Method for producing bamboo fiber

A production method and bamboo fiber technology, which are applied in the directions of fiber processing, fiber mechanical separation, and chemical production of bast fibers, etc. problem, to solve the problem of efficient large-scale production, superior performance-price ratio, and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

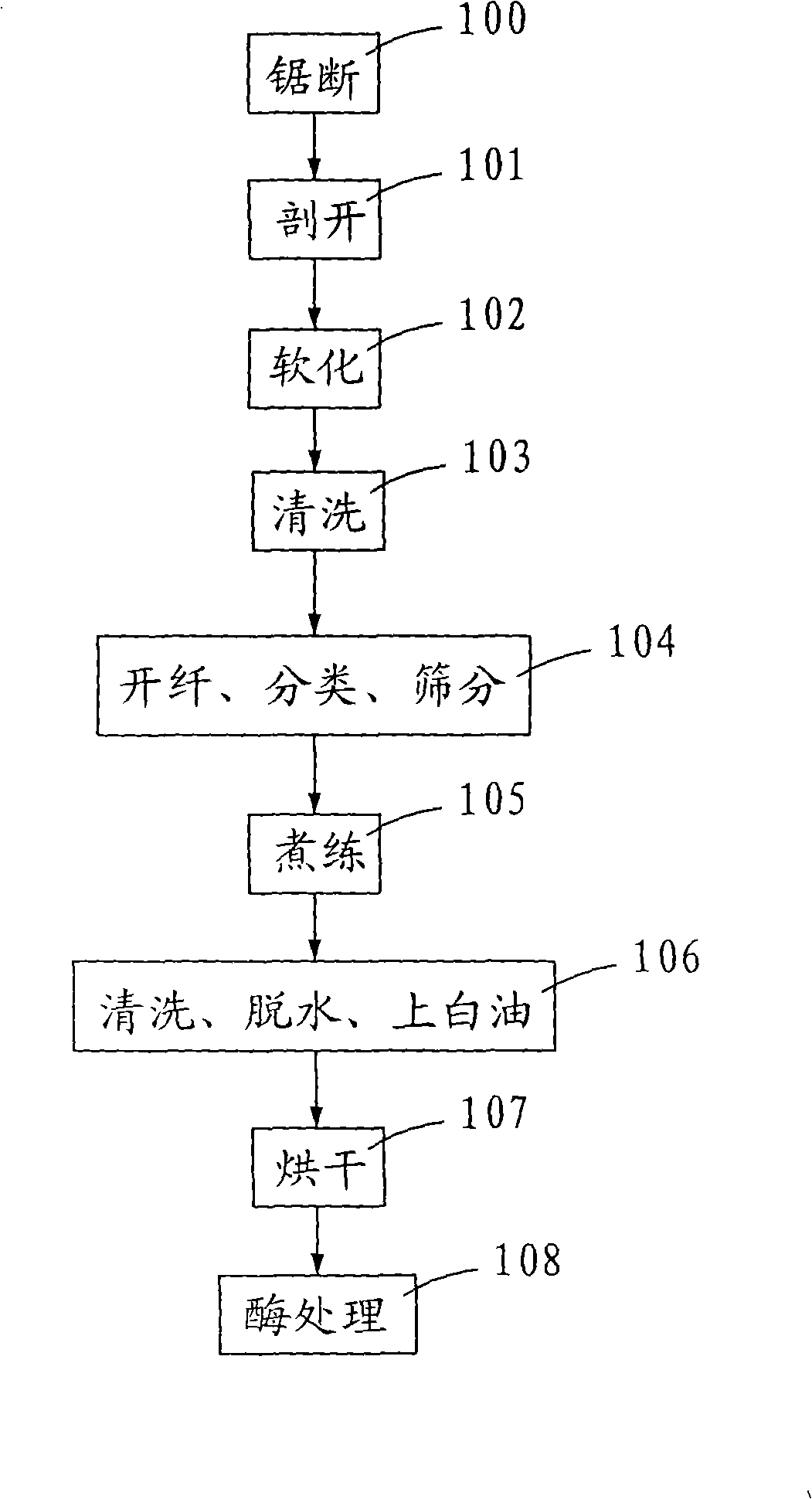

[0050] see figure 1 Shown is a schematic diagram of the process flow of the first embodiment of the present invention.

[0051] Step 100: sawing off: sawing bamboo materials such as three-year-old Moso bamboo, Ci bamboo or green bamboo according to the specified length of the tip, middle and head of the bamboo, wherein the length of the middle part is cut to 5 meters, and the length of the tip and head is 1 to 3 meters .

[0052] Step 101: Cut open: Cut the tip, middle and head of the bamboo into two half cylinders respectively.

[0053]Step 102: softening: then sent to the tip, middle, and head softening tanks for soaking and softening. The softening solution is water, sodium hydroxide, sodium carbonate, sodium sulfite, and sodium silicate in a mass ratio of 100:1:2:0.5:0.2 The ratio of bamboo is prepared, and the bamboo is completely submerged in the softening solution. When softening, it is heated to 90 ° C and kept for 150 minutes.

