Patents

Literature

32results about How to "Salt spray resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

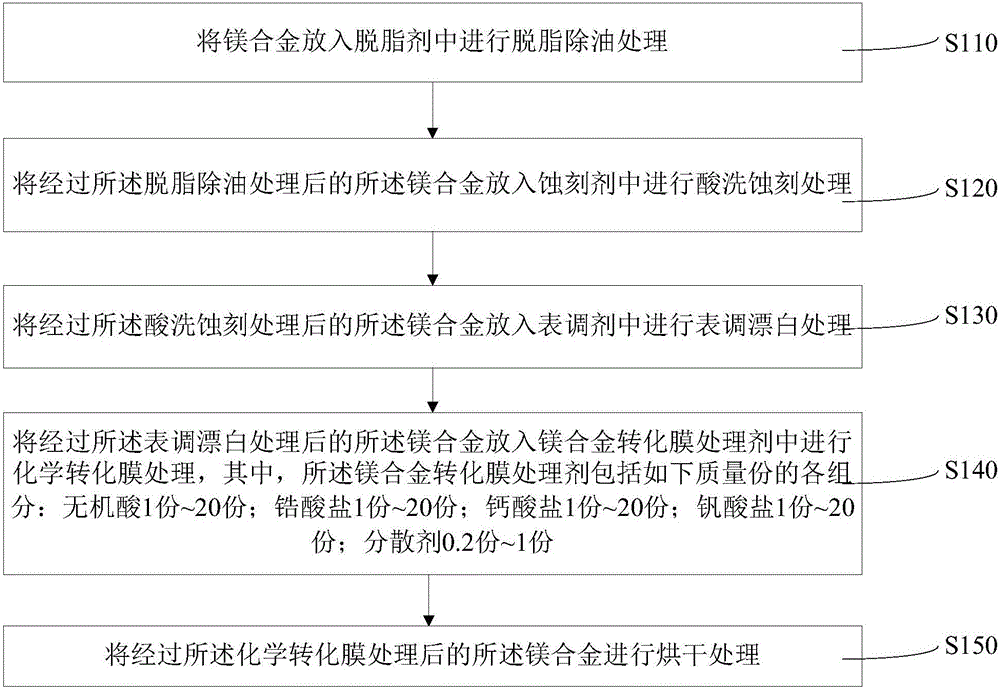

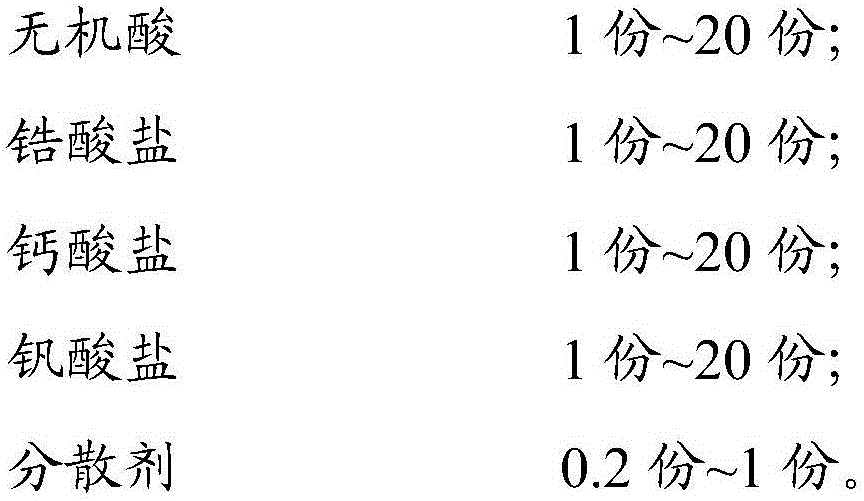

Magnesium alloy Zr-Ga-V conversion film treating agent and magnesium alloy Zr-Ga-V conversion film treating method

InactiveCN105951076AImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeZirconate

The invention relates to a magnesium alloy conversion film treating agent and a magnesium alloy conversion film treating method. The magnesium alloy conversion film treating agent comprises, by mass, 1-20 parts of inorganic acid, 1-20 parts of zirconate, 1-20 parts of calciate, 1-20 parts of vanadate and 0.2-1 part of a dispersing agent. Compared with a traditional phosphorus-containing chromium-free magnesium alloy conversion film treating agent which causes environmental pollution, the magnesium alloy conversion film treating agent adopts 1-20 parts of the inorganic acid, 1-20 parts of the zirconate, 1-20 parts of the calciate, 1-20 parts of the vanadate and 0.2-1 part of the dispersing agent, and thus a phosphorus-free chromium-free Zr-Ga-V conversion film can be formed on the surface of magnesium alloy; and the conversion film has the advantages of being good in adhesive force, high in corrosion resistance degree and good in salt fog resistance and film forming uniformity. The magnesium alloy conversion film treating agent is particularly suitable for a treatment process of a chemical conversion film of die casting magnesium alloy, such as AZ91D magnesium alloy.

Owner:广东东明新材科技有限公司

Water-based epoxy paint and preparation method thereof

InactiveCN104910759AIncrease crosslink densityImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention provides a water-based epoxy paint and a preparation method thereof. The paint comprises an amino resin, a leveling agent, distilled water, a water-based epoxy acrylic resin, a dispersing agent, a defoaming agent, iron oxide black, superfine talcum powder, precipitated baryte, zinc phosphate, a rust inhibitor and the like; and a nano MoS2 anti-wear agent and a nano CaCO3 ultraviolet absorbent are further added to enhance the properties. By reasonably designing the component types and contents, the thickness of the paint film can reach 100 mu m above, the water resistance is greater than 240 hours, the transmittivity for ultraviolet light with the wavelength of 290-400nm is less than 0.4, the wear-resistant revolution number is up to 1000-1400, the mass loss of the paint film is less than 0.07 g / 100r, and the salt spray resistance is greater than 200 hours. The paint can be brushed on the internal and external walls of an iron building, has excellent protective effect, and is especially suitable for protecting iron building cultural relics.

Owner:JIANGSU UNIV OF TECH

Auto-primer

InactiveCN102408815ALow temperature curingSalt spray resistantEpoxy resin coatingsZinc phosphateBarium sulfate

The invention provides an auto-primer comprising the following components: E-20 epoxy resin, magnetic ferric oxide, barium sulfate, talc powder, zinc phosphate, cyclohexanone and white carbon black. The auto-primer provided in the invention is prepared from the epoxy resin having excellent corrosion resistance and the magnetic ferric oxide pigment as major components and other auxiliaries added thereto, and has the characteristics of low temperature setting, quick drying, oil resistance, chemical corrosion resistance, salt mist resistance, non-toxicity and the like; besides, the auto-primer can be matched with other automobile coatings in use; therefore, the auto-primer is appropriate and cheap.

