High-performance modified asphalt and preparation method thereof

A modified asphalt, high-performance technology, applied in the direction of building components, building insulation materials, construction, etc., can solve problems such as difficult to meet, and achieve the effect of improved performance, uniform dispersion, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

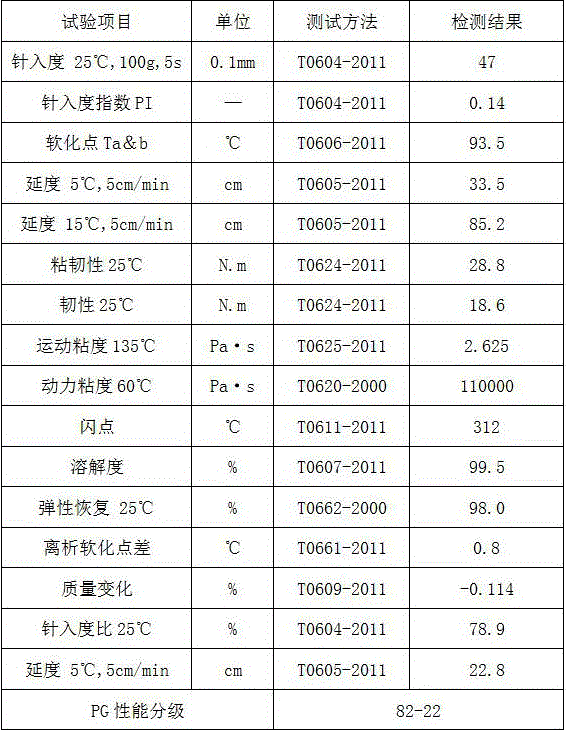

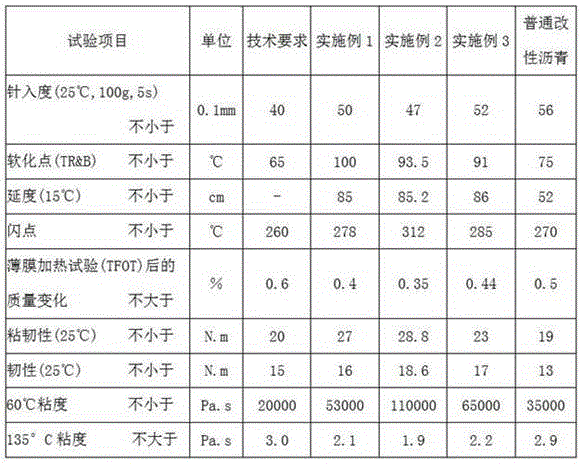

Embodiment 1

[0019] A high-performance modified asphalt whose component ratio is as follows: it consists of the following raw materials in parts by weight: 82 parts of asphalt, 3.5 parts of styrene-butadiene-styrene copolymer (SBS), 3.5 parts of vinyl bis stearate Amide (EBS) 1.8 parts, vulcanizing agent 0.6 parts, antioxidant 1.2 parts, methyl ethyl ketone 3 parts, antioxidant 2.4 parts, methyl phenol phenolic resin 1.7 parts, epoxy vegetable oil 0.7 parts, propionic acid 2.8 parts , 1.5 parts of nickel acetylacetonate, 1.2 parts of dibutyl ester; 2.7 parts of pentaerythritol stearate.

[0020] A kind of preparation method of high-performance modified asphalt, it comprises the following steps:

[0021] (1) Select the above-mentioned raw materials and their parts by weight for subsequent use;

[0022] (2) Put the base asphalt into an asphalt tank with a stirring device and heat it to 175°C, turn on the stirring device and add 1.8 parts of EBS;

[0023] (3) Add 2.7 parts of SBS and pentae...

Embodiment 2

[0029] A high-performance modified asphalt whose component ratio is as follows: it is composed of the following raw materials in parts by weight: 70 parts of asphalt, 3 parts of styrene-butadiene-styrene copolymer (SBS), 3 parts of vinyl bis stearate 0.01 part of amide (EBS), 0.2 part of vulcanizing agent, 0.1 part of antioxidant, 2 parts of methyl ethyl ketone, 2 parts of antiaging agent, 1.2 parts of methyl phenolic phenolic resin, 0.5 part of epoxy vegetable oil, 3.2 parts of acetic acid , 1 part of nickel acetylacetonate, 1 part of dibutyl ester; 1.5 parts of pentaerythritol stearate.

[0030] A kind of preparation method of high-performance modified asphalt, it comprises the following steps:

[0031] (1) Select the above-mentioned raw materials and their parts by weight for subsequent use;

[0032] (2) Put the base asphalt into an asphalt tank with a stirring device and heat it to 165°C, turn on the stirring device and add 0.01 part of EBS;

[0033] (3) Add 1.5 parts of...

Embodiment 3

[0039] A high-performance modified asphalt whose component ratio is as follows: it is composed of the following raw materials in parts by weight: 100 parts of asphalt, 7 parts of styrene-butadiene-styrene copolymer (SBS), 7 parts of vinyl bis stearate 2 parts of amide (EBS), 1 part of vulcanizing agent, 1.5 parts of antioxidant, 4 parts of methyl ethyl ketone, 3 parts of anti-aging agent, 2.5 parts of methyl phenol phenolic resin, 1 part of epoxy vegetable oil, 4 parts of acetic acid , 3 parts of nickel acetylacetonate, 3 parts of dibutyl ester; 3 parts of pentaerythritol stearate.

[0040] A kind of preparation method of high-performance modified asphalt, it comprises the following steps:

[0041] (1) Select the above-mentioned raw materials and their parts by weight for subsequent use;

[0042] (2) Put the base asphalt into an asphalt tank with a stirring device and heat it to 180°C, turn on the stirring device and add 2 parts of EBS;

[0043] (3) Add 3 parts of SBS and pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com