Patents

Literature

61results about How to "Change processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

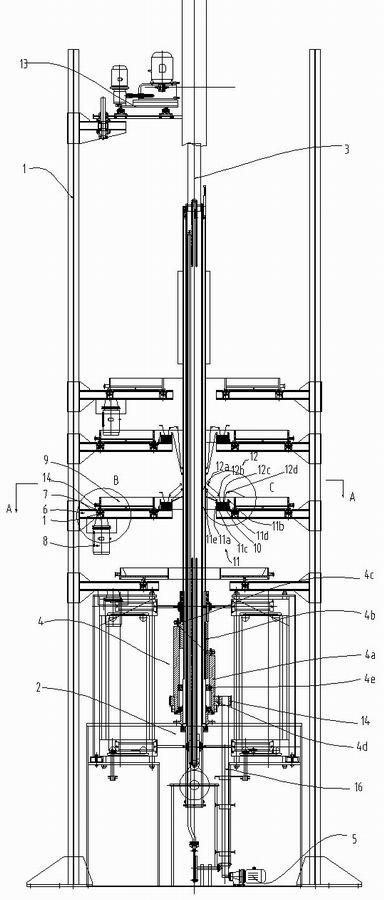

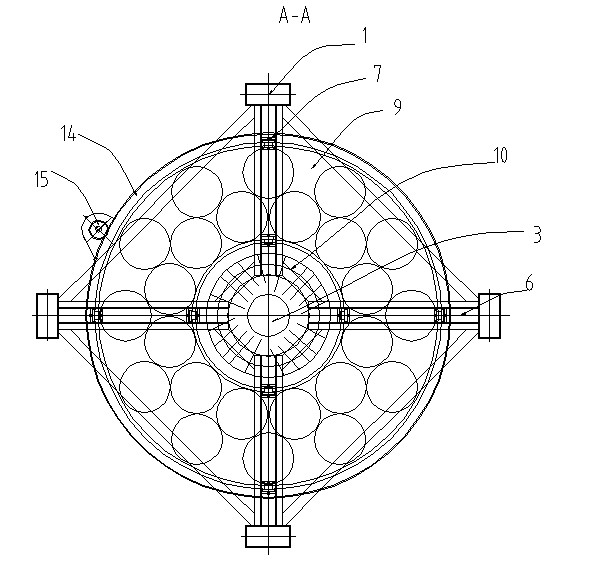

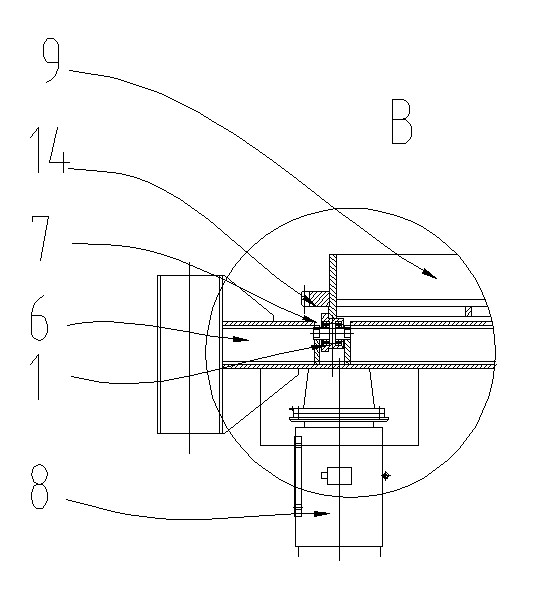

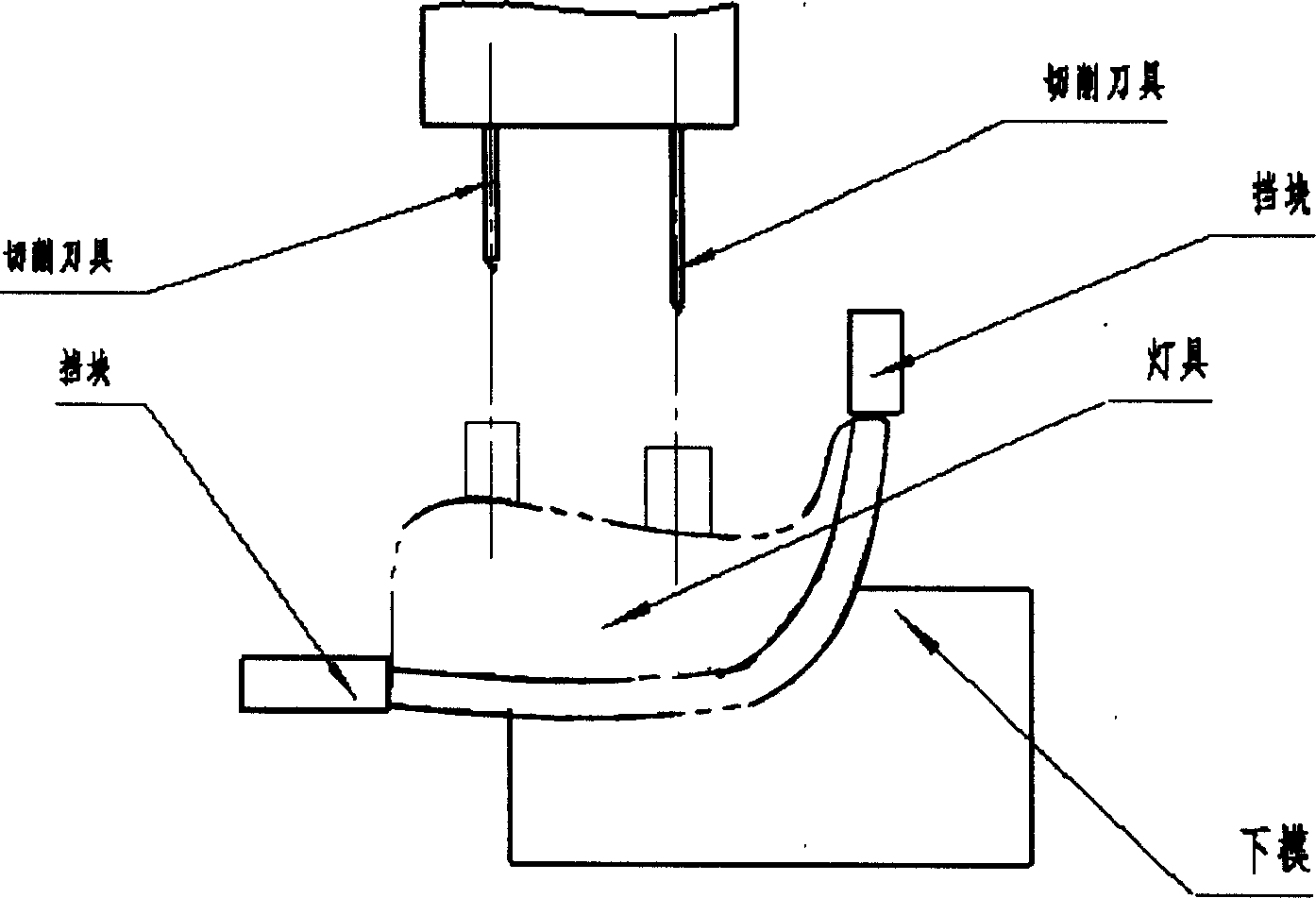

Vertical pipe production line

The invention discloses a vertical pipe production line. The vertical pipe production line is characterized in that: a core shaft support is arranged on a lower portion of a frame, a mold core shaft is erectly fixed on the core shaft support, a propulsion device connected with a first power generator is arranged on a lower portion of the mold core shaft; at least a support frame is fixed on the frame, a circular orbit and a second power generator are arranged on the support frame, the core shaft support is positioned in the center of the circular orbit, a circumferential yarn disk is arrange on the circular orbit and is connected with the second power generator; a circular dipping groove is arranged on the support frame approaching a circumference inside the circular orbit, a axial fiber position frame and a circumferential fiber position frame are distributed on the circular dipping groove; a product synchronization cutting apparatus is fixed on an upper end of the frame, the productsynchronization cutting apparatus is positioned above the mold core shaft. According to the present invention, the vertical pipe production line is adopted, such that circumferential winding of the continuous fibers and axial arrangement of the continuous fibers are combined well so as to improve product quality and processing stability.

Owner:李长城

Preparation process for high-strength high-conductivity micro copper wire

The invention discloses a preparation process for a high-strength high-conductivity micro copper wire. The preparation process comprises the following steps: S1, adding electrolytic copper into a smelting furnace, preserving heat and melting the electrolytic copper completely to obtain molten copper, introducing an inert gas, adding a composite refining agent, standing and slagging; S2, detecting that the molten copper comprises the following components in percentage by weight: 0.45 to 0.55 percent of Ti, 0.25 to 0.35 percent of Zr, 0.07 to 0.09 percent of Te, 0.07 to 0.09 percent of La, 0.03 to 0.05 percent of Y, 0.15 to 0.25 percent of Sn, less than or equal to 0.05 percent of Mg, and the balance of Cu; S3, enabling a crystallizer of a continuous casting machine to extend into the molten copper, and drawing upwards through a drawing roller mechanism to form an oxygen-free copper rod; S4, extruding the oxygen-free copper rod continuously and drawing repeatedly to obtain the high-strength high-conductivity micro copper wire. According to the copper wire which is prepared by the preparation process, the electric conductivity reaches over 95 percent IACS, and moreover, the tensile strength is also over 480 MPa.

Owner:安徽晋源铜业有限公司

Hot wind and microwave combined processing method for tilapia slice

InactiveCN101366408AChange singleChange processing performanceMeat/fish preservation by dryingSingle processEngineering

The invention provides a method for processing tilapia fillet by combination of hot wind and microwave, which belongs to the technical field of aquatic product processing, and relates to a novel technique for processing the tilapia fillet by dehydration. The method is to uses fresh tilapia or frozen tilapia as a raw material to produce a product through selecting, pretreating, flaking, slicing, hot wind drying, microwave drying, cooling, packaging and storing. The novel method for processing the tilapia fillet by the combination of hot wind and microwave solves the problems of long time consumption, low efficiency, reduced product quality and the like for the prior hot wind dehydration, overcomes the cracking defect which often occurs in processing a high water content material by microwave, organically integrates two processing technologies of hot wind and microwave, realizes that safe moisture content can be achieved in a short period, improves the dehydrating efficiency and product quality, prominently improves the storage quality of the tilapia, and is beneficial to change the situations of single processed product of the tilapia and unprogressive processing level. The method is also suitable for processing dehydrated fillets, such as bighead, chub, grass carp and other fresh-water fish.

