Preparation method of down fiber for processing antibacterial and deodorant duvet

A duvet and down technology, applied in the field of duvet processing, can solve the problems of incomplete elimination of impurities and bacteria, low binding rate of down fibers, high processing cost, etc., and achieve excellent antibacterial and deodorizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Down degreasing treatment: heat the degreasing agent to 35-40°C and mix for 5 minutes, then add the down that has been sterilized by high temperature and high pressure, so that the down is completely immersed in the degreasing agent, take out the down after 10 minutes, and wash it twice , and dried at 70-75°C;

[0025] (2) Preparation of antibacterial and deodorant treatment liquid: add boiling water to the antibacterial and deodorant finishing agent under stirring, so that the weight water content of the obtained antibacterial and deodorant treatment liquid reaches 65-70%, and naturally cool to room temperature;

[0026] (3) Down antibacterial and deodorizing treatment: crush 1kg of degreased down into coarse powder, pass through a 100-mesh sieve, then spray 0.05kg of antibacterial and deodorant treatment solution, mix thoroughly, and heat up at a rate of 2-3°C / min Heat up to 65-70°C and keep mixed for 15 minutes, then add water at 15-20°C dropwise at a rate of 2-3...

Embodiment 2

[0032] (1) Down degreasing treatment: heat the degreasing agent to 35-40°C and mix for 5 minutes, then add the down that has been sterilized by high temperature and high pressure, so that the down is completely immersed in the degreasing agent, take out the down after 10 minutes, and wash it twice , and dried at 70-75°C;

[0033] (2) Preparation of antibacterial and deodorant treatment liquid: add boiling water to the antibacterial and deodorant finishing agent under stirring, so that the weight water content of the obtained antibacterial and deodorant treatment liquid reaches 65-70%, and naturally cool to room temperature;

[0034](3) Down antibacterial and deodorant treatment: crush 1.5kg of degreased down into coarse powder, pass through a 100-mesh sieve, then spray 0.1kg of antibacterial and deodorant treatment solution, mix thoroughly, and heat up at 2-3°C / min Heat up to 65-70°C and mix for 15 minutes, then add water at 15-20°C dropwise at a rate of 2-3ml / min under stirri...

Embodiment 3

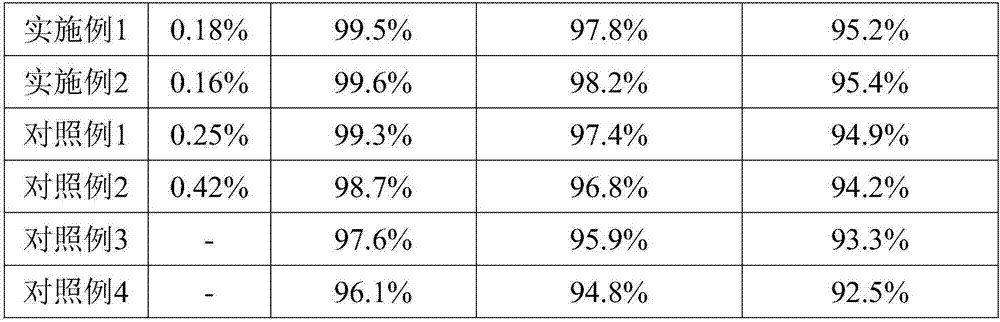

[0072] The eiderdown fiber of embodiment 1, embodiment 2, comparative example 1, comparative example 2 is carried out to measure the feather residual fat rate respectively, and measure embodiment 1, embodiment 2, comparative example 1, comparative example 2, comparative example 3 and The bacteriostatic rate of down fiber made in comparative example 4 to Staphylococcus aureus, Candida albicans and E. The bacteriostatic rate of coccus and Escherichia coli, the results are shown in Table 1.

[0073] Down residual fat rate and antibacterial rate of down fiber made by the present invention in table 1

[0074]

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com