Two-component silicone potting compound and its preparation process

A silicone potting glue, two-component technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of low light output rate, affecting life and application, and poor heat dissipation of high-power LEDs and other problems, to achieve the effect of excellent mechanical properties and good viscosity properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Component A: Vinyl silicone oil, dimethyl silicone oil, silicon micropowder, aluminum oxide, aluminum nitride, boron nitride, LSR base glue, platinum catalyst The weight ratio is: 100:60:25:8:8:8: 25:2;

[0034] Component B: Vinyl silicone oil, dimethyl silicone oil, methyl hydrogen siloxane, silicon micropowder, aluminum oxide, LSR base glue, white carbon black, tackifier, inhibitor weight ratio: 100:60:25 :25:8:25:10:0.5:2;

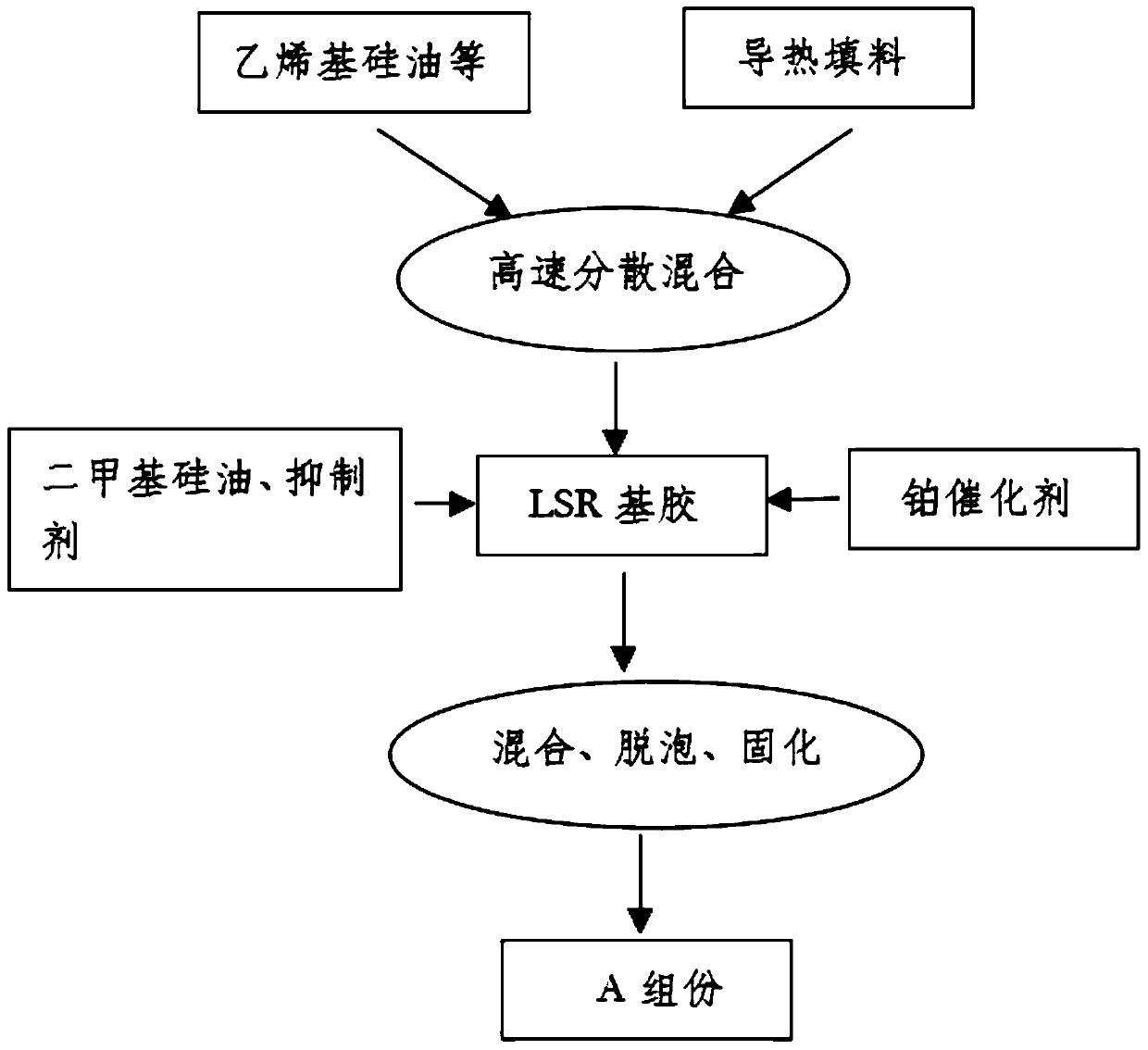

[0035] For component A: high-speed dispersion and mixing of vinyl silicone oil, silicon micropowder, aluminum oxide, aluminum nitride and boron nitride; add the high-speed dispersion and mixing material into LSR base glue and mix with platinum catalyst, dimethyl silicone oil, Degassing and curing to obtain component A;