Owner:陈瑜

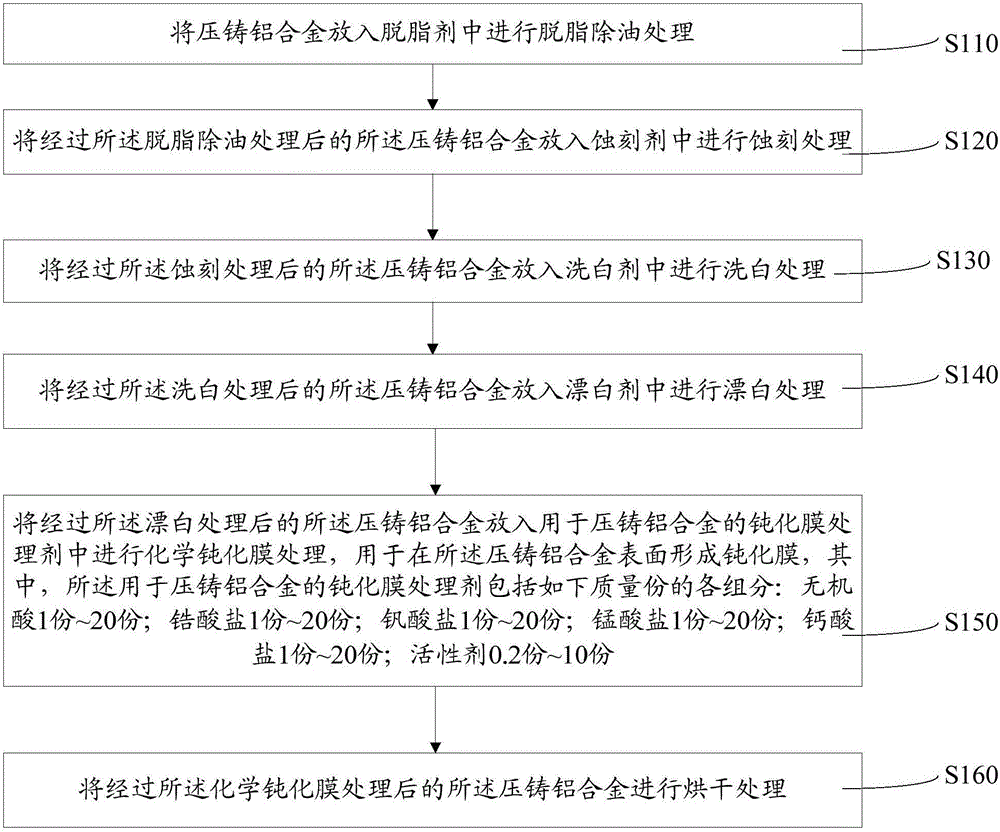

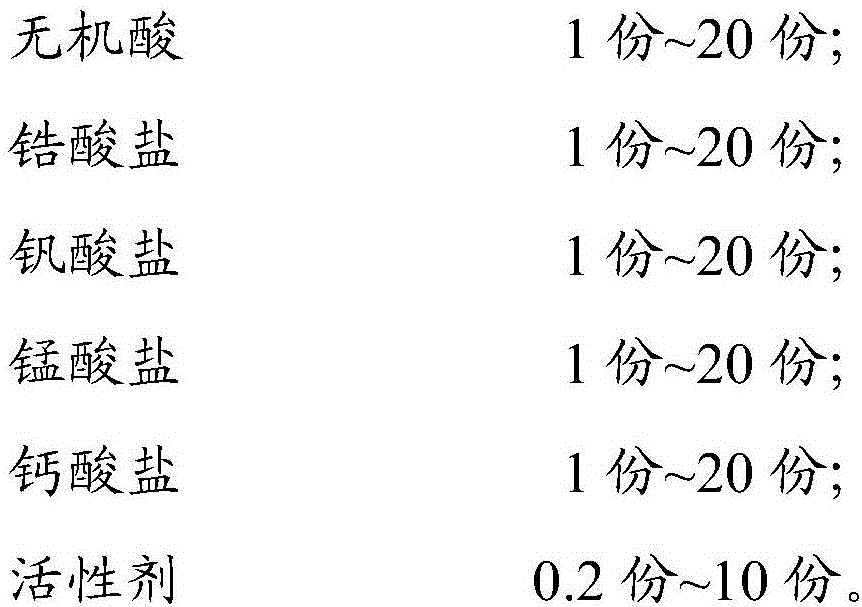

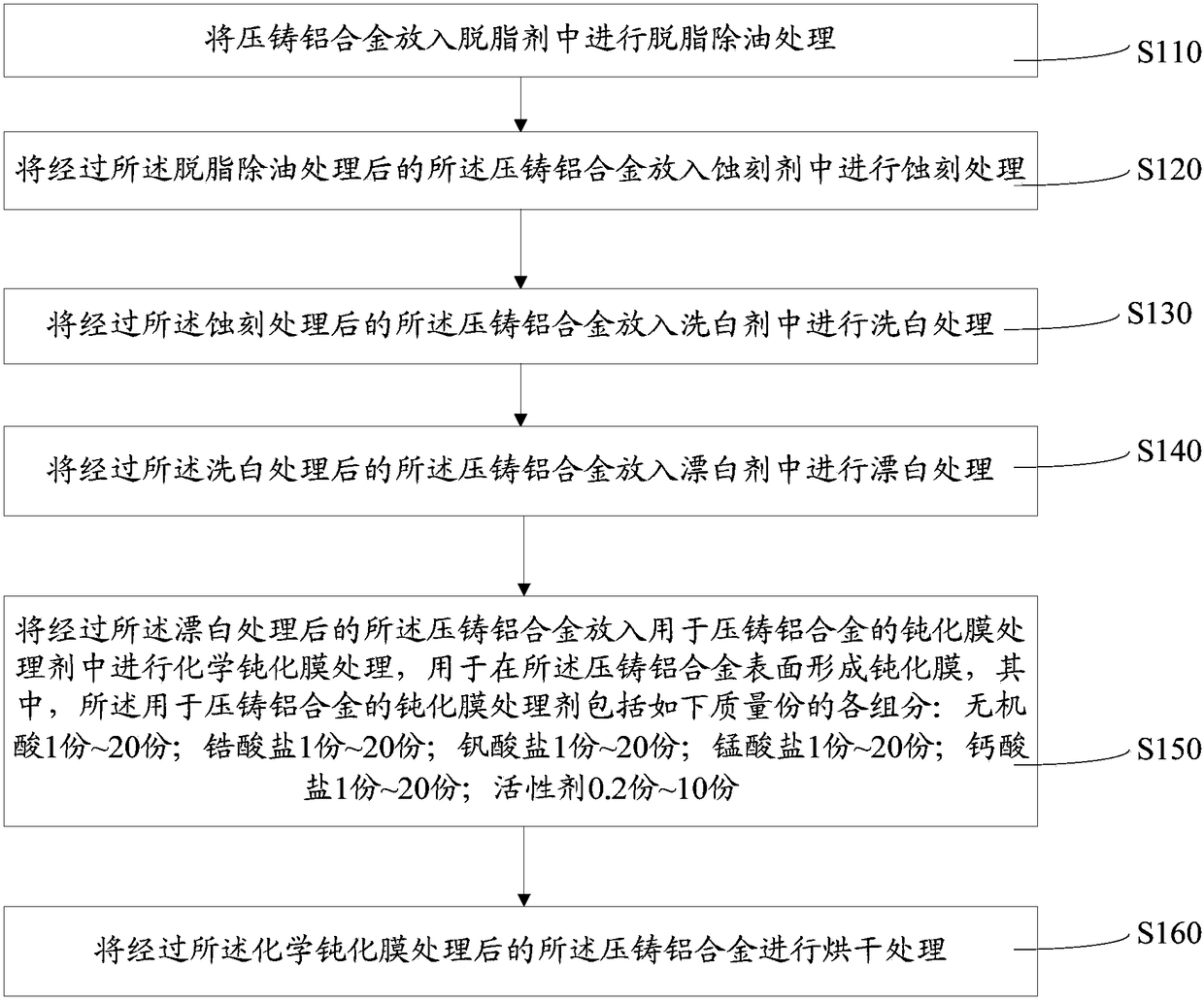

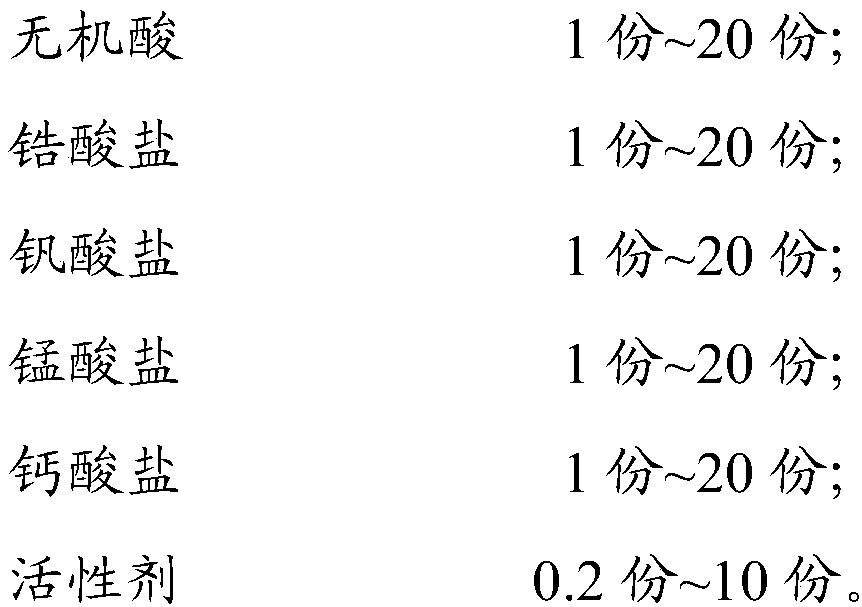

Zirconium-manganese-vanadium passive film treating agent for die cast aluminium alloy and treatment method thereof

ActiveCN106048580AGood adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeZirconate

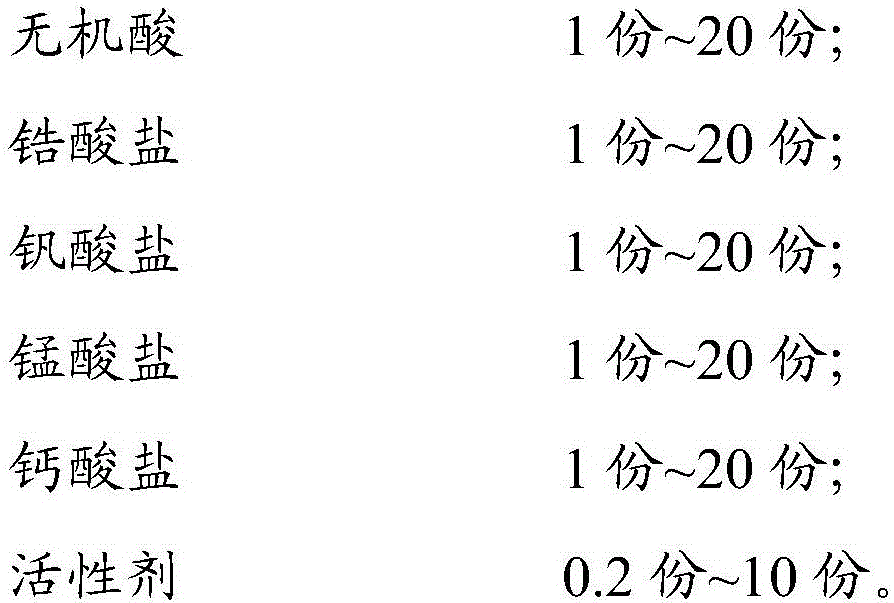

The invention discloses a passive film treating agent for die cast aluminium alloy and a treatment method thereof. The passive film treating agent for die cast aluminium alloy comprises the following components in parts by mass: 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of vanadate, 1 to 20 parts of manganate, 1 to 20 parts of calciate and 0.2 to 10 parts of an activating agent. Relative to a traditional phosphorus-containing chromium-free passive film treating agent for die cast aluminium alloy, which causes pollution to the environment, the passive film treating agent for die cast aluminium alloy can form a phosphorus-free chromium-free Zr-Mn-V passive film on the surface of die cast aluminium alloy, the passive film has the advantages that the adhesive force is good, the corrosion resistance is high, and the salt mist resistance and film forming uniformity are good, and besides, the obtained passive film can be guaranteed to have a silver white metal appearance the same as the die cast aluminium alloy.

Owner:广东东明新材科技有限公司

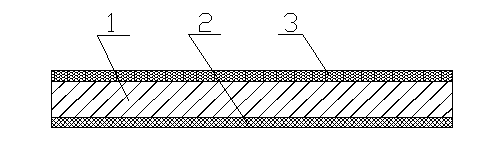

Film coated metal plate with high corrosion resistance, and manufacturing process thereof

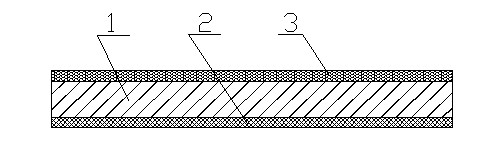

InactiveCN109263204ACorrosion resistanceImpact resistantRoof covering using slabs/sheetsConstruction materialSurface layerHigh volume manufacturing

The invention discloses a film coated metal plate with high corrosion resistance, and a manufacturing process thereof. The film coated metal plate comprises a first corrosion-resistant film layer, a first adhesive layer, a base plate layer, a second adhesive layer and a second corrosion-resistant film layer, wherein the first corrosion-resistant film layer, the first adhesive layer, the base platelayer, the second adhesive layer and the second corrosion-resistant film layer are sequentially arranged from top to bottom, the first corrosion-resistant film layer and the second corrosion-resistant film layer respectively comprise a surface layer, a function layer and an adhesion layer, and the surface layer, the function layer and the adhesion layer are sequentially arranged from top to bottom. The manufacturing process comprises: (1) unwinding; (2) adhesive adding; (3) drying; (4) compounding; and (5) winding. According to the present invention, the film coated metal plate has advantagesof impact resistance, hot water resistance, salt spray resistance, wear resistance, stain resistance, corrosion resistance, light aging resistance, acid resistance, alkali resistance, oil resistance,good flexibility and corrosion resistance, such that the film coated metal plate has long service life; and the process method is simple, and is suitable for mass production.

Owner:ZHEJIANG GREEN NEW MATERIALS

Phosphate/polyurethane modified waterborne alkyd anticorrosive coating

ActiveCN108276864AAffect water resistanceAffect transparencyAnti-corrosive paintsVegetable oilPhosphate

The invention relates to a phosphate / polyurethane modified waterborne alkyd anticorrosive coating. The coating is composed of phosphate / polyurethane modified waterborne alkyd resin, a cosolvent, a filler, an antirust pigment, an auxiliary agent and deionized water, wherein the phosphate / polyurethane modified waterborne alkyd resin is prepared by performing a reaction on vegetable oil fatty acid, isophthalic acid, an organic acid anhydride, a diol, a branched-chain polyol, dimethylolpropionic acid, alkyl acrylate phosphate, polyisocyanate and a neutralizer. The phosphate / polyurethane modified waterborne alkyd anticorrosive coating provided by the invention has a phosphate group and a metal substrate, forms a compact phosphating film, thereby improving water resistance and rust resistance ofa coating film; and the coating is combined with the characteristics of polyurethane chemical resistance, aging resistance, flexibility and wear resistance, and the prepared phosphate / polyurethane modified waterborne alkyd anticorrosive coating has excellent adhesion, water resistance, flash rust resistance, chemical resistance, aging resistance, corrosion resistance and salt spray resistance.

