Patents

Literature

75results about How to "Spinning smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

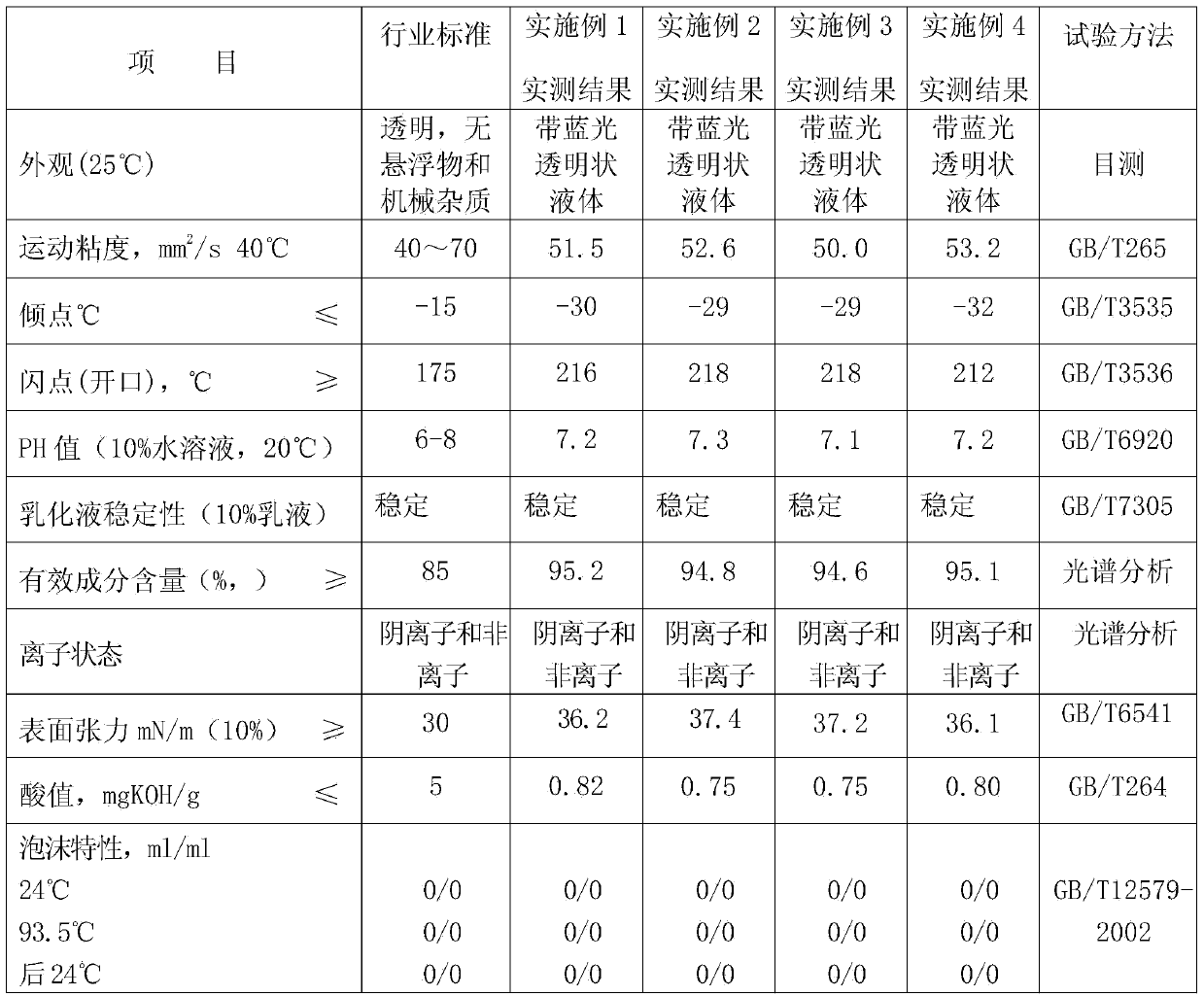

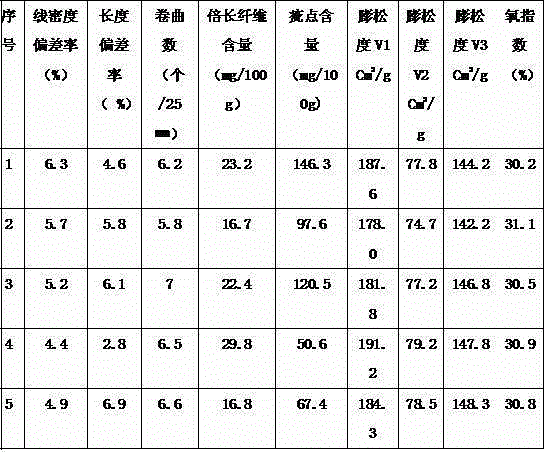

Fiber fully drawn yarn (FDY) spinning oil and preparation method thereof

The invention relates to a fiber fully drawn yarn (FDY) spinning oil which comprises a high-temperature smoothing agent, a composite antistatic agent, a bundling agent, a phenolic group antioxidant, a phenylamino group antioxidant, an olefine acid antioxidant, a high-temperature dispersant, a softening agent, an environment-friendly emulsifying agent, a defoaming agent, a preservative and an environment-friendly penetrating agent, wherein the high-temperature smoothing agent comprises hydrogenation paraffin-based oil and hydrogenation naphthenic oil. The invention also provides a preparation method of the fiber FDY spinning oil. The fiber FDY spinning oil is stable in emulsion and free from stratification and odor, and is not easily rotted; the fiber is easily not yellowed by dyeing, and the fiber FDY spinning oil is easy to rinse; the production process is stable, and the fiber FDY spinning oil has few broken ends, is good in heat resistance, does not have smoke formation, is not coked on a hot roller, has the excellent anti-static performance under the different humidity conditions, and thus the fiber FDY spinning oil can meet the requirements of high-speed spinning technologies of various specifications of fiber including thick fibers and thin fibers; after the fiber FDY spinning oil is used, the fiber can smoothly pass through the after the spinning of various equipment, so that the yield and the good rate of fiber spinning can be effectively increased.

Owner:上海中孚油品集团有限公司

Production method of recycled phosphorus flame retardant polyester staple fibre

ActiveCN102747455AGood flame retardant effectImprove compatibility and uniformityFlame-proof filament manufactureMonocomponent polyesters artificial filamentPhosphinic AcidsPolyester

The invention relates to a production method of recycled phosphorus flame retardant polyester staple fibre. Conventionally, waste PET (Polyethylene Terephthalate) bottle chips are adopted, and phosphorus flame retardant agent and the waste PET bottle chips are mixed, melted and modified to produce flame retardant master batches. At the basis of conventional spinning conditions, the technical difficulties that the thermal stability of the phosphorus flame retardant agent is poor, and due to the acidity of the phosphuret, the viscosity can be reduced in the spinning process, the spinning property is poor and defects are more can be solved though the optimization process. The production method provided by the invention includes the following steps of: firstly mixing phosphorus flame retardant agent 2-carboxyethyl-phenyl phosphinic acid and waste PET bottle chips at weight ratio of 10-12:8-90, and the melting, extruding and pelleting in a screw extruder to prepare the phosphorus flame retardant master batches; and secondly mixing the phosphorus flame retardant master batches and the waste PET bottle chips at weight ratio of 8-10:90-92 and then melt spinning. In such a way, the recycled phosphorus flame retardant polyester staple fibre with the index of flame retardant oxygen reaching above 30% can be obtained.

Owner:广东秋盛资源股份有限公司

Preparation method for sustainable antibacterial nano-zinc oxide alginate fibers

InactiveCN104928799AWide variety of sourcesLow costAlginate artificial filamentsWet spinning methodsFiberZno nanoparticles

The invention discloses a preparation method for sustainable antibacterial nano-zinc oxide alginate fibers. The preparation method comprises the following steps: at first, uniformly mixing sodium alginate powder and nano-zinc oxide powder; adding distilled water, and carrying out uniform ultrasonic dispersion to prepare sodium alginate-based nano-zinc oxide colloid; adding plenty of fiber-grade sodium alginate powder to prepare a spinning solution; preparing the finished product, namely the nano-zinc oxide alginate fiber by a wet spinning step. The preparation method has the advantages that a series of technological means, such as stepped introducing of sodium alginate, are adopted skillfully, nano-zinc oxide can be uniformly dispersed and exist stably in a system, the final product, namely the nano-zinc oxide alginate fiber, is uniform and stable in quality, the prepared nano-zinc oxide alginate fiber is remarkable in antibacterial effect, bacteria growth can be inhibited effectively, and the nano-zinc oxide alginate fiber is safe and nontoxic, and can be widely applied to fields of medical treatment, military, health textile and the like.

Owner:青岛源海新材料科技有限公司

Calcium alginate fiber with pH (Potential of Hydrogen) value indicating function and preparation method thereof

InactiveCN105803578AWith continuous color changing effectRaw materials are easy to getNatural dyesAlginate artificial filamentsAlkalinityFiber

The invention discloses calcium alginate fiber with a pH (Potential of Hydrogen) value indicating function and a preparation method of the calcium alginate fiber. The preparation method comprises the following steps: (1) preparation of natural dye; (2) preparation of a spinning solution; (3) wet spinning. The prepared and obtained calcium alginate fiber is red and has a pH value indicating function, and the color of the calcium alginate fiber can be subjected to red-purple-blue-green continuous change when the pH value of an external environment is changed from acidity to alkalinity. Raw materials adopted by the calcium alginate fiber have good biocompatibility, the obtained fiber has good color fastness and an obvious pH value discoloring function and can be used for medicinal textiles with the pH value indicating function, such as band-aids and dressing, and real-time monitoring on a wound infection situation is realized.

Owner:WUHAN TEXTILE UNIV

Cooling device and cooling method of solvent method cellulose fiber spinning

InactiveCN1924122ASimple structureImprove cooling effectArtificial filament physical treatmentCellulose fiberEngineering

This invention discloses one cooling device and method of solvent cellulose fiber spinning, which adopts side wind cooling device with speed as 2-12m / s and temperature as 10-35DEG C and relative temperature as 10%-80%. This invention device is of simple structure and easy control wind each parameter and good effect.

Owner:DONGHUA UNIV

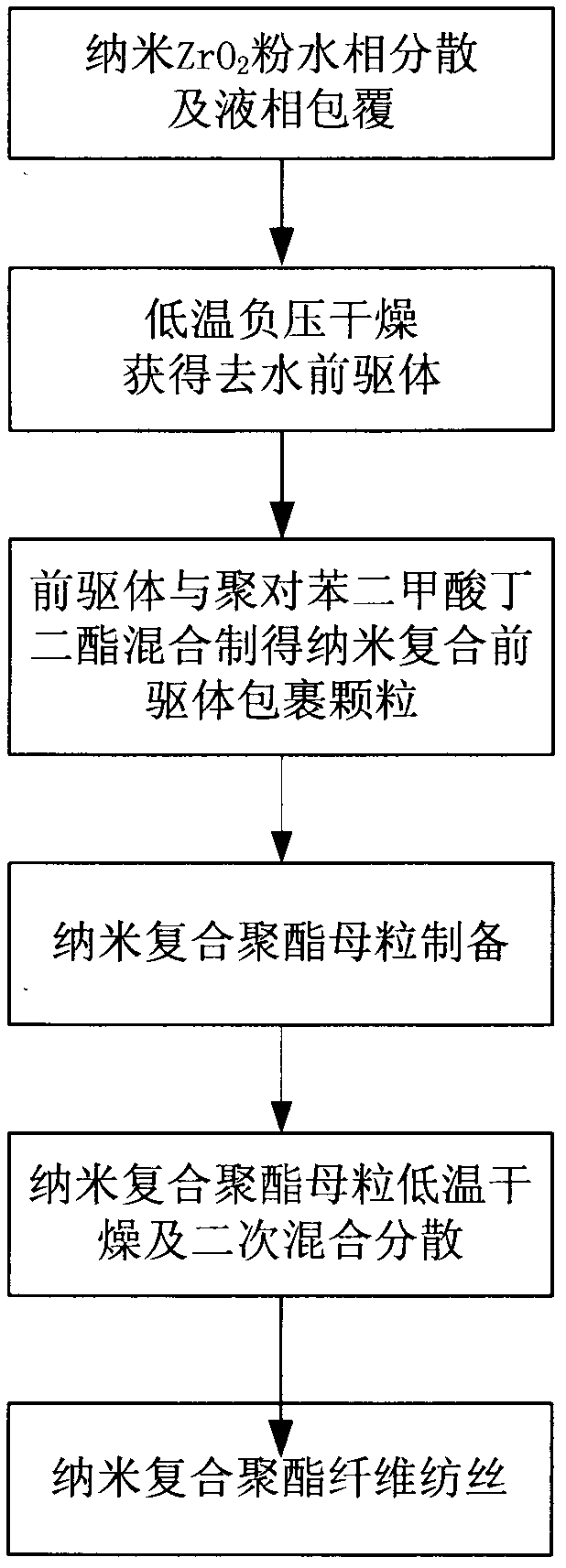

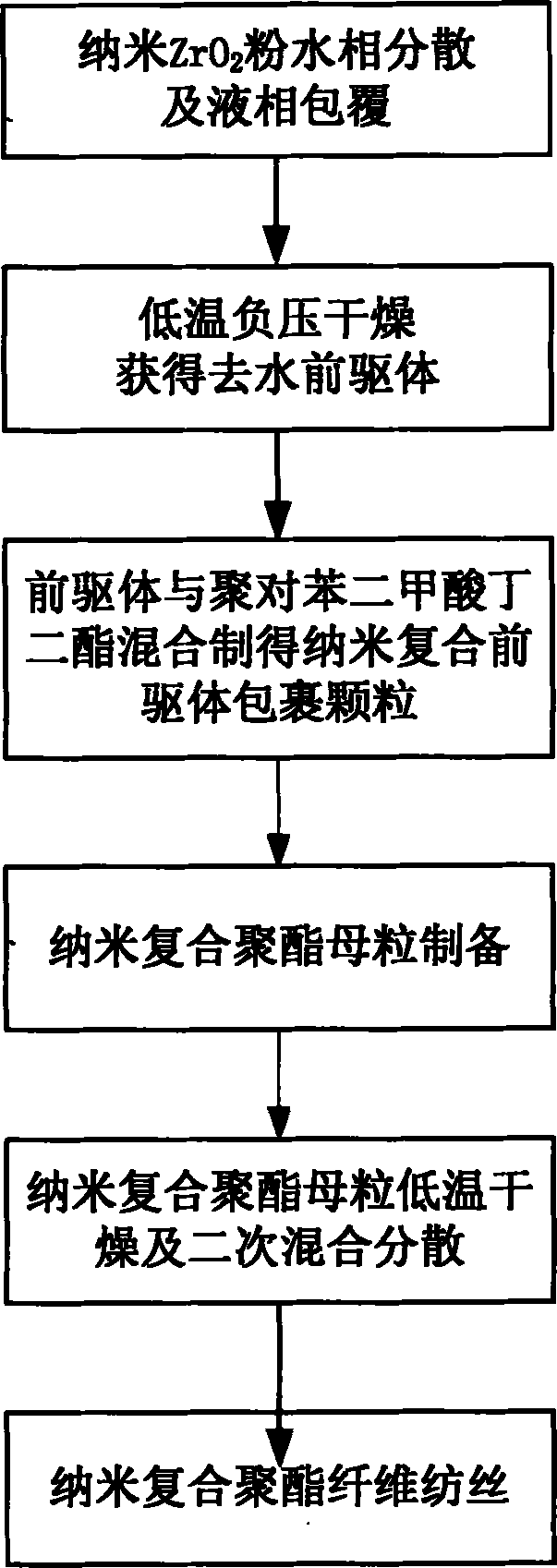

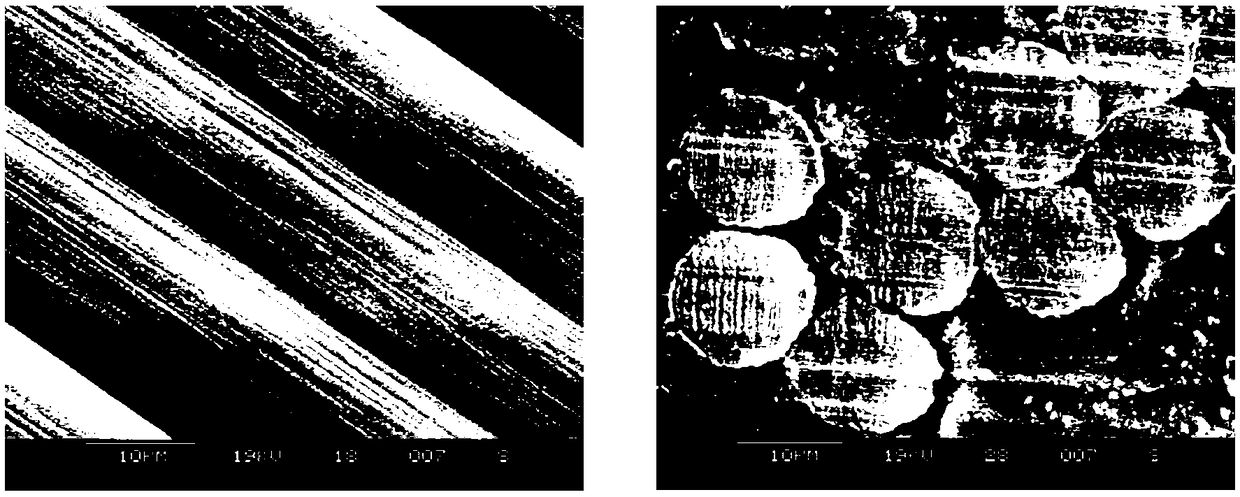

Nano ZrO2 composite polyester functional fiber, manufacturing method thereof and application

InactiveCN102660799AHigh surface energyImprove yieldConjugated synthetic polymer artificial filamentsArtifical filament manufactureState of artFiber

A nano ZrO2 composite polyester functional fiber contains ZrO2, polybutylene terephthalate, polyethylene terephthalate and a small quantity of auxiliaries, and is manufactured by means of a novel nano ZrO2 powder dispersing and wrapping process and by adjusting a spinning process. The nano ZrO2 composite polyester functional fiber realizes nano-dispersion of nano ZrO2 in a polyester carrier, hydrolysis of composite polyester master batch preparation and degradation of nano composite master batch in polybutylene terephthalate during secondary melting dispersion, and overcomes the shortcomings of the prior art, so that nano ZrO2 powder particles are uniformly distributed and organically compounded in polyester fibers, and mass production of the fiber is realized. A product made of the fiber can efficiently emit biological infrared waves in a long-acting manner, is ultraviolet-resistant, has the health care function of improving human microcirculation and has a sunscreen effect, and a novel fabric market is certainly activated owing to the advantages of functionality, comfort and variety and color diversity of the fiber.

