Technology for manufacturing real-scene full-color reflective film

A technology of reflective film and real scene, which is applied in the direction of decorative art, embossed decorative parts, layered products, etc., and can solve the problems of not being able to enter mass production, consuming a lot of man-hours, and cost waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. rear.

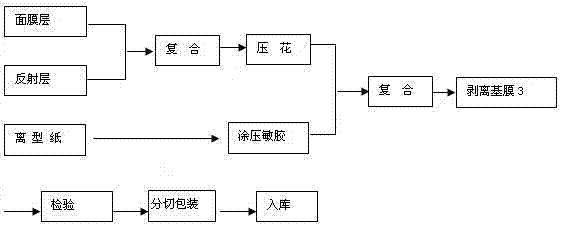

[0019] A real-scene full-color reflective film production technology, comprising the following steps:

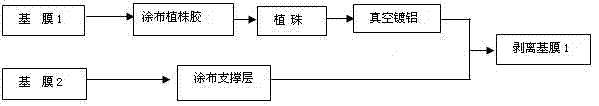

[0020] (1) Production of reflective layer

[0021] Such as figure 1 As shown, first coat the bead-planting glue in the base film layer 1, implant the special reflective microbeads for the reflective film at the best adhesion time of the colloid, and then carry out vacuum aluminum plating on the base layer where the reflective microbeads have been planted; Another base film 2 is coated with a support layer, and after the above process is completed, the base film layer 1 is peeled off;

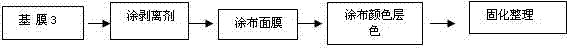

[0022] (2) Production of mask layer

[0023] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com