Owner:HAINAN UNIVERSITY

Method for processing summer multi-kind tea

InactiveCN105394227AImprove competitiveness and adaptabilityMeet needsPre-extraction tea treatmentBlack teaAdditional values

The invention provides a method for processing summer multi-kind tea and belongs to the tea processing technology field. In the method, black tea, dark tea, yellow tea and green tea are processed by utilization of summer tea in summer. The situation is changed that tea is not processed or only little black tea is processed in most tea regions in summer, and products with multiple tea kinds are produced. Multiple tea kinds are developed mainly according to different mature degrees of fresh leaf raw materials required by different tea kinds, collection and preparation time is adjusted effectively, the quality of each batch of finished tea is raised, and the additional value is raised. In addition, multiple tea kinds are developed, tea machines can be used in a crossing manner for multiple times, the idle machine time is shortened, the usage time of the machines is prolonged, the comprehensive utilization rate of the whole tea machines is raised fully, the depreciation cost is lowered, and the production benefit is raised.

Owner:GUANGXI POLYTECHNIC

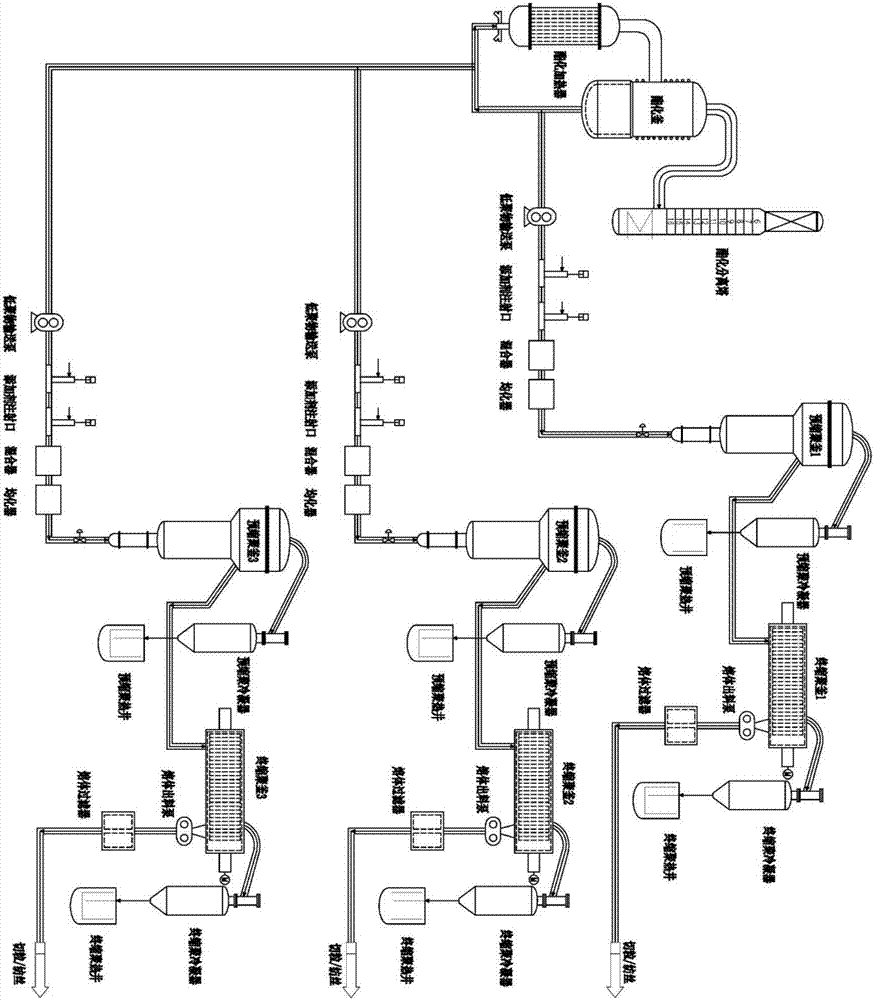

Method for producing multifunctional differentiated polyester fiber

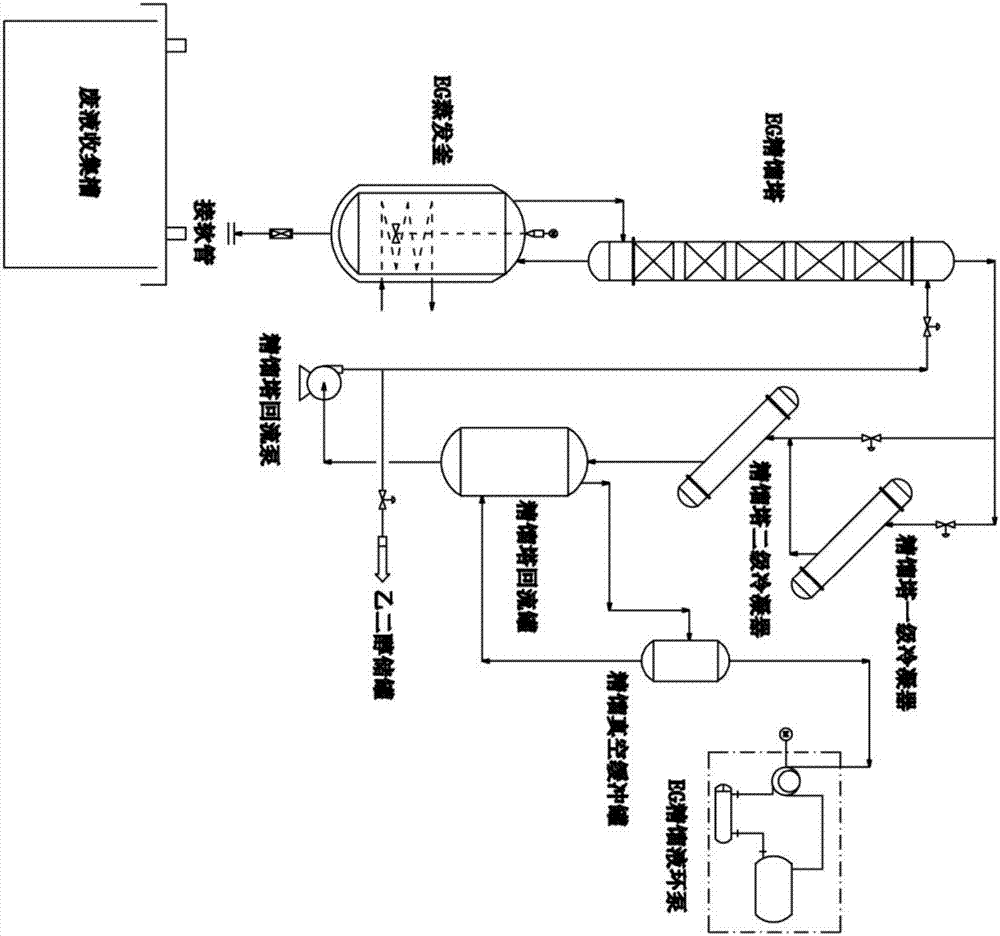

InactiveCN107090606AReduce lossImprove continuityMonocomponent polyesters artificial filamentFiberPolyethylene terephthalate glycol

The invention relates to a method for producing multifunctional differentiated polyester fiber. The method comprises the following steps that raw materials of purified terephthalic acid and ethylene glycol are firstly subjected to an esterification reaction in an esterification kettle to obtain a dimethyl terephthalate oligomer, then mixtures obtained after different modifiers are added into the dimethyl terephthalate oligomer on line separately through a pipeline are delivered to a first pre-polycondensation kettle, a second pre-polycondensation kettle and a third pre-polycondensation kettle separately to obtain pre-polymers of a certain viscosity, then the pre-polymers are delivered to a first final polycondensation kettle, a second final polycondensation kettle and a third final polycondensation kettle to obtain multifunctional and differentiated melt, and subsequently pelletizing or direct spinning is conducted. In the method for producing the multifunctional differentiated polyester fiber, a 'one head and three tails' technological process in a three-kettle procedure technology is adopted, the heat loss is effectively reduced, electric energy loss of electric equipment is reduced, more energy is saved, and the running cost is lower; the equipment layout is more compact, and the operation space is efficiently utilized.

Owner:TONGKUN GRP +1

High-strength high-electroconductivity rare-earth and copper alloy electromagnetic wire and preparation process thereof

InactiveCN103971781AImprove heat strengthEnhanced interactionMetal/alloy conductorsCable/conductor manufactureRare earthHigh intensity

The invention discloses a high-strength high-electroconductivity rare-earth and copper alloy electromagnetic wire and a preparation process thereof. The high-strength high-electroconductivity rare-earth and copper alloy electromagnetic wire is characterized in that the electromagnetic wire is composed of 1.05-1.10wt% of Ni, 0.55-0.60wt% of Zr, 0.25-0.30wt% of La, 0.25-0.30wt% of Y, smaller than or equal to 0.10wt% of Sc and the rest Cu. The high-strength high-electroconductivity rare-earth and copper alloy electromagnetic wire produced by the preparation process is high in strength and good in tensile performance, and electroconductivity is greatly improved.

