A kind of alkyd phase inversion emulsion and its preparation method and application

A phase-inversion and alkyd technology, which is applied in the field of alkyd phase-inversion emulsion and its preparation, can solve the problems of aggravated health hazards, slow coating film drying, high resin viscosity, etc., and achieves low environmental pollution, good adhesion, and oxidative drying fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

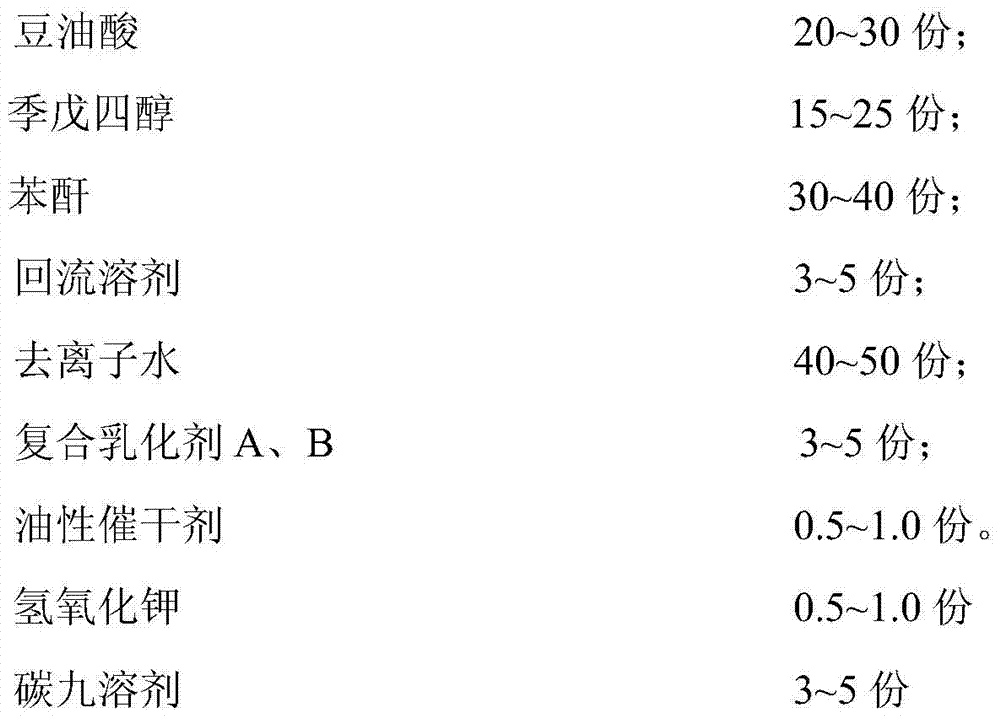

[0030] The alkyd phase inversion emulsion white paint comprises the following components by weight:

[0031]

[0032]

[0033] Wherein, the mass solid concentration of alkyd emulsion is 50%, and it is made up of the following components by weight:

[0034]

[0035] Wherein, the preparation method of alkyd phase inversion emulsion white paint comprises the following steps:

[0036] (1) After mixing 50% deionized water, defoamer A-10, pigments and fillers (rutile titanium dioxide), dispersant, and propylene glycol, disperse at a speed of 1000r / min for 20min, and grind until the fineness reaches 35μm, poured into paint pots;

[0037] (2) Add alkyd phase-inversion emulsion, add the remaining amount of deionized water and stir evenly, and disperse at a speed of 700r / min for 5-15min;

[0038] (3) Add rheological agent 8w and rheological agent 2020, and stir at 700r / min for 30min to obtain the product.

[0039] Wherein, the alkyd phase inversion emulsion resin is prepared...

Embodiment 2

[0048] The alkyd phase inversion emulsion white paint comprises the following components by weight:

[0049]

[0050] Wherein, the mass solid concentration of alkyd emulsion is 52%, and it is made up of following components by weight:

[0051]

[0052] Wherein, the preparation method of alkyd phase inversion emulsion white paint comprises the following steps:

[0053] (1) After mixing 40% deionized water, defoamer A-10, pigments and fillers (rutile titanium dioxide), dispersant, and propylene glycol, disperse at a speed of 800r / min for 25min, and grind until the fineness reaches 35μm, poured into paint pots;

[0054] (2) Add alkyd phase-inversion emulsion, add the remaining amount of deionized water and stir evenly, and disperse for 15 minutes at a speed of 600r / min;

[0055] (3) Then add rheological agent 8w and rheological agent 2020, and stir at a speed of 600r / min for 35min to obtain the product.

[0056] Wherein, the alkyd phase inversion emulsion resin is prepar...

Embodiment 3

[0065] The alkyd phase inversion emulsion white paint comprises the following components by weight:

[0066]

[0067]

[0068] Wherein, the mass solid concentration of alkyd emulsion is 48%, and it is made up of the following components by weight:

[0069]

[0070] (1) After mixing 60% deionized water, defoamer A-10, pigments and fillers (rutile titanium dioxide), dispersant, and propylene glycol, disperse at a speed of 1200r / min for 15min, and grind until the fineness reaches 35μm, poured into paint pots;

[0071] (2) Add alkyd phase-inversion emulsion, add the remaining amount of deionized water and stir evenly, and disperse for 5 minutes at a speed of 800r / min;

[0072] (3) Add rheological agent 8w and rheological agent 2020, and stir at 800r / min for 25min to obtain the product.

[0073] Wherein, the alkyd phase inversion emulsion resin is prepared by the following method:

[0074] (1) Put soy oil, phthalic anhydride, pentaerythritol and reflux solvent into an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com