Owner:NANJING LONGYI TEXTILE TECH DEV

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

Spinning method of nickel base alloy bottom-carried cylindrical part

InactiveCN107309317AReduce consumptionReduce labor costsShaping toolsSocial benefitsEconomic benefits

The invention relates to a spinning method of a GH4169 nickel base alloy bottom-carried cylindrical part. The spinning method comprises the following steps: (1) a GH4169 nickel base alloy blank is prepared; (2) a core mold is preheated before spinning; (3) a nickel base alloy plate is heated in a heating furnace or directly heated on the core mold for spinning formation; and a lubricating agent is uniformly coated during spinning; (4) the spinning formation is performed on a spinning machine; (5) the spinning final formation is performed; after final formation, the annealing is performed in a vacuum furnace; and the furnace cooling or the air cooling is performed; and (6) a spun part is machined. The invention finds out a hot spinning process aiming at the GH4169 nickel base alloy bottom-carried cylindrical part; the material waste problem in the production process of the nickel base alloy bottom-carried cylindrical part can be reduced; and huge economic benefit and social benefit are achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

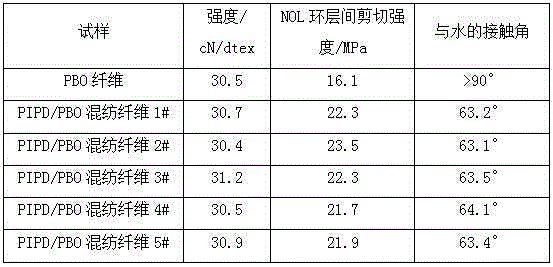

Preparation method of PIPD/PBO (poly(dihydroxyphenylene pyridobisimidazole)/poly-p-phenylene ben-zobisthiazole) blend fiber

ActiveCN104862826AGood compatibilityImprove wettabilityArtificial thread manufacturing machinesFilament/thread formingPropanolaminePolymer chemistry

The invention relates to a preparation method of a PIPD / PBO (poly(dihydroxyphenylene pyridobisimidazole) / poly-p-phenylene ben-zobisthiazole) blend fiber and belongs to the technical field of blend fibers. The technology comprises the steps of preparation of a PIPD / PPA (phenyl-propanolamine) polymer solution, preparation of a PBO / PPA polymer solution, mixed preparation of a PIPD / PBO polymer, preparation of freshly formed filaments, drawing, solidification, water washing and drying. According to the PIPD / PBO blend fiber prepared by the method, the PIPD polymer is introduced into a PBO fiber, that is to say, a little PIPD is added into a PBO polymer matrix. The wettability and bonding performance of the PBO fiber with a resin matrix are improved on the premise that the excellent mechanical property, high-temperature resistance and flame resistance of the PBO fiber are not reduced.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

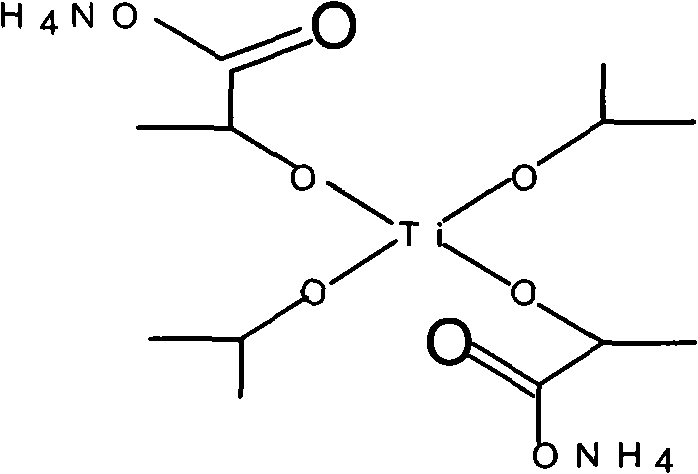

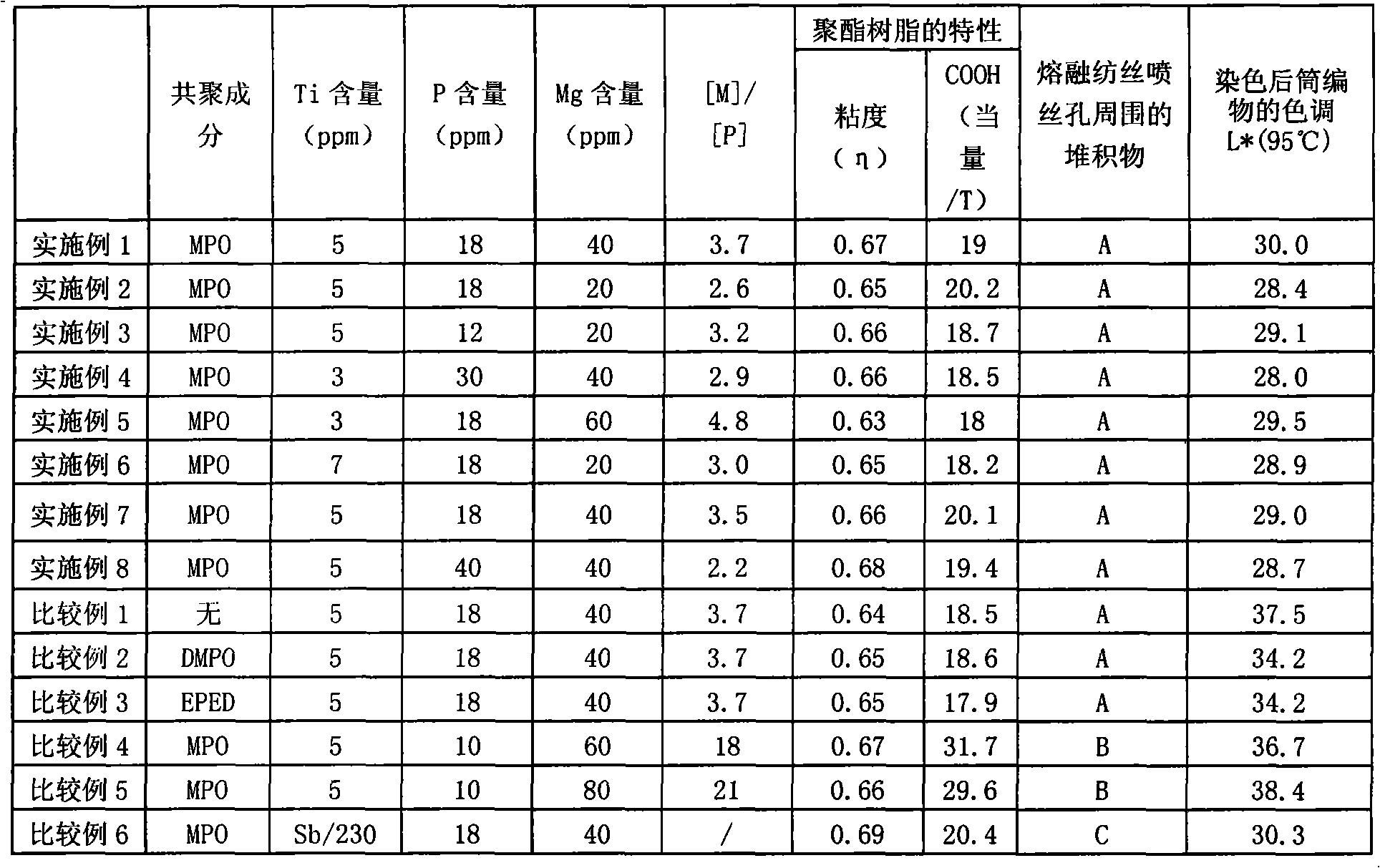

Copolyester and application thereof

InactiveCN102030890AImprove dyeing effectImprove stabilityMonocomponent polyesters artificial filamentFiberSide chain

The invention relates to copolyester and application thereof. The copolyester is prepared from diacid and dihydric alcohol through polymerization reaction in the presence of a catalyst. In components of diacid for forming the copolyester, the content of terephthalic acid structural unit is over 90 mol percent; in components of dihydric alcohol for forming the copolyester, the content of glycol structural unit is 70 to 99 mol percent, the content of aliphatic diol structural unit is 1 to 30 mol percent; and the content of antimony element is less than or equal to 5ppm in based on the total weight of the copolyester. In the polymerization process, a non-antimony catalyst is used and environment-friendly, reduces pollution on spinneret orifices in the spinning process and has environmental safety; the polymer has excellent tone; and the obtained copolyester fibers are high in heat resistance and good in dyeing property.

Owner:TORAY IND INC

Mono-fiber yarn process for Chinese hemp fiber

The invention provides a mono-fiber yarn process for Chinese hemp fiber. The process is characterized by comprising the following steps of: selecting 2,500 to 3,000 metric counts of good-quality Chinese hemp fibers, tearing the Chinese hemp fibers into uniform pieces, uniformly a spraying solution which is 8 percent of the weight of the Chinese hemp fiber on the pile of the Chinese hemp fiber, and performing enzymatic treatment on the Chinese hemp fiber for 72 hours and then putting into production in a tank; and performing Chinese hemp fiber, blowing, cotton carding, drawing, roving and spinning. In all procedures, the relative humidity is kept between 58 to 65 percent. The products produced by the process provided by the invention can be made into various blended fabric, and a purely natural and comfortable textile product is added to the textile field.

Owner:JIHUA 3542 TEXTILE CO LTD

Friction-weight increasing agent as well as preparation and application thereof to crystal cotton fiber spinning

The invention relates to a friction-weight increasing agent as well as preparation and application thereof to crystal cotton fiber spinning. The friction-weight increasing agent is mixed solution of a high molecular polymer, an emulsifying agent, a softening agent, inorganic metal salt, an anionic surfactant and a nonionic surfactant. In the preparation method, the friction-weight increasing agent is formed by emulsifying and stirring the raw materials. The application method comprises the following steps: treating the crystal cotton fiber at the temperature of 20-30 DEG C by utilizing the friction-weight increasing agent; and then balancing for 12-48 hours under the condition of constant temperature and humidity to obtain friction-weight increased crystal cotton fiber. According to the invention, the operation method is simple, the raw materials are cheap, the cost is low and better energy-saving effect is achieved because of operation at normal temperature, and the preparation method and the application method are ecological friendly and environmental friendly and easy for industrialized production; and the obtained friction-weight increased crystal cotton fiber has the advantages of better cotton carding, slivering and spinning performances, thus breaking through the spinning bottleneck problem of the crystal cotton fiber in the textile field.