Owner:ZHUHAI JELEE CHEM ENTERPRISE CO LTD

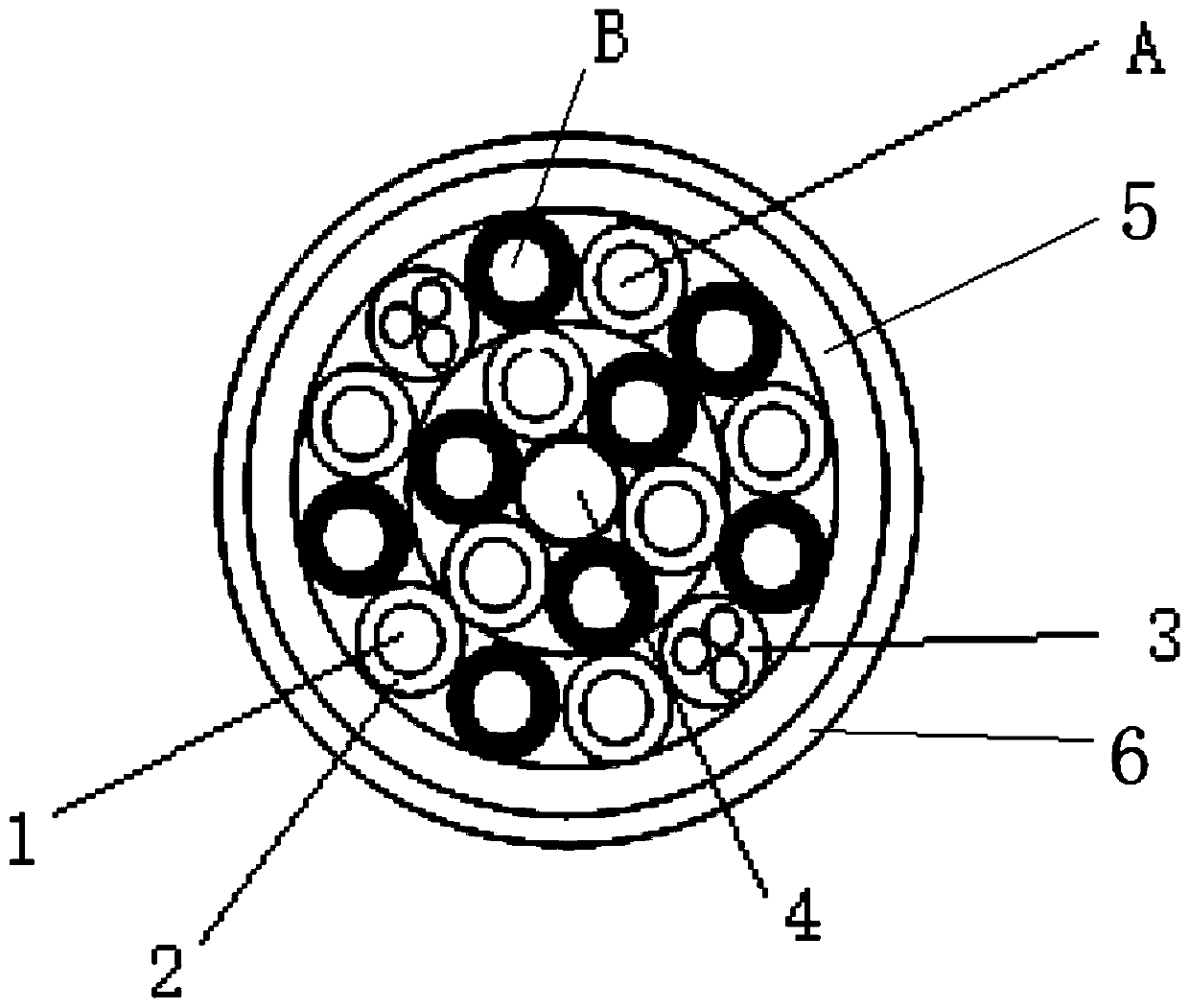

Optical fiber composite shore power cable

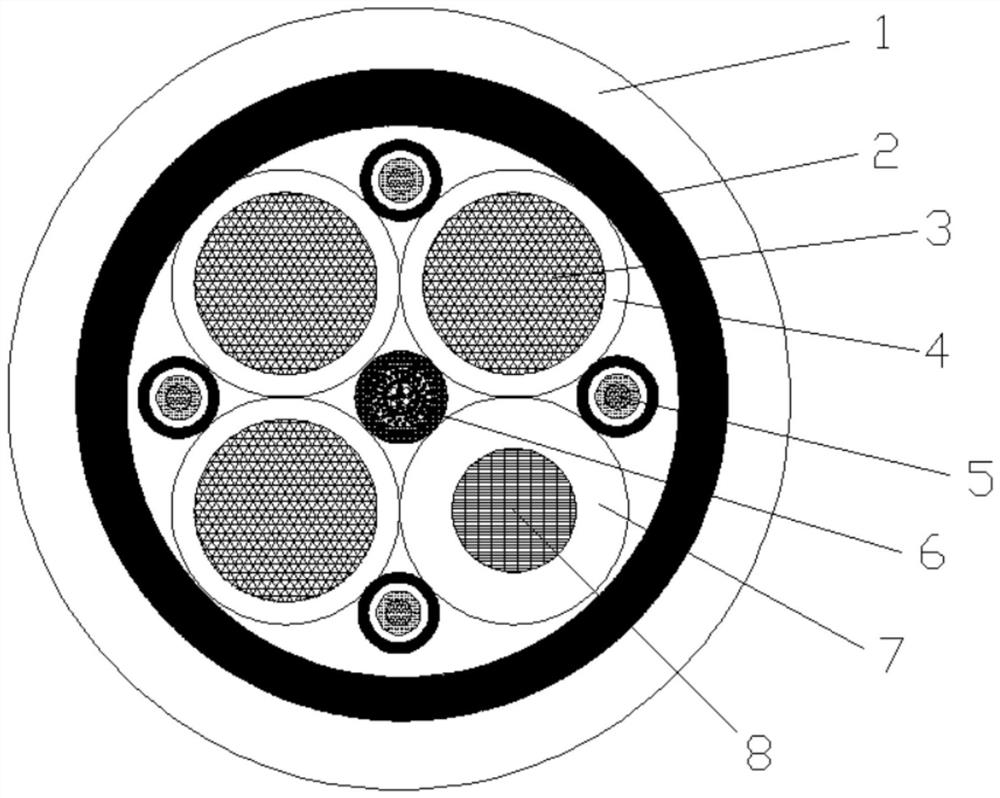

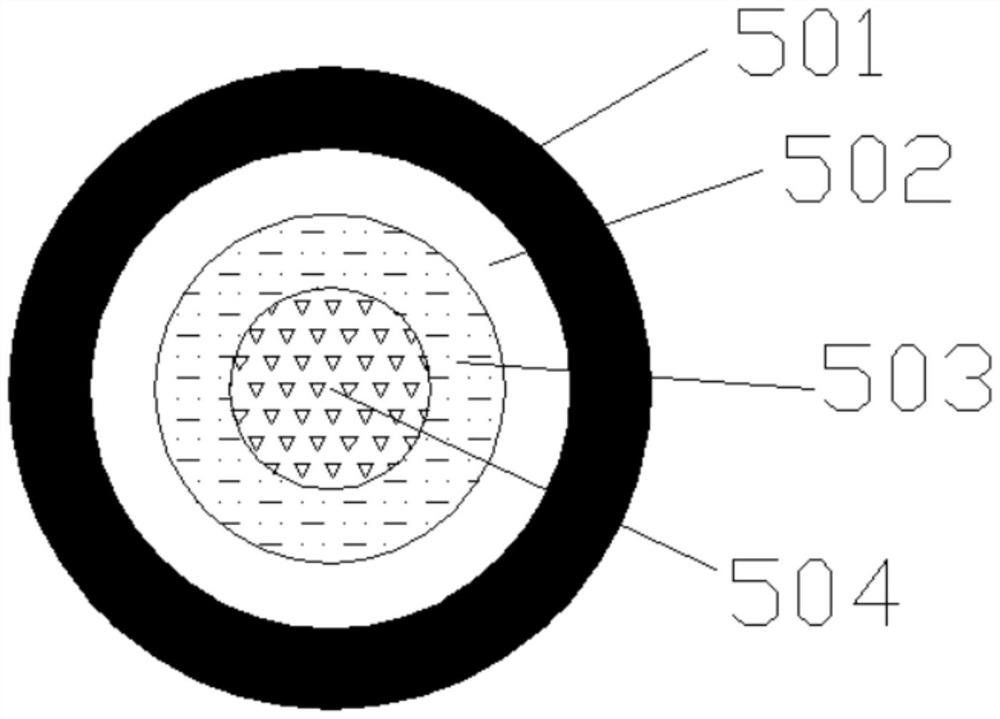

InactiveCN113571242AImprove transmission performanceGuaranteed transmission performancePower cables including communication wiresCommunication cablesPower cableEngineering

The invention relates to the technical field of power cables, in particular to an optical fiber composite shore power cable which is composed of an outer sheath layer, a reinforcing layer, a plurality of power line units, a ground wire unit, a plurality of signal line units and an optical fiber unit. The reinforcing layer is located at the inner side of the outer sheath layer, the power line units, the ground wire unit, the signal line units and the optical fiber unit are jointly coated with the reinforcing layer and the outer sheath layer, and through testing, the prepared optical fiber composite shore power cable manufactured of the present invention is subjected to dynamic bending testing under the bending radius of four times of the outer diameter of the cable, and the core of the bare optical fiber is not broken when the number of times of bending exceeds 50,000.

