Nano ZrO2 composite polyester functional fiber, manufacturing method thereof and application

A technology for compounding polyester and functional fibers, applied in the direction of conjugated synthetic polymer rayon, rayon manufacturing, fiber chemical characteristics, etc., to achieve the effect of similar material structure and performance, improved conventional performance, and improved surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

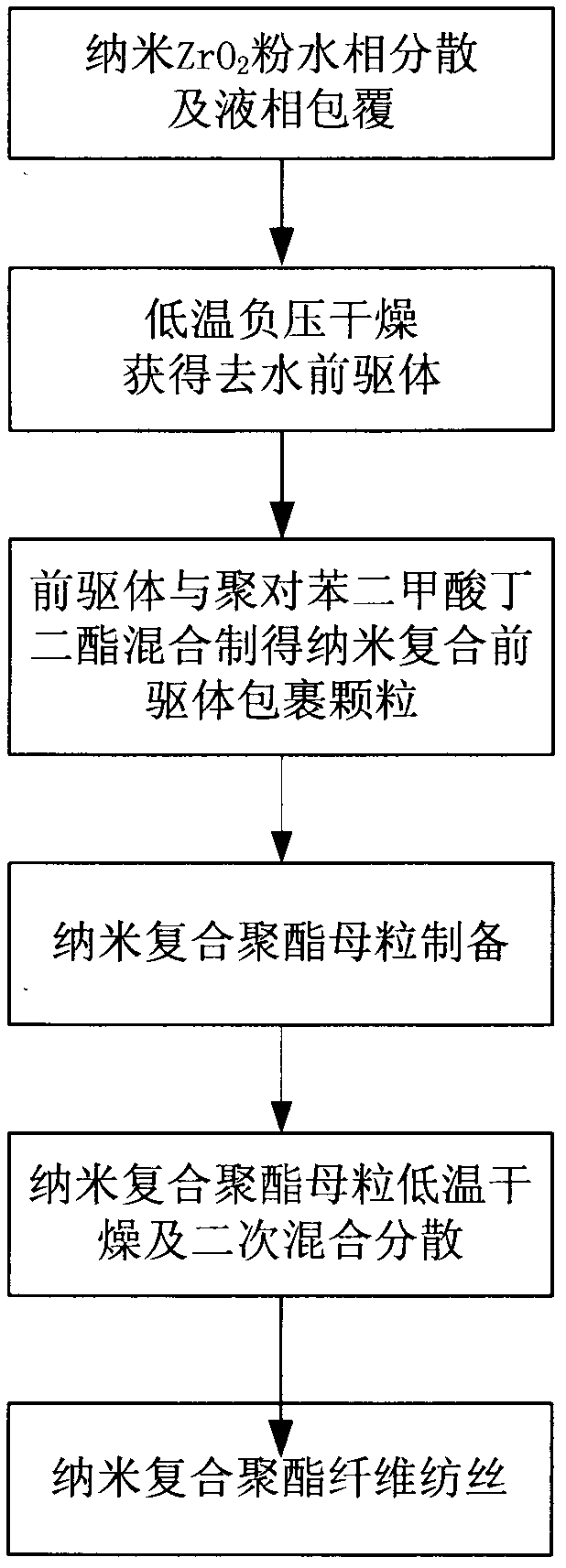

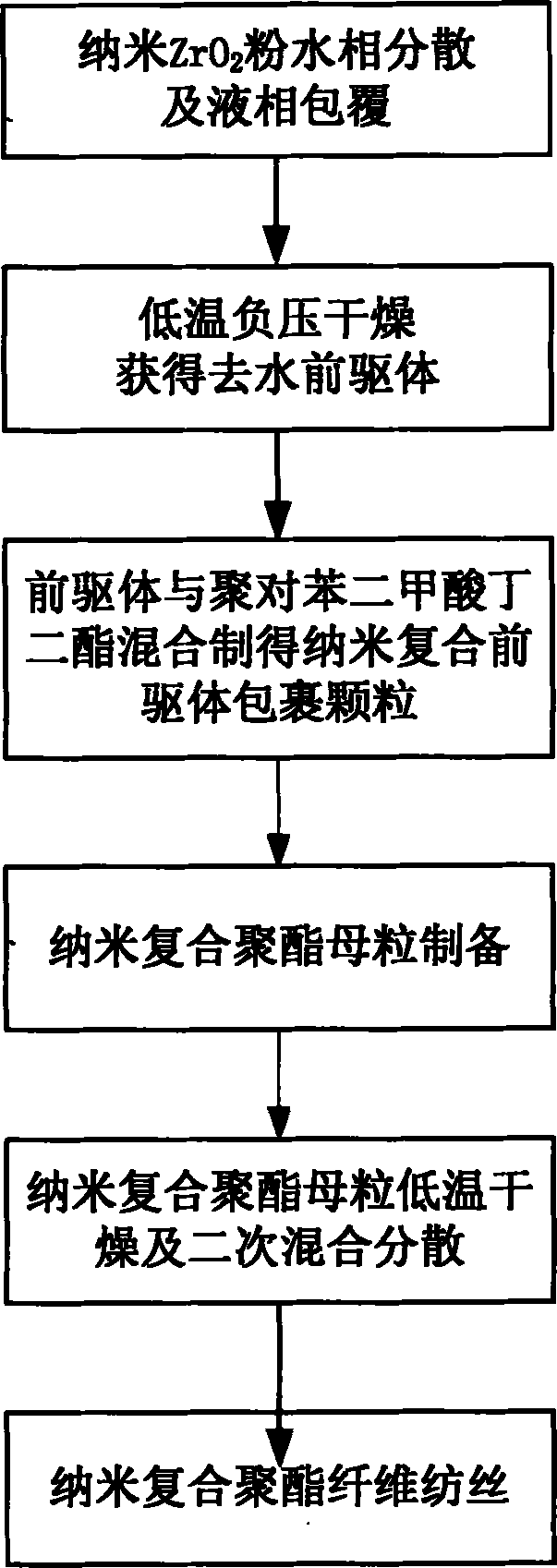

Method used

Image

Examples

Embodiment 1

[0042] Nano-ZrO 2 Composite polyester functional fiber, 3 parts by weight of nano ZrO 2 , 2 parts of polybutylene terephthalate, 95 parts of polyethylene terephthalate and a small amount of additives, among which nano-ZrO 2 The particle size of the powder is 10-50nm. First, weigh 3 parts of nano-ZrO 2 Powder, add potassium ethyl oleate sulfonate and water of 10wt% of powder weight, and ball mill for 24hr to obtain a water dispersion slurry with a concentration of 20wt%; add ethylene-acrylic acid copolymer and No. 120 solvent of 15wt% of powder weight in water The dosages of oil, mineral spirits and water are respectively nano ZrO 2 30wt% and 20 times of the powder weight, add the above slurry at 80-95°C and stir to form a water-oil two-phase mixed liquid phase system, then add 10wt% of the powder weight rosin amine, through a chemical reaction, the nanoparticles from the water The phase is separated and covered by the copolymer and enters the oil phase. The solvent oil is ...

Embodiment 2

