Primer with strong adhesion on aluminum and preparation method thereof

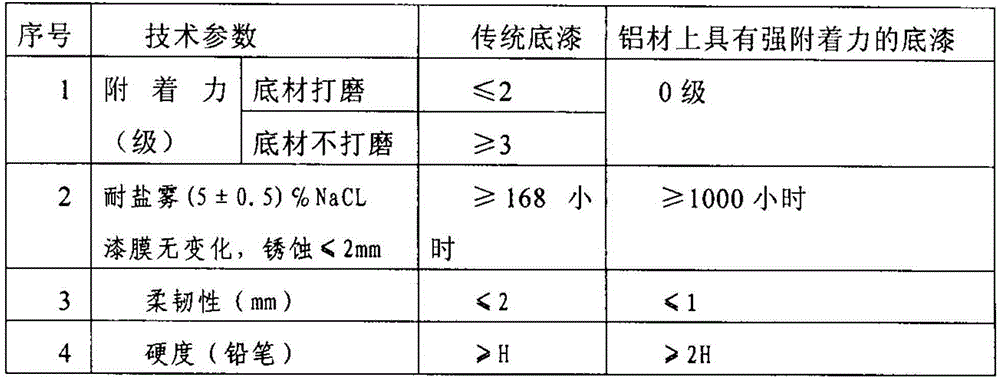

A technology of strong adhesion and primer, applied in the direction of coating, epoxy resin coating, etc., can solve the problems of poor adhesion of paint film, large manpower, material force, paint peeling, etc., achieve excellent chemical resistance, improve adhesion The effect of focusing and strengthening adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the modified epoxy primer with strong adhesion on the aluminum material, the method comprises the following process steps:

[0029] (1) 28 kilograms of E-20 epoxy resin, 50 kilograms of titanium dioxide, 1 kilogram of polyacrylate polymer and 17 kilograms of methyl isobutyl ketone were first put into the dispersion tank according to the formula requirements, and stirred at high speed for 30 minutes;

[0030] (2) grinding the above-mentioned mixed material to a fineness of 20 microns with a grinder;

[0031] (3) add 2 kilograms of E-20 epoxy resin again, stir 10 minutes;

[0032] (4) measure solid content, and adjust coating to 65wt% with 2 kilograms of methyl isobutyl ketone;

[0033] (5) After the solid content detection is qualified, the modified epoxy primer with strong adhesion on the aluminum material is prepared, and weighed and packaged.

Embodiment 2

[0035] The preparation method of the modified epoxy primer with strong adhesion on the aluminum material, the method comprises the following process steps:

[0036] (1) 20 kilograms of E-20 epoxy resin, 50 kilograms of titanium dioxide, 5 kilograms of polyacrylate polymer, and 10 kilograms of methyl isobutyl ketone were first put into the dispersion tank according to the formula requirements, and stirred at high speed for 30 minutes;

[0037] (2) grinding the above-mentioned mixed material to a fineness of 18 microns with a grinder;

[0038] (3) add 10 kilograms of E-20 epoxy resin again, stir 20 minutes;

[0039] (4) measure solid content, and adjust coating to 60wt% with 5 kilograms of methyl isobutyl ketone;

[0040] (5) After the solid content detection is qualified, the modified epoxy primer with strong adhesion on the aluminum material is prepared, and weighed and packaged.

Embodiment 3

[0042] The preparation method of the modified epoxy primer with strong adhesion on the aluminum material, the method comprises the following process steps:

[0043] (1) 28 kilograms of E-20 epoxy resin, 45 kilograms of titanium dioxide, 0.5 kilograms of polyacrylate polymer, and 16 kilograms of methyl isobutyl ketone were first put into the dispersion tank according to the formula requirements, and stirred at high speed for 30 minutes;

[0044] (2) grinding the above-mentioned mixed material to a fineness of 13 microns with a grinder;

[0045] (3) add 7 kilograms of E-20 epoxy resin again, stir 15 minutes;

[0046] (4) measure solid content, and adjust coating to 70wt% with 3.5 kilograms of methyl isobutyl ketone;

[0047] (5) After the solid content detection is qualified, the modified epoxy primer with strong adhesion on the aluminum material is prepared, and weighed and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com