Owner:HUNAN LIANDA FENGRONGTONG ALUMINUM

Antibacterial stainless steel and preparation method thereof

InactiveCN103451631AReduce manufacturing costDoes not affect mechanical propertiesLiquid/solution decomposition chemical coatingMechanical propertyBond Force

The invention discloses antibacterial stainless steel and a preparation method thereof. The method comprises the steps of ultrasonic deoiling, pickling, diffusion coating, flushing and drying. According to the method, a nano-titanium-dioxide antibacterial material is formed on the surface of stainless steel through diffusion coating, the preparation cost is low, the process is simple, and the bonding force between an antibacterial layer and a stainless steel base body is strong. Different from that antibacterial elements are added into the stainless steel, nano titanium dioxide is formed on the surface of the stainless steel through diffusion coating, so that the mechanical properties of the stainless steel are not affected, and the processability of a stainless-steel material is not changed. Different from ionic antibacterial materials, nano titanium dioxide is non-toxic and harmless and can not release metal ions to a contact environment during the process of disinfecting bacteria or inhibiting bacterial growth; meanwhile, the catalytic disinfection capacity of nano titanium dioxide is strong, so that harmful bacteria, such as Escherichia coli, staphylococcus aureus and the like, can be effectively disinfected.

Owner:庞晋山

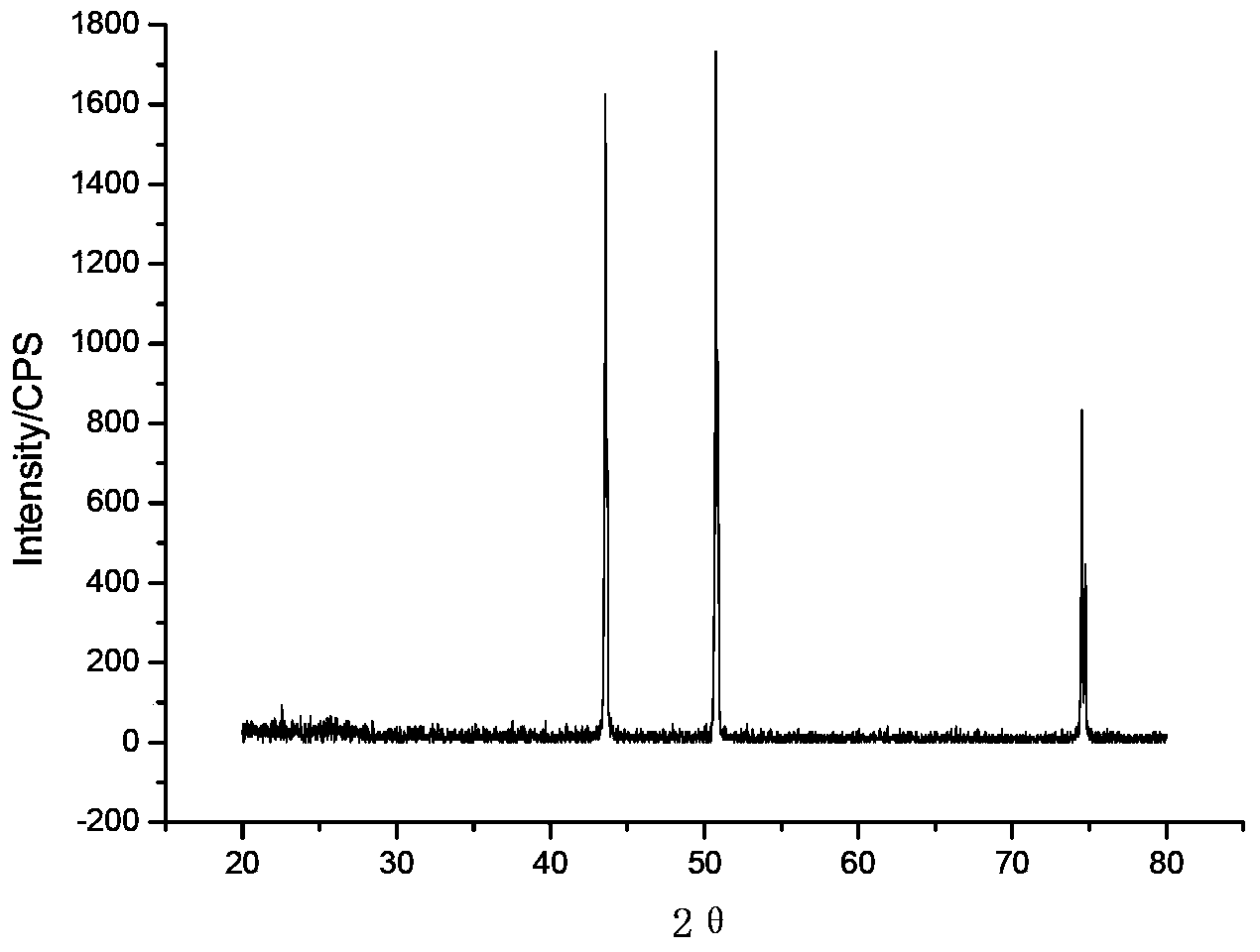

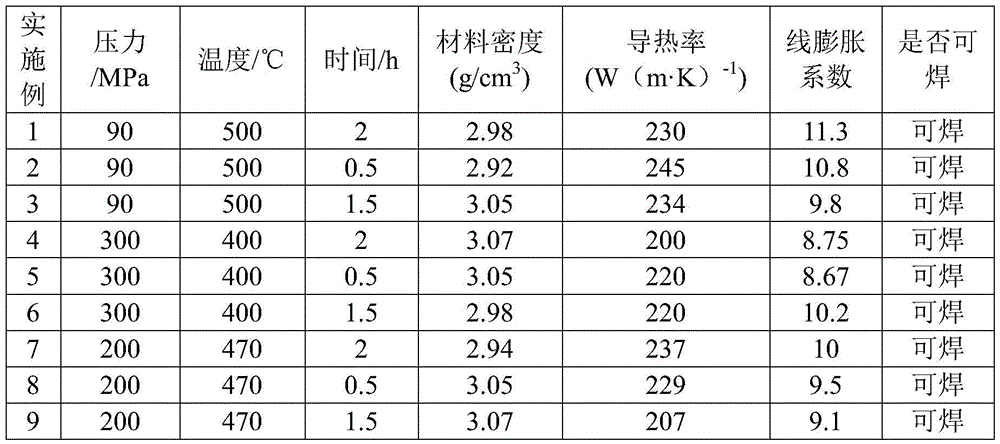

Preparing method of electronic packaging material

The invention provides a preparing method of an electronic packaging material. The electronic packaging material is composed of a base body and a reinforcement body; the base body comprises an aluminum alloy, and the reinforcement body comprises graphene oxide and SiC particles and comprises, by mass percentage, 2% of graphene oxide, 50% of SiC particles and the balance aluminum alloy powder; and the aluminum alloy powder comprises 70% of Al-Si, 10% of Al-Ti-B, 10% of Al-Be and 10% of Al powder. By the adoption of the method, the light electronic packaging material with the density lower than 3.1g / cm<3> and thermal conductivity larger than 180 W / (m K) can be prepared, and therefore the comprehensive performance of a military electronic device can be greatly improved; and the preparing method is suitable for producing and preparing of packaging materials of portable devices, military power hybrid circuits of aerospace and other fields sensitive to weight, carriers of microwave tubes, and heat-sink and super-power modules of a multi-chip assembly.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

