight, the decline of comprehensive performance, and the lack of ultra-high molecular weight polyethylene composite film production equipment. And the description of production methods, etc., to achieve the effect of improving adhesion, improving external adhesion performance, improving wear resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

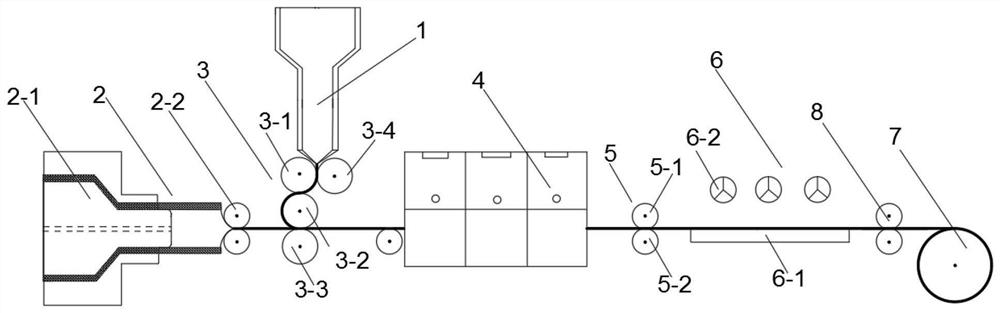

[0042] As shown in the figure, the production equipment of the ultra-high molecular weight polyethylene composite film includes: a four-roll calender (3), a rubber elastic layer supply device (1) and an ultra-high molecular weight polyethylene layer supply device (2). The four-roll calender (3) further includes a vulcanizing drying tunnel (4), an embossing roller group (5), a cooling device (6) and a winding roller (7) in sequence.

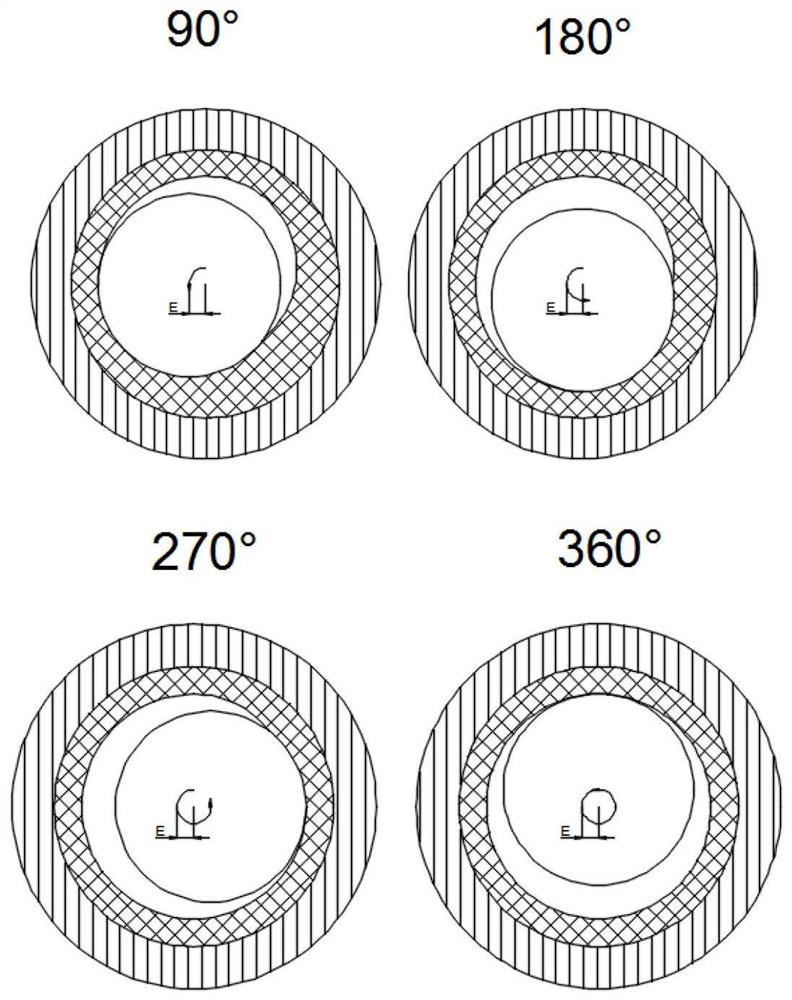

[0043] The four-roll calender (3) includes an upper roll (3-1), a middle roll (3-2), and a lower roll (3-3) arranged in sequence, and a side roll (3) is arranged beside the upper roll (3-1). -4); Each roll of the four-roll calender (3) is equipped with a position adjustment mechanism, which controls the gap between the middle roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com