Owner:湖南华菱线缆股份有限公司

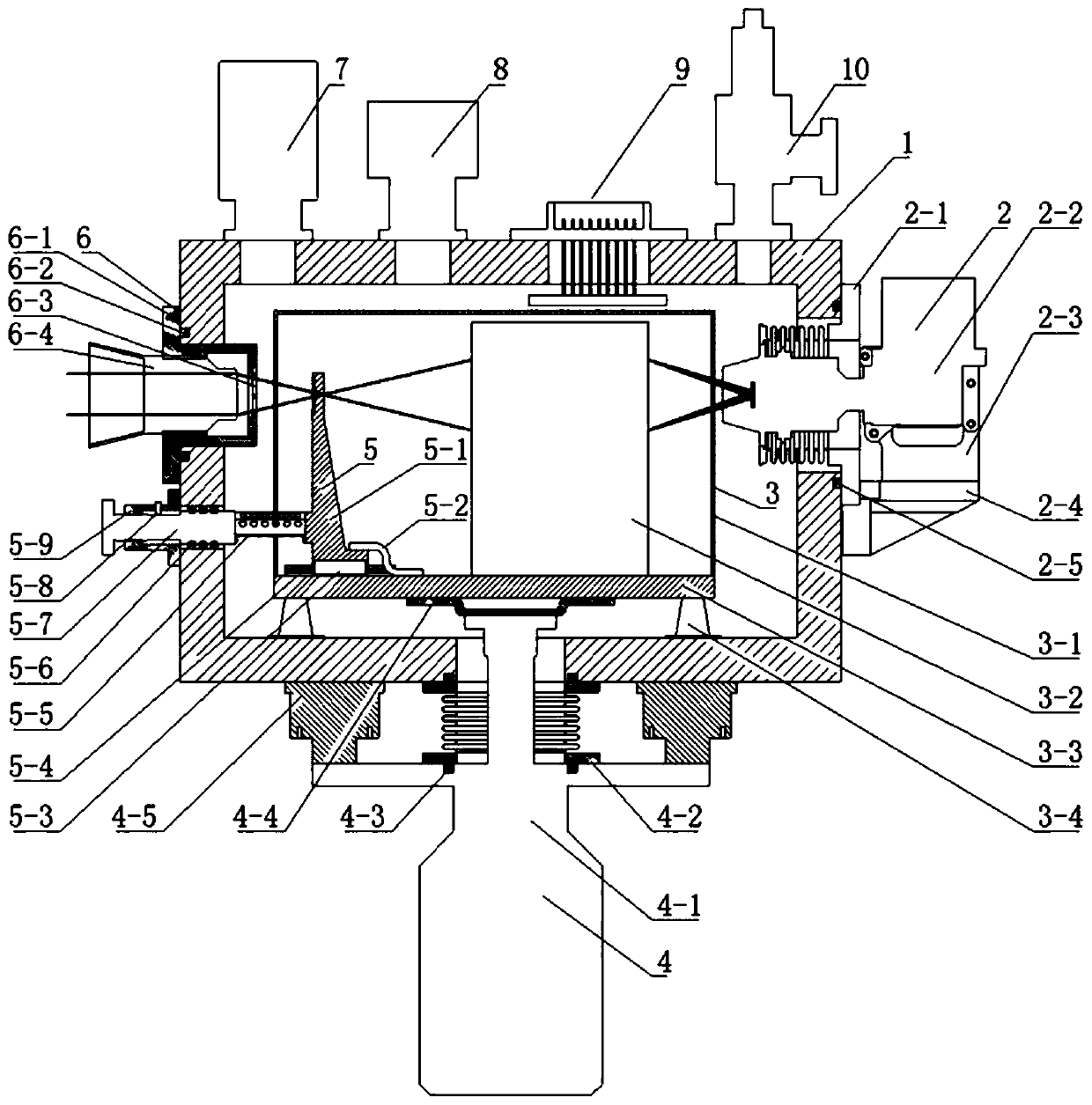

Anti-reflection film coating liquid preparation method

InactiveCN108676393APrevent oxidationEasy to cleanAntifouling/underwater paintsPaints with biocidesVanadium dioxidePolymer science

The invention discloses an anti-reflection film coating liquid preparation method and belongs to the technical field of film coating liquid preparation. A tea seed extracting solution of the preparation method disclosed by the invention contains rich oxidized antibacterial substances; permanent electrostatic fields exist at the peripheries of added tourmaline particles, so that metal is preventedfrom being oxidized, electrons are prevented from being taken away, and the metal is prevented from being corroded; thus, the film coating liquid has certain salt spray resistance. The tea seed extracting solution in the preparation method disclosed by the invention is subjected to oxidizing treatment, so that the surface of the tea seed extracting solution carries many hydrophilic groups. Tea saponin in the tea seed extracting solution of the preparation method disclosed by the invention is a main green natural non-ionic surface active agent and is also called as theasaponin, oil and water can be separated on the surface of a film coating matrix, and a good cleaning effect on a film layer is generated. By means of the film coating liquid disclosed by the invention, a titanium dioxide / vanadium dioxide composite membrane layer can be formed; a vanadium dioxide crystal layer can obstruct high-energy infrared light, and titanium dioxide can improve transmittance of a film layer to visiblelight; thus, light transmittance characteristic is enhanced, the film layer has a temperature adjusting capacity when applied to glass, and the film layer has a wide application prospect.

Owner:陈建峰

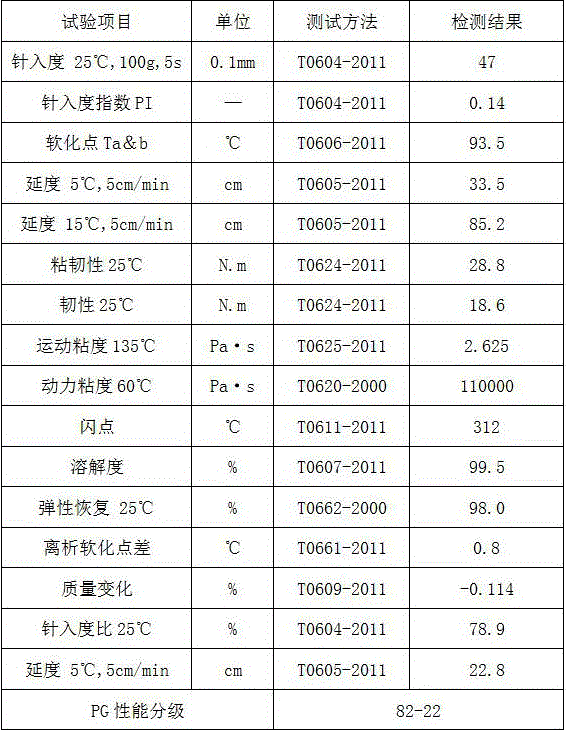

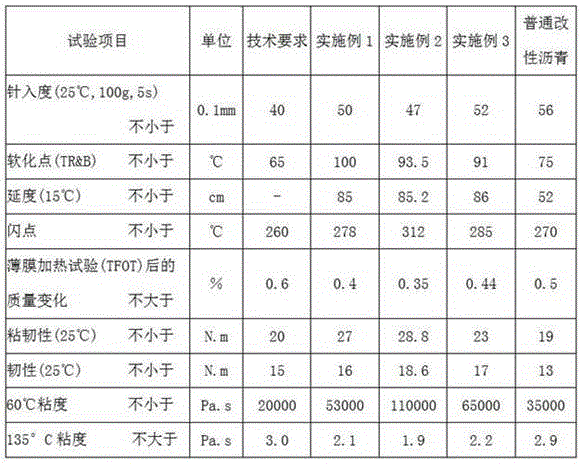

High-performance modified asphalt and preparation method thereof

The invention provides high-performance modified asphalt, consisting of the following raw materials in parts by weight: 70-100 parts of asphalt, 3-7 parts of a styrene-butadiene-styrene copolymer (SBS), 0.01-2 parts of ethylene bis-stearamide (EBS), 0.1-1 part of a vulcanizing agent, 0.1-1.5 parts of an antioxidant, 2-4 parts of methyl ethyl ketone, 2-3 parts of an anti-aging agent, 1-2.5 parts of methyl phenol type phenolic resin, 0.5-1 part of epoxidized vegetable oil, 2-4 parts of propyl acetic acid, 1-3 parts of nickel acetylacetonate, 1-3 parts of dibutyl ester, and 1-3 parts of pentaerythritol tetrastearate. The high-performance modified asphalt provided by the invention has excellent high-temperature stability, salt fog resistance and ageing resistance, and the high-temperature viscosity of the modified asphalt can be reduced; and the modified asphalt meets a high-viscosity modification index requirement, and can be applied to special occasions including OGFC (Open Graded Friction Course) drainage asphalt pavements, heavy-loaded traffic road asphalt pavements and the like.

Owner:漳州新立基沥青有限公司

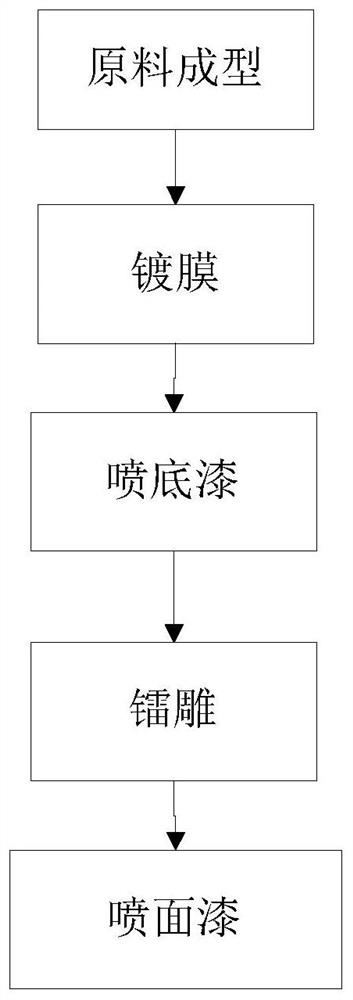

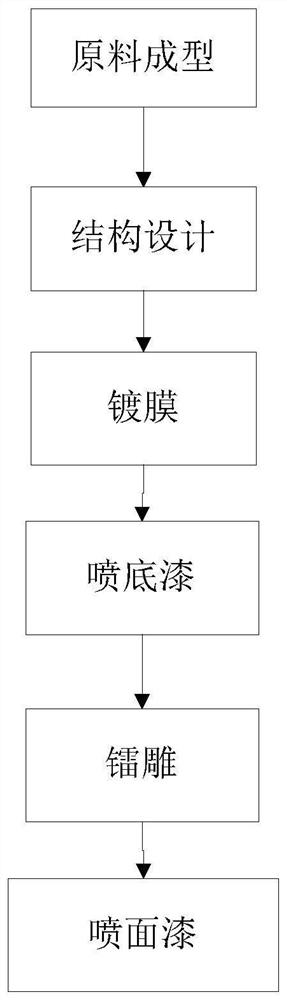

Crystal ball head manufacturing method and crystal ball head

PendingCN113232448ASalt spray resistantWith high and low temperatureVacuum evaporation coatingSpecial ornamental structuresAdhesiveMonochromatic color

The invention discloses a crystal ball head manufacturing method. The crystal ball head manufacturing method comprises the following steps of forming a raw material, specifically, manufacturing a crystal raw material into a required shape; carrying out coating, specifically, shielding the front face of the ball head, carrying out vacuum coating on the back face of the ball head, adopting a sputtering coating technology adopted, wherein the film thickness is 90-110 nm; spraying primer, specifically, spraying paint on the back face of the ball head, wherein the paint thickness is 10-20 microns; engraving a mark, specifically, engraving the mark on the ball head; and carrying out finish paint spraying, specifically, carrying out paint spraying on the back face of the ball head again, wherein the paint thickness is 10-20 microns. According to the crystal ball head manufacturing method, combined treatment of the vacuum coating and paint spraying technology is carried out on the back face of the ball head, so that the crystal ball head presents a gradual change or monochromatic mirror face effect, and the crystal ball head has the performance of salt mist resistance, high and low temperature resistance, good paint film adhesive force and the like.

Owner:GAC COMPONENT CO LTD

Low-temperature optical mechanical system based on SiC particle reinforced aluminum matrix composite vacuum cooling box

InactiveCN110470392ACorrosion resistanceReduce weightRadiation pyrometrySpectrum investigationCold chainEngineering

The invention discloses a low-temperature optical mechanical system based on a SiC particle reinforced aluminum matrix composite vacuum cooling box. The cooling box is made of light high-modulus SiC particle reinforced aluminum matrix composite. A detector is connected with a corrugated pipe flange to realize five-dimensional adjustment. A light splitting assembly works in a low-temperature stateand is insulated from a heat insulation support through multiple layers. A mechanical refrigerator realizes the refrigeration and vibration reduction functions through a shock absorber, a corrugated pipe and a flexible cold chain. A slit assembly realizes low-temperature work and axial adjustment through a guide rail, the flexible cold chain, an adjusting screw, a heat insulation cylinder and a sealing ring. A telescope assembly is at normal temperature, and fine adjustment is realized through threads. The cooling box is provided with a vacuum gauge pipe, an ion pump, a vacuum flange and a metal valve, so that vacuum measurement, maintenance, temperature measurement, heating and air exhaust sealing are realized. The low-temperature optical mechanical system based on the SiC particle reinforced aluminum matrix composite vacuum cooling box, provided by the invention, has the characteristics of light weight and vibration suppression, and the telescope assembly, the slit assembly and the detector have the capability of being simultaneously adjusted at low temperature in vacuum inside and normal temperature and pressure outside, thereby being suitable for the field of medium and long wavelength spectral imaging detection.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

On-line toning electrophoresis paint and preparation method thereof

ActiveCN101250348BWithstand voltageSalt spray resistantRosin coatingsPaints for electrolytic applicationsGas liquid chromatographicElectrophoresis

The invention relates to on-line color-mixing electrophoresis paint, which is characterized in that the paint comprises following components with parts by weight of 50-70 parts of water-base resin, 1-3 anti-rot pigment, 6-9 titanium dioxide, 1-3 yellow pigment, 2-4 red pigment, 3-6 filling, 0.5-1 anti-immersion pigment, 0.2-0.6 dispersing agent, 1-3 neutralizing agent, 8-15 deionized water and 6-10 auxiliary solvent. The beneficial effect of the invention is that on-line color-mixing electrophoresis has the characteristics of voltage resistance, salt fog resistance and easy dispersion, can beprepared into complex pigment, and has excellent paint film property and favorable stability. The paint has excellent of pigment wetting dispersing function, can be used to research on-line color-mixing color master-batch paint through optimizing pigment, anti-immersion agent and auxiliary agent and the like, achieves the technical requirements of on-line color-mixing paint, monitors the generation of tank liquor of electrophoresis paint production flow in different time through utilizing the beam splitting and color measurement technology and gas chromatography technology, the change of paint film and color difference delta E, and realizes the on-line color-mixing.

