Silicon rubber material containing titanate component

A technology of silicone rubber and titanate, which is applied in the field of silicone rubber materials, can solve the problems of silicone rubber tearing and limited processing performance improvement, and reduce the physical properties of products, and achieve the effects of improved stiffness, reasonable design, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

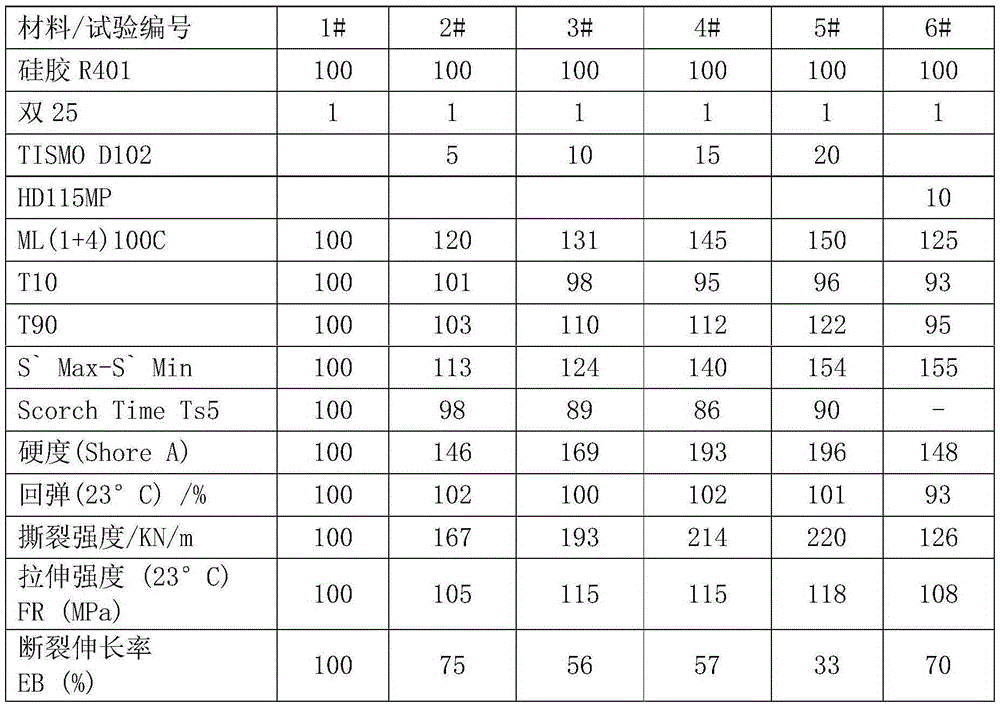

Embodiment 1

[0015]

[0016] Wherein 1# is the reference formula.

[0017] Silica gel R401 was purchased from Wacker Chemicals (China) Co., Ltd.

[0018] Acicular potassium titanate: D102, which is acicular potassium titanate fiber treated with silane on the surface, was purchased from Zhangjiagang Otsuka Chemical Co., Ltd.

[0019] White carbon black: HD115MP, purchased from Wuxi Quecheng Silicon Co., Ltd.

[0020] Vulcanizing agent double 25: purchased from Hubei Minhe Chemical Co., Ltd.

[0021] Mix the silicone rubber, potassium titanate fiber and vulcanizing agent in an open mill to prepare the rubber compound, which can be vulcanized by conventional vulcanization methods, such as in an oil heating, steam heating or electric heating vulcanizing machine, or by Manufactured by extrusion or calendering equipment, the vulcanization temperature is 150-200°C.

[0022] Can draw by embodiment 1:

[0023] 1. After adding potassium titanate fiber, as the number of parts increases, the cr...

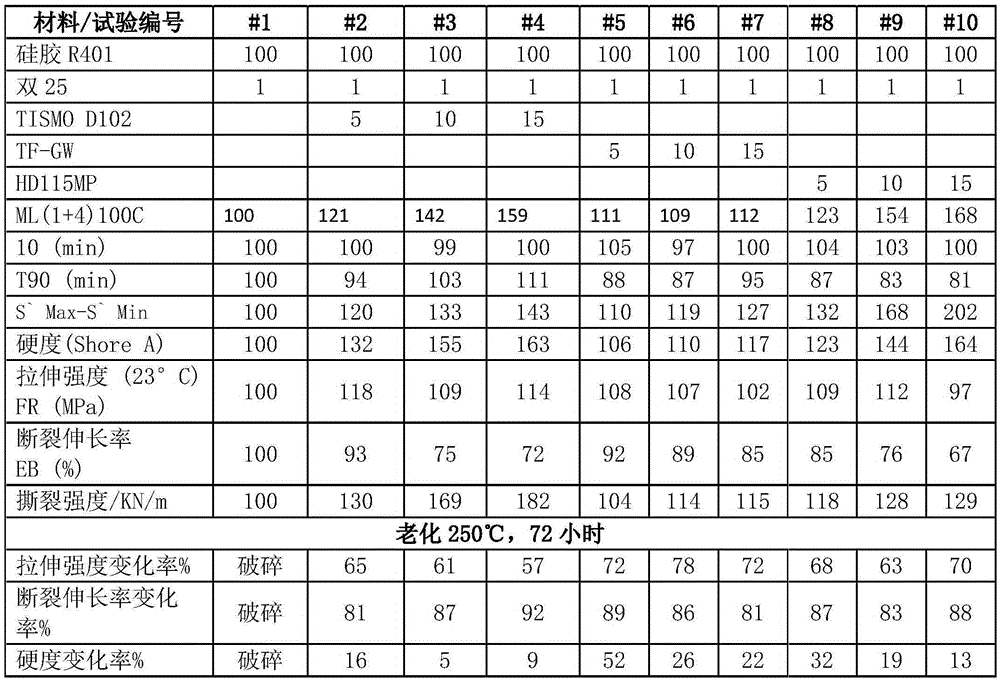

Embodiment 2

[0027]

[0028] Wherein 1# is the reference formula.

[0029] Silica gel R401 was purchased from Wacker Chemicals (China) Co., Ltd.

[0030] Vulcanizing agent double 25: purchased from Hubei Minhe Chemical Co., Ltd.

[0031] Acicular potassium titanate: D102, which is acicular potassium titanate fiber treated with silane on the surface, was purchased from Zhangjiagang Otsuka Chemical Co., Ltd.

[0032] TF-GW is silane-treated flaky potassium titanate, purchased from Zhangjiagang Otsuka Chemical Co., Ltd.

[0033] White carbon black: HD115MP, purchased from Wuxi Quecheng Silicon Co., Ltd.

[0034] Mix silicone rubber, potassium titanate fiber and peroxide vulcanizing agent in a rubber mill to prepare a compound rubber, which can be vulcanized using conventional vulcanization methods, such as oil heating, steam heating or electric heating vulcanizing machine , It can also be made by extrusion or calendering equipment, and the vulcanization temperature is 150-200 °C.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com