Environmentally-friendly energy-saving gasoline engine oil and preparation method thereof

A gasoline engine oil, environment-friendly technology, applied in the direction of processing hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., can solve the problems of poor dispersion performance of gasoline engine oil, poor lubrication and anti-friction effect, poor viscosity-temperature performance, etc., to achieve Reduces frictional heat, saves fuel consumption, and has excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

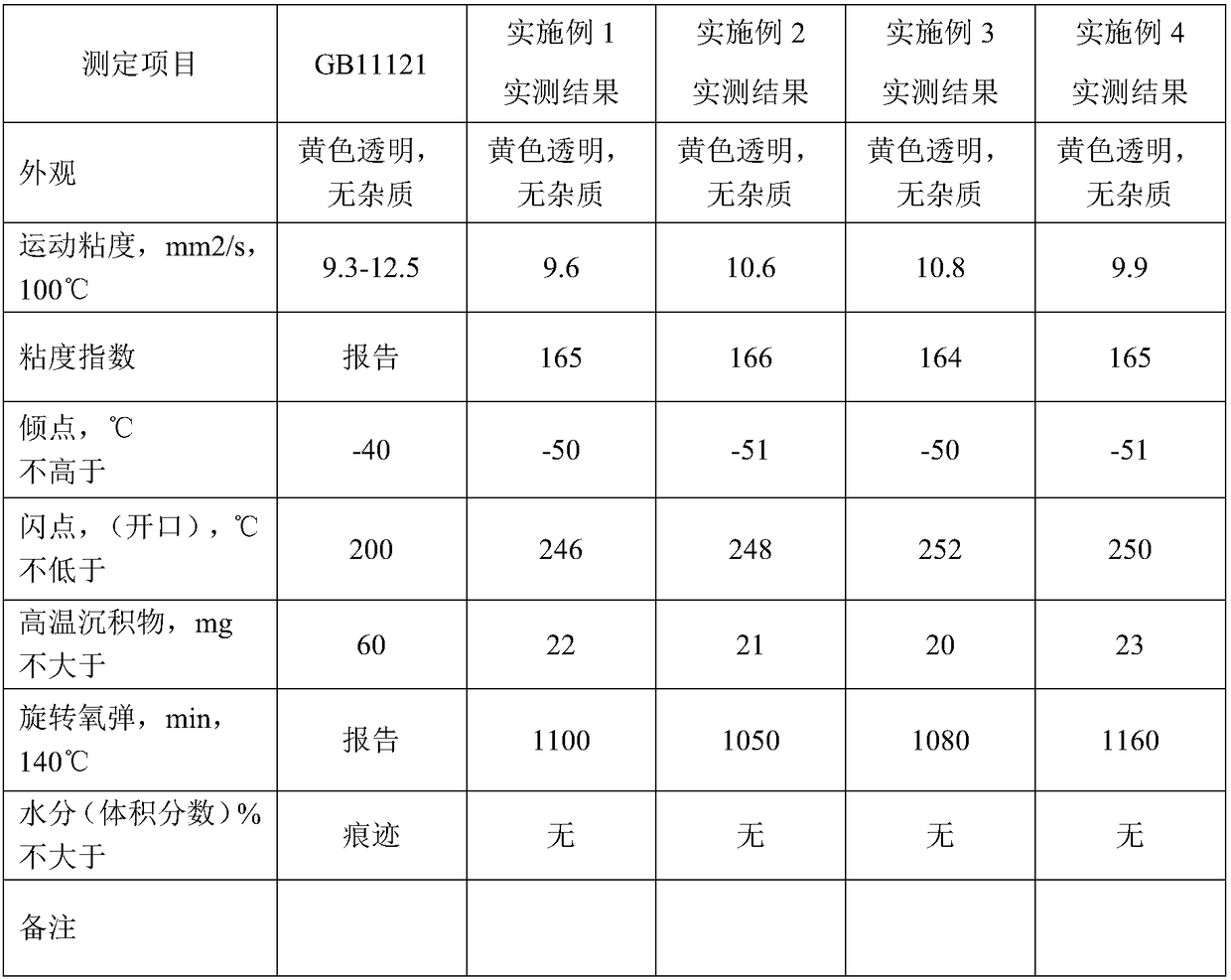

Embodiment 1

[0026] The invention provides an environment-friendly energy-saving gasoline engine oil, which is composed of polyalphaolefin, triple hydrogenated low-point base oil, viscosity index improver, detergent, ashless dispersant, antioxidant and anticorrosion agent and organic molybdenum.

[0027] Firstly, put the three-time hydrogenated base oil into the rectification tower and carry out atmospheric and vacuum distillation. The vacuum distillation process is a residual pressure of 1-70mmHg, and cut the distillate oil at 500-550°C, and then carry out hydrofining. Hydrofining process The reaction pressure of the medium reactor is 20-25MPa, the reaction temperature is 550-560°C, the total space velocity of the oil feed is 0.35-0.65 / h, the reaction hydrogen-oil volume ratio is 800-950, and the space velocity of the hydrogenation catalyst is 0.5 ~0.85 / h, relative to the hydrofining catalyst space velocity of 0.85-1.95 / h, the catalyst in the hydrofinishing process is Co-Mo-W / Al 2 o 3 , ...