Owner:DONGHUA UNIV

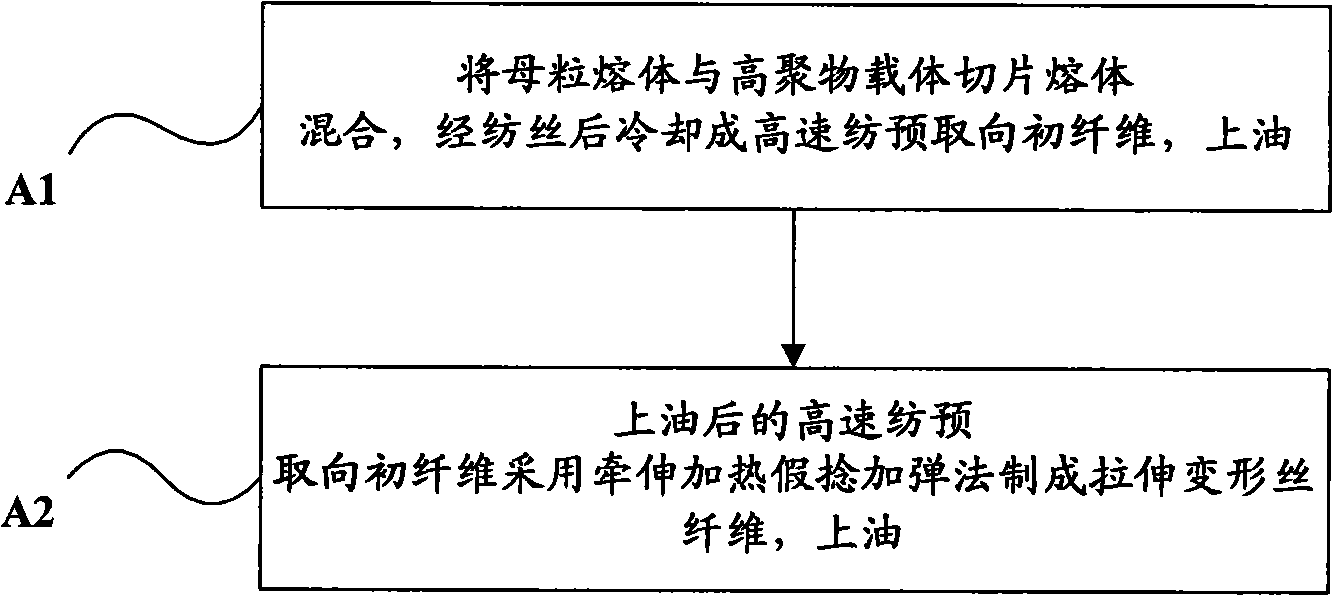

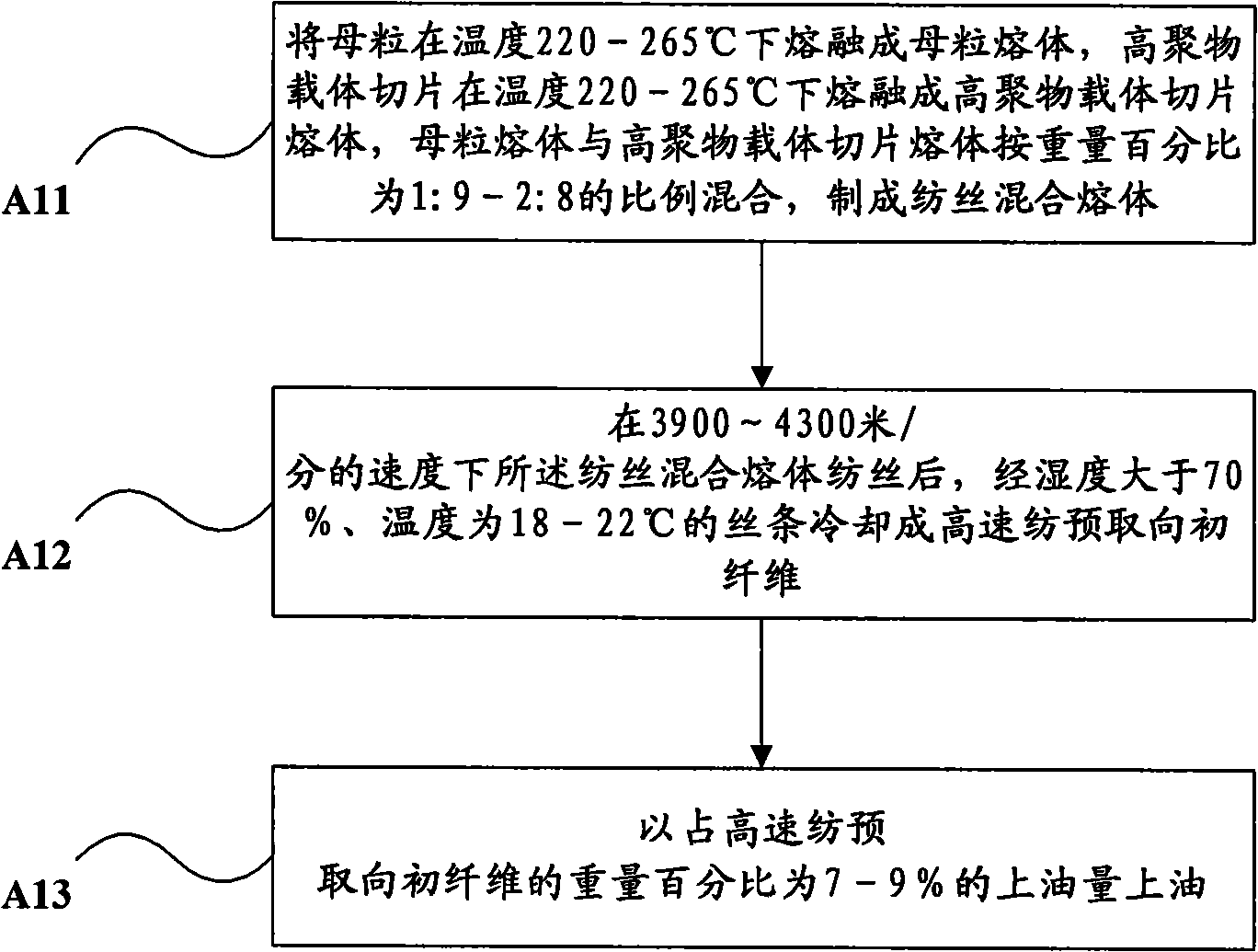

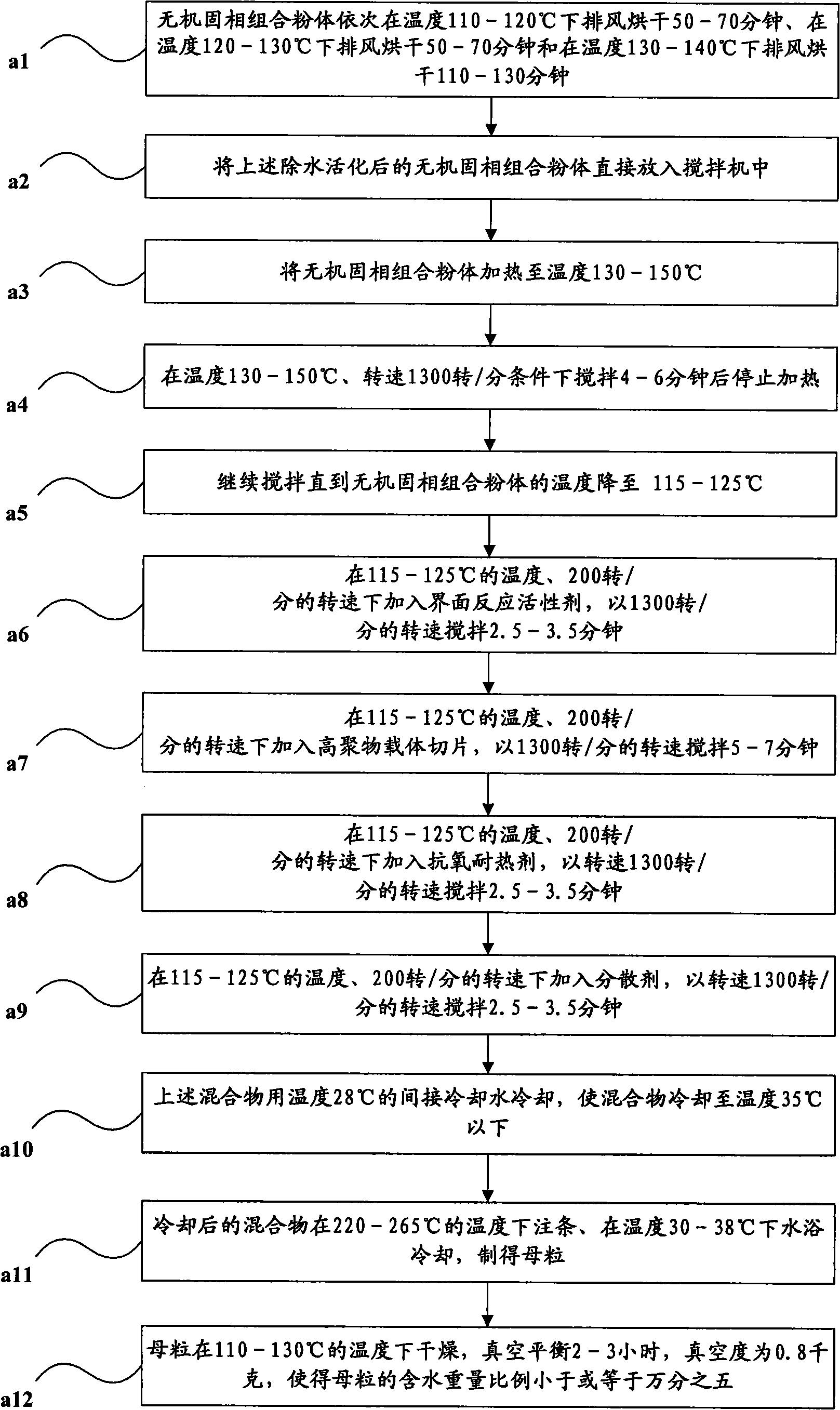

Method for preparing fibre

ActiveCN101314870AGood effectHigh sterilization rateMonocomponent polypropylene artificial filamentMelt spinning methodsMaterials scienceFiber size

The invention relates to a fiber manufacturing method which comprises the following steps: a master batch melt and a polymer support section melt are mixed and are cooled into a high-speed spinning pre-oriented embryo fiber after spinning, and then oiling is carried out; the high-speed spinning pre-oriented embryo fiber after oiling is made into a draw texturing silk fiber by adopting an intra-drawing heating fast-twist method, and then is oiled. The silver content of the fiber of the invention can reach 3-10 percent, the sterilizing rate is high, the ultraviolet blocking rate is high, the efficacy is lasting and safe, and no toxic or side effects exist; the fiber spinnability is good, and the indexes such as the fiber size, etc. accord with the first order standards of the national fiber; the water absorbability, the air permeability, the dying uniformity and the electric conductivity of the fiber are greatly improved, thereby increasing the drapability and the comfortableness of the fiber fabrics.

