Preparation method of PIPD/PBO (poly(dihydroxyphenylene pyridobisimidazole)/poly-p-phenylene ben-zobisthiazole) blend fiber

A technology of blended fiber and PBO polymer, which is applied in the field of blended fiber, can solve the problems of deterioration of mechanical properties of PBO fiber, poor bonding performance of resin matrix on the surface of PBO fiber, etc., and achieve the goal of improving application performance, increasing molecular weight and increasing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

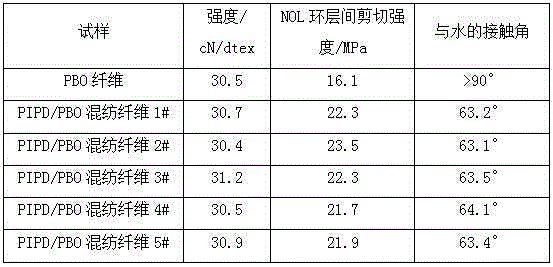

Examples

Embodiment 1

[0044] A preparation method for PIPD / PBO blended fibers, comprising the following processing steps:

[0045] A, preparation of PIPD / PPA polymer solution

[0046] Put 2,5-dihydroxyterephthalic acid, tetraaminopyridine trihydrochloride monohydrate, polyphosphoric acid and phosphorus pentoxide into a polymerization kettle for polymerization to obtain a PIPD / PPA polymer solution;

[0047] B, preparation of PBO / PPA polymer solution

[0048] Put terephthalic acid, 4,6-diaminoresorcinol hydrochloride, polyphosphoric acid and phosphorus pentoxide into a polymerization kettle for polymerization to obtain a PBO / PPA polymer solution;

[0049] C, mixed preparation PIPD / PBO polymer

[0050] The PIPD / PPA polymer solution obtained in step A is mixed with the PBO / PPA polymer solution obtained in step B in a mass ratio of 1:5 to obtain a PIPD / PBO polymer;

[0051] D. Preparation of spun silk

[0052] The PIPD / PBO polymer obtained in step C is homogenized and degassed by a twin-screw extrud...

Embodiment 2

[0056] A preparation method for PIPD / PBO blended fibers, comprising the following processing steps:

[0057] A. Preparation of PIPD / PPA polymer solution

[0058] Put 2,5-dihydroxyterephthalic acid, tetraaminopyridine trihydrochloride monohydrate, polyphosphoric acid and phosphorus pentoxide into a polymerization kettle for polymerization to obtain a PIPD / PPA polymer solution;

[0059] B, preparation of PBO / PPA polymer solution

[0060] Put terephthalic acid, 4,6-diaminoresorcinol hydrochloride, polyphosphoric acid and phosphorus pentoxide into a polymerization kettle for polymerization to obtain a PBO / PPA polymer solution;

[0061] C, mixed preparation PIPD / PBO polymer

[0062] The PIPD / PPA polymer solution that step A obtains is mixed with the PBO / PPA polymer solution that step B obtains by the mass ratio of polymer as 1:20, obtains PIPD / PBO polymer;

[0063] D. Preparation of spun silk

[0064] The PIPD / PBO polymer obtained in step C is homogenized and degassed by a twin...

Embodiment 3

[0068] A preparation method for PIPD / PBO blended fibers, comprising the following processing steps:

[0069] A, preparation of PIPD / PPA polymer solution

[0070] Put 2,5-dihydroxyterephthalic acid, tetraaminopyridine trihydrochloride monohydrate, polyphosphoric acid and phosphorus pentoxide into a polymerization kettle for polymerization to obtain a PIPD / PPA polymer solution;

[0071] B, preparation of PBO / PPA polymer solution

[0072] Put terephthalic acid, 4,6-diaminoresorcinol hydrochloride, polyphosphoric acid and phosphorus pentoxide into a polymerization kettle for polymerization to obtain a PBO / PPA polymer solution;

[0073] C, mixed preparation PIPD / PBO polymer

[0074] The PIPD / PPA polymer solution that step A obtains is mixed with the PBO / PPA polymer solution that step B obtains by the mass ratio of polymer as 1:12.5, obtains PIPD / PBO polymer;

[0075] D. Preparation of spun silk

[0076] The PIPD / PBO polymer obtained in step C is homogenized and degassed by a tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com