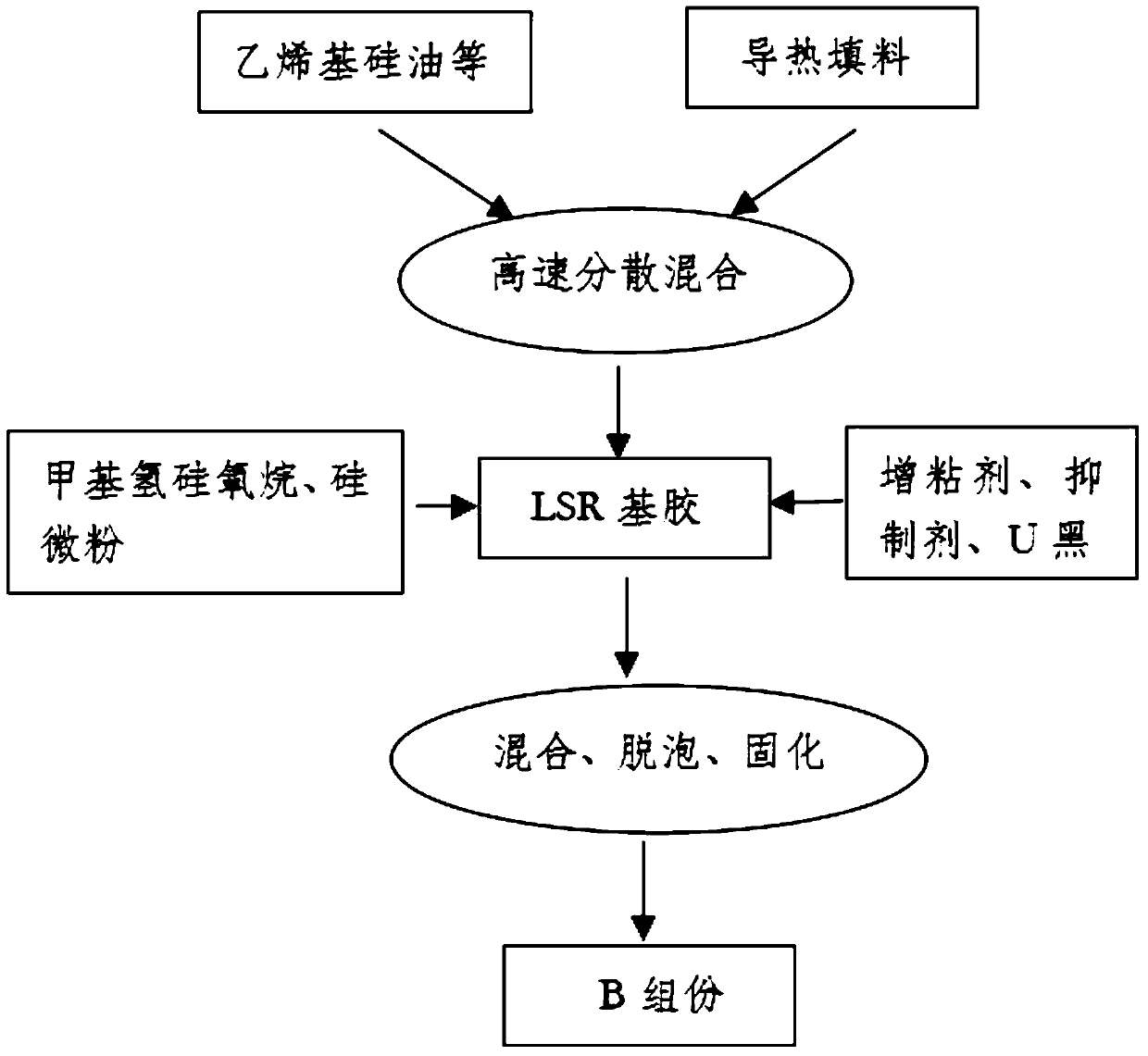

[0036] For component B: Disperse and mix vinyl silicone oil, simethicone oil and alumina at high speed; add the material after high-speed dispersion and mixing to LSR base glue and mix with methyl hydrogen siloxane, silicon mic...

Embodiment 2

[0039] Embodiment 2 differs from Embodiment 1 in that:

[0040] Component A: Vinyl silicone oil, dimethyl silicone oil, silicon micropowder, aluminum oxide, aluminum nitride, boron nitride, LSR base glue, platinum catalyst The weight ratio is: 100:50:20:5:5:5: 20:0.5;

[0041] Component B: Vinyl silicone oil, dimethyl silicone oil, methyl hydrogen siloxane, silicon micropowder, aluminum oxide, LSR base glue, white carbon black, tackifier, inhibitor weight ratio: 100:50:20 :20:5:20:5:0.1:0.1.

Embodiment 3

[0043] Embodiment 3 differs from Embodiment 1 in that:

[0044] Component A: Vinyl silicone oil, dimethyl silicone oil, silicon micropowder, aluminum oxide, aluminum nitride, boron nitride, LSR base glue, platinum catalyst The weight ratio is: 100:65:30:10:10:10: 30:3;

[0045] Component B: Vinyl silicone oil, dimethyl silicone oil, methyl hydrogen siloxane, silicon micropowder, aluminum oxide, LSR base glue, white carbon black, tackifier, inhibitor weight ratio: 100:65:30 :30:10:30:15:1:3.

[0046] For the product that embodiment 1~3 makes, we have carried out measurement, draw following result:

[0047] Curing time<480min(25℃),<20min(80℃);

[0048] Thermal conductivity ≥ 3.0W / m·k;

[0049] Dielectric strength ≥ 27kV / mm;

[0050] Dielectric constant 3.0 ~ 3.3 (1.2MHz);

[0051] Volume resistivity ≥ 1.0×1014Ω·cm (25°C);

[0052] Linear expansion coefficient≤2.2×10-4m / (m·K)

[0053] Therefore, the present invention has high thermal conductivity and good flame retardancy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com