Owner:天津灯塔涂料工业发展有限公司

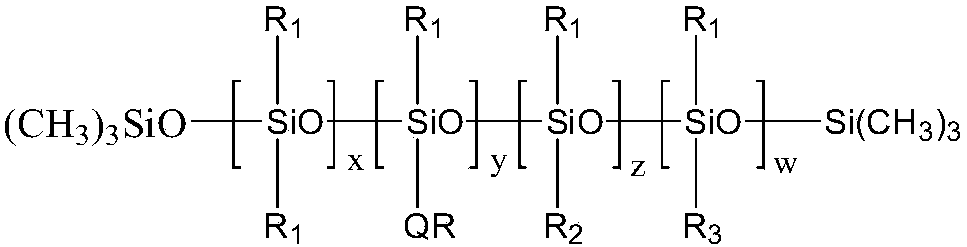

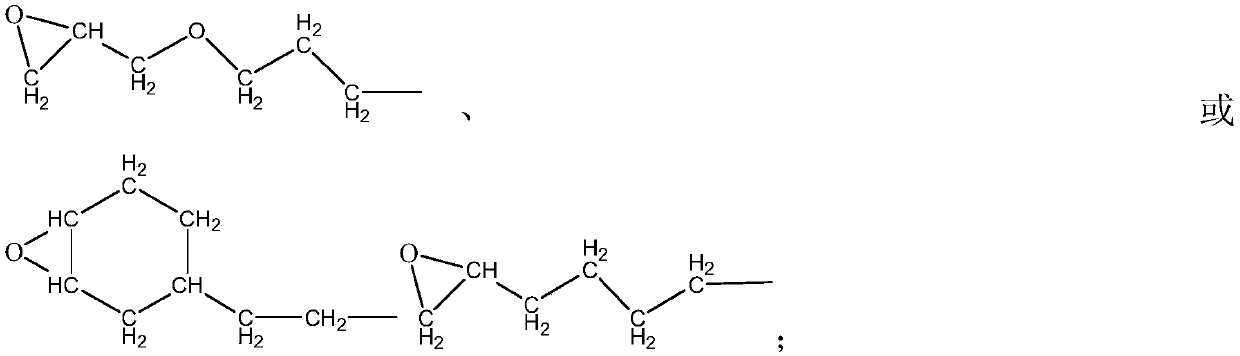

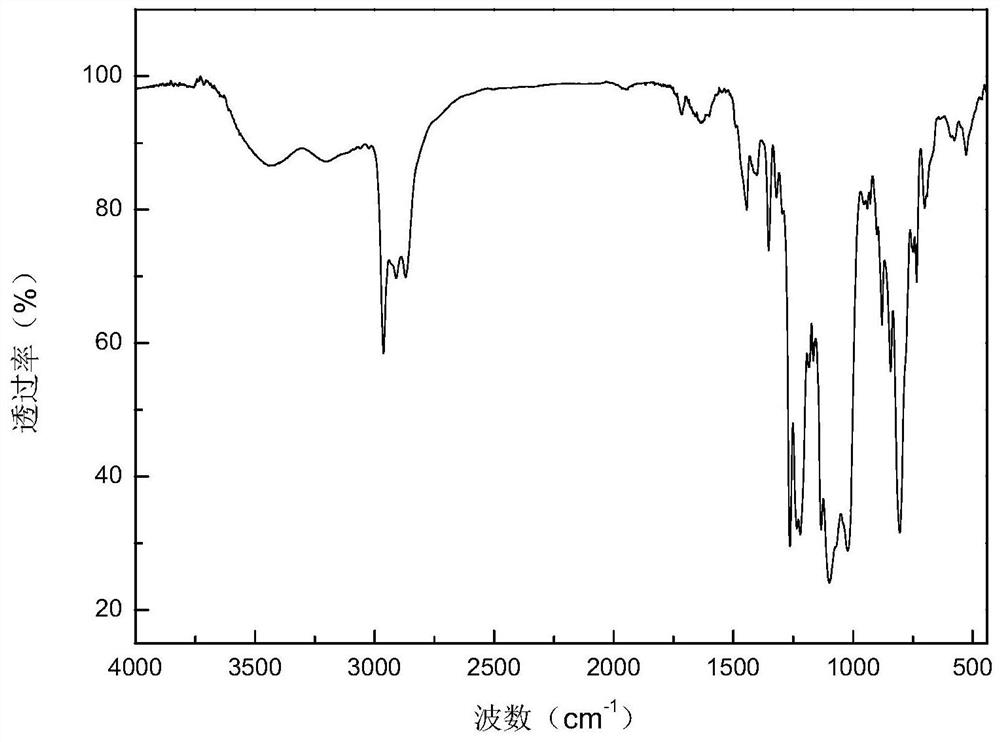

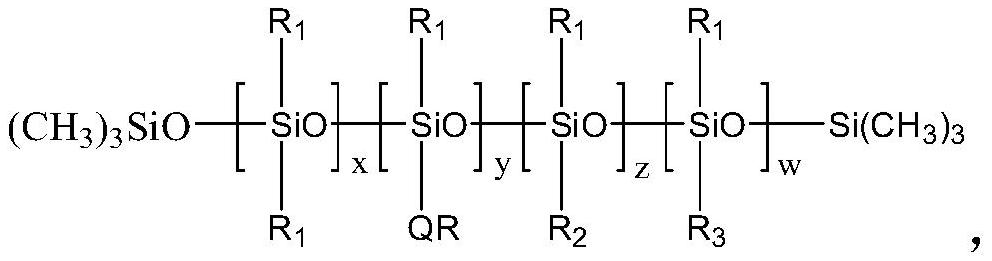

Crosslinkable flame-retardant fluorine-containing silicone oil, preparation method thereof and flame-retardant release coating

ActiveCN108676134AGood flame retardancyImprove flame retardant effectFireproof paintsPolymer chemistryCoating

The invention discloses crosslinkable flame-retardant fluorine-containing silicone oil, a preparation method thereof and a flame-retardant release coating. The crosslinkable flame-retardant fluorine-containing silicone oil is characterized in that the structural formula of the crosslinkable flame-retardant fluorine-containing silicone oil is as shown in the following formula (I), and the crosslinkable flame-retardant fluorine-containing silicone oil has good flame retardancy.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

