Method for preparing fibre

A manufacturing method and fiber technology, applied in the field of fiber manufacturing, can solve the problems of short efficacy and insignificant fiber efficacy, and achieve the effects of lasting efficacy, no toxic side effects, and promoting dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

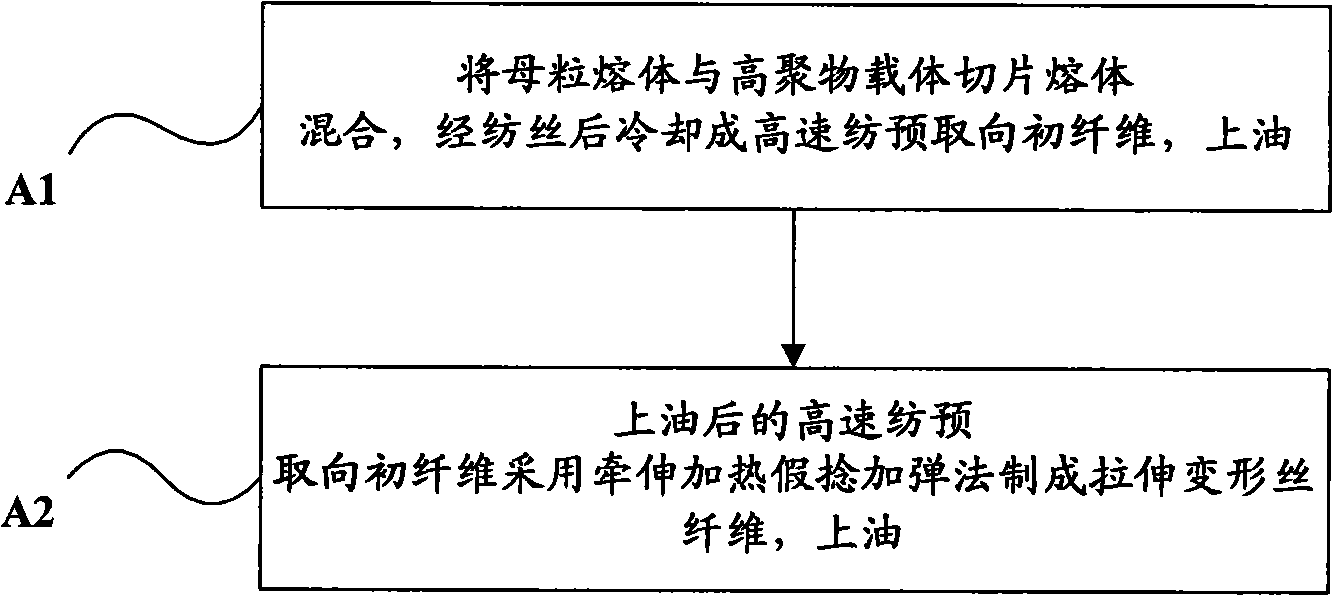

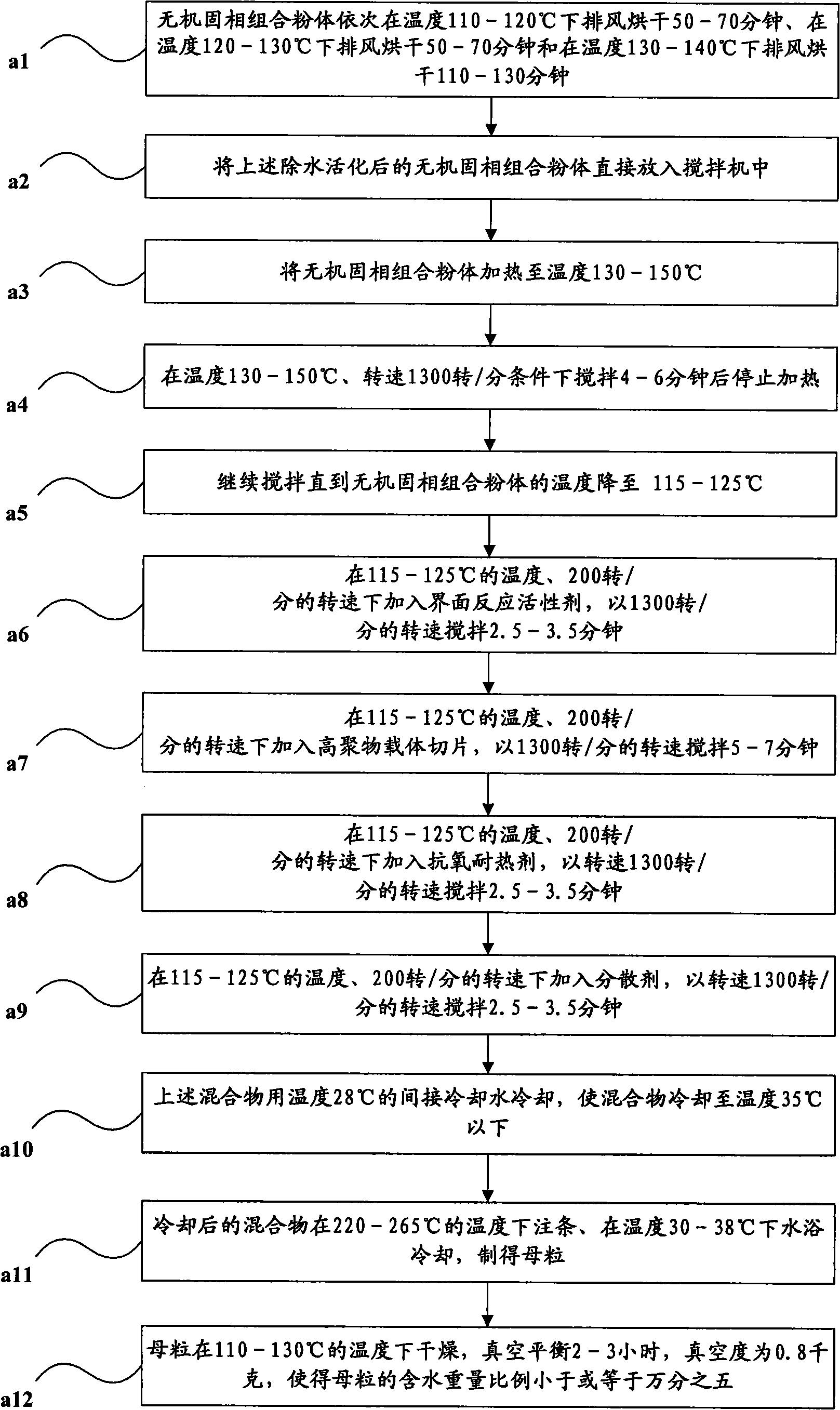

Method used

Image

Examples

no. 1 example

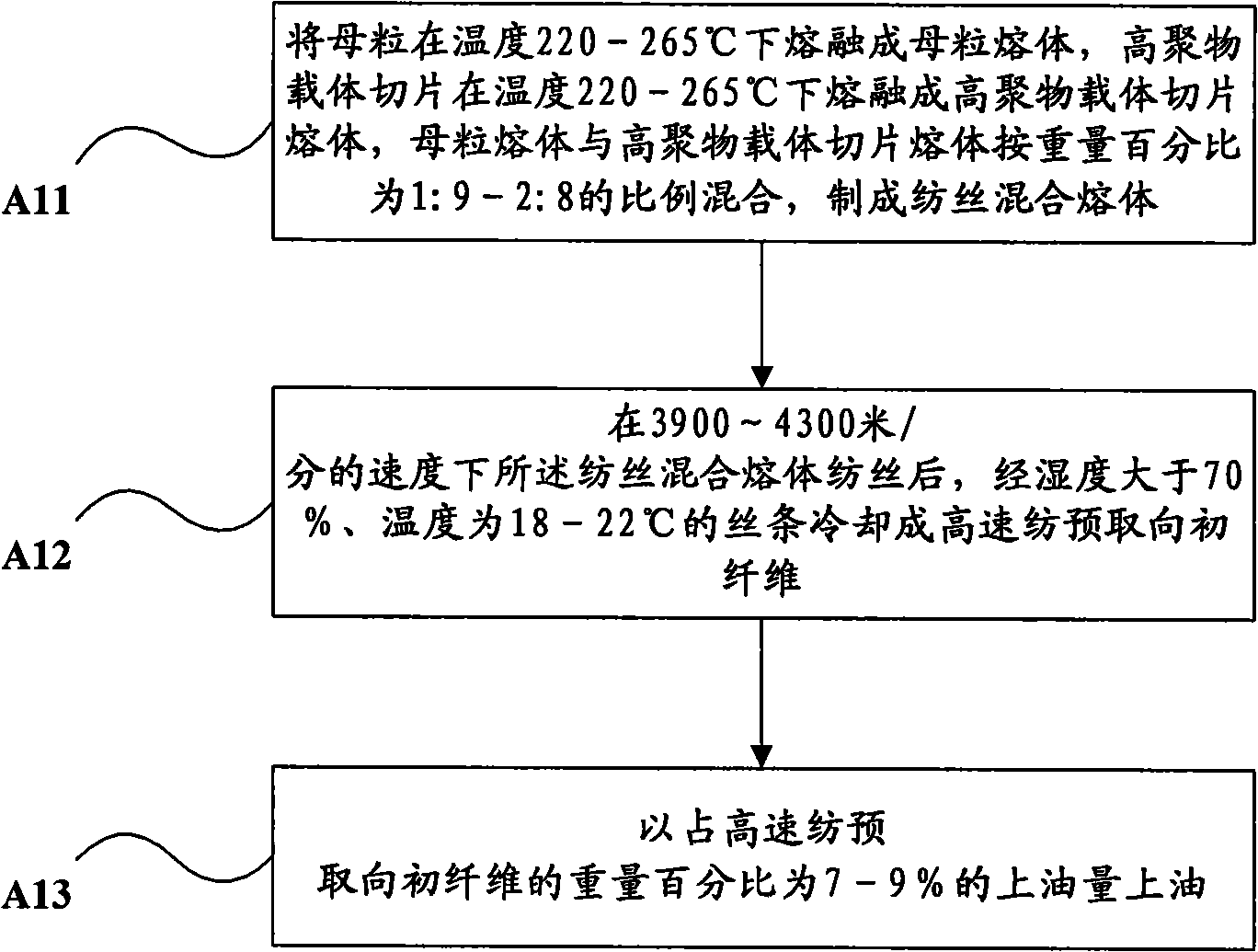

[0048] Step A101, adding the masterbatch into a small extruder, melting it into a masterbatch melt in the small extruder at a temperature of 240°C, and melting the high polymer carrier chip into a high polymer carrier chip melt at a temperature of 240°C , the masterbatch melt and the high polymer carrier chip melt are mixed in a ratio of 1:9 by weight to make a spinning mixed melt, and the spinning mixed melt in the twin-screw extruder passes through the insulation pipe from Zone 2 of the extruder enters the spinning extruder;

[0049] Step A102, after spinning mixed melt spinning at a speed of 4300 m / min, cooling the filaments with a humidity of 75% and a temperature of 20°C to form high-speed spinning pre-oriented primary fibers;

