Novel application of hexafluoroisobutylene

A new application technology of hexafluoroisobutylene, which is applied in the new application field of hexafluoroisobutylene, can solve the problems that affect the energy-saving upgrade of household refrigerators and freezers, the poor heat insulation effect of polyurethane foam, and high thermal conductivity, so as to shorten the demoulding time, Increase the effect of heat preservation and reduce the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

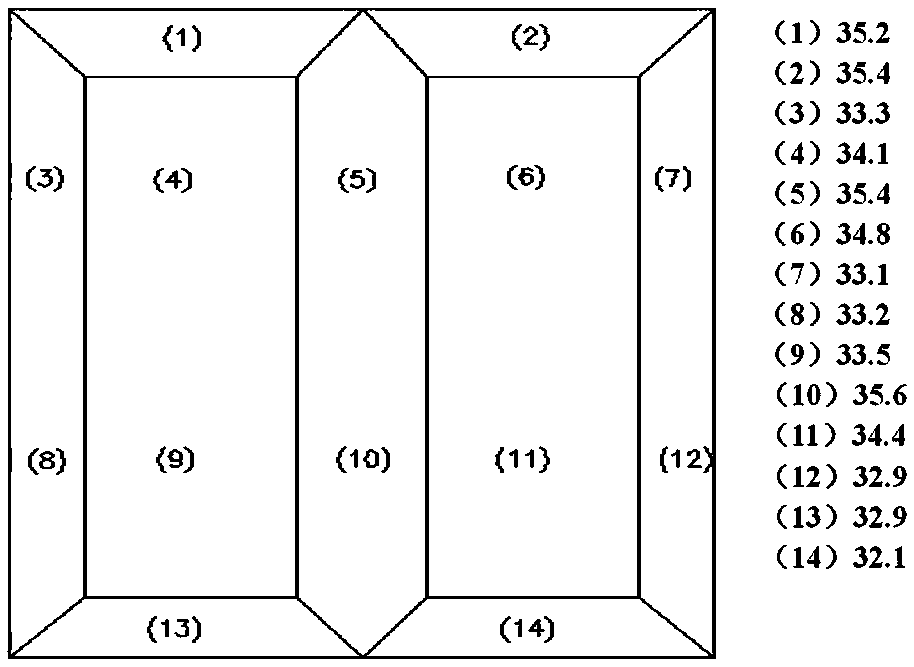

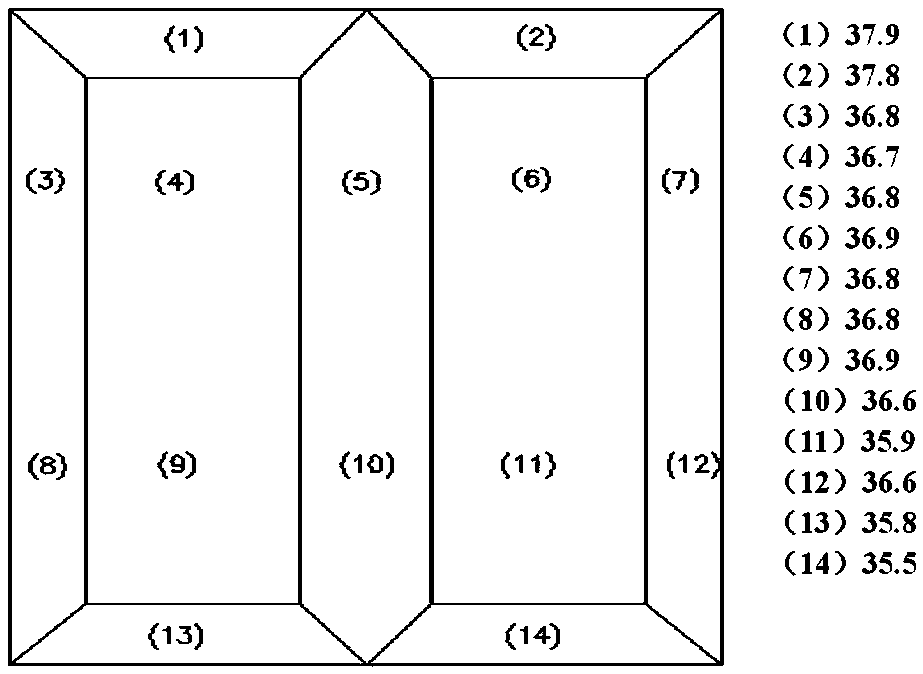

[0031] Embodiment 1 Refrigerator foaming (composite with cyclopentane and use as blowing agent)