Owner:天津益康世纪抗菌新材料科技股份有限公司

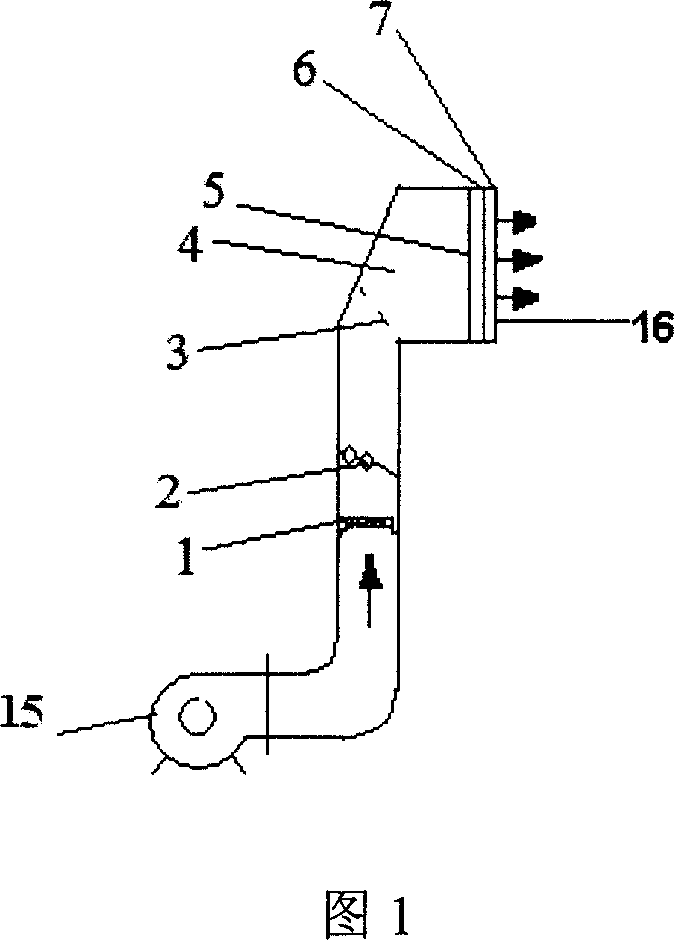

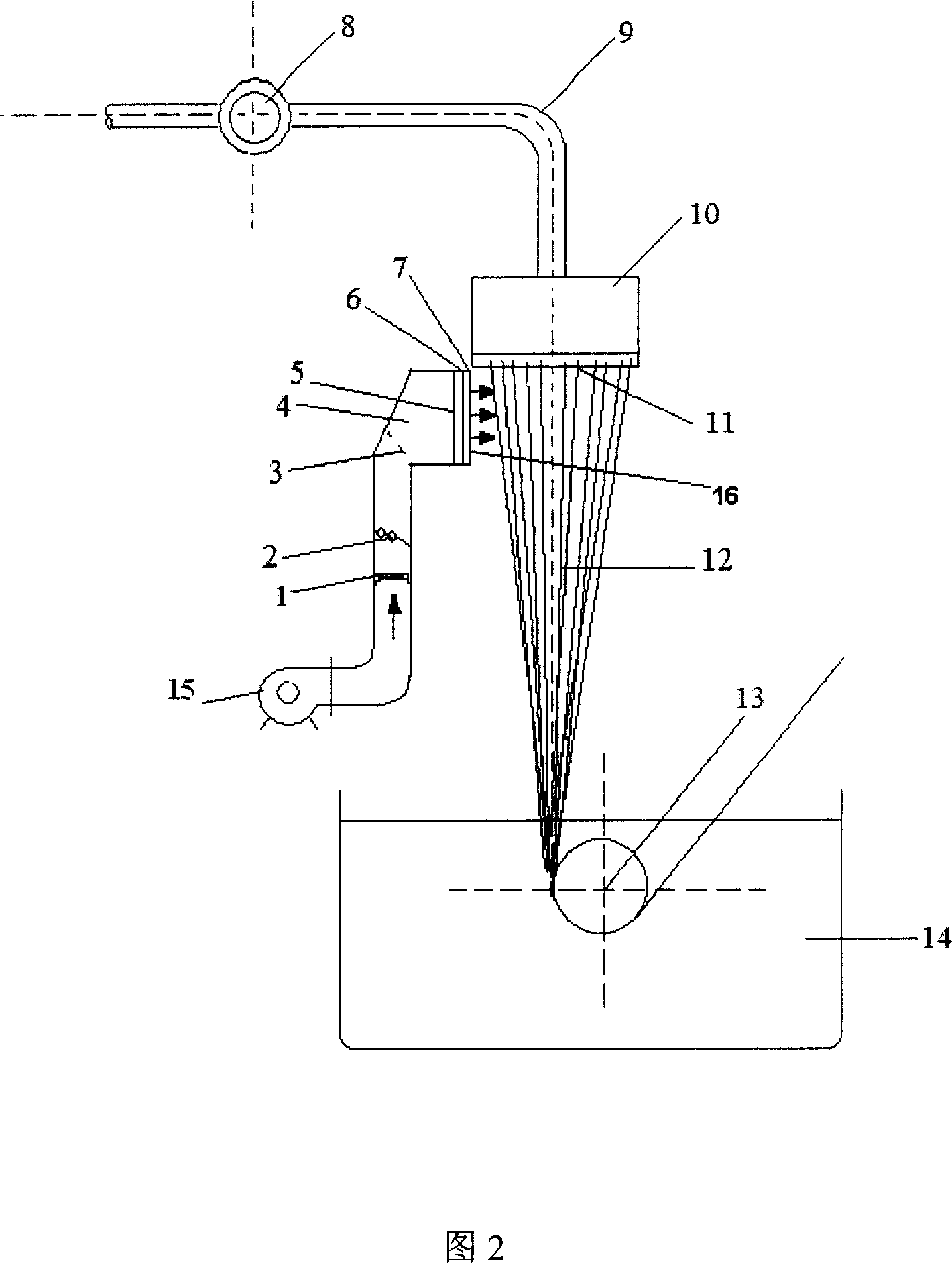

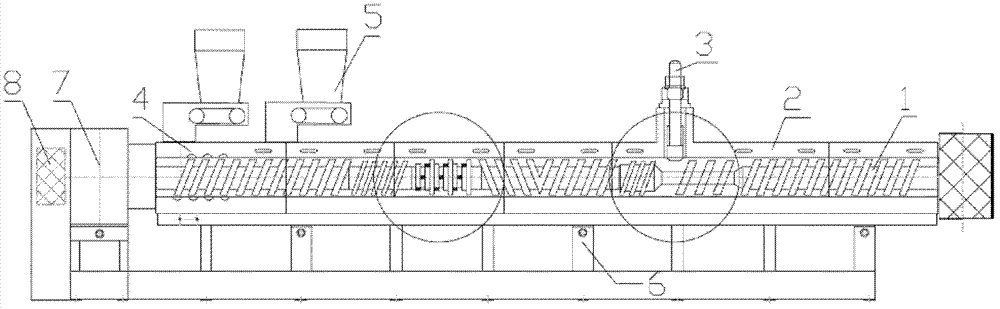

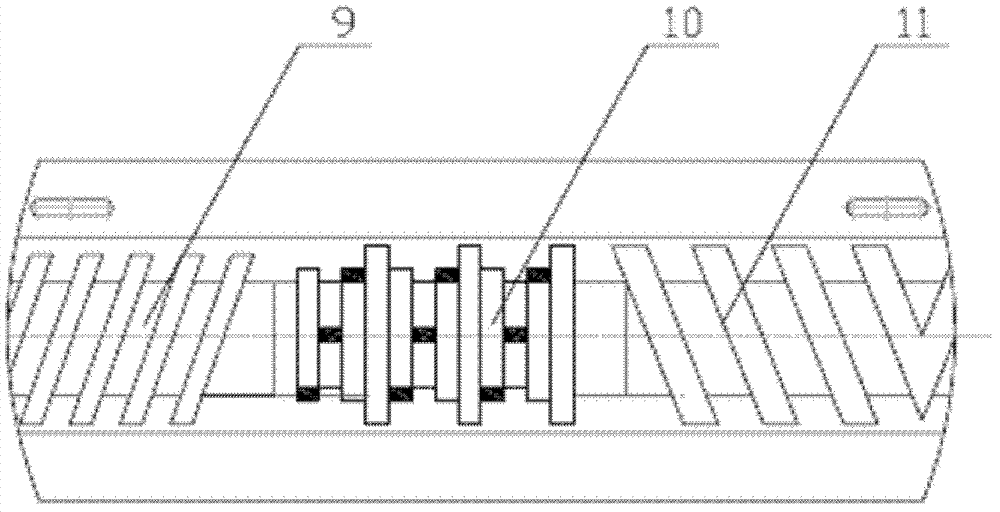

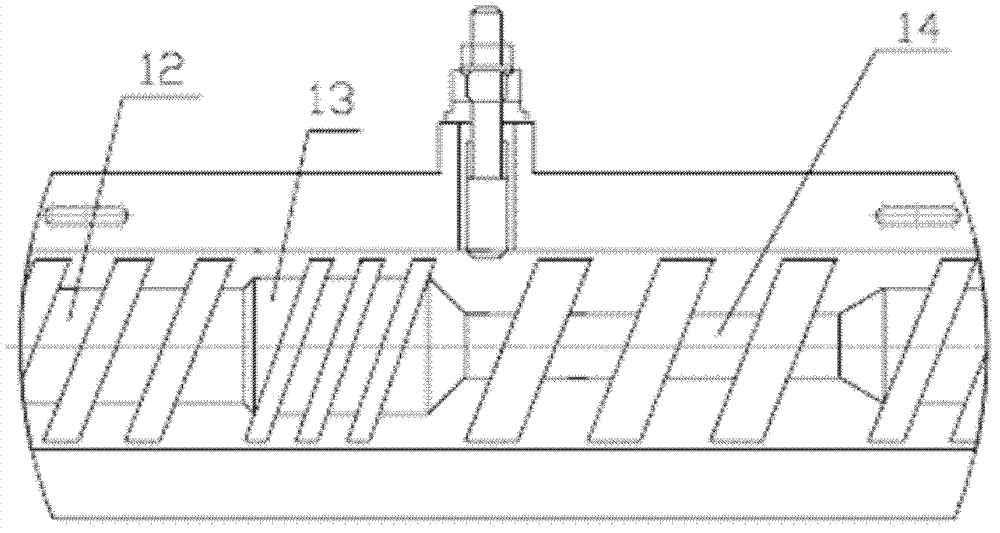

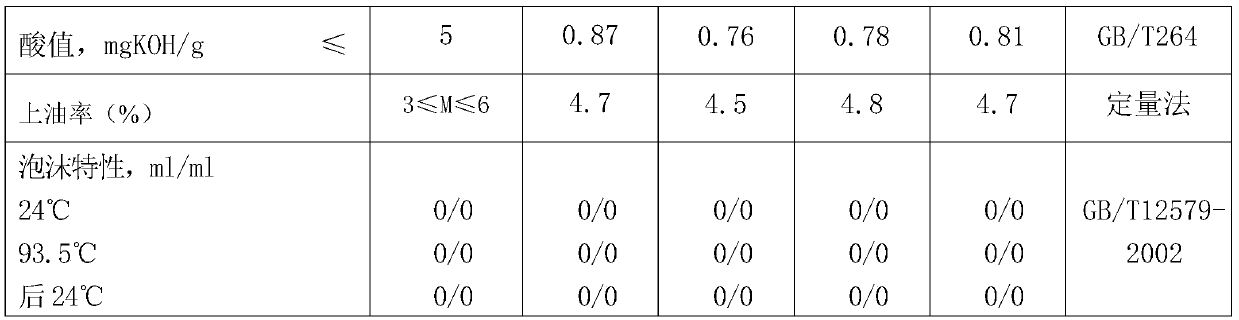

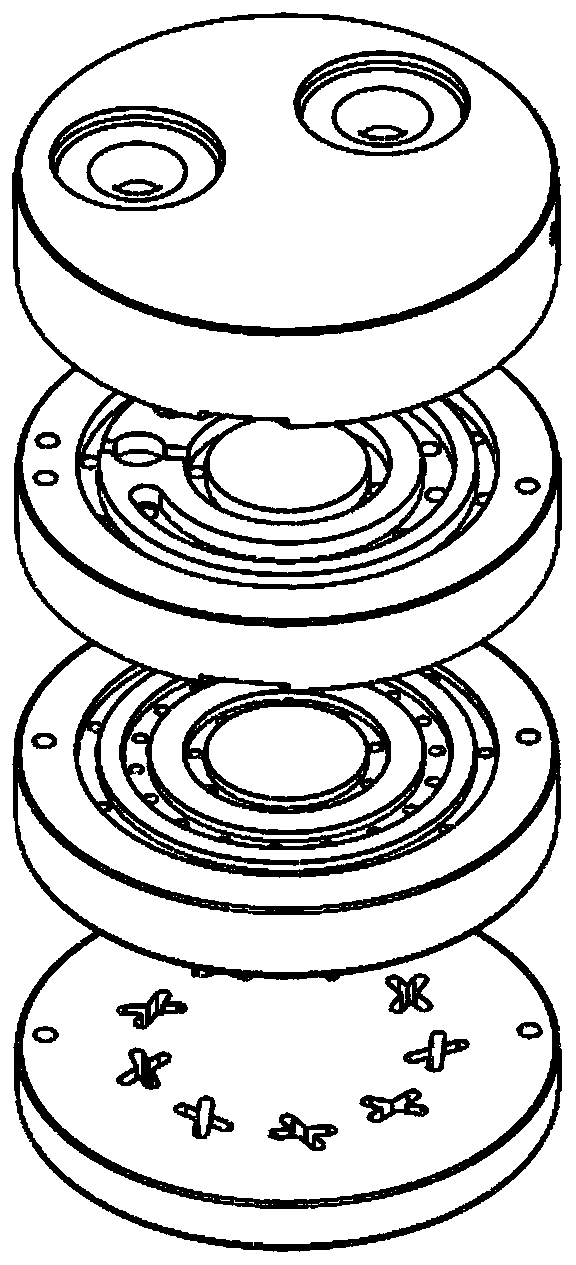

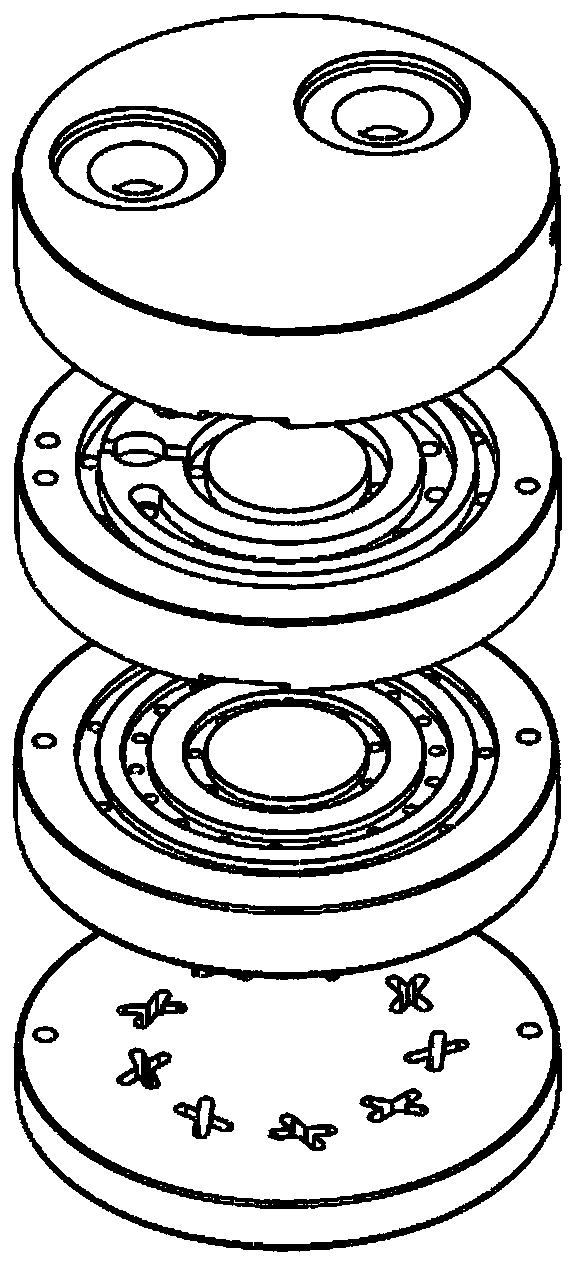

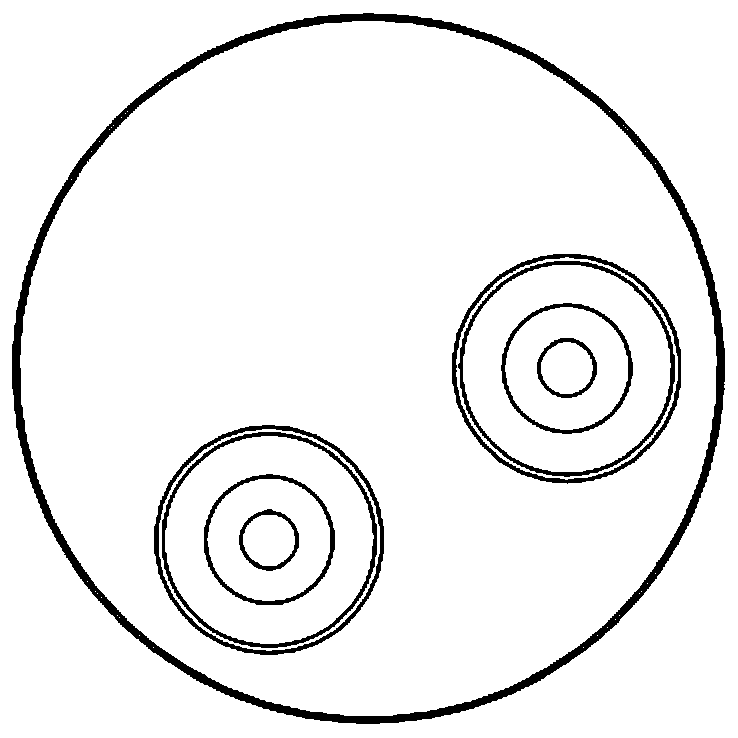

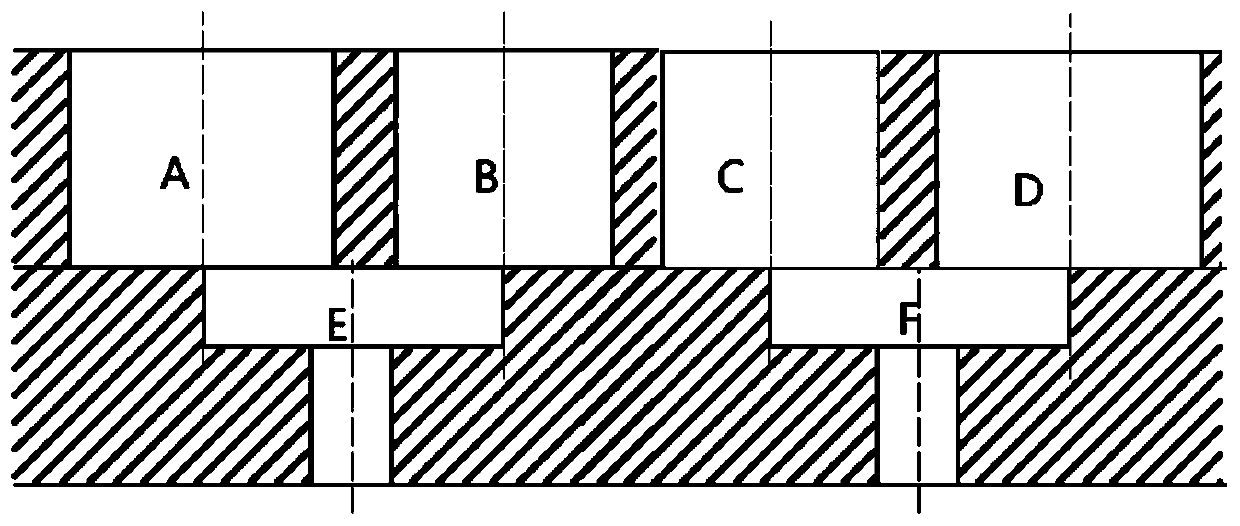

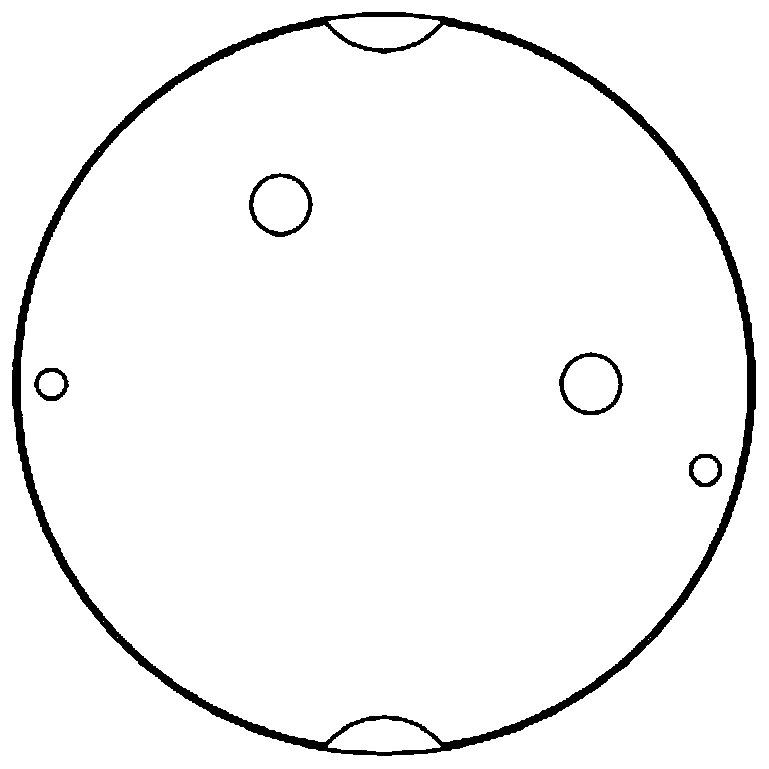

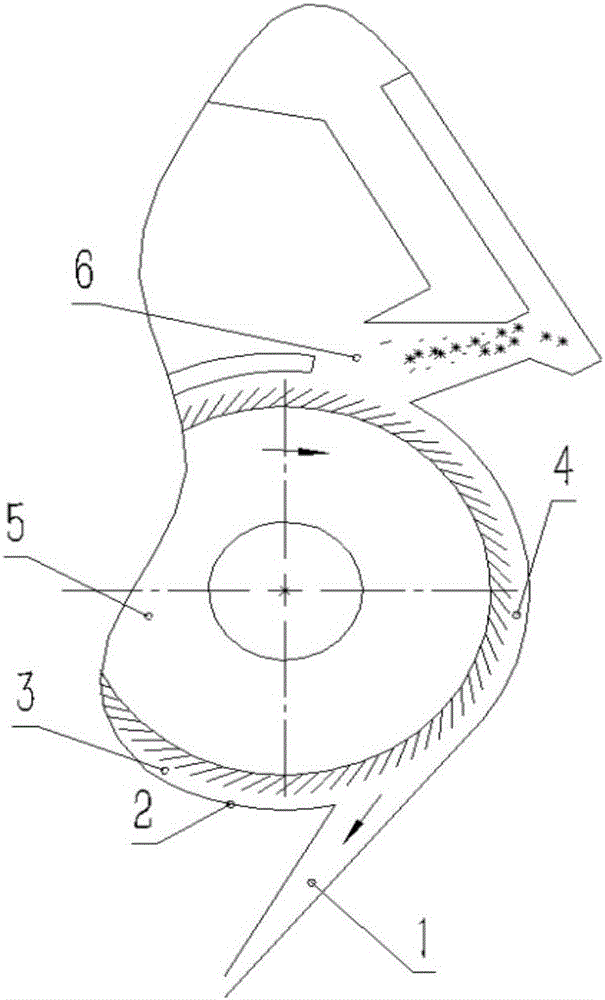

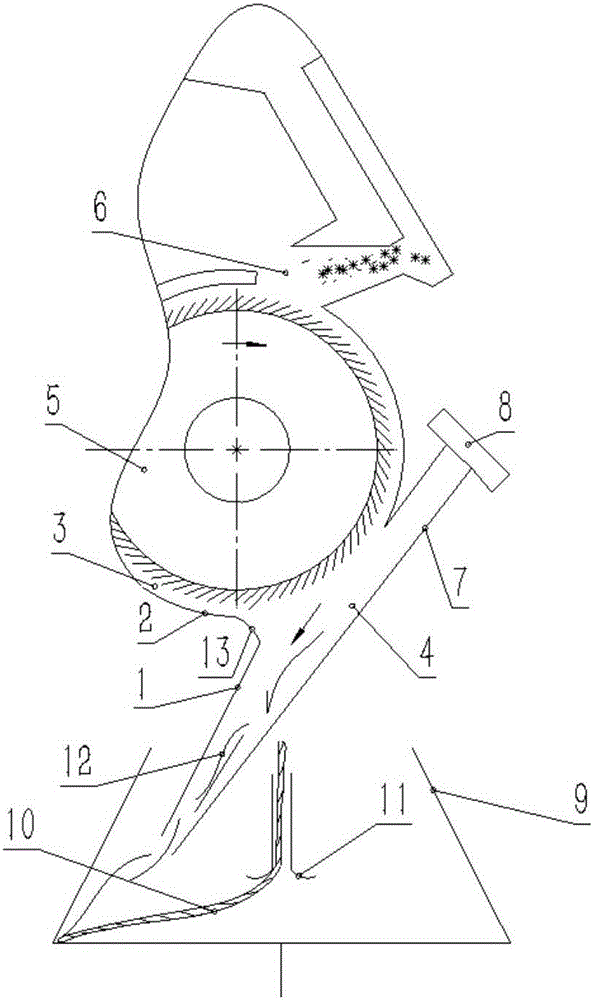

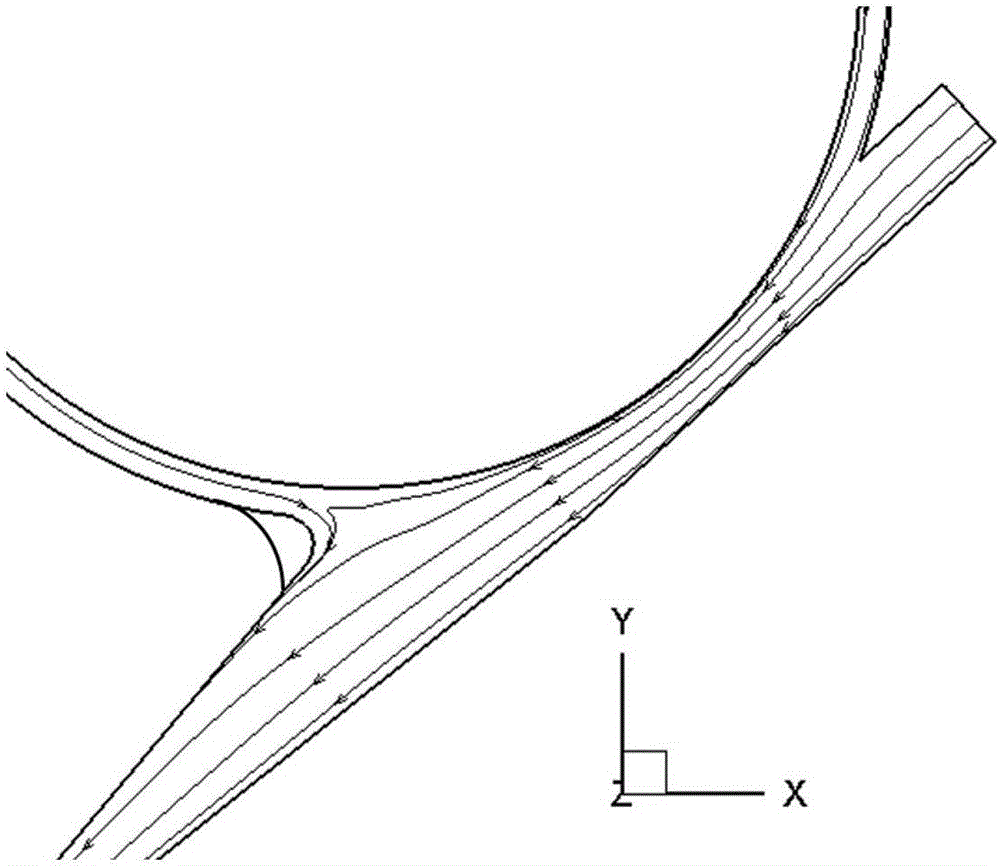

Continuous adjustable and controllable water vapor sealing type double screw rod extruder

InactiveCN102776579AWell mixedIncrease productivityFilament forming substance formingSpinning head liquid feederTemperature controlPolyvinyl alcohol

The invention relates to a continuous adjustable and controllable water vapor sealing type double screw rod extruder, which is mainly used for polyvinyl alcohol fiber melt spinning by using water as plasticizers and comprises double screw rods (1), a jacket (2), a sealing type pressure control valve (3), a cooling sleeve (4), a metering feeding device (5), a screw rod temperature control device (6), a driving transmission system (7), a motor (8) and the like. The continuous adjustable and controllable water vapor sealing type double screw rod extruder is characterized in that 1, the double screw rods at least consist of a metering feeding device (4), a small-lead-stroke positive threaded element (9), an engaging block (10) and an opposite threaded element (11), and the swelling and melting continuity is realized; 2, the threaded elements of the double screw rods at least consist of a first threaded element (12), a second threaded element (13) and a third threaded element (14), and the water vapor is sealed by utilizing the pressure difference; and 3, through the arrangement of the sealed pressure control valve (3), the pressure can be regulated when the process is changed, and the water vapor sealing is realized.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