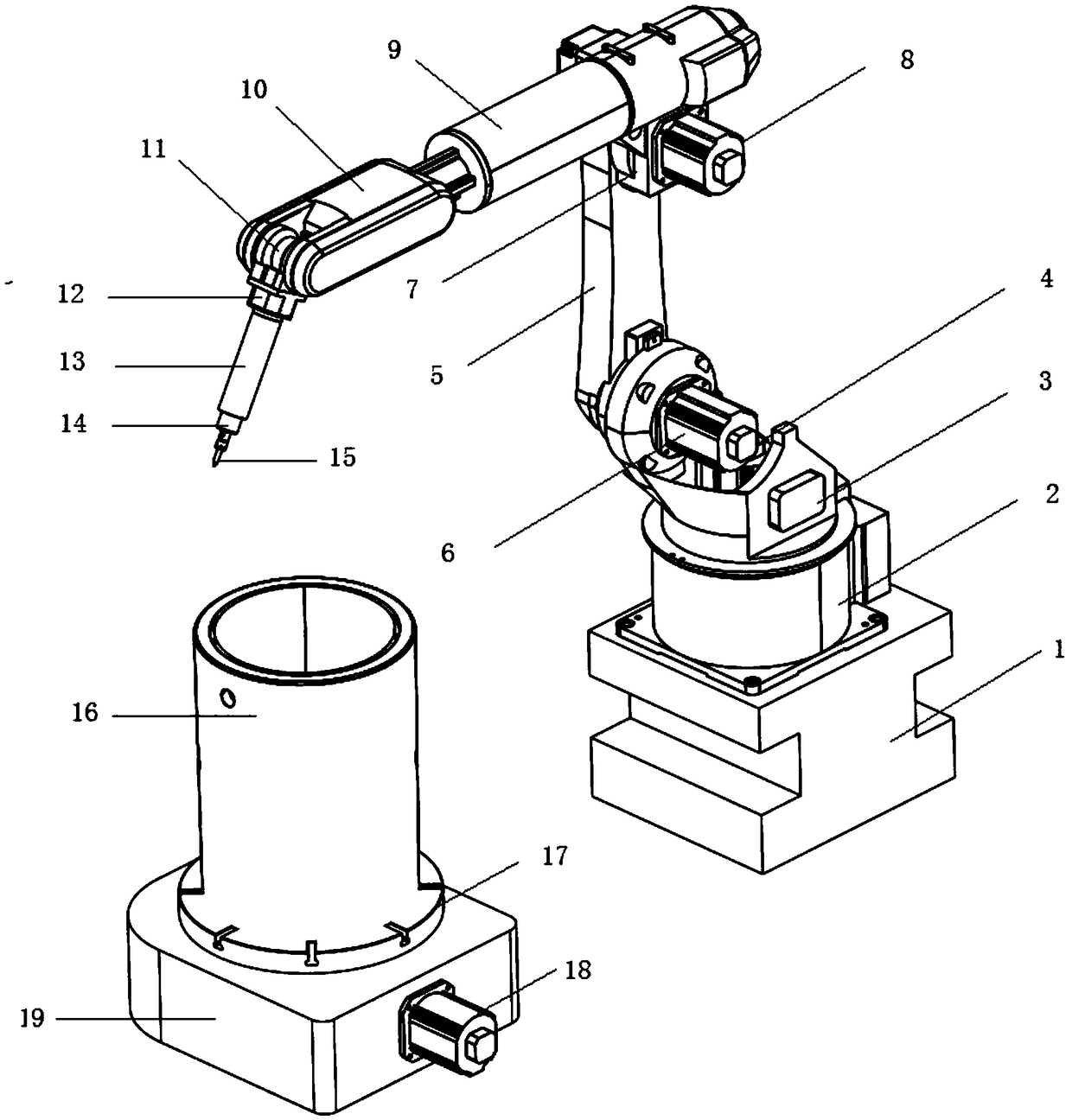

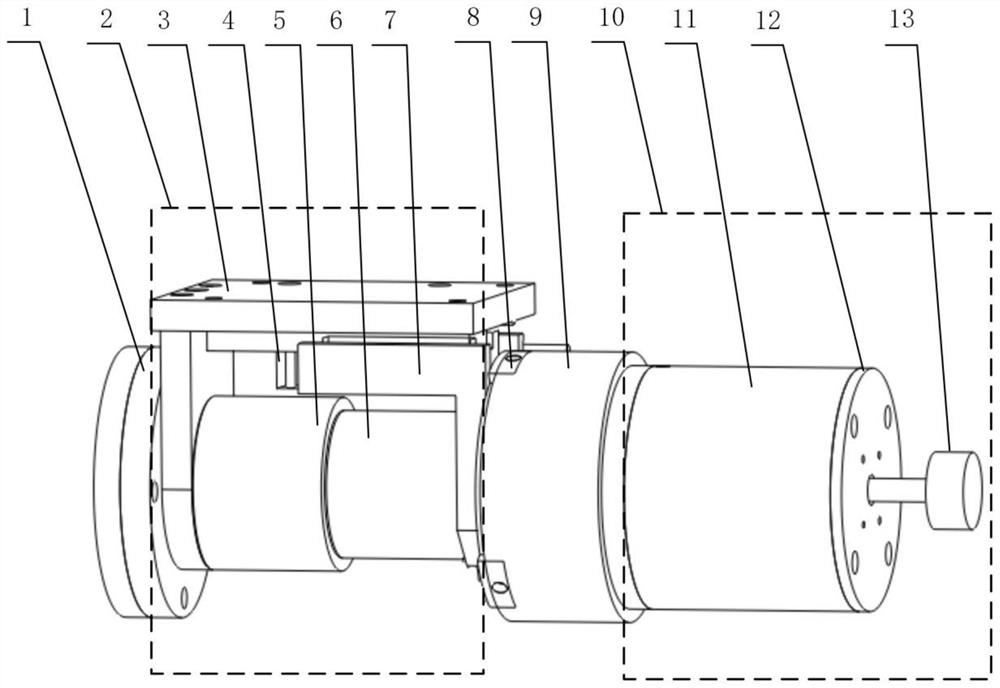

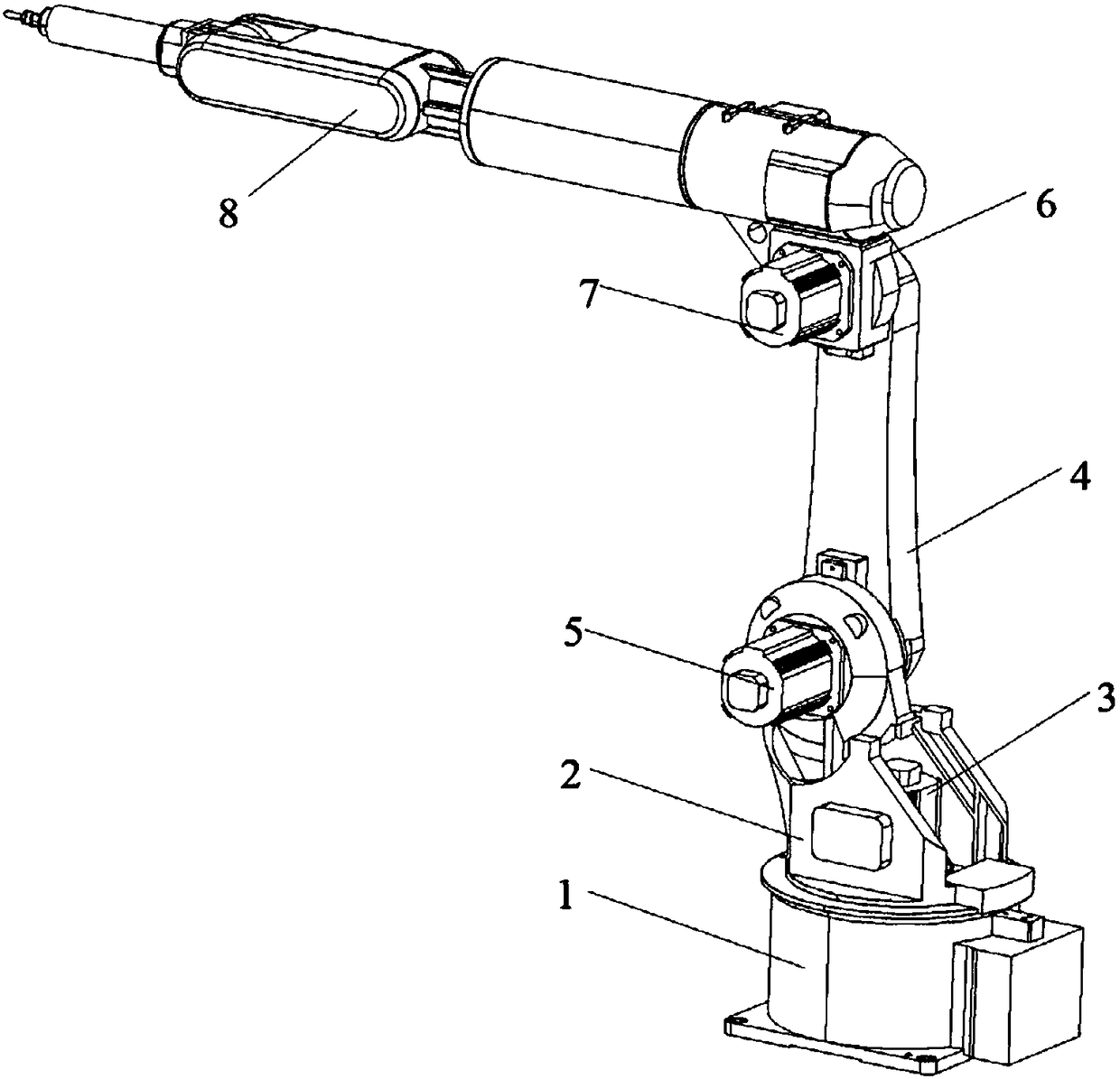

Automatic robot milling machining device for inner walls of cylindrical parts

PendingCN108655477AChange processing performanceSimple structureMilling equipment detailsManipulatorControl theoryMachining

The invention provides an automatic robot milling machining device for the inner walls of cylindrical parts. The automatic robot milling machining device mainly comprises a mechanical arm operation system, a wrist body system, a main shaft system and a rotation system. The mechanical arm operation system drives the wrist body system to move; the wrist body system drives the main shaft system to move; a tool of the main shaft system rapidly rotates under the driving of an air source; and the rotation system drives a workpiece to rotate at a constant speed. The device provided by the invention is simple and compact, and applicable to milling machining for the inner walls with different thicknesses, of various magnesium alloy parts. The specific structural dimensions can be specially customized according to the different magnesium alloy parts; and the design flow is as follows: the dimensions of a rotation chuck are selected according to the dimensions of the machined workpiece, the rotational speed of a main shaft, the dimensions of the tool and the rotational speed of the rotation chuck are selected according to material characteristics, and a preset program flow of a robot is determined according to the structures of the inner walls of the parts. The automatic robot milling machining device is quite suitable for ultraprecision machining.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