[0044] Nano-ZrO 2 Composite polyester functional fiber, weight component formula 4 nanometer ZrO 2 , 10 parts of polybutylene terephthalate, 85 parts of polyethylene terephthalate and appropriate amount of additives, among which nano-ZrO 2 The particle size of the powder is 30-60nm. Weigh parts by weight of ZrO according to fiber composition requirements 2 4 parts of powder, add 12wt% sodium cocoa oleate ethyl sulfonate and water of nanopowder weight, stir 24hr to obtain the water dispersion slurry of 20wt%; Add respectively the ethylene-acrylic acid copolymer and the 10wt% powder weight in water No. 100 solvent oil, the amount of solvent oil and water are respectively 40wt% and 20 times of the powder weight, through the same reaction and coating treatment process as in Example 1, a dry and dehydrated organic coating precursor is made. The amount of rosinamine added is ZrO 2 12wt% of it, then mix it with 10 parts by weight of polybutylene terephthalate in a high-speed mixe...

Embodiment 3

[0046] Nano-ZrO 2 Composite polyester functional fiber, weight component formula 7 nanometer ZrO 2 , 20 parts of polybutylene terephthalate, 70 parts of polyethylene terephthalate and an appropriate amount of additives, of which nano-ZrO 2 The particle size of the powder is 50-100nm. Weigh parts by weight of ZrO according to fiber composition requirements 2 7 parts of powder, add 6wt% sodium cocoa oleate sulfonate and water of powder weight, respectively stir 48hr to obtain 40wt% nano water dispersion slurry; add 5wt% ethylene-acrylic acid copolymer of powder weight respectively in water and No. 120 solvent naphtha, the consumption of solvent naphtha and water are respectively 40wt% and 30 times of powder weight, through the same reaction and coating process as in Example 1, a dry and dehydrated organic coating precursor is made. The amount of rosinamine added in the process is ZrO 2 6wt% by weight, then mix it with 20 parts of polybutylene terephthalate in a high-speed mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com