Preparation method and application of plasticized melt-spun commodity-grade active PAN precursors

A commercial-grade, melt-spinning technology, which is applied in melt-spinning, rayon manufacturing, textiles and papermaking, etc., can solve the problems of low environmental friendliness, difficulty in imparting modification effect to raw silk, increasing CFs preparation cost, difficulty in CFs performance regulation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Choose the viscosity average molecular weight as 5.2×10 4 g / mol, acrylonitrile content is 88 mole percent (mol%) copolymerized PAN as raw material, high-purity commercial grade BMiMCI as plasticizer, sodium dodecylbenzenesulfonate as dispersant, the mass ratio of the three is 6 : 3.96: 0.04, using a pulverizer to fully mix the three raw materials.

[0028] The blend is made into strips and pelletized by using a twin-screw extruder, and the temperatures in each zone of the twin-screw are set to 120°C, 130°C, 140°C, 150°C, 150°C, and 140°C respectively. The material is immediately pelletized and packaged. Keep the ambient temperature not higher than 25°C and the humidity not higher than 5% during the process of mechanical blending, sliver making and pelletizing.

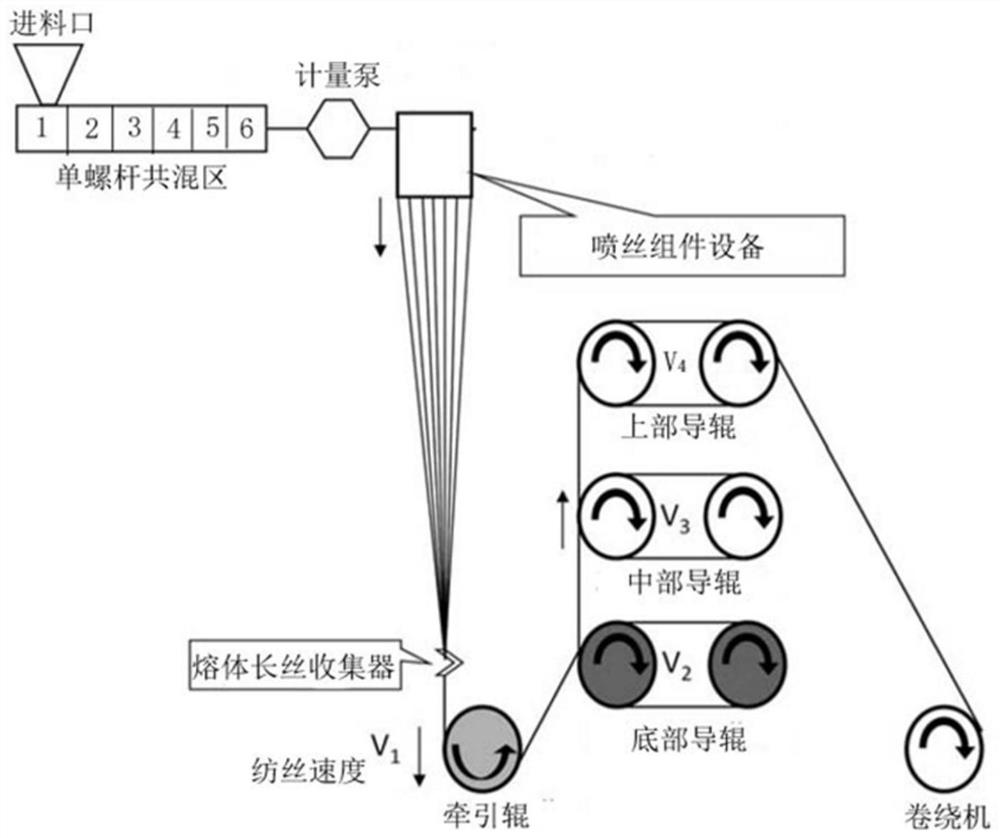

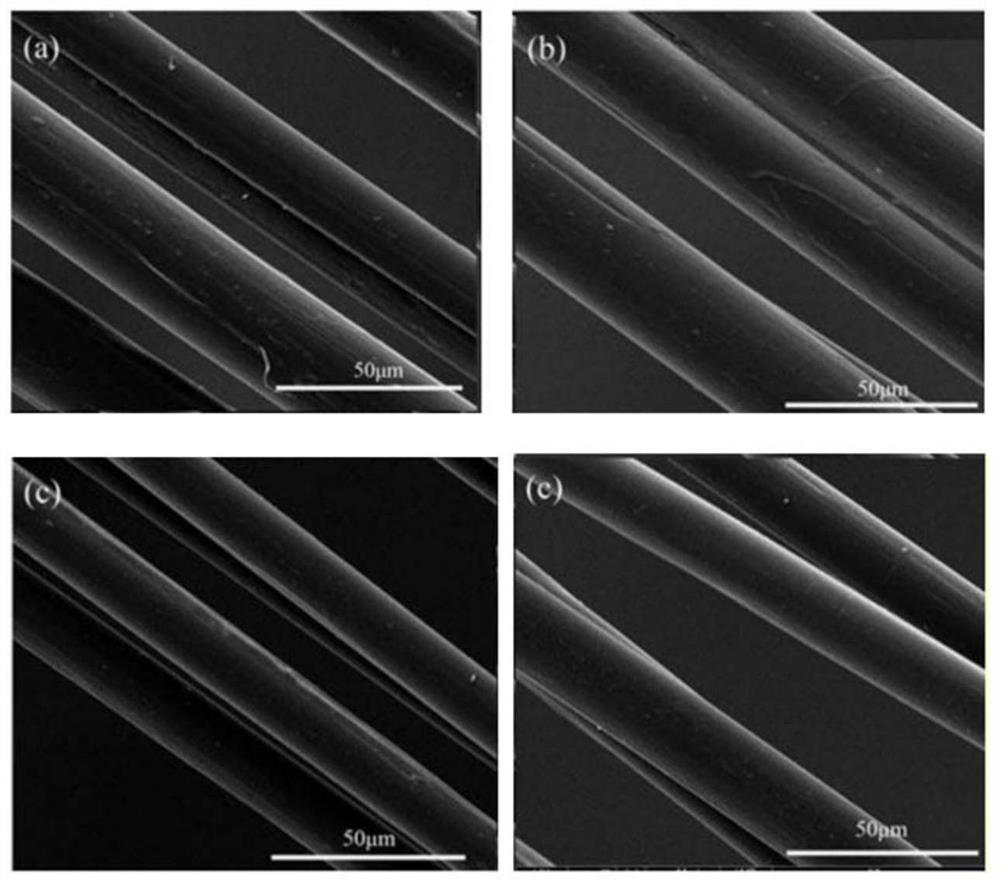

[0029] The prepared particles are used as raw materials in the melt spinning process, and are spun by a single-screw melt spinning machine. The number of spinneret holes is 36, the diameter is 0.3mm, the pump...

Embodiment 2