[0050] Step A103, oiling with an oiling amount of 8% of the weight percentage of the high-speed spinning pre-oriented primary fibers;

[0051] Step A104, drafting the high-speed spinning pre-oriented primary fiber after oiling, the drafting ratio...

no. 2 example

[0053] Step A201, adding the masterbatch into the small extruder, melting it into a masterbatch melt in the small extruder at a temperature of 220°C, and melting the high polymer carrier chip into a high polymer carrier chip melt at a temperature of 220°C , the masterbatch melt and the high polymer carrier chip melt are mixed in a ratio of 1.5:8.5 by weight to make a spinning mixed melt. Zone 3 of the extruder enters the spinning extruder;

[0054] Step A202, after spinning mixed melt spinning at a speed of 3900 m / min, cooling the strands with a humidity of 71% and a temperature of 18°C to form high-speed spinning pre-oriented primary fibers;

[0055] Step A203, oiling with an oiling amount of 7% of the weight percentage of the high-speed spinning pre-oriented primary fibers;

[0056] Step A204, drafting the high-speed spinning pre-oriented primary fiber after oiling, the drafting ratio is 1.5 times, and adopting the heating false twisting method to make stretched textured ...

no. 3 example

[0058] Step A301, adding the masterbatch into the small extruder, melting it into a masterbatch melt in the small extruder at a temperature of 265°C, and melting the high polymer carrier chip into a high polymer carrier chip melt at a temperature of 265°C , the masterbatch melt and the high polymer carrier chip melt are mixed in a ratio of 2:8 by weight to make a spinning mixed melt, and the spinning mixed melt in the twin-screw extruder passes through the insulation pipe from the spinning Zone 2 of the extruder enters the spinning extruder;

[0059] Step A302, after spinning mixed melt spinning at a speed of 4100 m / min, cooling the sliver with a humidity of 80% and a temperature of 22°C to form high-speed spinning pre-oriented primary fibers;

[0060] Step A303, oiling with an oiling amount of 9% of the weight percentage of the high-speed spinning pre-oriented primary fibers;

[0061] Step A304, drafting the high-speed spinning pre-oriented primary fiber after oiling, the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com