Dispersing agent for polyolefin catalyst

A technology of dispersant and catalyst is applied in the field of dispersant of polyolefin catalyst to achieve the effect of non-volatile, favorable for smooth operation of polymerization and clean working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The dispersant of olefin polymerization catalyst in the present embodiment is made of following components:

[0051] (1) The mass percentage of PAO10 is 95%;

[0052] (2) The mass percentage of PB400 is 5%.

[0053] Solvent properties: kinematic viscosity (40°C): 69.2mm 2 / s; pour point: -51℃; water content <30μg / g, non-volatile matter <0.001g / 100mL, benzene content <50μg / g, sulfur content <100μg / g.

[0054] After testing, 1.68% of hexane leachables in polypropylene products.

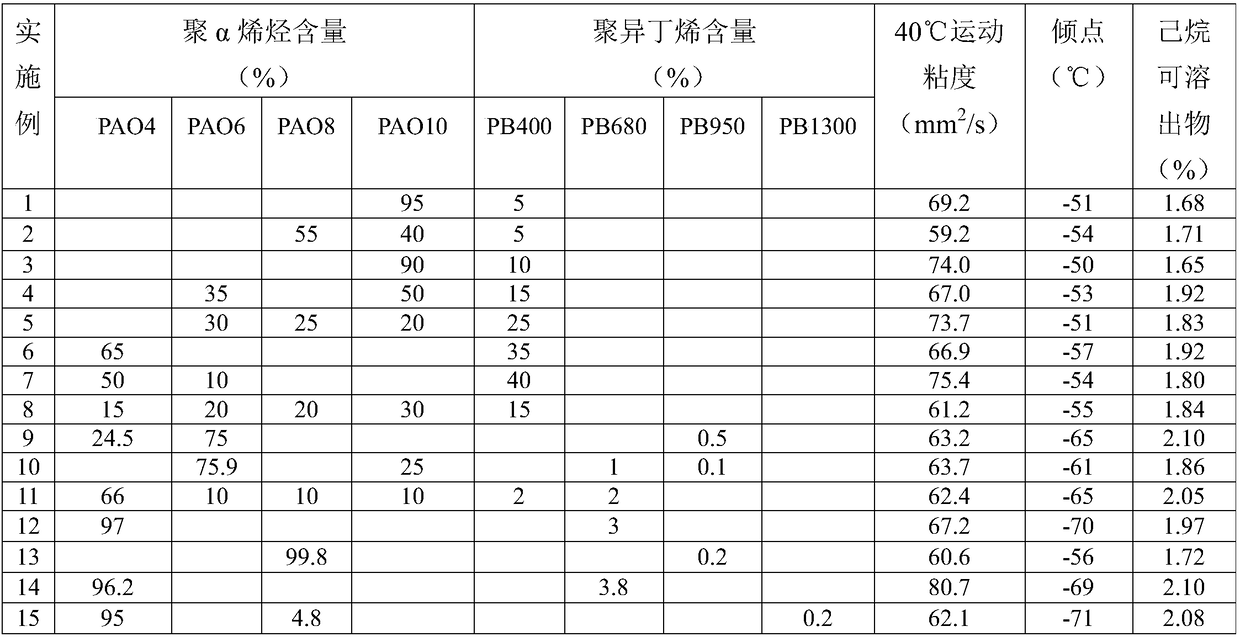

Embodiment 2~15

[0056] Please refer to Table 1 for the components of the dispersant of the olefin polymerization catalyst in Examples 2-15 and their respective contents, solvent properties, and contents of hexane leached matter in polypropylene products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com