Sports type knitted fabric and preparation method thereof

A kind of knitting fabric, sports technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problem of uneven stripes and other problems, achieve good moisture absorption and perspiration performance, and maintain the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

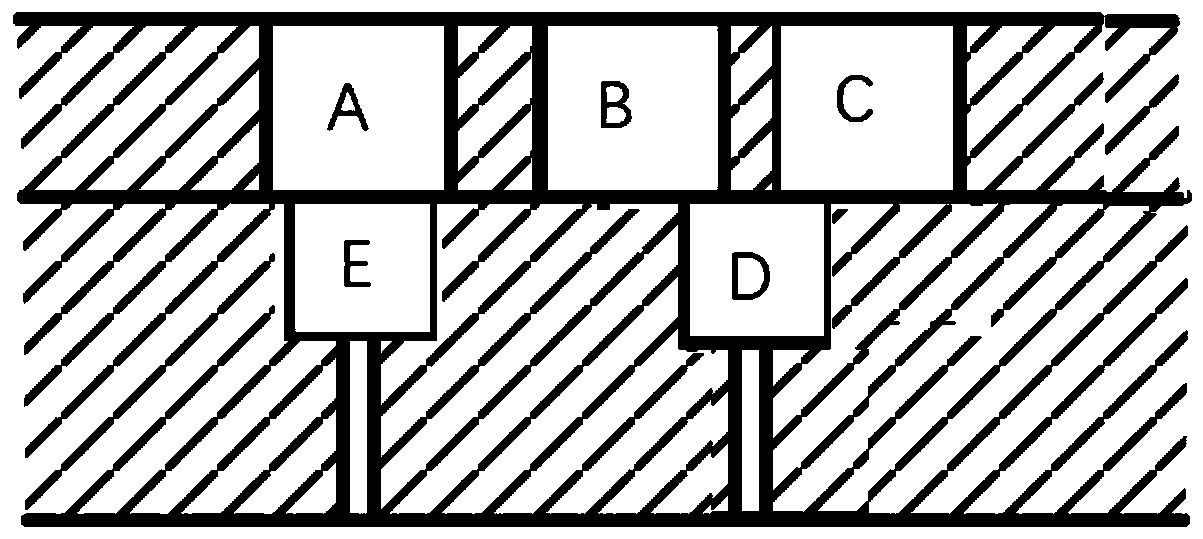

Image

Examples

Embodiment 1

[0044] The preparation method of sports knitted fabric, its process is as follows:

[0045] (1) Preparation of self-curling elastic fibers:

[0046] (1.1) Self-curling elastic fibers are extruded on the same spinneret, specifically:

[0047] Divide CDP melt (intrinsic viscosity 0.6dL / g) into two paths: one path is directly extruded after distribution; the other path is distributed with PTT melt (intrinsic viscosity 1.1dL / g) in parallel composite spinning squeeze out

[0048] The ratio between the number of spinneret holes m (four-lobed spinneret holes) that are directly extruded and flowed through and the number of spinneret holes n (circular spinneret holes) that are extruded and flowed through after distribution according to the parallel composite spinning method The ratio is 1:7; the mass ratio of the mass of the CDP melt passing through the spinneret n to the mass of the PTT melt is 50:50, and the ratio of the equivalent diameter of the spinneret m to the spinneret n is ...

Embodiment 2

[0061] The preparation method of sports knitted fabric, its process is as follows:

[0062] (1) Preparation of self-curling elastic fibers:

[0063] (1.1) Self-curling elastic fibers are extruded on the same spinneret, specifically:

[0064] Divide CDP melt (intrinsic viscosity 0.57dL / g) into two paths: one path is directly extruded after distribution; the other path is distributed with PTT melt (intrinsic viscosity 1.16dL / g) in parallel composite spinning squeeze out

[0065] The ratio between the number of spinneret holes m (four-lobed spinneret holes) that are directly extruded and flowed through and the number of spinneret holes n (circular spinneret holes) that are extruded and flowed through after distribution according to the parallel composite spinning method The ratio is 1:6; the mass ratio of the mass of the CDP melt passing through the spinneret n to the mass of the PTT melt is 50:50, and the ratio of the equivalent diameter of the spinneret m to the spinneret n i...

Embodiment 3

[0075] The preparation method of sports knitted fabric, its process is as follows:

[0076] (1) Preparation of self-curling elastic fibers:

[0077] (1.1) Self-curling elastic fibers are extruded on the same spinneret, specifically:

[0078] Divide the CDP melt (intrinsic viscosity 0.58dL / g) into two paths: one path is directly extruded after distribution; the other path is distributed with PTT melt (intrinsic viscosity 1.18dL / g) in parallel composite spinning squeeze out

[0079] The ratio between the number of spinneret holes m (four-lobed spinneret holes) that are directly extruded and flowed through and the number of spinneret holes n (circular spinneret holes) that are extruded and flowed through after distribution according to the parallel composite spinning method The ratio is 1:7; the mass ratio of the mass of the CDP melt passing through the spinneret n to the mass of the PTT melt is 50:50, and the ratio of the equivalent diameter of the spinneret m to the spinneret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com