Self-reinforced polymer composite and preparation method thereof

A technology of composite materials and polymers, which is applied in the fields of physical treatment, textile and papermaking, radioactive element fiber treatment, etc., can solve the problems of strict preparation process requirements, and achieve the effect of simple preparation method and realization of structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention at first provides a kind of preparation method of self-reinforced polymer composite material, and this method comprises:

[0018] Step 1: put polyethylene fiber (ethylene fiber) into Co-60 source or electron beam, under vacuum or nitrogen atmosphere, carry out irradiation crosslinking to polyethylene fiber, obtain the polyethylene after crosslinking;

[0019] Step 2: Mixing the cross-linked polyethylene obtained in Step 1 with polyethylene to obtain a self-reinforced polymer composite material.

[0020] According to the present invention, there is no special limitation on the polyethylene fibers, commercially available products can be used, preferably polyethylene chopped fibers or polyethylene continuous fibers, and the irradiation dose is preferably 30-300 kGy, more preferably 50 ~250kGy.

[0021] According to the present invention, the polyethylene fiber to polyethylene mass ratio is preferably (10-100): 100, more preferably 50: 100; the polyet...

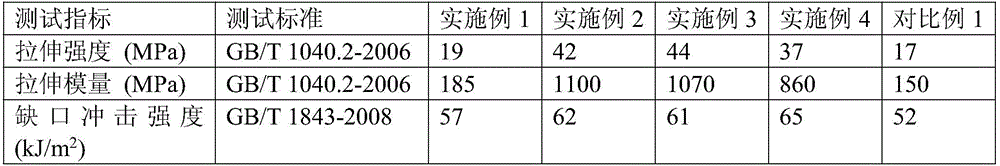

Embodiment 1

[0025] Weigh 10g of chopped polyethylene fiber, put it into a Co-60 source, and irradiate in a vacuum atmosphere with a radiation dose of 50kGy, then add the irradiated polyethylene fiber and 100g of polyethylene pellets to the banburying In the machine, melt blending was carried out at 140°C to obtain self-reinforced polyethylene composites. The mechanical properties of the self-reinforced polyethylene composite material obtained in Example 1 are shown in Table 1.

Embodiment 2

[0027] Weigh 500g of continuous polyethylene fiber, put it into a Co-60 source, and irradiate it in a nitrogen environment with a radiation dose of 220kGy; put the irradiated polyethylene fiber and 500g of polyethylene pellets into the twin-screw extrusion The extruder feeding system was used for extrusion processing, and the temperature of the twin-screw extruder was set at 160°C to obtain self-reinforced polyethylene composites. The mechanical properties of the self-reinforced polyethylene composite material obtained in Example 2 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com