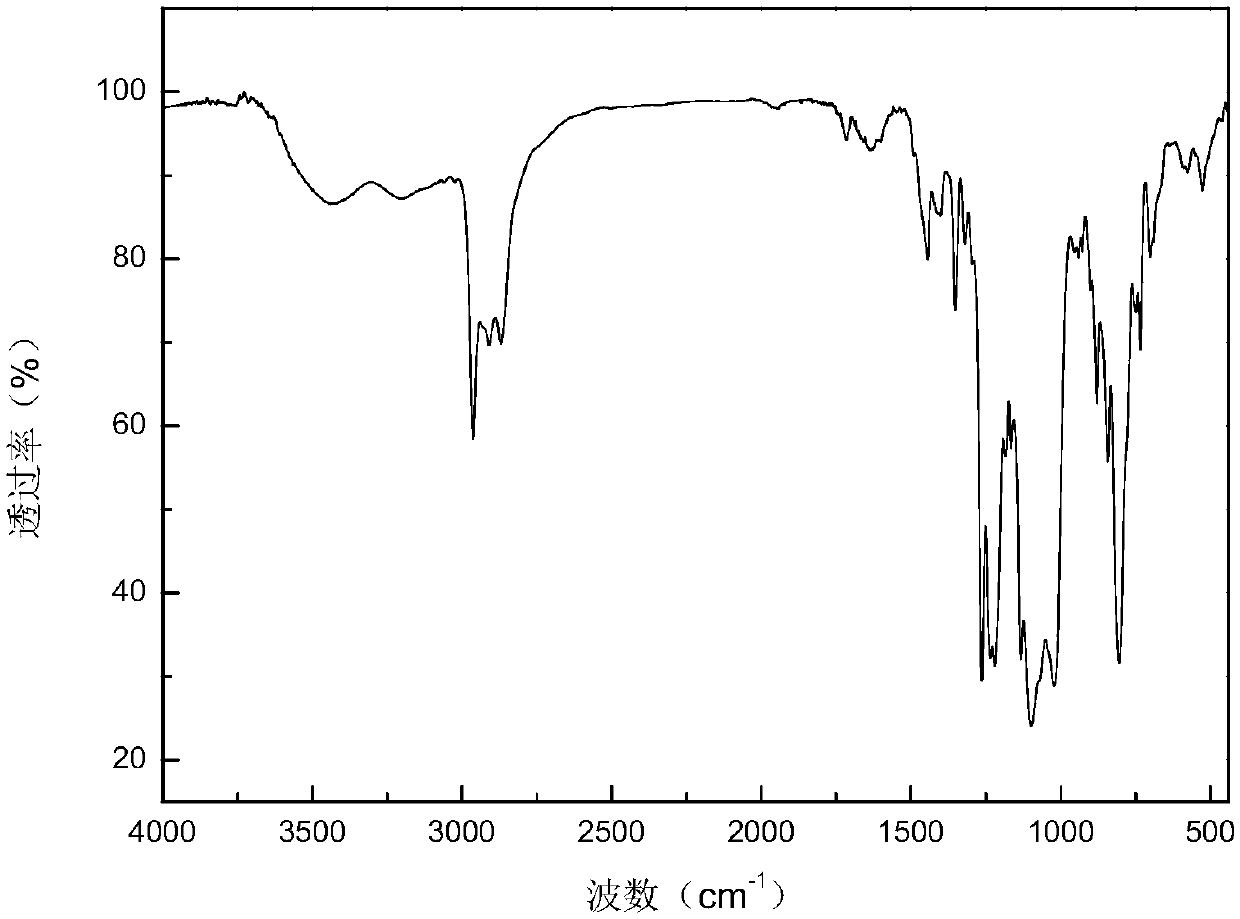

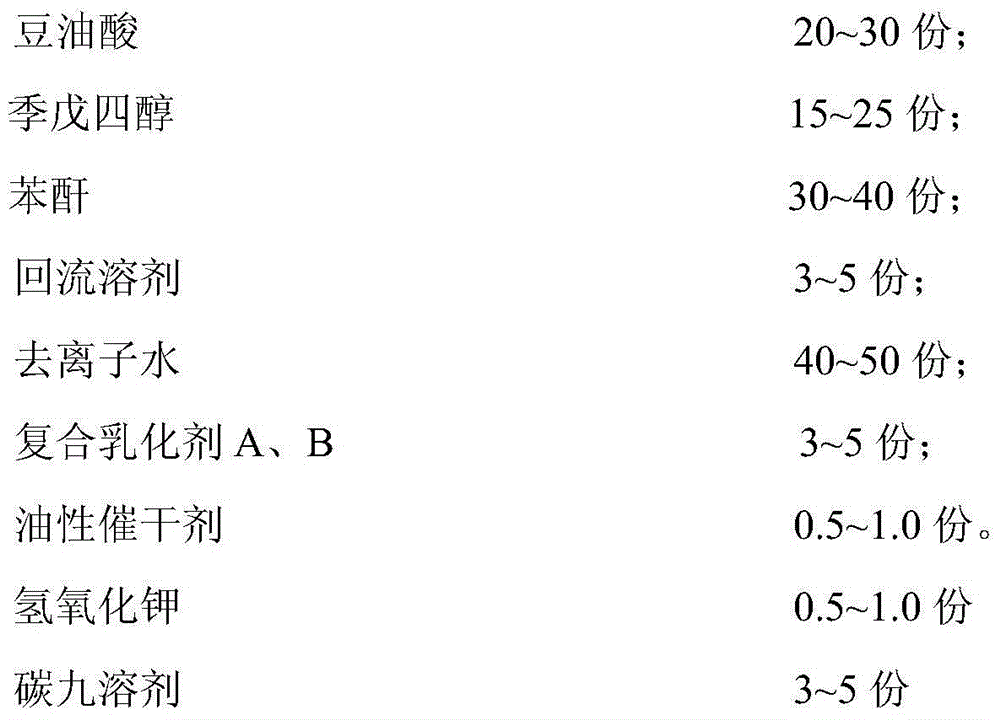

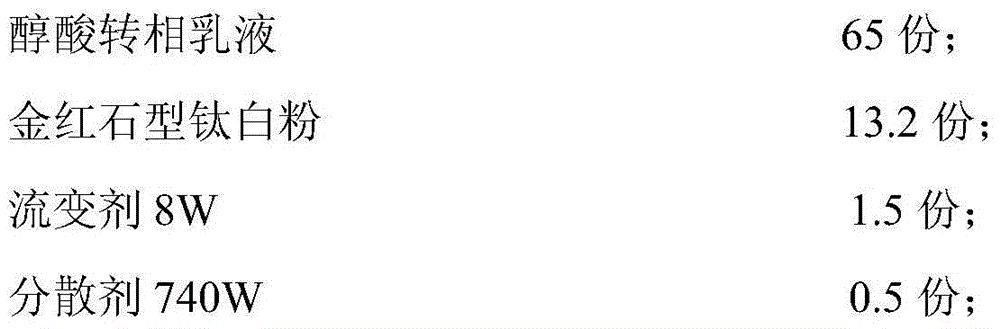

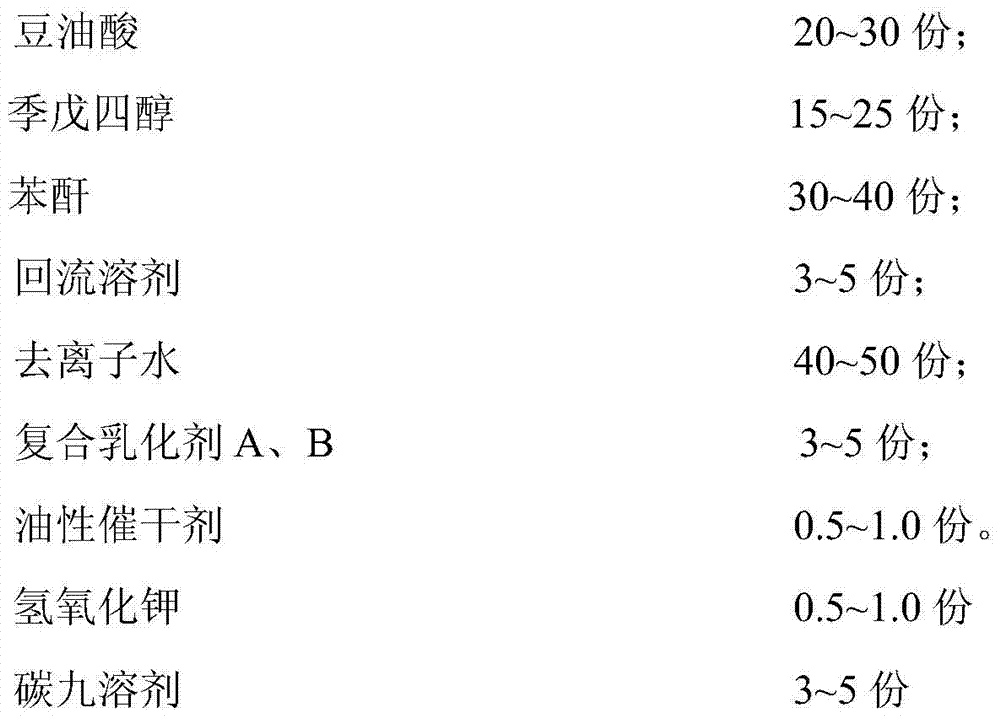

Alcohol acid phase-inverted emulsion as well as preparation method and application of alcohol acid phase-inverted emulsion

The invention provides an alcohol acid phase-inverted emulsion coating. The alcohol acid phase-inverted emulsion coating comprises the following components in parts by weight: 60-70 parts of alcohol acid phase-inverted emulsion, 10-20 parts of pigment filler, 1-1.5 parts of a rheological agent, 0.05-0.1 part of a defoamer, 0.5-1 part of an oil-based drier and 10-25 parts of deionized water. The alcohol acid phase-inverted emulsion coating has an extremely low VOC value and is good in chemical resistance, waterproofness and salt fog resistance and wide in application range.

Owner:山东奔腾漆业股份有限公司

Preparation method of alkyd resin emulsion

The invention discloses a preparation method of alkyd resin emulsion, which comprises the following steps: S1, synthesis of alkyd resin: adding unsaturated fatty acid, a polyhydroxy compound, acid anhydride and an esterification catalyst into a reaction kettle, heating to a preset temperature for reaction, cooling when the acid value is lower than a set value, adding vinyl silicone oil and an oily initiator, and reacting for preset time; and S2, preparation of alkyd resin emulsion: cooling the reaction system obtained in the step S1, adding the modified epoxy emulsifier, cucurbituril and organic amine, continuously stirring, adding water, uniformly dispersing, and discharging to obtain the alkyd resin emulsion. In the synthesis process of the alkyd resin, vinyl silicone oil is used for modifying the alkyd resin, and a polysiloxane chain segment with high weather resistance and low surface energy is introduced, so that the alkyd resin has excellent weather resistance, stain resistance and salt spray resistance of organic silicon resin.

Owner:湖南林特科技有限公司

A kind of cross-linkable flame-retardant fluorine-containing silicone oil, its preparation method and flame-retardant release coating

ActiveCN108676134BImprove flame retardant performanceWith high and low temperature resistanceFireproof paintsPolymer scienceSilicone oil

Owner:安庆龙驰氟硅新材料有限公司

Primer-topcoat polyurethane protective paint

InactiveCN112358799AExcellent high resistance and quick dryingGood wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSteel platesSiloxane

The invention discloses a primer-topcoat polyurethane protective coating, and belongs to the technical field of paint coatings. According to the product, the modified hydroxyl acrylic resin is used asmatrix resin, and through specific modification components, the prepared coating product not only has super-strong adhesive force and can be applied to coating of bottom plates with low surface treatment degree, such as steel plates and aluminum plates, but also has excellent high resistance and quick-drying property and can be effectively applied to various climates and environments; through cooperation of activated siloxane modified nano mica powder, ultrafine talcum powder, ultrafine barium sulfate and other granular materials, the prepared urethane protective paint also has good wear resistance. The invention also discloses a preparation method of the primer-topcoat polyurethane protective paint, and the preparation method has simple operation steps and can be used for industrial large-scale production. The invention also discloses application of the primer-topcoat polyurethane protective paint as a low surface treatment plate paint.

Owner:GUANGDONG YATU CHEM

Nano environment-friendly reinforced floor and manufacturing method

ActiveCN102182289AImprove corrosion resistanceImprove scratch resistanceWood working apparatusFlooringWeather resistanceUltraviolet radiation

The invention relates to a nano environment-friendly reinforced floor with weather resistance, salt mist resistance, abrasion resistance, scrubbing resistance, excellent adhesive force, impact resistance, corrosion resistance, scratching resistance and waterproof performance and a manufacturing method. The nano environment-friendly reinforced floor comprises a base layer and a bottom layer, wherein the base layer is a density board, the bottom layer is a waterproof diaphragm layer and compounded on one side of the base layer, and the other side of the base layer is provided with a nano layer.The nano environment-friendly reinforced floor has the advantages that: 1, a new field of manufacturing the reinforced floor by using a nano material is created, and the nano reinforced floor has weather resistance, salt mist resistance, abrasion resistance, scrubbing resistance, excellent adhesive force, impact resistance, corrosion resistance, scratching resistance and waterproof performance; and 2, the nano material has effects on sterilization, rot resistance, deodorization, filtration and ultraviolet radiation resistance, so the reinforced floor is environment-friendly and healthy, and radically eliminates the harm of the noxious odor of the conventional reinforced floor to the environment and people.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

Zirconium-manganese-vanadium passivation film treatment agent and treatment method for die-casting aluminum alloy

ActiveCN106048580BImprove adhesionHigh degree of corrosion resistanceMetallic material coating processesChromium freeZirconate

The invention discloses a passive film treating agent for die cast aluminium alloy and a treatment method thereof. The passive film treating agent for die cast aluminium alloy comprises the following components in parts by mass: 1 to 20 parts of inorganic acid, 1 to 20 parts of zirconate, 1 to 20 parts of vanadate, 1 to 20 parts of manganate, 1 to 20 parts of calciate and 0.2 to 10 parts of an activating agent. Relative to a traditional phosphorus-containing chromium-free passive film treating agent for die cast aluminium alloy, which causes pollution to the environment, the passive film treating agent for die cast aluminium alloy can form a phosphorus-free chromium-free Zr-Mn-V passive film on the surface of die cast aluminium alloy, the passive film has the advantages that the adhesive force is good, the corrosion resistance is high, and the salt mist resistance and film forming uniformity are good, and besides, the obtained passive film can be guaranteed to have a silver white metal appearance the same as the die cast aluminium alloy.