Full-dull elastic yarn and preparation method thereof

ActiveCN111118617AGuaranteed performanceImprove performanceSpinning head liquid feederHollow filament manufacturePolymer scienceSpinning

The present invention relates to a full-dull elastic yarn and a preparation method thereof. The full-dull elastic yarn is extruded on a same spinneret plate; a PET melt is split into two flows, one flow is directly extruded after being distributed, and the other flow and a PBT melt are together extruded in a parallel composite spinning mode after the other flow is distributed; each of the PET meltand the PBT melt contains 2.5-3.0wt% of TiO2; the number ratio of spinneret holes m through which one flow of the PET melt is directly extruded to spinneret holes n through which the other flow of the PET melt and the PBT melt are extruded in the parallel composite spinning mode after the other flow is distributed is 1:(5-8); the spinneret holes m are hollow spinneret holes, and the spinneret holes n are circular spinneret holes; and FDY is prepared according to an FDY technology after extrusion, and then slack heat treatment is performed to obtain the full-dull elastic yarn. The crimping directions of monofilaments in the prepared full-dull elastic yarn are in random distribution. The problem of strip unevenness of a knitted fabric prepared from PET / PBT parallel bicomponent full-dull composite fibers is effectively solved.

Owner:JIANGSU HENGLI CHEM FIBER

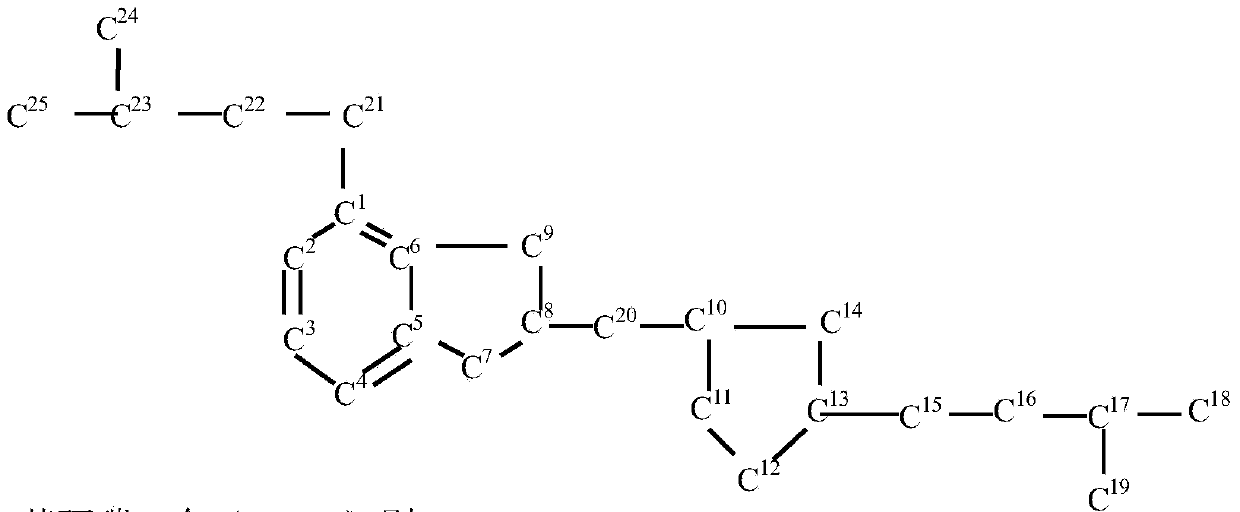

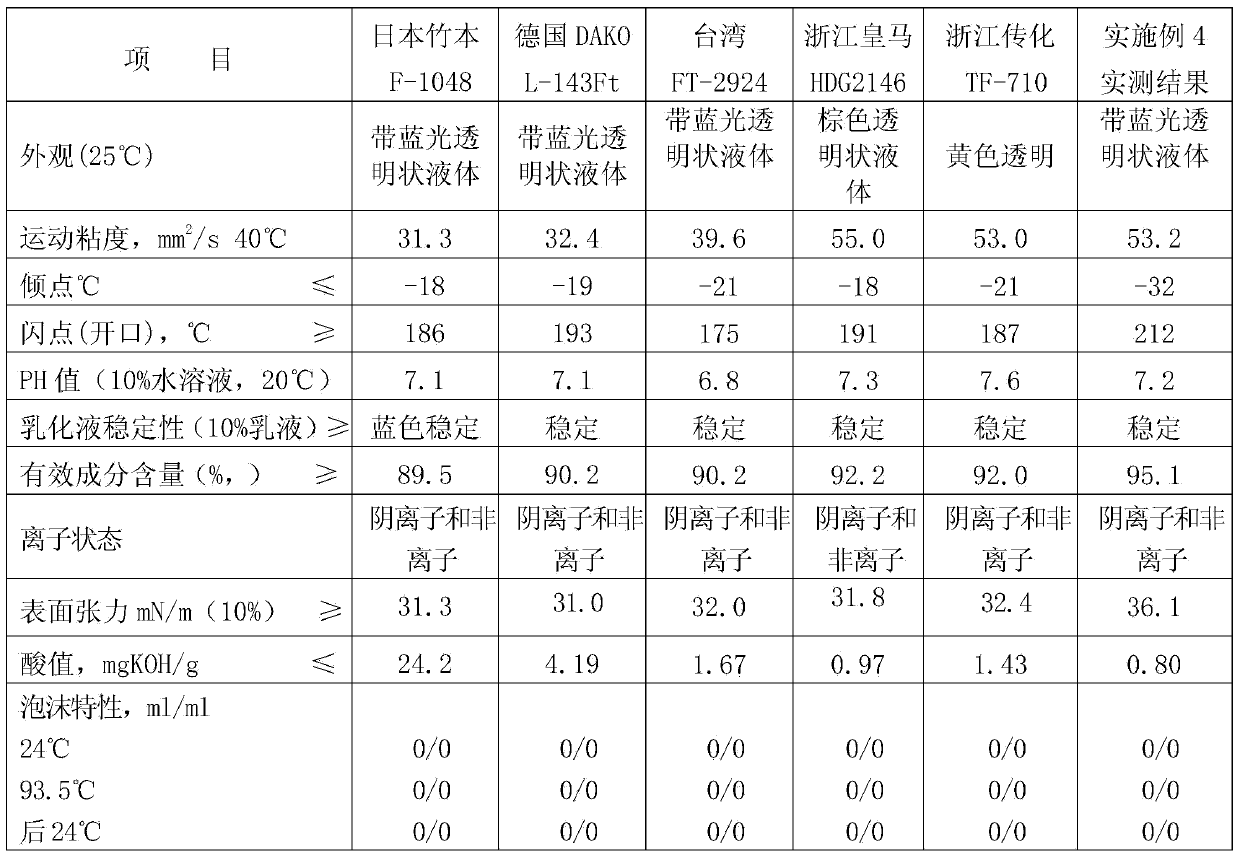

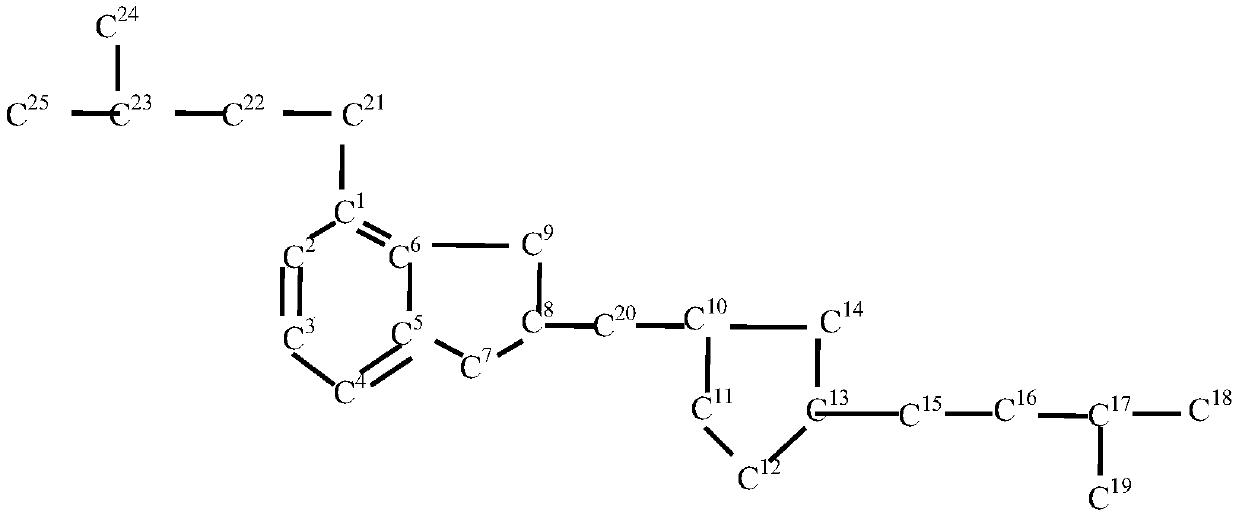

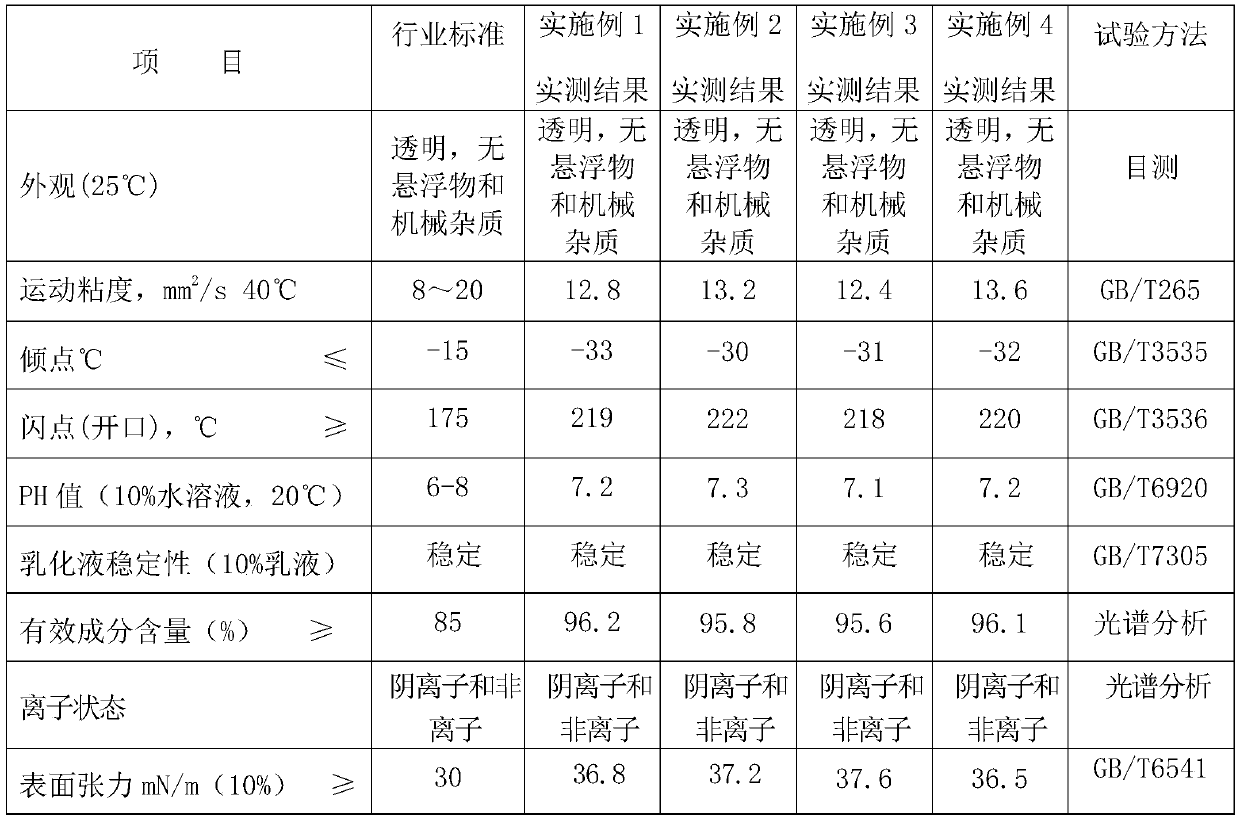

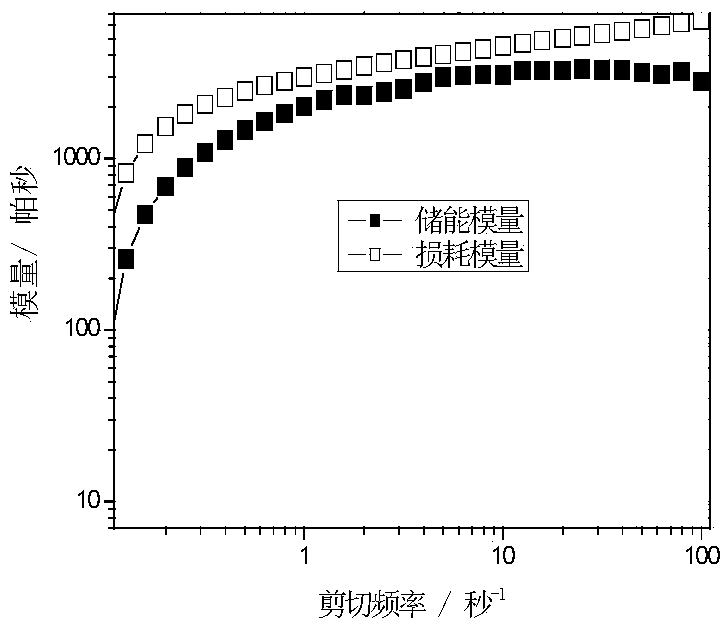

Dry antistatic spandex spinning oil and preparation method thereof

ActiveCN111206422AImprove high temperature resistanceModerate coefficient of frictionGrip property fibresPolymer scienceSpinning