[0032] Choose the viscosity average molecular weight as 6.5×10 4g / mol, copolymerized PAN with acrylonitrile content of 90mol% as raw material, high-purity commercial grade [Bmim]Cl as plasticizer, sodium dodecylbenzenesulfonate as dispersant, the mass ratio of the three is 5:4.95 : 0.05, using a pulverizer to fully mix the three raw materials. A twin-screw extruder is used for strip making and pelletizing, and the temperature of each zone of the twin-screw is set to 130°C, 140°C, 140°C, 150°C, 150°C, and 140°C, and the strip-making material is immediately pelletized , and encapsulate. Keep the ambient temperature not higher than 25°C and the humidity not higher than 10% during the process of mechanical blending, sliver making and pelletizing.

[0033] The prepared particles are used as raw materials in the melt spinning process, the number of holes in the spinneret is 36, the diameter is 0.3mm, the pump supply is 35g / min, the spinning length is 5m, and the melt blending zone...

Embodiment 3

[0036] Choose the viscosity average molecular weight as 7×10 4 g / mol, copolymerized PAN with acrylonitrile content of 92mol% as raw material, high-purity commercial grade [Bmim]Cl as plasticizer, sodium dodecylbenzenesulfonate as dispersant, the mass ratio of the three is 6:3.96 : 0.04, using a pulverizer to fully mix the three raw materials.

[0037] A twin-screw extruder is used for strip making and pelletizing, and the temperature of each zone of the twin-screw is set to 130°C, 140°C, 150°C, 150°C, 150°C, and 140°C, and the strip-making material is immediately pelletized , and encapsulate. Keep the ambient temperature not higher than 25°C and the humidity not higher than 10% during the process of mechanical blending, sliver making and pelletizing.

[0038] The prepared particles are used as the raw material in the melt spinning process, the number of holes in the spinneret is 36, the diameter is 0.3mm, the pump supply is 35g / min, the spinning length is 4.5m, and the spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com