Owner:广东东明新材科技有限公司

Nano environment-friendly reinforced floor and manufacturing method

ActiveCN102182289BImprove corrosion resistanceImprove scratch resistanceWood working apparatusFlooringWeather resistanceUltraviolet

The invention relates to a nano environment-friendly reinforced floor with weather resistance, salt mist resistance, abrasion resistance, scrubbing resistance, excellent adhesive force, impact resistance, corrosion resistance, scratching resistance and waterproof performance and a manufacturing method. The nano environment-friendly reinforced floor comprises a base layer and a bottom layer, wherein the base layer is a density board, the bottom layer is a waterproof diaphragm layer and compounded on one side of the base layer, and the other side of the base layer is provided with a nano layer. The nano environment-friendly reinforced floor has the advantages that: 1, a new field of manufacturing the reinforced floor by using a nano material is created, and the nano reinforced floor has weather resistance, salt mist resistance, abrasion resistance, scrubbing resistance, excellent adhesive force, impact resistance, corrosion resistance, scratching resistance and waterproof performance; and 2, the nano material has effects on sterilization, rot resistance, deodorization, filtration and ultraviolet radiation resistance, so the reinforced floor is environment-friendly and healthy, and radically eliminates the harm of the noxious odor of the conventional reinforced floor to the environment and people.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

A kind of preparation method of alkyd resin emulsion

Owner:湖南林特科技有限公司

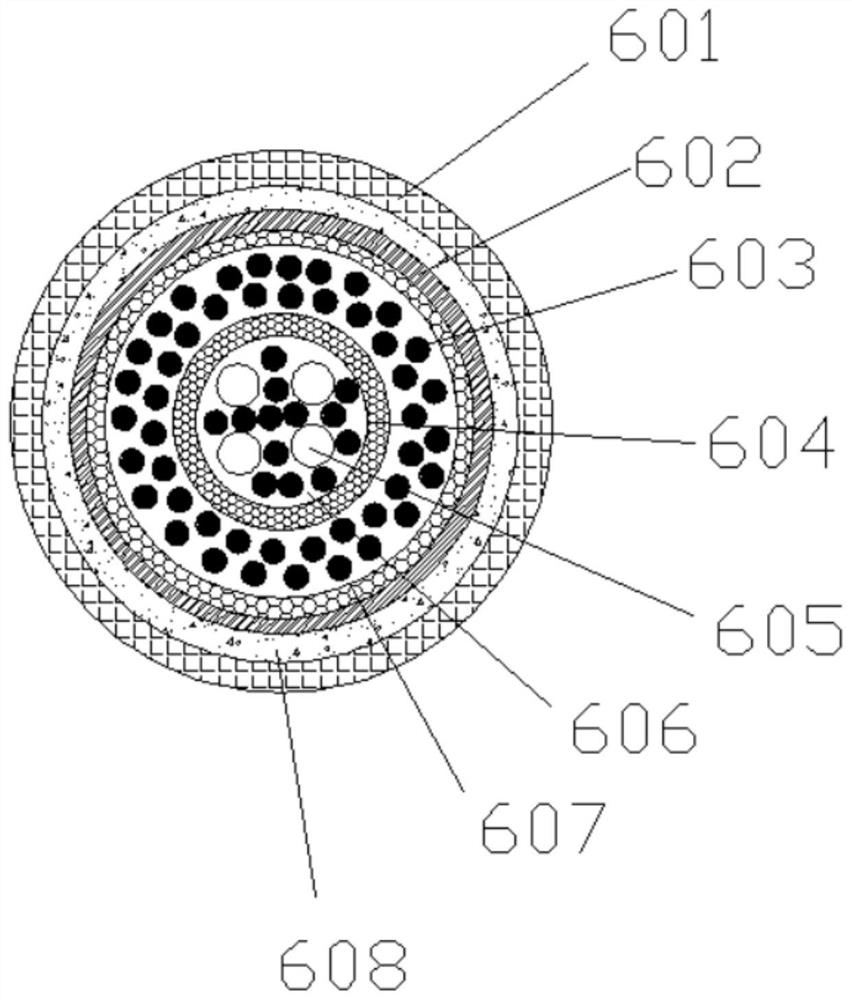

Anti-nuclear electromagnetic multi-core pulse direct-current cable

InactiveCN111489860AReduce Galvanic CorrosionGuarantee the quality of power transmissionPower cables including communication wiresPower cables with screens/conductive layersElectrical conductorPulsed DC

The invention belongs to the technical field of wires and cables and particularly relates to an anti-nuclear electromagnetic multi-core pulse direct-current cable which comprises conductors, insulators, a central filling core, a shielding layer and a sheath, the insulators wrap the conductors to serve as current-carrying wire cores, the multiple current-carrying wire cores are closely arranged andstranded outside the central filling core to form a cable with a multilayer structure, the cable is wrapped by the shielding layer, and the shielding layer is wrapped by the sheath, the current-carrying wire cores are divided into positive wire cores A and negative wire cores B, the positive wire cores A and the negative wire cores B on the same layer are alternately arranged, and adjacent positive wire core A and negative wire core B on the same layer form a group of loops; or all the positive wire cores A and the negative wire cores B in the cable are crossed and connected in parallel to form a loop. By optimizing the arrangement of the current-carrying wire cores, stray electromagnetic fields in any axial direction can be reduced or counteracted, the high-current power transmission quality is ensured, and the electric corrosion to equipment around the cable is reduced.

Owner:NANJING QUANXIN CABLE TECH

A kind of alkyd phase inversion emulsion and its preparation method and application

Owner:山东奔腾漆业股份有限公司

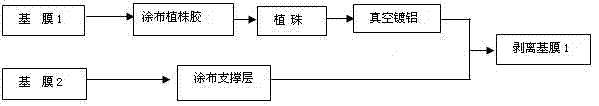

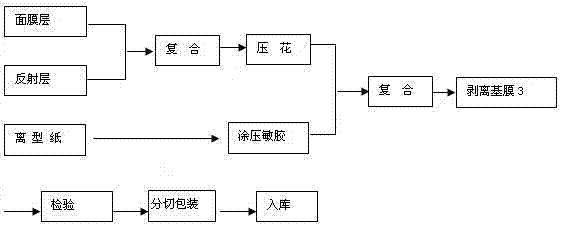

Technology for manufacturing real-scene full-color reflective film

ActiveCN102514298AReduce waste costsStrong high and low temperature resistanceMetal layered productsEmbossing decorationsGraphicsCompound a

The invention relates to a technology for manufacturing a real-scene full-color reflective film and belongs to the field of manufacturing of traffic signs. The technology comprises the following steps of: manufacturing a reflective layer; manufacturing a mask layer; and embossing and compounding a finished product. In the process of manufacturing the reflective film, for full-color patterns which can be subjected to mass production, the production efficiency can be greatly improved by the technology; moreover, the reflective film has vivid colors, the patterns have attractive appearances; and compared with a common cutting technology, the technology can reduce the waste of corner films, adopts one-step molding and does not require combined film lamination. Compared with that produced by the traditional spray painting process, the full-color reflective film produced by the manufacturing process has higher outdoor stability.

Owner:NANJING SKY TRAFFIC IND

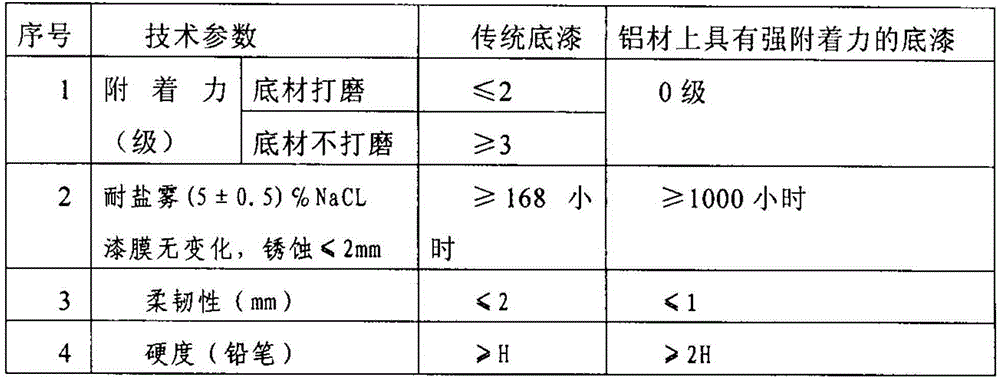

Primer with strong adhesion on aluminum and preparation method thereof

The invention relates to priming paint with strong adhesive force on an aluminum material and a preparation method of the priming paint. The priming paint is prepared from the following raw materials in parts by weight: 20 to 35 parts of modified epoxy resin, 30 to 50 parts of pigments and fillers, 0.5 to 5 parts of accessory ingredients, 10 to 20 parts of solvent. The preparation method comprises the following steps: placing 80 to 90 percent of resin, 60 to 70 percent of solvent and pigments and fillers as well as accessory ingredients into a reaction container according to the formula, stirring the raw materials at a high speed, grinding the materials into the particles with the granularity of less than or equal to 20 micrometers, adding surplus resin, and adjusting the solid content to a theoretical value by utilizing the surplus solvent, thereby preparing the priming paint with the strong adhesive force on the aluminum material. Compared with the prior art, the adhesion performance is improved, and the chemical drug resistance is excellent.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