The invention discloses dry antistatic spandex spinning oil, which is prepared from a compound high-temperature smoothing agent, a compound antistatic agent, a phenolic antioxidant, a phenylamino antioxidant, a gadoleic acid antioxidant, a high-temperature dispersant, a softening agent, an environment-friendly emulsifier, metallic stearates, a preservative and a defoamer, wherein the compound high-temperature smoothing agent is prepared by compounding hydrogenated paraffin base oil, hydrogenated naphthenic base oil and methyl silicone oil. The invention further provides a preparation method ofthe dry antistatic spandex spinning oil. According to the dry antistatic spandex spinning oil, spandex spinning has excellent antistatic property in different humidity conditions and is suitable forhigh-speed spinning process requirements of spandex denier filaments of various specifications. The dry antistatic spandex spinning oil has good smoothness, excellent high and low temperature resistance and excellent yellowing resistance, and has good dispersion and isolation to spandex at the same time.

Owner:上海中孚油品集团有限公司

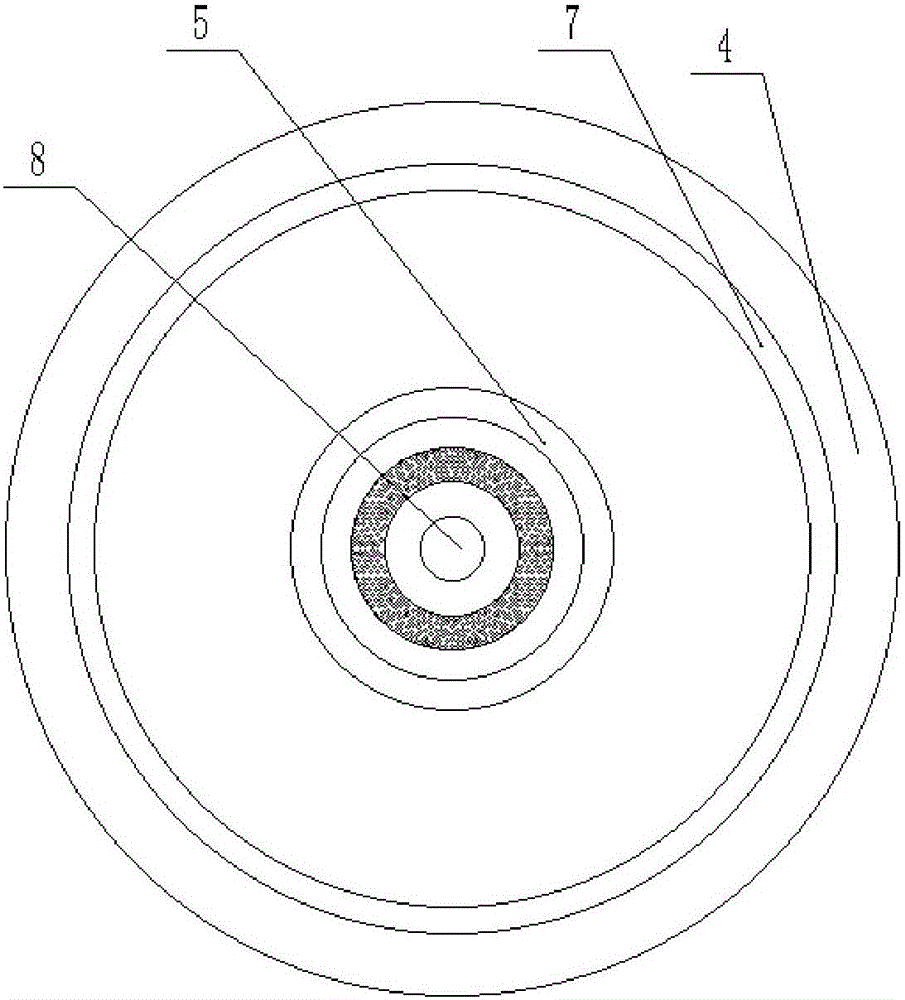

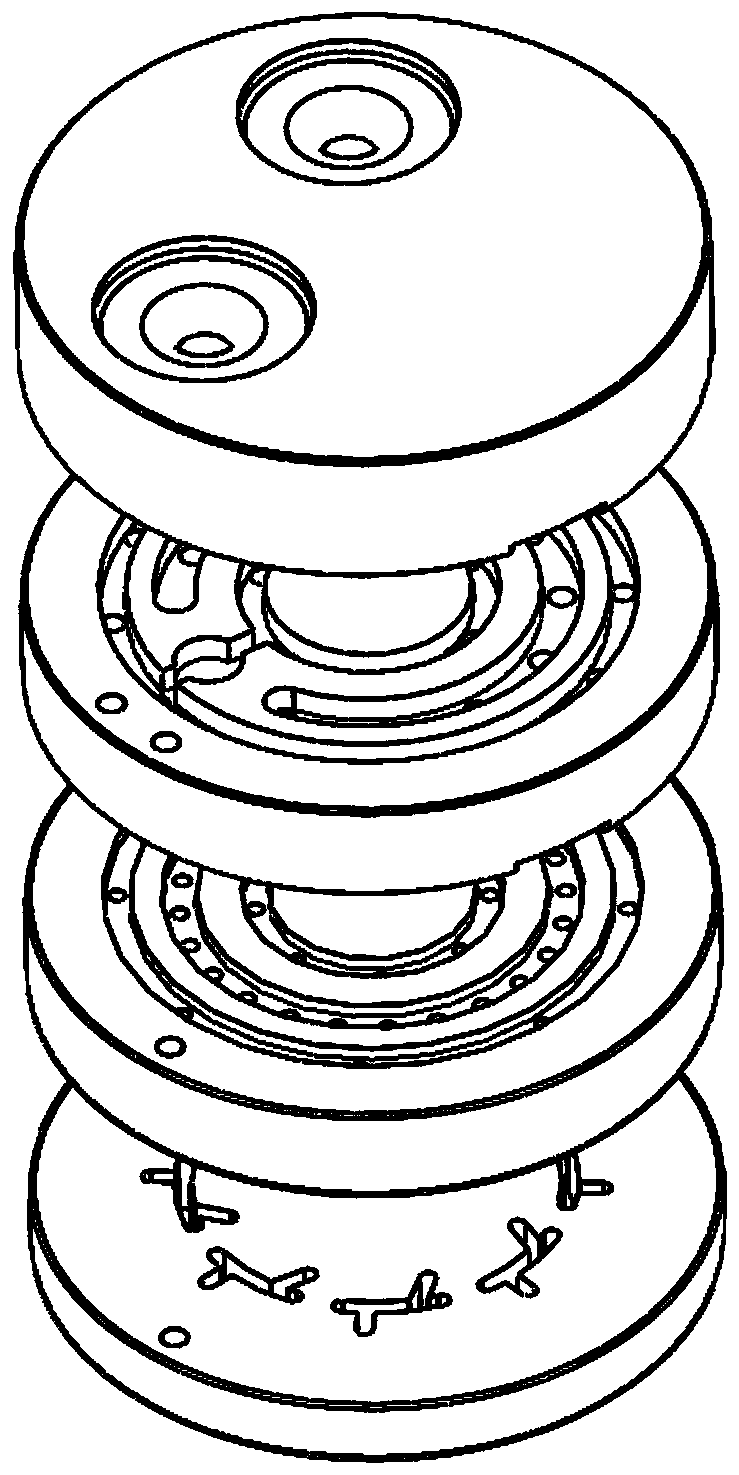

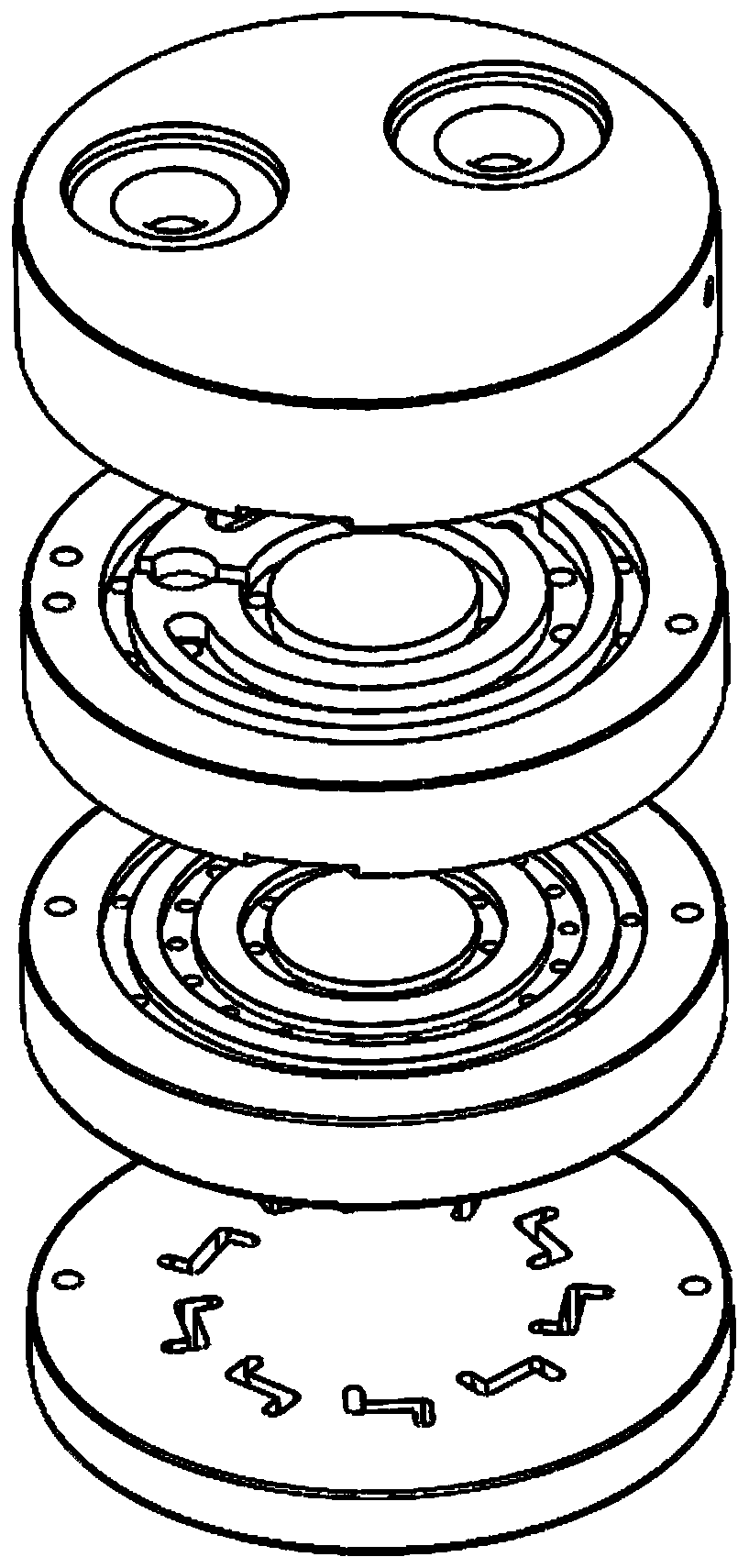

Magnetic suspension-type centrifugal electrostatic spinning device

ActiveCN105755557AHelp refineSpinning smoothlyFilament/thread formingEngineeringCylindrical electrode

The invention relates to a magnetic suspension-type centrifugal electrostatic spinning device, and belongs to the field of spinning.The magnetic suspension-type centrifugal electrostatic spinning device comprises infrared heating tubes, a small magnetic suspension ball, a collection cylinder, a magnetic suspension base, a cylindrical electrode, triangular clamping devices, a high-speed rotating disc, a support frame and a small counterweight ball; the small magnetic suspension ball is a hollow sphere and provided with a feeding hole, multiple circles of centrifugal spinning holes are formed in the portion near the waist of the small magnetic suspension ball, the counterweight ball is arranged on the lower portion of the small magnetic suspension ball, the magnetic suspension base is arranged on the bottom face of the collection cylinder, the small magnetic suspension ball is located over the magnetic suspension base, the triangular clamping devices, the high-speed rotating disc and the infrared heating tubes are sequentially installed on the support frame above the small magnetic suspension ball, and the cylindrical electrode is located in the middle of the inner wall of the collection cylinder.The holes are distributed on the whole small hollow metal ball, when a higher speed V is given to the small magnetic suspension ball, a melt in the small magnetic suspension ball is tossed out, centrifugal spinning is conducted, and the kinetic energy loss in the rotating process of the small metal magnetic suspension ball is less.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing polyvinyl chloride fibers for artificial hair through ultrahigh pressure spinning

ActiveCN102560715AHigh viscosityImprove liquidityArtificial filament heat treatmentMelt spinning methodsUltra high pressureResin matrix

The invention relates to the technical field of manufacturing artificial filaments and analogues through polyvinyl chloride resin, in particular to a method for producing polyvinyl chloride fibers for artificial hair through ultrahigh pressure spinning, wherein the ultrahigh pressure spinning is adopted to convert cohesive energy of melts into system friction heat; material in a system is prompted to be heated uniformly; the utilization of heat resistant chlorinated vinyl chloride resin and heat stabilizers is reduced at the same time; the spinning fluidity is improved; the method chooses and utilizes the ultrahigh pressure melt spinning technology to prepare the polyvinyl chloride fibers, and the spinning pressure can reach 800 to 1000 kg / cm<2>; the application of the ultrahigh pressure spinning technology can improve the situations that the viscosity of vinyl chloride series resin is high and the fluidity is not good to a great extent; meanwhile, additives such as compatible chlorinated vinyl chloride resin matrix heat resistant chlorinated vinyl chloride resin can be omitted; in addition, the method enables the spinning process to be simplified and can improve the efficiency, and finished products have excellent performances.

Owner:HENAN REBECCA HAIR PRODS TNC

High-moisture-conductivity polyester fiber and preparation method thereof

InactiveCN111041575AIncreased ability to export moistureSpinning smoothlySpinning head liquid feederFilament/thread formingPolyesterFiber

The invention relates to a high-moisture-conductivity polyester fiber and a preparation method thereof. After a PET melt and a PTT melt are distributed according to an FDY process, an FDY yarn is extruded from spinneret holes in the same spinneret plate, the FDY yarn is subjected to relaxation heat treatment to obtain the high-moisture-conductivity polyester fiber; the spinneret holes are of a shape, wherein the shape is as shown in the specification and is composed of a transverse line and a diagonal line I and a diagonal line II vertically connected with the transverse line; the included angle between the diagonal I and the transverse line is 50-60 degrees; the length ratio of the diagonal line I to the diagonal line II to the transverse line is 1 to 1 to 2, and the intersection point ofthe diagonal line I or the diagonal line II and the horizontal line is the midpoint of the horizontal line; the widths of the diagonal line I, the diagonal line II and the horizontal line are equal;the ratio of the length to the width of the transverse line is 2.5-3.5 to 1; the distribution refers to controlling the PET melt to flow through the transverse line, meanwhile, controlling the PET melt to flow through the diagonal line I and the diagonal line II; and the finally prepared high-moisture-conductivity polyester fiber has a distorted shape. According to the preparation method disclosedby the invention, a simple preparation method is adopted to prepare the polyester fiber which is beneficial to moisture export.