[0054] Step 103: Cleaning: soak the ...

no. 2 example

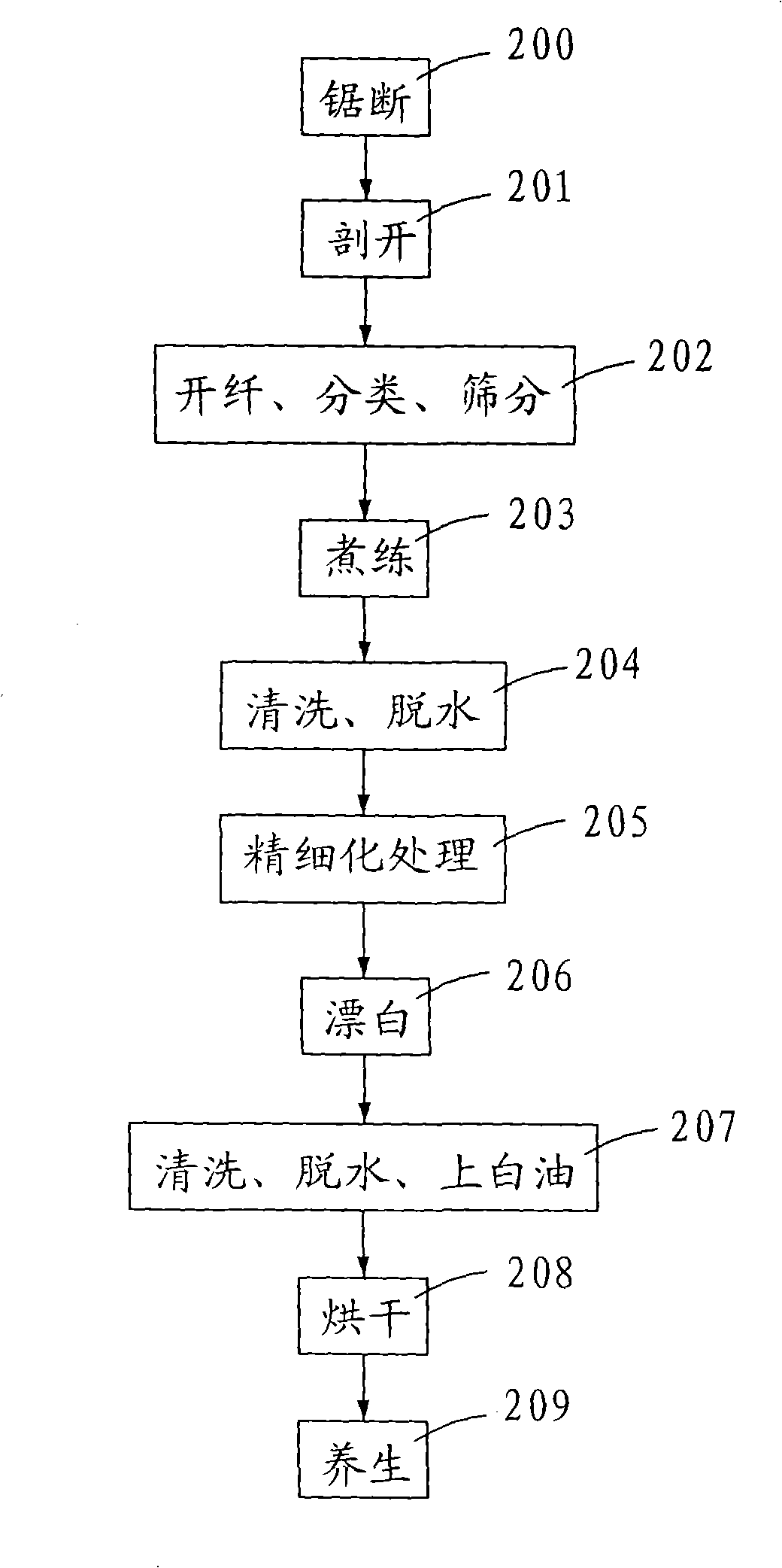

[0062] see figure 2 Shown is a schematic diagram of the process flow of the second embodiment of the present invention.

[0063] Step 200: sawing off: sawing the bamboo materials such as annual moso bamboo, Ci bamboo or green bamboo according to the specified length of the tip, middle and head of the bamboo, wherein the length of the middle part is cut to 8 meters, and the length of the tip and head is 1-2 meters.

[0064] Step 201: Cut open: Then cut the tip, middle and head of the bamboo into two half cylinders.

[0065] Step 202: Fiber opening, classification, and screening: send the bamboo to the bamboo fiber opening separator for processing. After combing, fiber opening, and airflow classification, the bamboo powder is removed by a vibrating screen to obtain graded bamboo filaments shaped fibers.