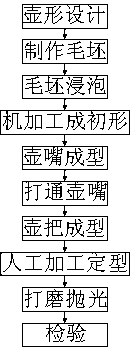

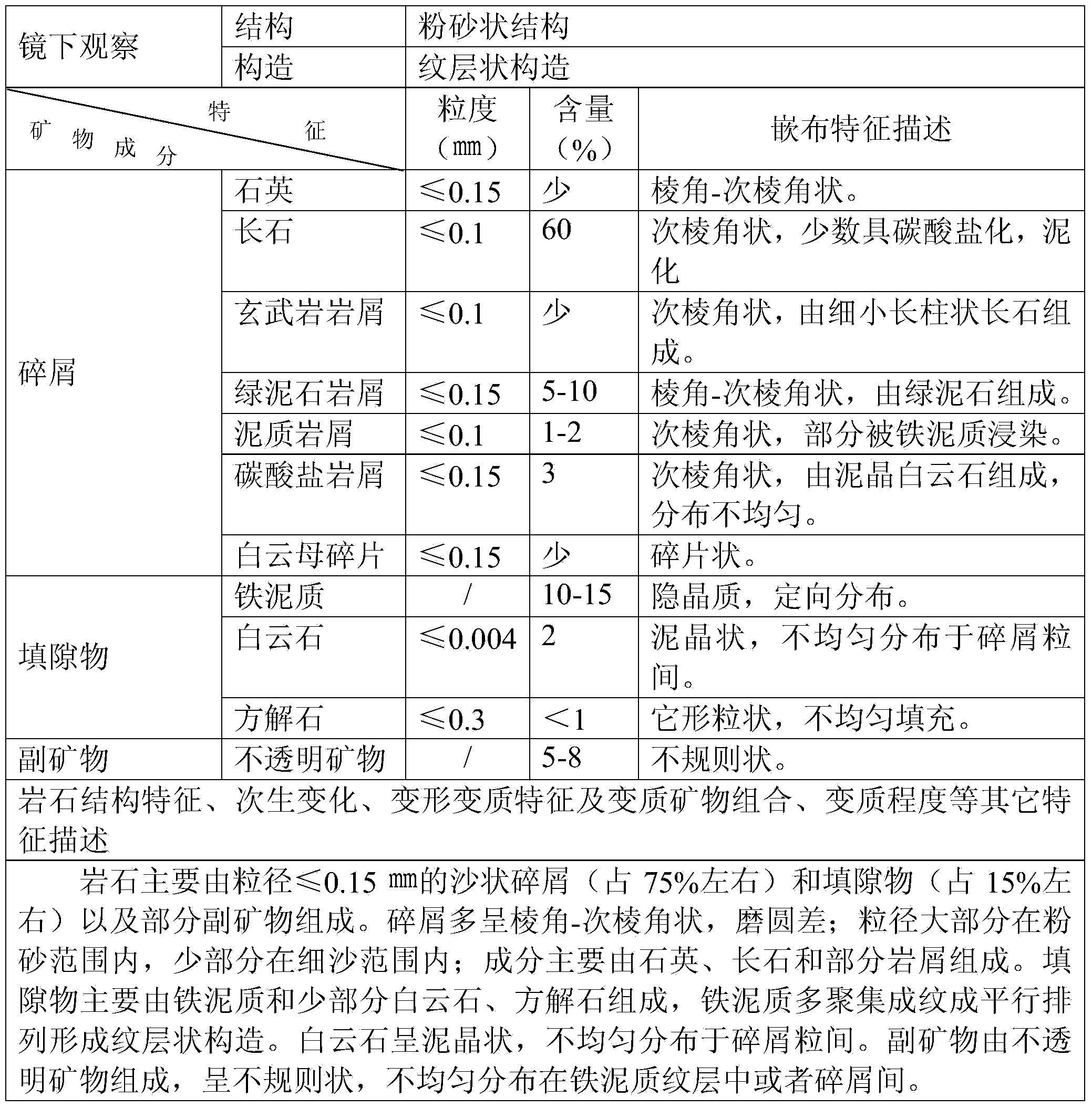

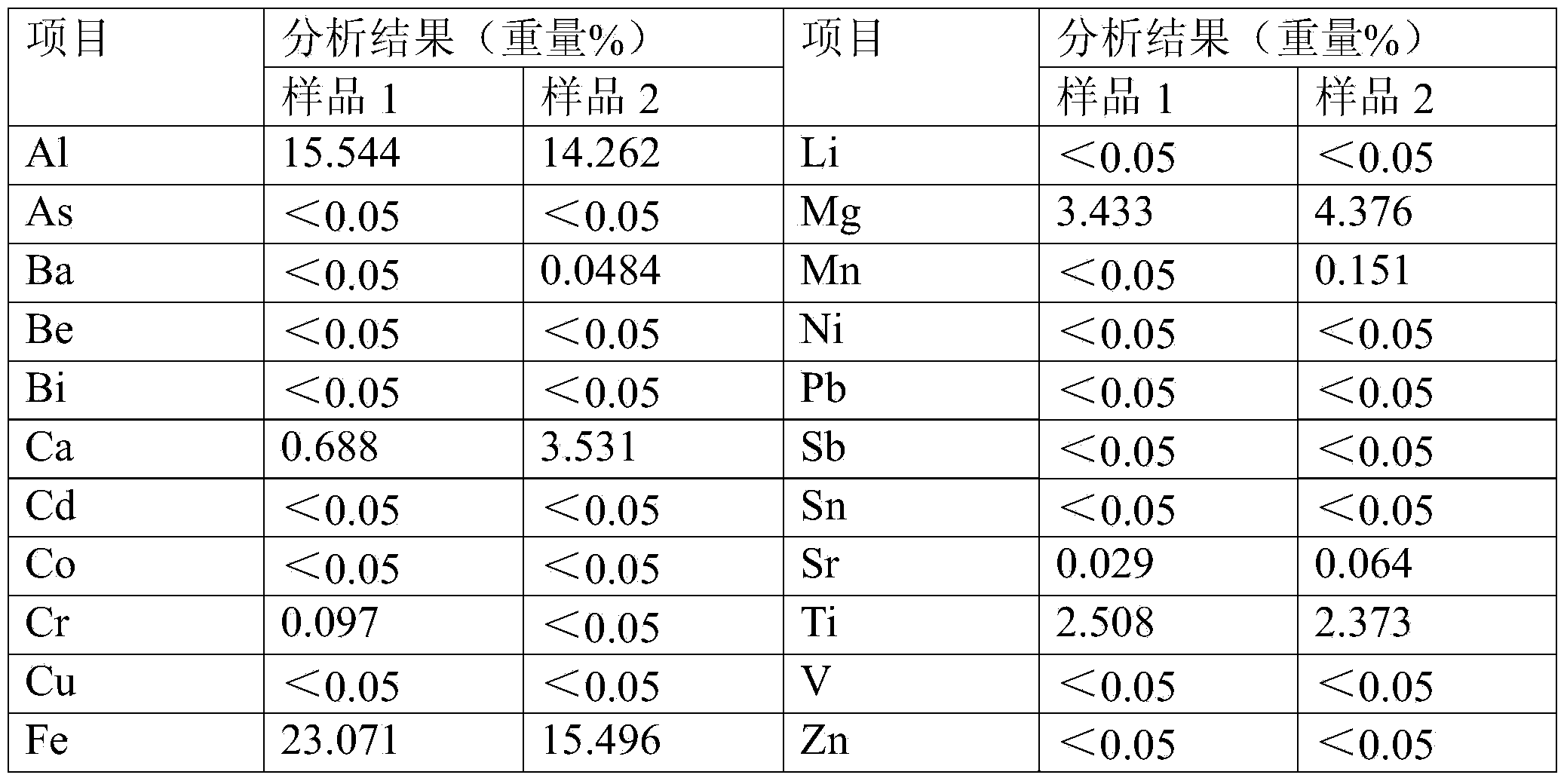

Technology method using siltstone for manufacturing stone pot

The invention discloses a technology method using siltstone for manufacturing a stone pot. The purpose is to provide the technology method which is high in machined finished product rate and good in quality. The technology method includes the following steps that (1), according to pot shape designing, the pot shape is designed according to the stone grain of the siltstone, and drawing is performed; (2), according to blank manufacturing, the big siltstone is cut into small blanks according to designing requirements; (3), according to blank soaking, the blanks are soaked into cold water for two or more days; (4), the blanks are machined to be in a initial type to form a teapot semi-finished product; (5), according to spout forming, a carving machine is adopted for machining the shape of a spout; (6), the spout is got through; (7), a pot handle is formed; (8), according to manual machining and shaping, the stone pot is machined locally and manually until the stone pot is machined to be in a designed size and a designed shape; (9), according to grinding and polishing, the outer surface and the inner surface of a pot body are ground and polished, so that a smooth surface of the pot body is formed; (10), the product is detected, and if detected to be qualified, the product is packaged to be put in storage.

Owner:赵剑锋 +2

Preparation method of damping paint

InactiveCN105176259AImprove sound insulationImprove insulation effectFireproof paintsJet aeroplaneEmulsion

The invention provides a preparation method of damping paint and belongs to the technical field of paint. The prepared paint is mainly used for vibration and noise reduction in the fields of automobiles, trains, steamboats, airplanes, engineering machinery and the like. The preparation method includes the following steps that firstly, acrylic emulsion and deionized water are weighed out and arranged in a stirring container, filler, mica powder, dispersant, defoamer and halogen-free flame retardant are added, the mixture is stirred for 20-28 min at the rotating speed of 500-800 r / min, and then mixed liquor is obtained; secondly, a coalescing agent, dispersant, defoamer and halogen-free flame retardant are added to the mixed liquor obtained in the first step, the mixture is stirred for 10-18 min at the rotating speed of 100-120 r / min, and then a thickening agent is added for thickness adjustment. The prepared paint has good damping, sound insulation, heat preservation and flame retardation performance.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Process for preparing cellulose acrylate composited high molecular degradable material

A degradable high-molecular cellulose-acrylate composition is prepared from lipophilic cellulose powder, water, emulsifier chosen from sodium laurysulfonate, polyoxyvinyl nonylphenolether, octylphenol polyoxyvinylether and sodium maleate, stabilizer (hexadecane) and disperser through proportional mixing, stirring while adding acrylate, heating, adding persulfate as trigger, heating while reacting, and baking.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