Owner:深圳市宏翔新材料发展有限公司

Yarn spinning technology for semi-worsted and blended colored yarn and yarn

InactiveCN104878493AImprove insulation effectIncrease elasticityBleaching apparatusYarnCardingWorsted

The invention relates to a yarn spinning technology for semi-worsted and blended colored yarn and the yarn prepared with the technology. The technological steps mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise cotton fiber, nylon fiber and viscose fiber. The cotton fiber is treated with a more efficient bleaching method, meanwhile, nylon and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are improved; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

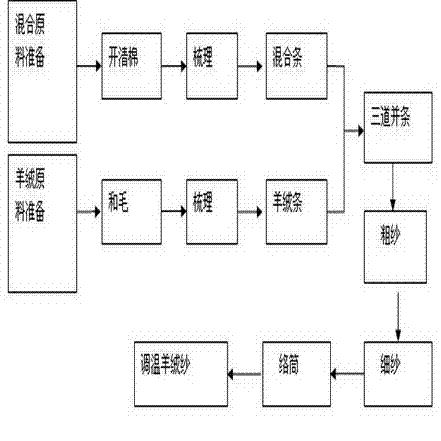

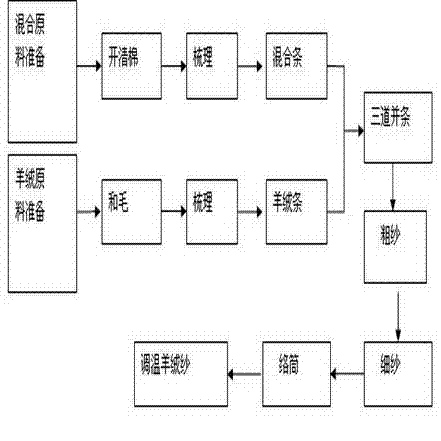

Thermoregulation cashmere yarn and production method thereof

The invention discloses a thermoregulation cashmere yarn and a production method thereof. The thermoregulation cashmere yarn is characterized in that the fineness is 33.3-100tex, the thermoregulation cashmere yarn is formed by blending the following components according to mass ratio: 30-60% of thermoregulation fiber, 30-60% of cashmere fiber and 10-30% of third fiber; the thermoregulation fiber is rayon-based thermal-storage thermoregulation fiber, the fineness is 1.7-2.2dtex, and the length is 38-42nm; for the cashmere fiber, the fineness is 14-16mum, and the length is 36-44mm; and the third fiber is modal fiber, polyster fiber or milk protein fiber, the fineness is 1.7-2.2dtex, and the length is 38-42mm. The production method is suitable for the thermoregulation cashmere yarn, and comprises the following steps: respectively producing the thermoregulation fiber, third fiber mixed strips and cashmere strips, then drawing and doubling the mixed strips and the cashmere strips according to design, then roving, finely spinning and spooling the mixed strips and the cashmere strips in sequence, and finally obtaining the thermoregulation cashmere yarn.

Owner:内蒙古焱太经贸有限责任公司 +1

Polyacrylonitrile carbon fiber prepared by using waste polyacrylonitrile fiber and preparation method thereof

InactiveCN109322010AAchieve reuseIncrease added valueFibre chemical featuresPolymer scienceCarbon fibers

The invention discloses a polyacrylonitrile carbon fiber prepared by using waste polyacrylonitrile fiber and a preparation method thereof, and the method comprises the following steps: (1) dehydratingthe waste polyacrylonitrile fiber to obtain a completely dehydrated waste polyacrylonitrile fiber; (2)chopping the fully dehydrated waste polyacrylonitrile fiber, mixing with a solvent, swelling at room temperature, stirring at a high temperature to prepare a polymer solution, filtering, and defoaming to obtain a spinning solution; (3) spinning the spinning solution to obtain a polyacrylonitrileraw silk; (4)pre-oxidizing and carbonizing the polyacrylonitrile raw silk to obtain a polyacrylonitrile carbon fiber. The method is adopted to obtain a completely dehydrated waste silk, a spinning solution of carbon fiber raw silk having a polyacrylonitrile mass concentration of 19-22% is prepared, and the raw silk prepared by the spinning solution is pre-oxidized and carbonized to finally obtaina polyacrylonitrile carbon fiber with linear density of 38 to 66 g / km, tensile strength of 3.8 to 5.6 GPa, and tensile modulus of 230 to 300 GPa.

Owner:BEIJING UNIV OF CHEM TECH +1

Preparation method of pen point of mark pen

ActiveCN111055611AImprove performanceConsider performanceSpinnerette packsFilament/thread formingPolymer sciencePolyurethane adhesive

The invention relates to a preparation method of a pen point of a mark pen. The method comprises the following steps of: (1) washing and drying the pen point by using polyamide fibers; (2) dipping byadopting a two-component polyurethane adhesive; (3) preheating and curing and foaming the soaked fiber bundles; (4) cutting and grinding fully foamed fiber bars; and (5) cleaning and drying to obtainthe pen point of the mark pen. The preparation process of the polyamide fibers for the pen point comprises the following steps: distributing high / low viscosity PA6 melts according to the FDY process,extruding the high / low viscosity PA6 melts from spinneret holes on the same spinneret plate to obtain FDY filaments, and performing relaxation heat treatment to obtain the polyamide fibers for the penpoint. The cross section of each spinneret hole is in a shape seen the specification, and each spinneret hole comprises a transverse line and further comprises an oblique line I and an oblique line II which are connected with the transverse line; and distributing refers to controlling the flow of the high viscosity PA6 melt through the transverse line while controlling the flow of the low viscosity PA6 melt through the oblique line I and the oblique line II. The preparation method is simple, and the prepared pen point of the mark pen has good writing experience.

Owner:深圳市宏翔新材料发展有限公司

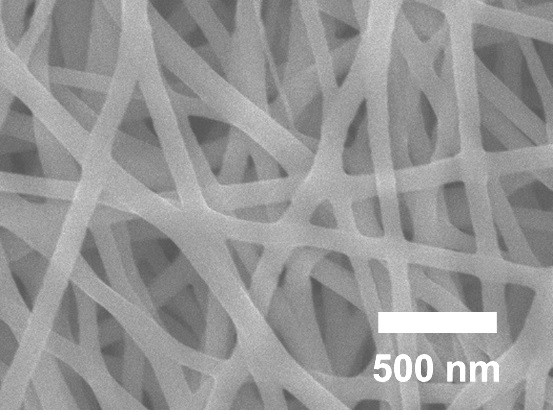

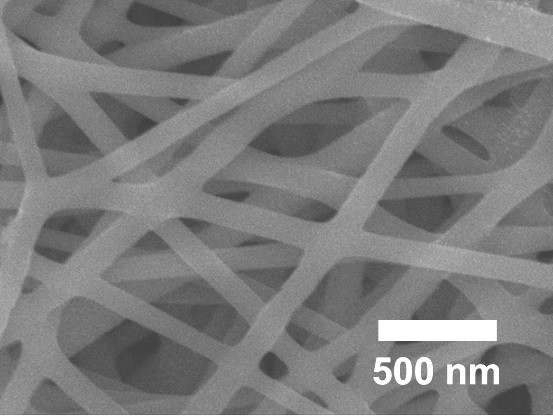

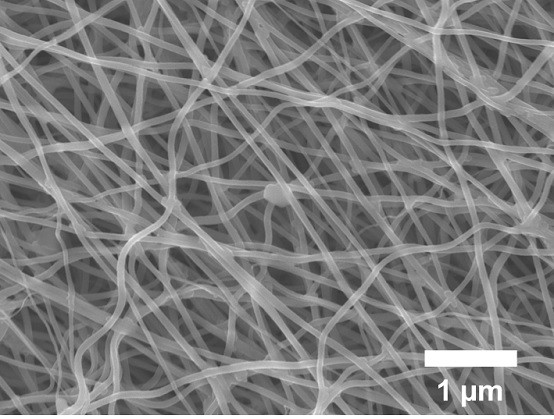

Gelatin-based carbon nanofibers and preparation method thereof

ActiveCN112301464AImprove thermal stabilitySolve the problem of not maintaining fiber shapeMonocomponent protein artificial filamentElectro-spinningFiberPolymer science

The invention discloses gelatin-based carbon nanofibers and a preparation method thereof. The preparation method comprises the following steps that gelatin solid particles are added into deionized water, heating and stirring are carried out, then an iron (III) complex which can be dissolved in water and has a high stability constant is added into a gelatin aqueous solution to prepare a mixed spinning solution, and electrostatic spinning is carried out to prepare gelatin-based fibers; and pre-oxidation and carbonization treatment are performed on the spun gelatin-based fibers to obtain the gelatin-based carbon nanofibers. The preparation method has the advantages that gelatin is used as a precursor to prepare the carbon nanofibers, so that efficient utilization of resources is realized; andthe iron (III) complex with the high stability constant is used as an auxiliary agent, so that crosslinking agglomeration of ferric ions and gelatin molecules is prevented, and meanwhile the defect that gelatin fibers are melted into blocks at high temperature and the fiber morphology is difficult to maintain due to low glass-transition temperature is overcome. The preparation method is simple and environmentally friendly, and the obtained gelatin-based carbon nanofibers are smooth in surface, uniform in thickness and high in porosity and has certain application prospects in the fields of catalysis, adsorption and the like.

