Preparation method of ammonium carboxymethylcellulose

A technology of carboxymethyl cellulose and sodium carboxymethyl cellulose, which is applied in the field of preparation of ammonium carboxymethyl cellulose (CMC-NH4), can solve the problem of high cost, and achieve short reaction period, low consumption of raw materials, and low ash content. The effect of less residual amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

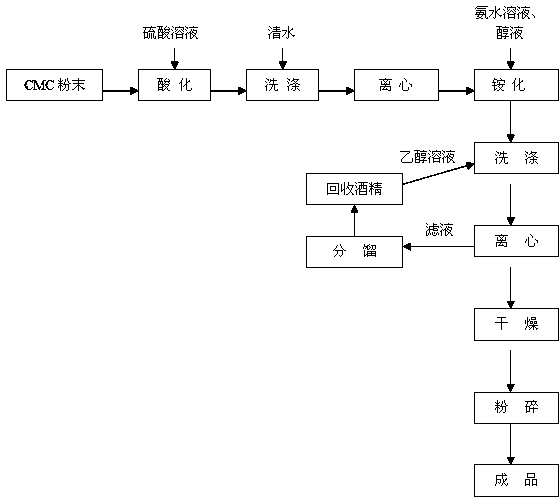

Method used

Image

Examples

Embodiment 1

[0022] A certain amount of sodium carboxymethyl cellulose powder (2% NDJ-79 viscosity 850, degree of substitution 0.62), 6.5 times the mass concentration of 10% sulfuric acid aqueous solution, stirred for 60 minutes, and then left to acidify for 40 minutes; then a certain amount of water Add to the product, stir and wash, and centrifuge; after centrifugation, add 0.5 times the mass of 10% ammonia solution, and at the same time add 2.0 times the mass of 70% ethanol solution, stir and mix, let it stand for 150 minutes, and then again Centrifuge and dry in an oven for 120min at a temperature of 60-80°C to obtain refined CMC-NH 4 Finished product, the viscosity of 1% aqueous solution measured by Brookfield type viscometer is 92, and the ash content is 0.20%.

Embodiment 2

[0024] A certain amount of sodium carboxymethyl cellulose powder (2% NDJ-79 viscosity 850, degree of substitution 0.62), 7.5 times the mass of 20% sulfuric acid aqueous solution, stirred for 60 minutes, and then left to acidify for 90 minutes; add a certain amount of water In the product, stir and wash, and centrifuge; add 1.0 times the mass of ammonia solution with a concentration of 15% after centrifugation, and add 4.0 times the mass of an 80% ethanol solution at the same time, stir and mix, let it stand for 180 minutes, and then centrifuge again Separation and drying in an oven for 120min at a drying temperature of 60-80°C to obtain refined CMC-NH 4 Finished product, the viscosity of 1% aqueous solution measured by Brookfield type viscometer is 97, and the ash content is 0.15%.

Embodiment 3

[0026] A certain amount of sodium carboxymethyl cellulose powder (2% NDJ-79 viscosity 850, degree of substitution 0.62), 8.0 times the mass concentration of 20% sulfuric acid aqueous solution, stirred for 60 minutes, and then left to acidify for 120 minutes; then remove the supernatant, Add a certain amount of water to the product, stir and wash, and centrifuge; add 1.5 times the mass of ammonia solution with a concentration of 20% after centrifugation, and at the same time add 3.0 times the mass of an ethanol solution with a concentration of 90%, stir and mix well and let it stand React for 210 minutes, then centrifuge again, and dry in an oven for 120 minutes at a temperature of 60-80°C to obtain refined CMC-NH 4 Finished product, the viscosity of 1% aqueous solution measured by Brookfield type viscometer is 105, and the ash content is 0.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com