[0032] Polyurethane foam: adopt the following raw materials in parts by mass: 100 parts of combined polyether (comprising polyether polyol, foam stabilizer, catalyst), 11.5 parts of cyclopentane, 5.5 parts of blowing agent hexafluoroisobutylene of the present invention; Polymerized MDI) 146 parts.

[0033] From Table 2 and figure 1 It can be seen that the foaming agent of the present invention forms a binary mixed foaming agent with cyclopentane, and its foaming process parameters and foam quality fully meet the requirements for use. In other embodiments, when compounding with cyclopentane, the mass ratio of hexafluoroisobutene to cyclopentane can be within the range of 1:(1-3), preferably 1:2.09. In other embodiments, It can be combined with HFC blowing agent or HFO blowing agent. The mass ratio of hexafluoroisobutene to HFC blowing agent or HFO blowing agent is 1: (1~1.5). The...

Embodiment 2

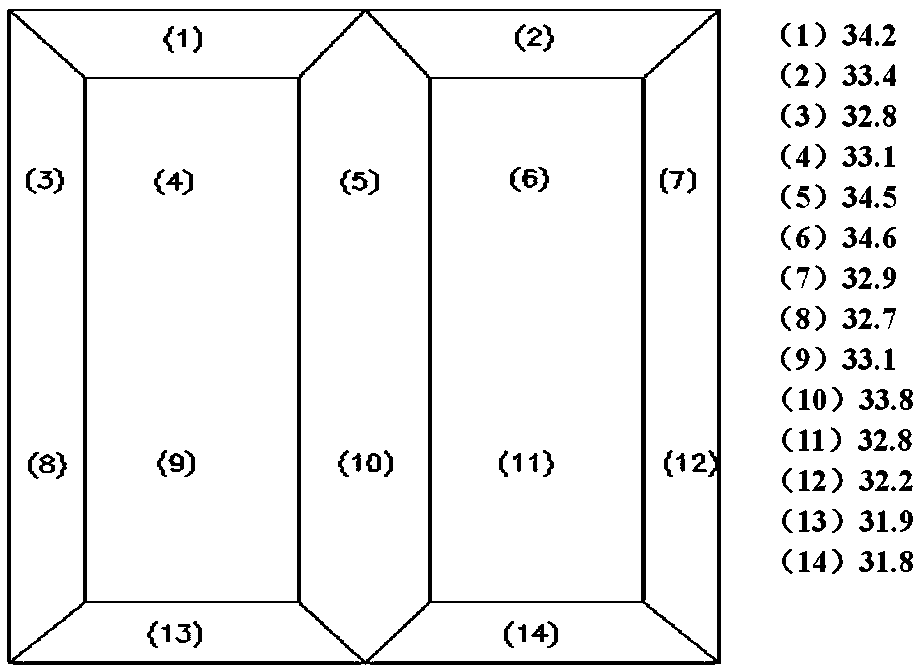

[0036] Embodiment 2 Refrigerator foaming (hexafluoroisobutylene is used alone)

[0037] Table 3 embodiment 2 foaming material formula and test result

[0038]

[0039] from Table 3 and figure 2 It can be seen that the foaming process parameters and foam quality of the foaming agent of the present invention fully meet the requirements for use. In other embodiments, the weight ratio of the mixture of foaming agent and combined polyether to isocyanate is 1:(1.1~1.3) during application, and the weight ratio of combined polyether and blowing agent is 100:(13 ~30) can be in any range, preferably 100:(17~25).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| ozone depletion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com