Owner:BEIJING UNIV OF CHEM TECH

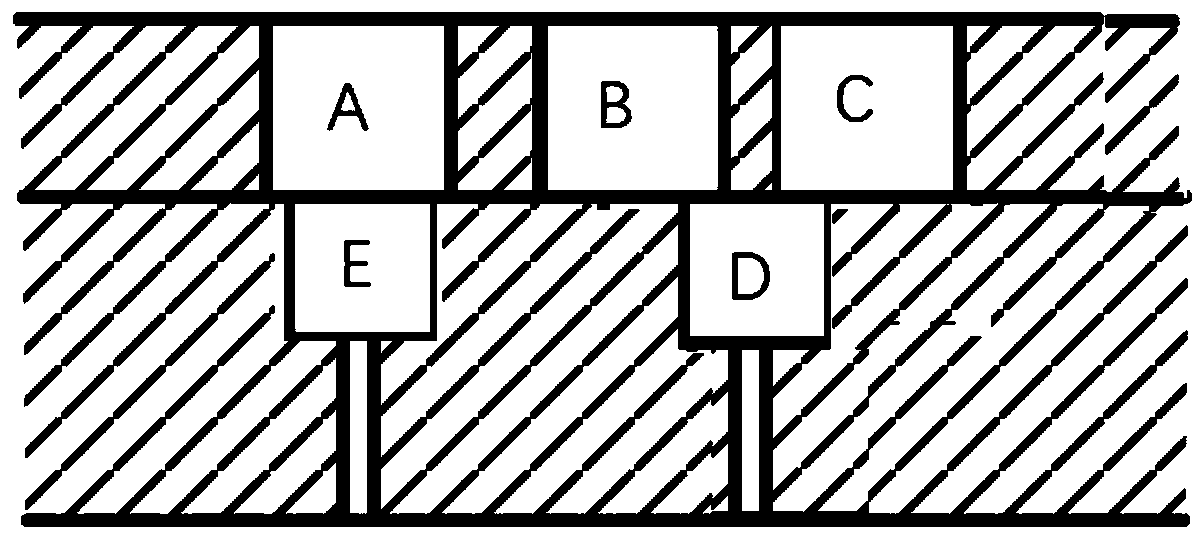

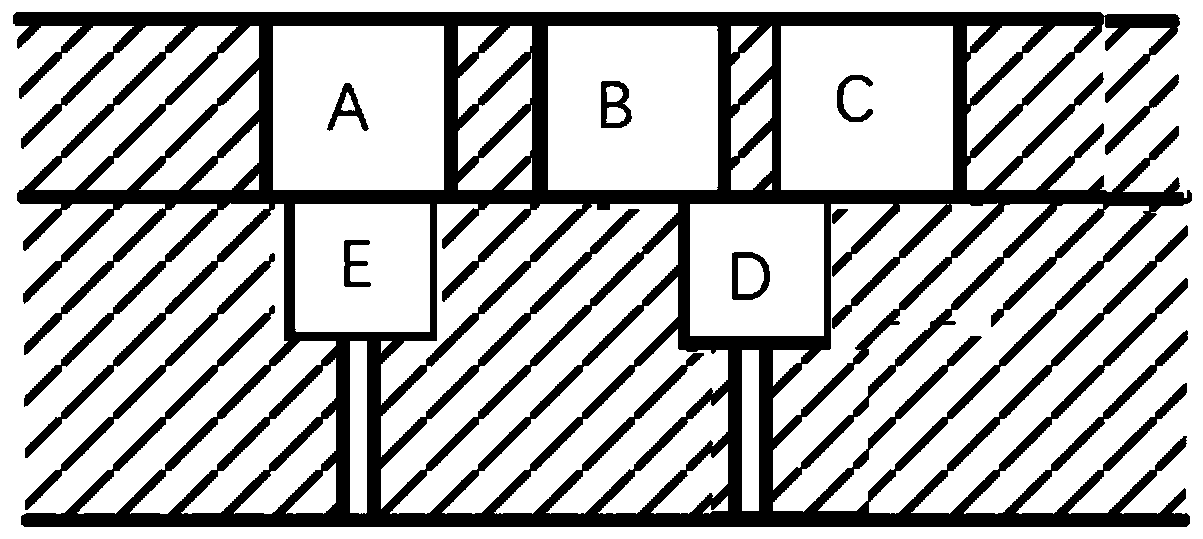

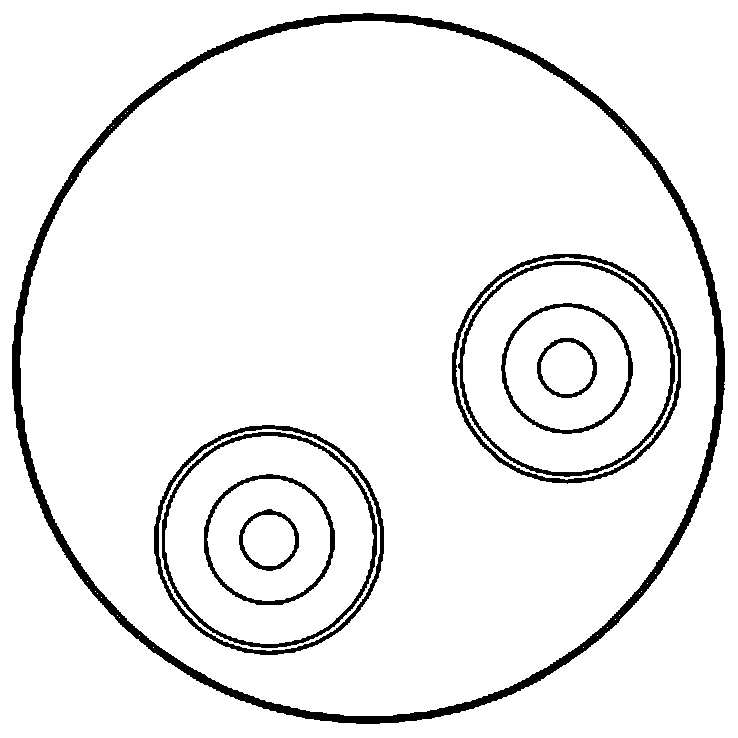

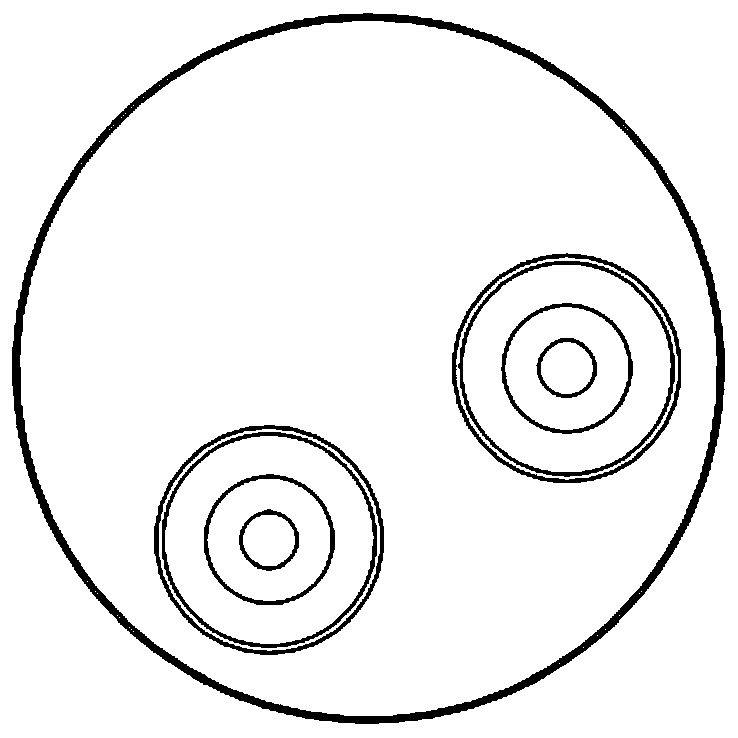

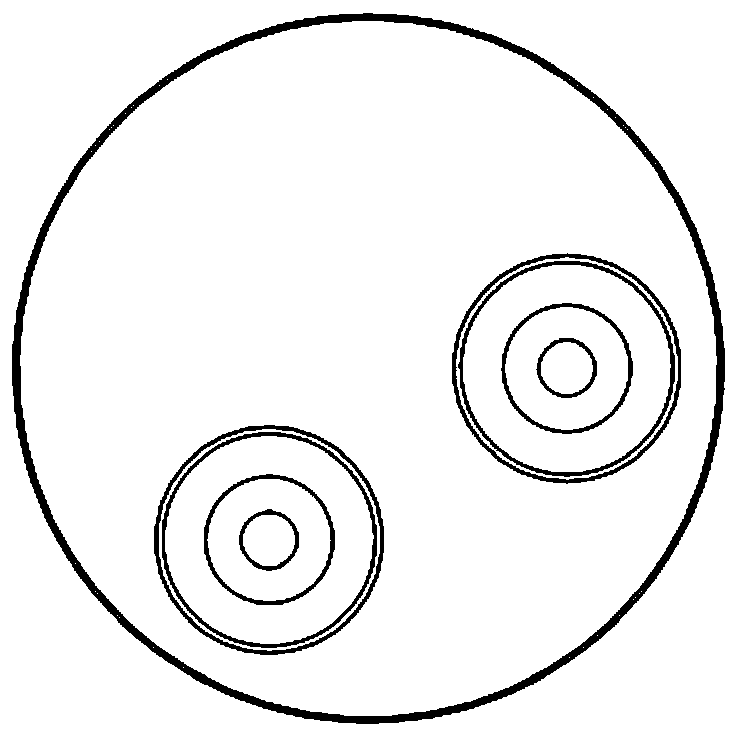

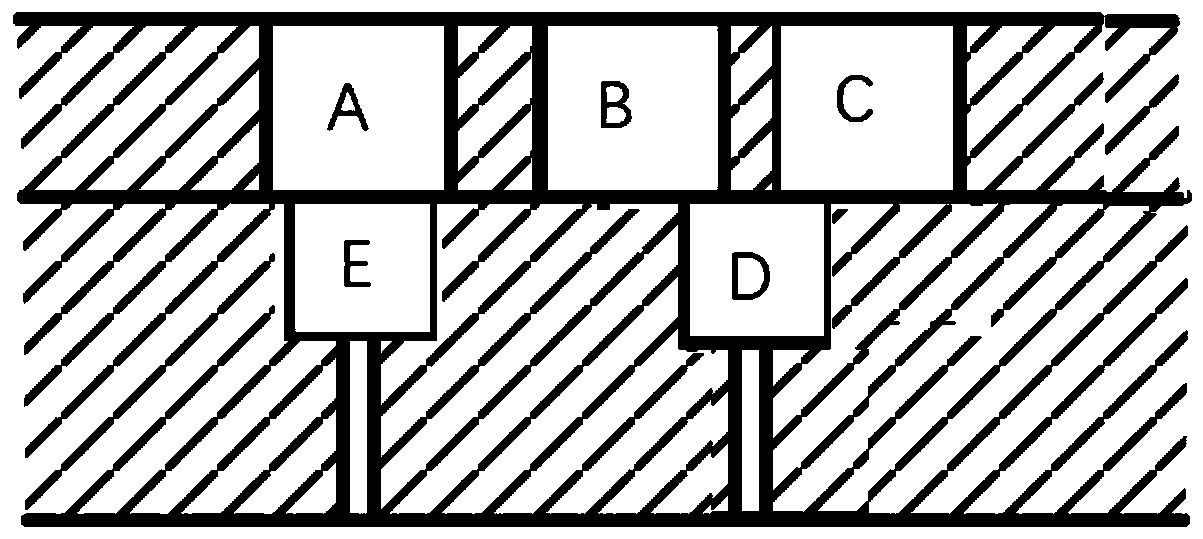

PTT/PET double-component elastic yarn and preparation method thereof

ActiveCN110983466AEvenly distributedThe apparent viscosity is close toFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolymer chemistry

The present invention relates to a PTT / PET double-component elastic yarn and a preparation method thereof. PET and PTT melts were dispensed according to an FDY process, and FDY yarns are manufacturedby extruding from spinneret holes m and n in the same spinneret plate to be subjected to relaxation heat treatment, wherein the PTT and PET melts are dispensed through dispensing holes A and B to flowto the spinneret hole m and then are dispensed through dispensing holes C and D to flow to the spinneret hole n; in the inlets of the dispensing holes A, B, C and D, the apparent viscosity of the PETmelt and the PTT melt are not greater than 5%; the dispensing holes A and B are cylinder holes of the same heights and have the diameter ratio of 1.24 to 1; the dispensing holes C and D are cylinderholes of the same heights and have the diameter ratio of 1 to 1.24; and the prepared double-component elastic yarn is composed of a plurality of PTT / PET side-by-side composite monofilaments of different ratios, and the single-filament curling directions of the double-component elastic yarn are randomly distributed. The PTT / PET double-component elastic yarn fabric does not have the problem of uneven strip shapes.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of lampblack air filtering material

InactiveCN110983624AImprove filtration efficiencyIncrease surface areaFilament/thread formingMembrane filtersAir filtrationSpinning

The invention relates to a preparation method of a lampblack air filtering material. The raw material is a self-twisted fiber. The technological process comprises the following steps of opening, blending and cotton feeding, carding, laying and web forming, flame-retardant adhesive preparation, flame-retardant adhesive spraying, drying and reinforcing, ironing and trimming and lapping. The preparation process of the self-twisted fiber comprises the following steps of distributing a PET melt and a PTT melt according to a staple spinning process, and extruding from a spinneret orifice in the samespinneret plate to obtain a staple fiber, namely the self-twisted fiber, wherein the staple spinning process comprises a relaxation heat setting procedure, and the temperature is 100-110 DEG C; the cross section of the spinneret orifice is (formula)-shaped and is formed by a transverse line, a vertical line vertically connected to the transverse line and a diagonal line obliquely connected to thetransverse line; and the distribution refers to controlling the PET melt to flow through the transverse line while controlling the PTT melt to flow through the vertical line and the diagonal line. According to the preparation method, a simple preparation method is adopted to prepare the fiber with the twisted structure, so that the lampblack air filter material with high filtration efficiency isprepared.

Owner:深圳市宏翔新材料发展有限公司

Preparation method of water-repellent canvas

InactiveCN111058113AMeet the needs of useImprove mechanical propertiesSpinnerette packsFilament/thread formingFiberPolymer science

The invention relates to a preparation method of water-repellent canvas. After a high-viscosity CDP melt and a low-viscosity CDP melt are distributed according to a spinning process, and an industrialyarn is obtained through extrusion from spinneret holes in the same spinneret plate, relaxation heat treatment is carried out to obtain a self-twisted fiber; then the self-twisted fiber is woven intocloth, and next, the cloth is padded with a waterproof finishing agent and coated with a waterproof coating to prepare the water-repellent canvas. The spinning process comprises two times of stretching and three times of shaping; the intrinsic viscosity of the high-viscosity CDP melt is 1.10-1.23dL / g, and the intrinsic viscosity of the low-viscosity CDP melt is 0.70-0.75dL / g; the cross section ofthe spinneret hole is in the shape as shown in the speciation, and the shape is composed of a horizontal line and a vertical line I and a vertical line II connected vertically with the horizontal line; and the distribution refers to controlling the low-viscosity CDP melt to flow through the vertical lines I and II, and simultaneously controlling the high-viscosity CDP melt to flow through the horizontal line. According to the preparation method, the mechanical properties and the contact area with the waterproof finishing agent of the double-component composite fiber are improved, and the high-peel-strength water-repellent canvas is prepared.

Owner:深圳市宏翔新材料发展有限公司

Sports type knitted fabric and preparation method thereof

ActiveCN110965196AGood moisture absorption and perspirationModerate proportionWeft knittingInspecting textilesYarnPolymer science

The invention relates to a sports type knitted fabric and a preparation method thereof. Cotton fibers are taken as a surface yarn raw material, self-curling elastic fibers are taken as an intermediateyarn raw material, fine-denier cruciform PET fibers are taken as a ground yarn raw material, three-wire adding yarn weaving and finishing are carried out, and the sports type knitted fabric is prepared; the self-curling elastic are prepared according to an FDY process, and a CDP melt is split into two paths, wherein one path is directly extruded after being dispensed, and the other path is extruded after being distributed in a parallel composite spinning mode along with the PTT melt. The sports type knitted fabric prepared by the invention does not have the problem of non-uniform strip-like shape, and the gram weight of the sports type knitted fabric is 120-160 g / m2. The rate of change of the washing size in the warp direction and the weft direction is between -1.0% and 1.0%, the water absorption rate of the sports type knitted fabric is greater than or equal to 275%, the drip diffusion time is less than or equal to 2.2 seconds, the wicking height is greater than or equal to 142 mm, and the evaporation rate is greater than or equal to 0.33g / h , and the moisture permeability is greater than or equal to 128000 g / (m2.d).

Owner:JIANGSU HENGLI CHEM FIBER

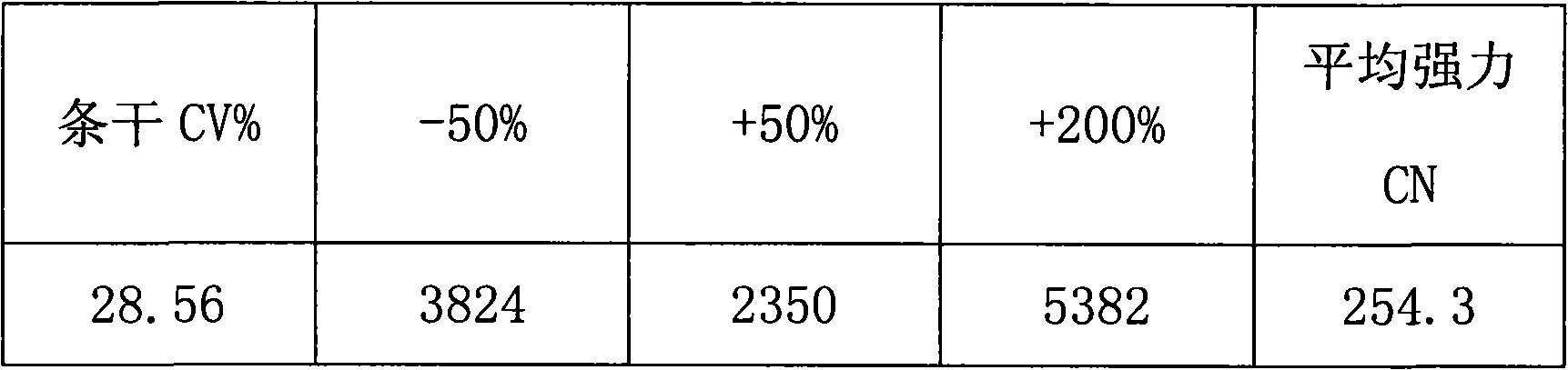

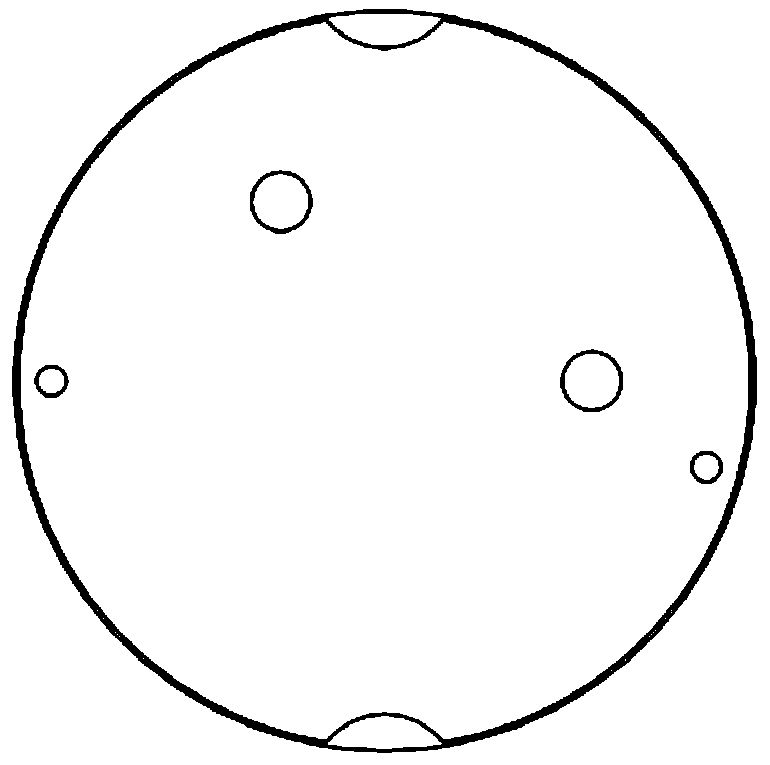

Rotor-spinning method for spinning of high-strength yarns

InactiveCN106567165AEasy to shapeImprove straightnessContinuous wound-up machinesOpen-end spinning machinesAir pumpYarn strength

The invention relates to a rotor-spinning method for spinning of high-strength yarns. The rotor-spinning method for the spinning of the high-strength yarns is characterized in that the spinning is conducted by a rotor-spinning device which eliminates vortexes. The rotor-spinning device which eliminates the vortexes comprises a fiber conveying channel and a bypass channel connected to an air-supply air pump, wherein center axes of the bypass channel and the fiber conveying channel are located on the same straight line, and the bypass channel is located in the direction opposite to a fiber conveying direction; an entrance of the fiber conveying channel located on one side of a vortex elimination channel is connected to a corresponding gap of a carding roller cover shell by the entrance of the fiber conveying channel, and the other side edge of the vortex elimination channel is straight edge without a gap; and the fiber conveying channel is in arc transition connection with the carding roller cover shell. According to the invention, the carding roller cover shell is in arc connection with the fiber conveying channel, and the bypass channel is used to supply air flows by the air-supply air pump, so the vortexes at the entrance of the fiber conveying channel can be eliminated; harmful fiber forms such as bending, hooking and folding can be reduced; parallel straightness of fibers can be increased; and final yarn strength can be enhanced.

Owner:苏州多道自动化科技有限公司 +1

Friction-weight increasing agent as well as preparation and application thereof to crystal cotton fiber spinning

The invention relates to a friction-weight increasing agent as well as preparation and application thereof to crystal cotton fiber spinning. The friction-weight increasing agent is mixed solution of a high molecular polymer, an emulsifying agent, a softening agent, inorganic metal salt, an anionic surfactant and a nonionic surfactant. In the preparation method, the friction-weight increasing agent is formed by emulsifying and stirring the raw materials. The application method comprises the following steps: treating the crystal cotton fiber at the temperature of 20-30 DEG C by utilizing the friction-weight increasing agent; and then balancing for 12-48 hours under the condition of constant temperature and humidity to obtain friction-weight increased crystal cotton fiber. According to the invention, the operation method is simple, the raw materials are cheap, the cost is low and better energy-saving effect is achieved because of operation at normal temperature, and the preparation method and the application method are ecological friendly and environmental friendly and easy for industrialized production; and the obtained friction-weight increased crystal cotton fiber has the advantages of better cotton carding, slivering and spinning performances, thus breaking through the spinning bottleneck problem of the crystal cotton fiber in the textile field.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com