Embodiment 2

[0036] The invention provides an environment-friendly energy-saving gasoline engine oil, which is composed of polyalphaolefin, triple hydrogenated low-point base oil, viscosity index improver, detergent, ashless dispersant, antioxidant and anticorrosion agent and organic molybdenum.

[0037] Firstly, put the three-time hydrogenated base oil into the rectification tower and carry out atmospheric and vacuum distillation. The vacuum distillation process is a residual pressure of 1-70mmHg, and cut the distillate oil at 500-550°C, and then carry out hydrofining. Hydrofining process The reaction pressure of the medium reactor is 20-25MPa, the reaction temperature is 550-560°C, the total space velocity of the oil feed is 0.35-0.65 / h, the reaction hydrogen-oil volume ratio is 800-950, and the space velocity of the hydrogenation catalyst is 0.5 ~0.85 / h, relative to the hydrofining catalyst space velocity of 0.85-1.95 / h, the catalyst in the hydrofinishing process is Ni-W-Co / Al 2 o 3 , ...

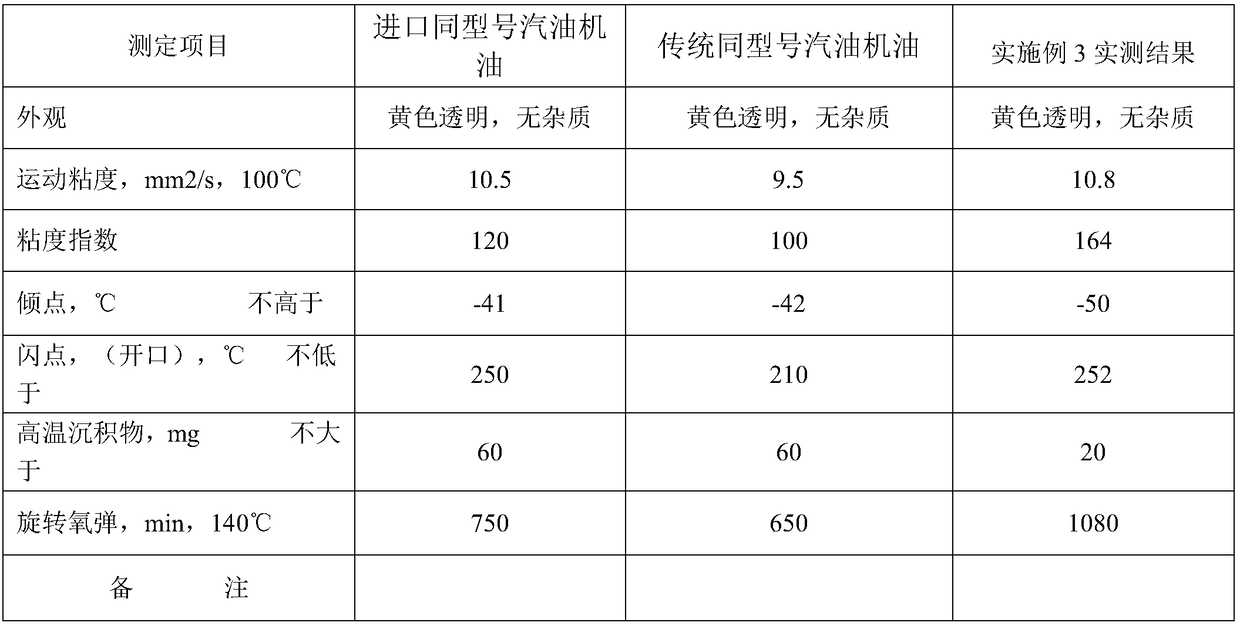

Embodiment 3

[0047] The invention provides an environment-friendly energy-saving gasoline engine oil, which is composed of polyalphaolefin, triple hydrogenated low-point base oil, viscosity index improver, detergent, ashless dispersant, antioxidant and anticorrosion agent and organic molybdenum.

[0048] Firstly, put the three-time hydrogenated base oil into the rectification tower and carry out atmospheric and vacuum distillation. The vacuum distillation process is a residual pressure of 1-70mmHg, and cut the distillate oil at 500-550°C, and then carry out hydrofining. Hydrofining process The reaction pressure of the medium reactor is 20-25MPa, the reaction temperature is 550-560°C, the total space velocity of the oil feed is 0.35-0.65 / h, the reaction hydrogen-oil volume ratio is 800-950, and the space velocity of the hydrogenation catalyst is 0.5 ~0.85 / h, relative to the hydrofining catalyst space velocity of 0.85-1.95 / h, the catalyst in the hydrofinishing process is Co-Mo-W / Al 2 O, to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com