[0066] Step 203: scouring: put the bamboo filamentous fiber into a cooking pot (pool) and heat and scorch for 60 minutes. The temperature during scouring is 100° C., and the...

no. 3 example

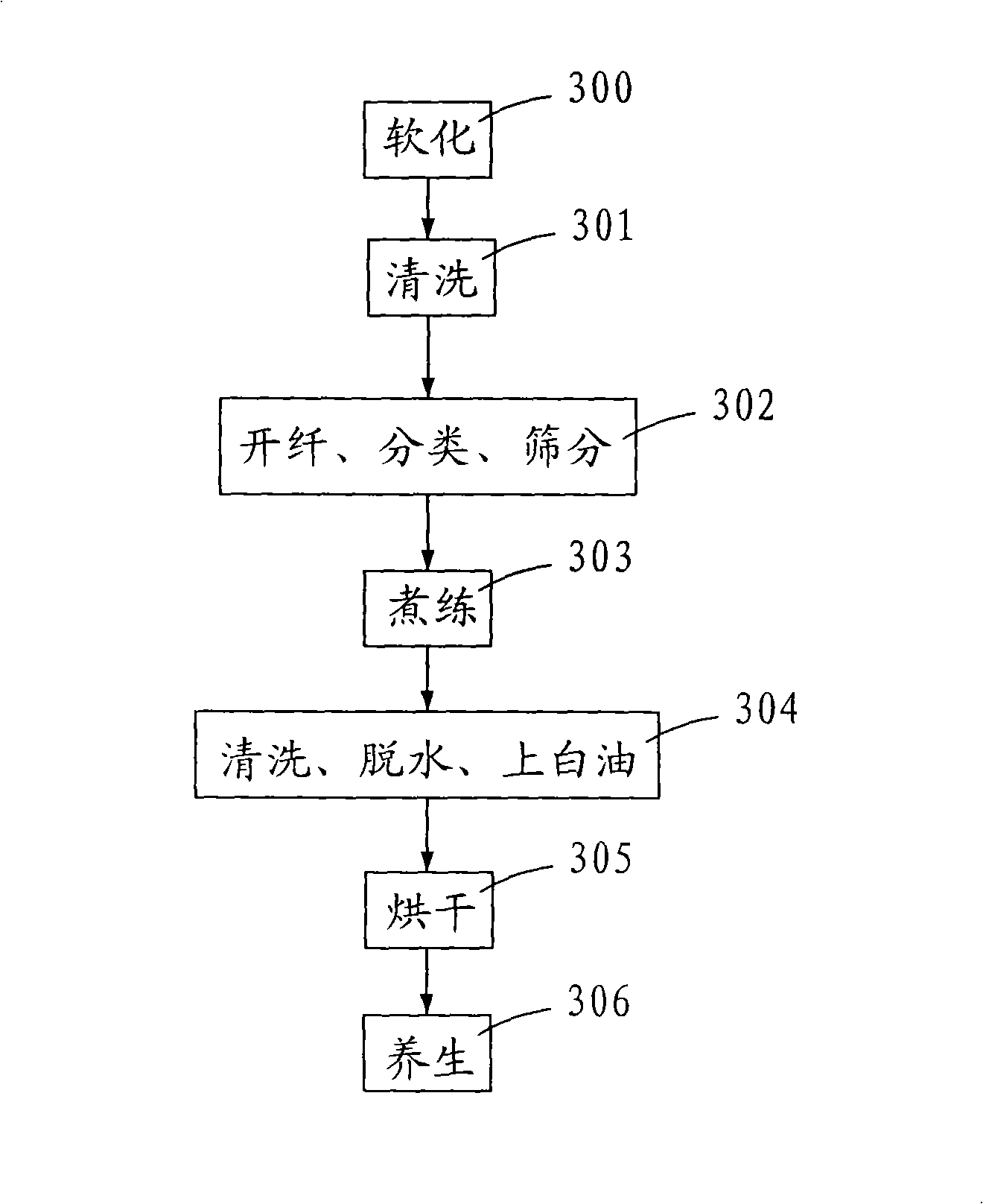

[0075] see image 3 Shown is a schematic process flow diagram of the third embodiment of the present invention.

[0076] Step 300: softening: put the bamboo leftovers into the softening pool to soak and soften, the softening solution is prepared with water, sodium hydroxide, sodium carbonate, sodium sulfite, and sodium silicate according to the mass ratio of 25:1:2:0.5:0.2, and make The bamboo is completely submerged in the softening solution, and the softening time is 10 days at room temperature.

[0077] Step 301: Cleaning: soak the softened bamboo in a designated cleaning pool for 15 minutes, then rinse and send to the area to be processed to dry.

[0078] Step 302: Fiber opening, classification, and screening: send the dried bamboo to the bamboo fiber opening and separating machine for processing, and then use a vibrating screen to remove the bamboo powder to obtain a graded product after combing, fiber opening, and airflow classification Bamboo filaments.

[0079] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com