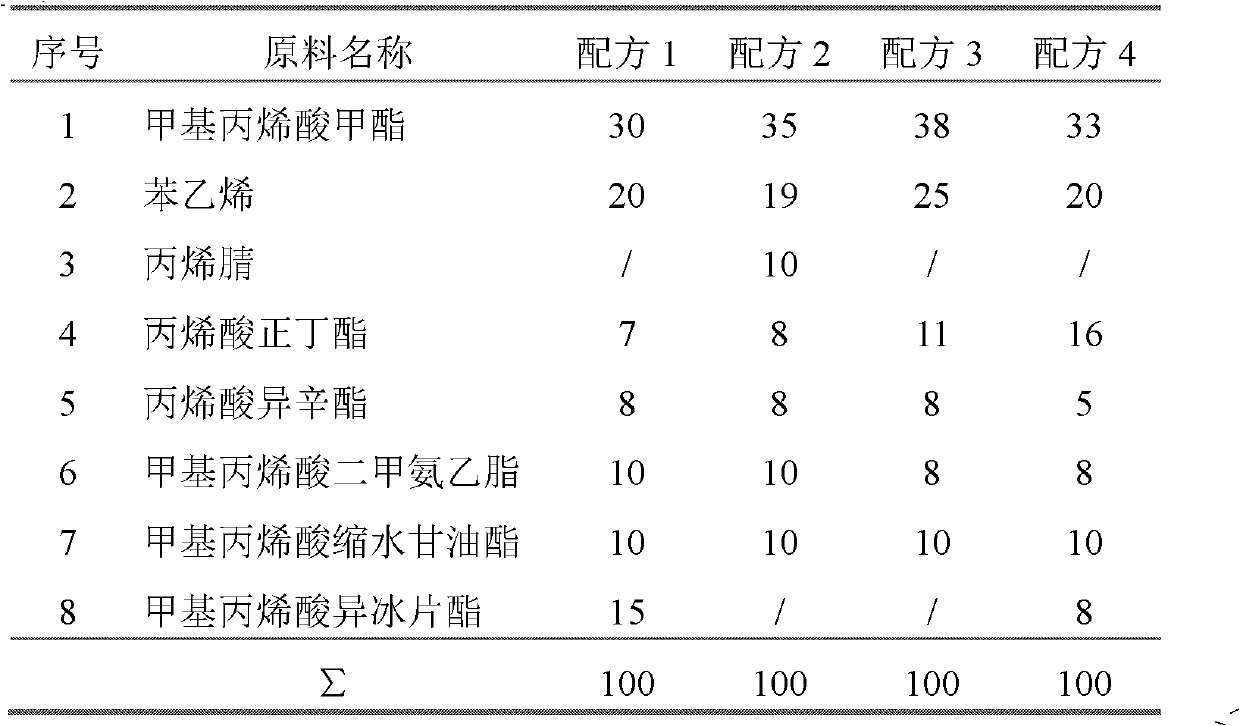

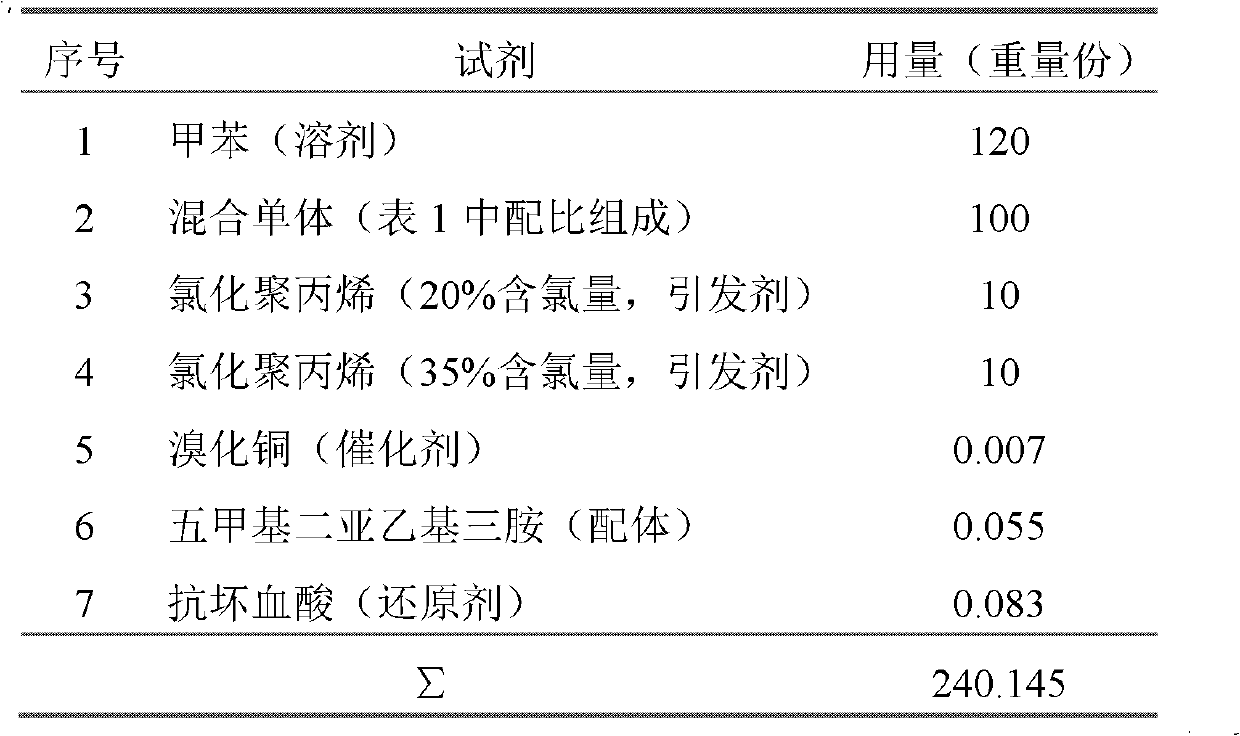

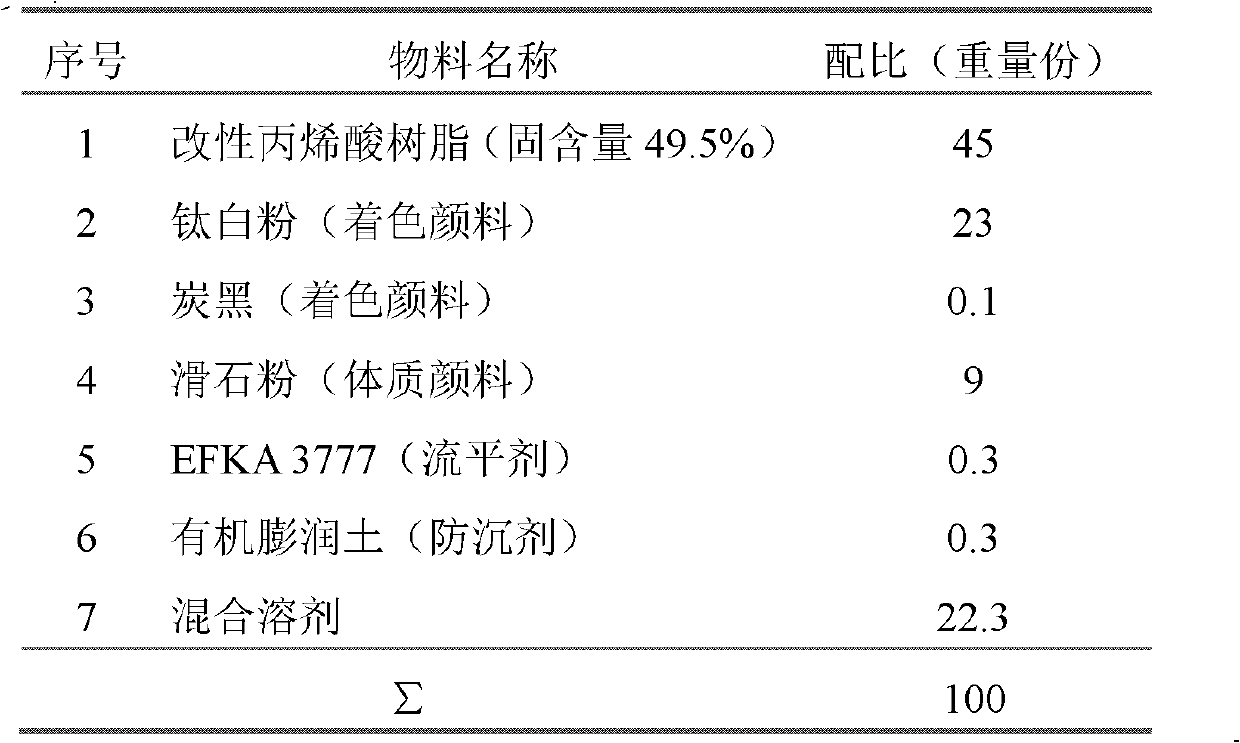

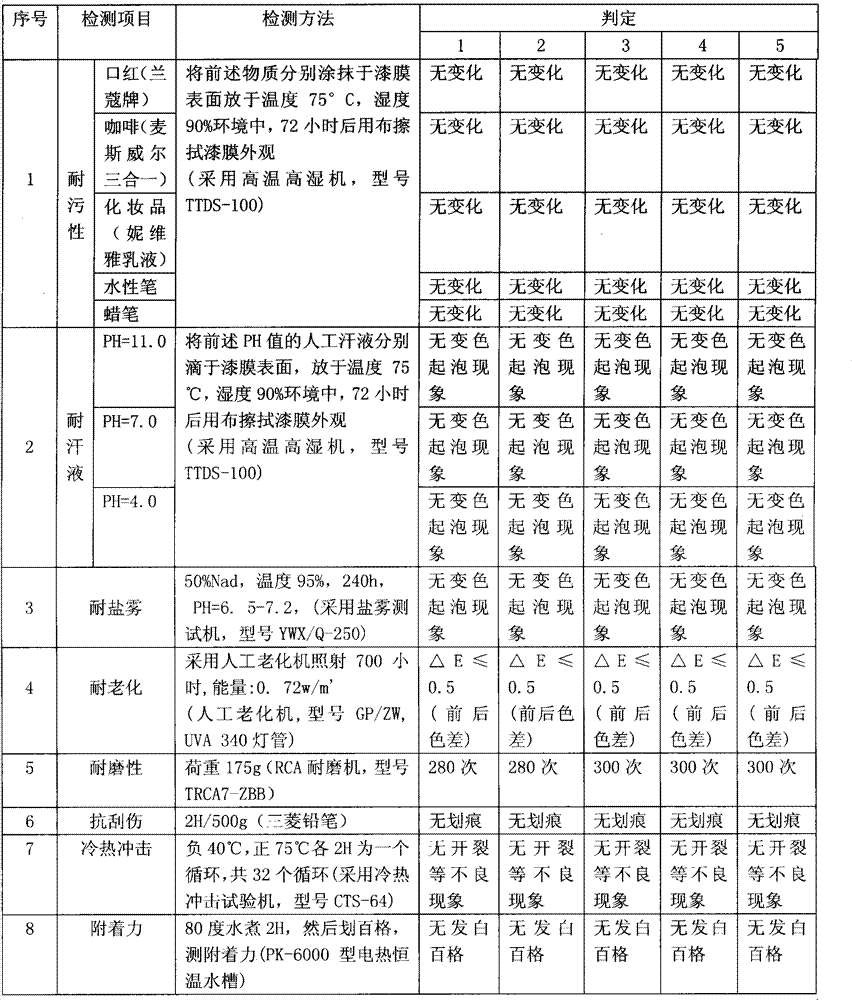

Modified acrylic resin as well as paint and application thereof

The invention provides a modified acrylic resin, which is prepared by activators regenerated by electron transfer-atom transfer radical polymerization (ARGET-ATRP) from chlorinated polyolefin, dimethylamino ethyl methacrylate and vinyl monomer. According to the invention, an atom transfer radical polymerization method is adopted, thus the defects of randomness, uncontrollable graft ratio and the like of traditional radical polymerization are overcome; and activators regenerated by electron transfer are adopted, thus the use amount of the catalyst is reduced by scores of ppm of a system and the complicated filtering and washing process of large-use-amount catalyst and ligand after reaction in traditional ATRP reaction is omitted. The prepared resin has good performances, such as high drying rate, good adhesion, good water resistance; and the paint prepared from the resin has the characteristics of good adhesion, good water resistance, salt mist resistance, moist heat resistance, temperature change resistance and the like, and can be used as primer and single-pass finishing coat.

Owner:常州市弘可利办公用品有限公司

Anticorrosion antiwear ceramic paint

InactiveCN1148429CUnchanged immersion performanceImprove soaking effectAnti-corrosive paintsEpoxy resin coatingsGlass fiberEpoxy

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

UV-Heat Dual Curing Coatings

Owner:苏州佩琦材料科技有限公司

Crystal key manufacturing method and crystal key

PendingCN113241277ASalt spray resistantWith high and low temperatureElectric switchesLaser etchingAdhesive

The invention discloses a manufacturing method of a crystal key. The manufacturing method comprises the following steps: raw material forming: manufacturing a crystal raw material into a required shape; structural design: arranging a plurality of refracting surfaces on the back face of a key; film plating: shielding the front face of the key, and carrying out vacuum film plating on the back face of the key by using an evaporation coating technology, wherein the film thickness is 0.3-1 micrometer; primer spraying: spraying a paint on the back face of the key, wherein the paint thickness is 10-20 microns; laser etching: carrying out laser etching on marks on the key; and top coat spraying: spraying a paint on the back face of the key again, wherein the paint thickness ranges from 10 micrometers to 20 micrometers. According to the invention, a plurality of refraction faces are made on the back face of the key to achieve refraction and reflection effects, so that the whole key is in a mirror face effect when seen from the front face; and through combination of a vacuum coating process and a paint spraying process, the key has the performance of salt mist resistance, high and low temperature resistance, good paint film adhesive force and the like, and the crystal key meets the industrial black or gray color tone requirement. The invention further relates to the crystal key manufactured according to the manufacturing method of the crystal key.

Owner:GAC COMPONENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com