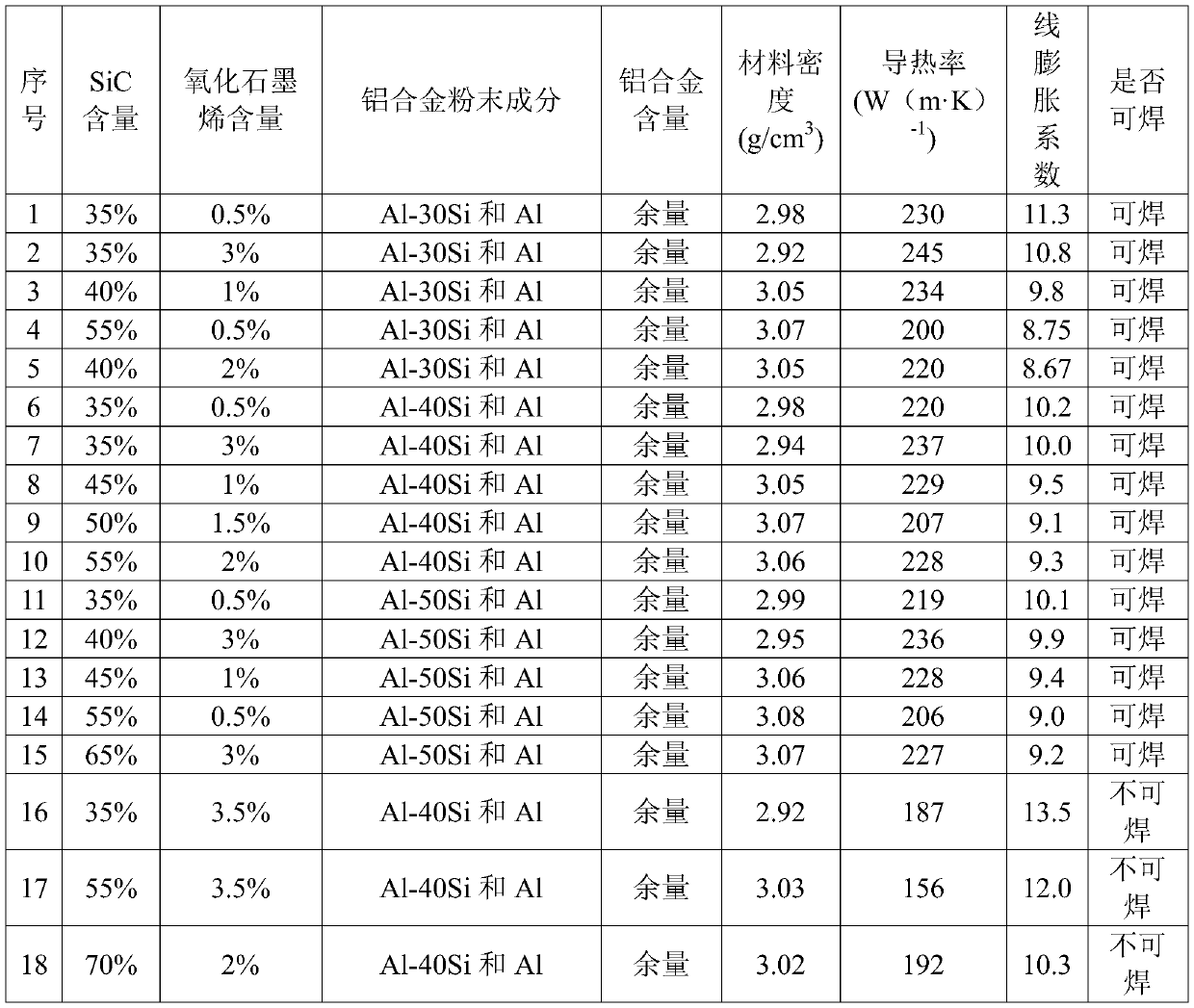

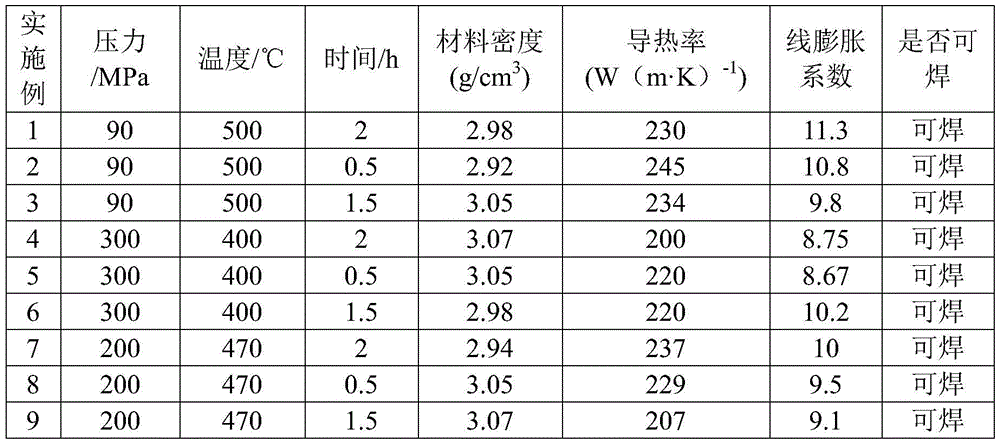

Electronic packaging material

InactiveCN105506402AImprove performanceGood effectSemiconductor/solid-state device detailsSolid-state devicesMicrowave tube5005 aluminium alloy

The invention provides an electronic packaging material which consists of a matrix and an enhanced body, wherein the matrix comprises an aluminium alloy, the enhanced body comprises, by mass percent, 0.5-3% of oxidized graphene, 35-65% SiC particles and the balance aluminium alloy powder consisting of 50% Al-Si alloy powder and 50% of Al alloy powder. With the adoption of the scheme, the light electronic packaging material with the density being under 3.1g / cm<3> and the heat conductivity being greater than 180W / (m.K) can be prepared, so that the comprehensive performances of military electronic equipment are improved greatly, and the electronic packaging material is applicable to portable components, military power hybrid circuits in the field of aerospace and in other fields sensitive to weight, carriers of microwave tubes, heat sinks of multi-chip modules, and super-high power modules.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method for electronic packaging material

The invention provides a preparation method for an electronic packaging material. The electronic packaging material is composed of a substrate and a reinforcement body, the substrate comprises aluminum alloy, and the reinforcement body comprises graphene oxide and SiC particles. The electronic packaging material comprises, by mass, 2% of the graphene oxide, 50% of the SiC particles, and the balance aluminum alloy powder. The aluminum alloy powder comprises 50% of Al-40Si alloy powder and 50% of Al-Be alloy powder. By means of the preparation method, the light electronic packaging material with the density being lower than 3.1 g / cm<3> and the thermal conductivity being larger than 180 W / (mK) is prepared, and accordingly the combination property of military electronic equipment is improved significantly; the method is suitable for producing and preparing packaging materials for portable devices, military power hybrid circuits used for the aerospace field and other fields which are sensitive to weights, carriers of microwave tubes, heat sinks of multi-chip assemblies and super-high-power modules.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Processing method for raising tail lamp matching precision

InactiveCN1868663AImprove matching accuracyGuaranteed matching accuracyOther manufacturing equipments/toolsFriction weldingAgricultural engineering

A manufacture method for improving the match accuracy of the tail lamp of car includes such steps as welding the casing of tail lamp with front cover, using said front cover to determine the installation position on tail lamp, and manufacturing the installation mechanism at determined position.

Owner:长春海拉车灯有限公司

Polyether, polyurethane thermoplastic elastomer

InactiveCN101153114AGood physical propertiesPromote environmental protectionPolyolefinPolymer science

A polyether and polyurethane thermoplastic elastomer is prepared through the following steps: 1) the trimethylolpropane and macromolecule phosphate react at a temperature between 50 DEG C and 70 DEG C according to a ratio of from (1 to 0.05) to (1 to 0.15); 2) the diphenylmethane diisocyanate and 1, 4-butanediol are added for secondary reaction, and the prepared polymer is cooled, cut, dehydrated and dried; 3) the polymer, ethylene-butadiene-styrene copolymer, triphenyl phosphate ester polymer, vinyl alcohol polymer, polyolefin base, four-pentaerythritol ester, 2-hydroxy-4-octanoxy-benzophenone, 2-methyl-4-isothiazolone and quarter ammonia salt compound are added into a high-speed mixer and are mixed for 30 minutes to 60 minutes; 4) the mixed materials are added into an extruder for preheat, melting, plasticization, molding and extrusion; 5) the extruded polymer is cooled, cut and dried to get the product. The present invention has the outstanding physical properties, environmental protection and flame resistance; the whole production process has no 'three-waste' emission.

Owner:安徽硕冠电子科技有限公司

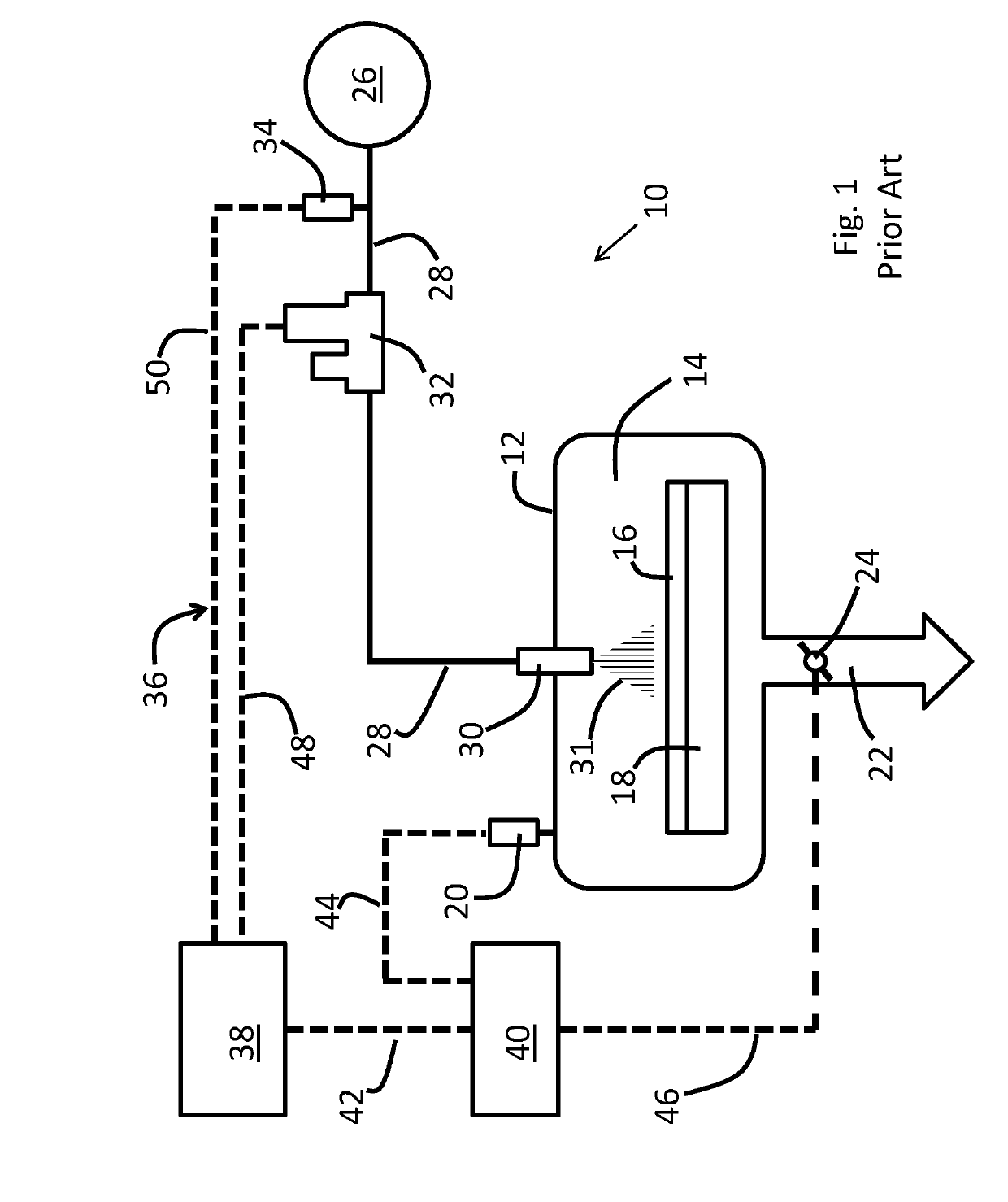

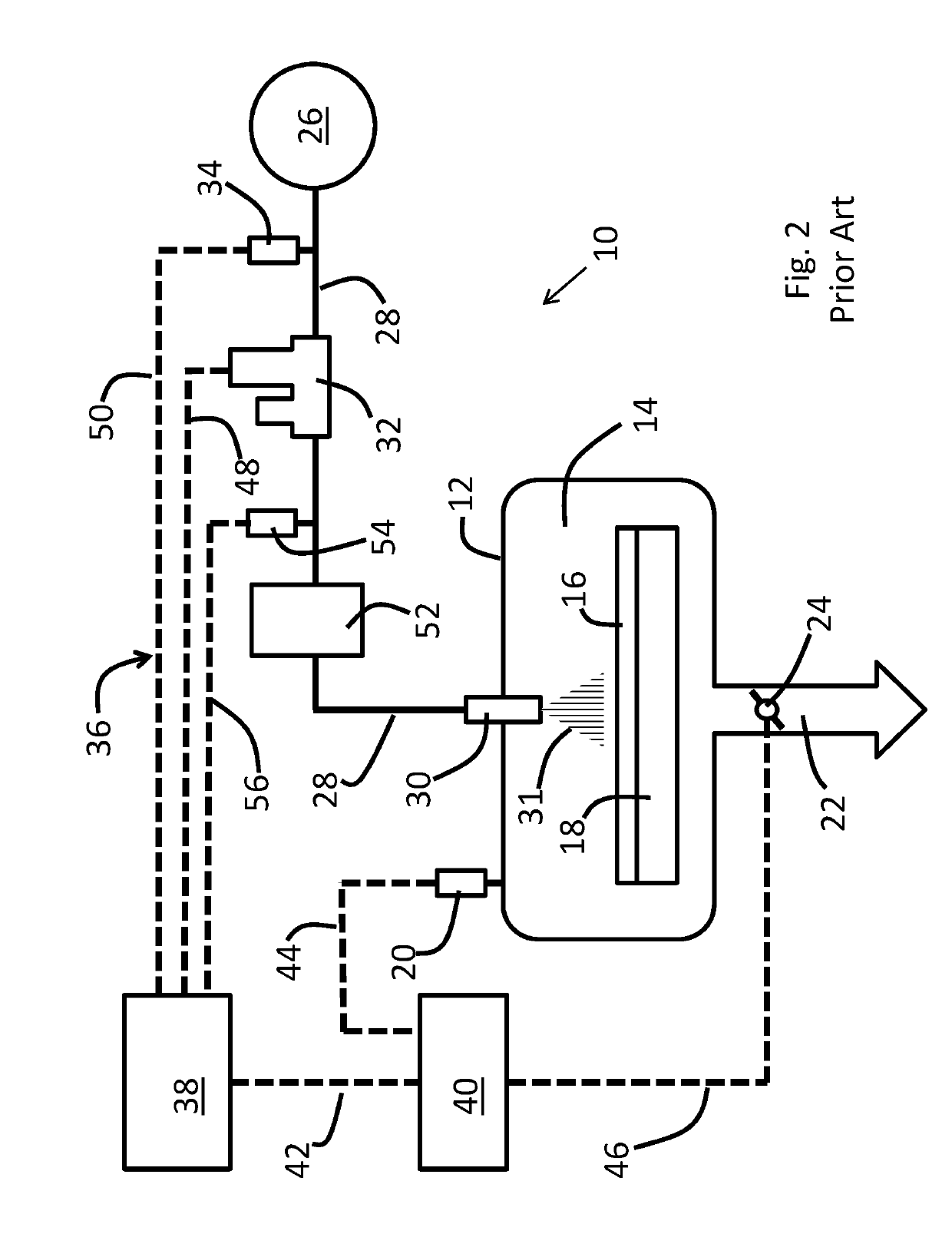

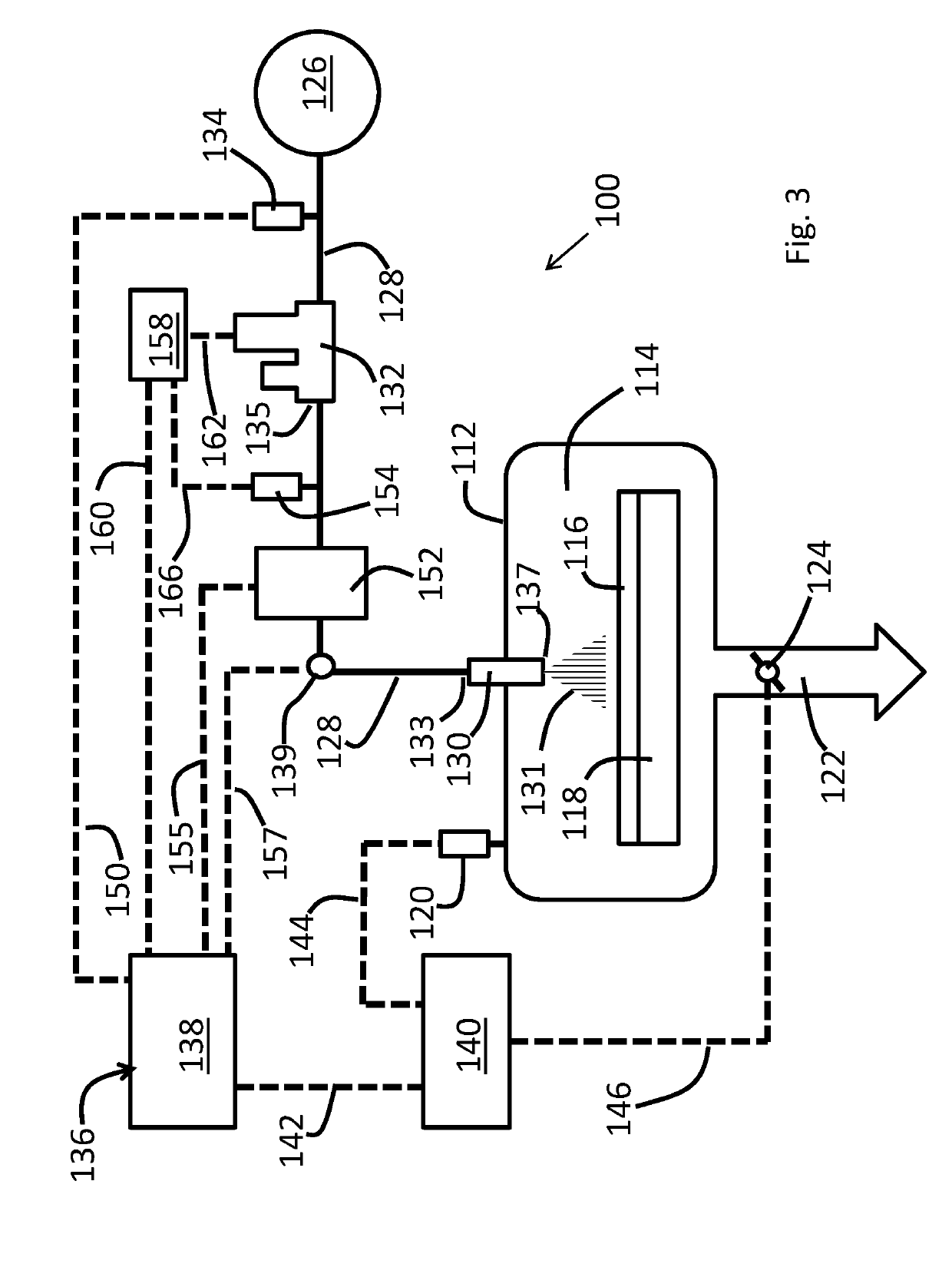

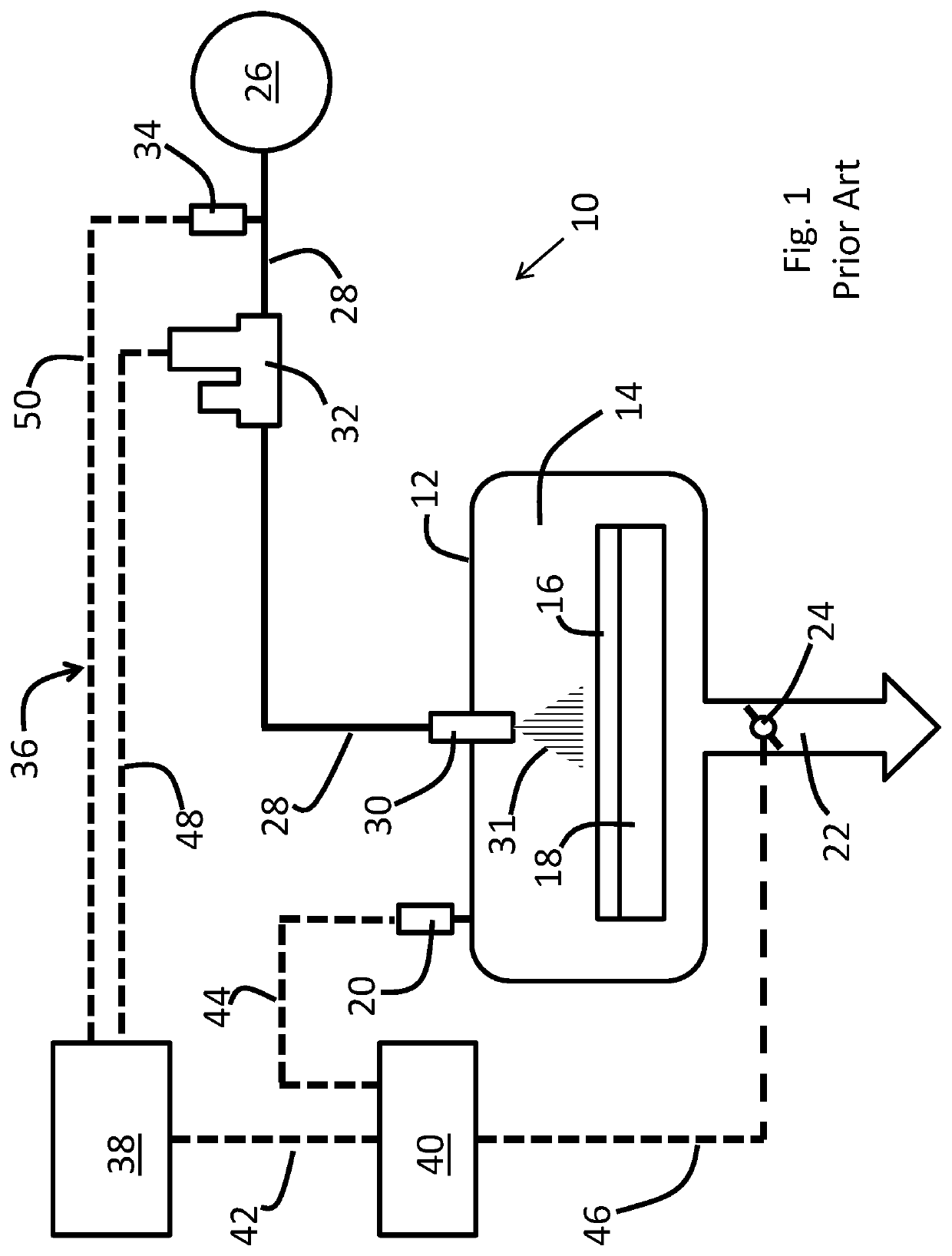

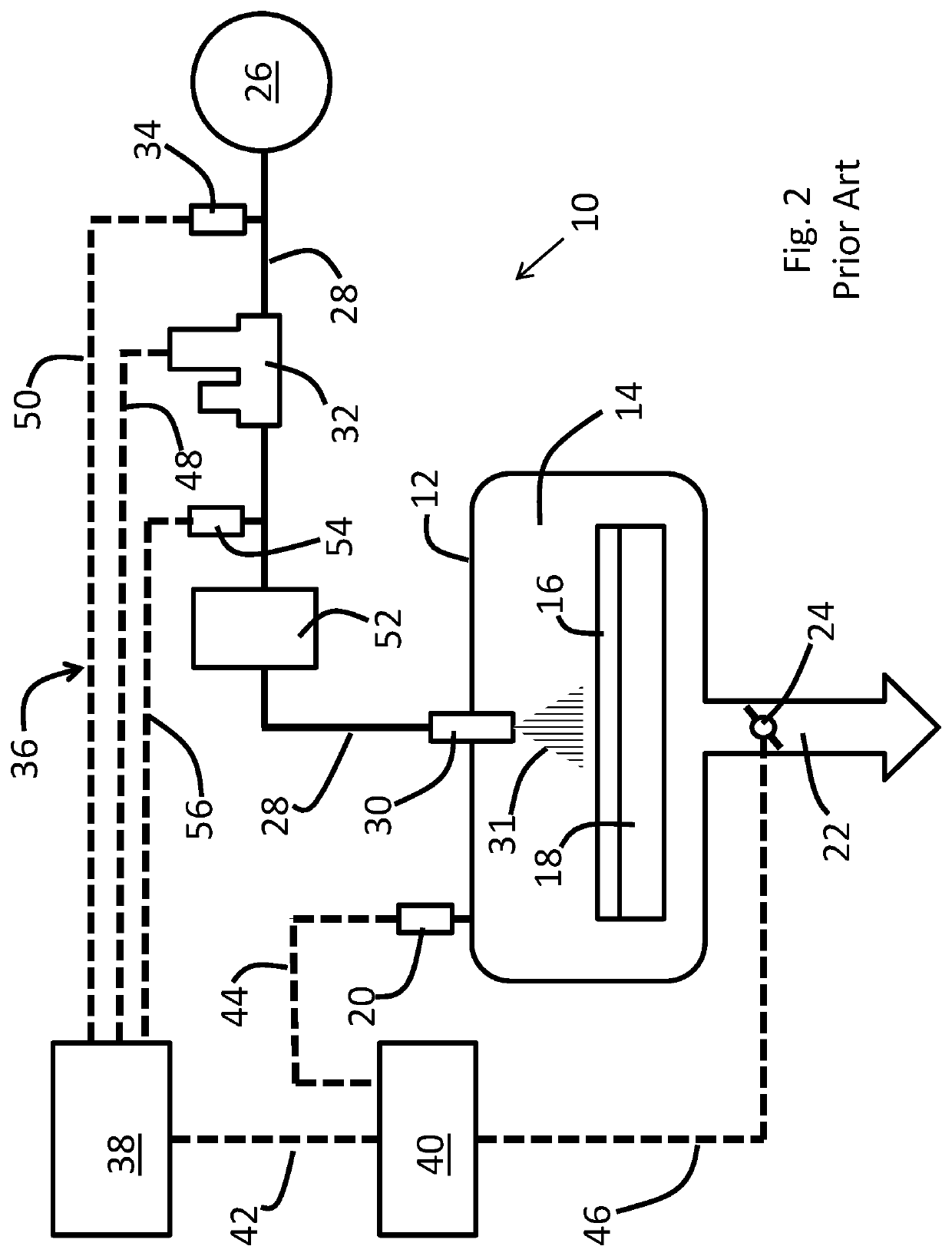

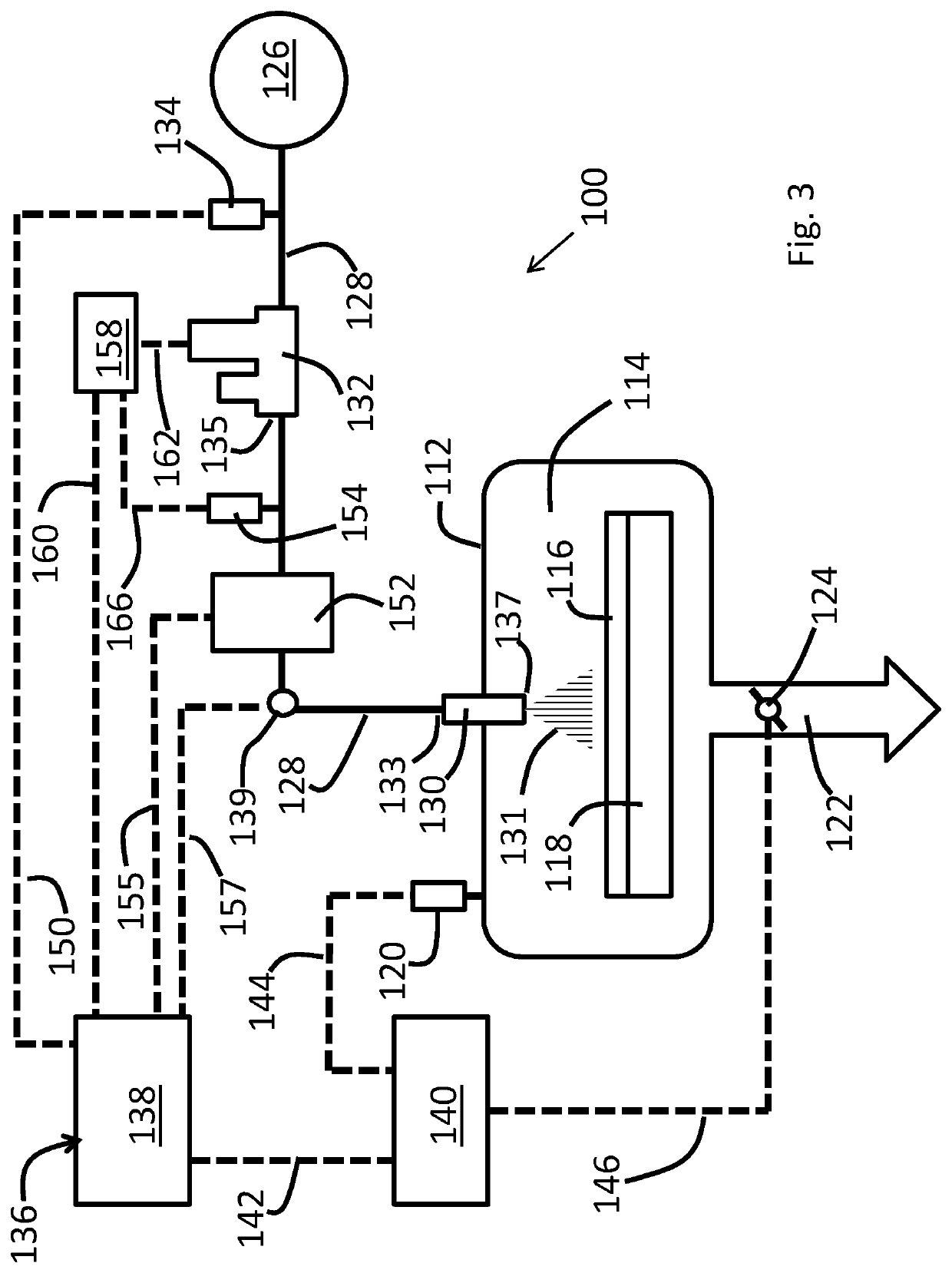

Pressure Control Strategies to Provide Uniform Treatment Streams in the Manufacture of Microelectronic Devices

ActiveUS20190291144A1Easy to controlWay accurateSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringPressure controlled ventilation

The present invention provides techniques to more accurately control the process performance of treatments in which microelectronic substrates are treated by pressurized fluids that are sprayed onto the substrates in a vacuum process chamber. control strategies are used that adjust mass flow rate responsive to pressure readings in order to hold the pressure of a pressurized feed constant. In these embodiments, the mass flow rate will tend to vary in order to maintain pressure uniformity.

Owner:TEL EPION

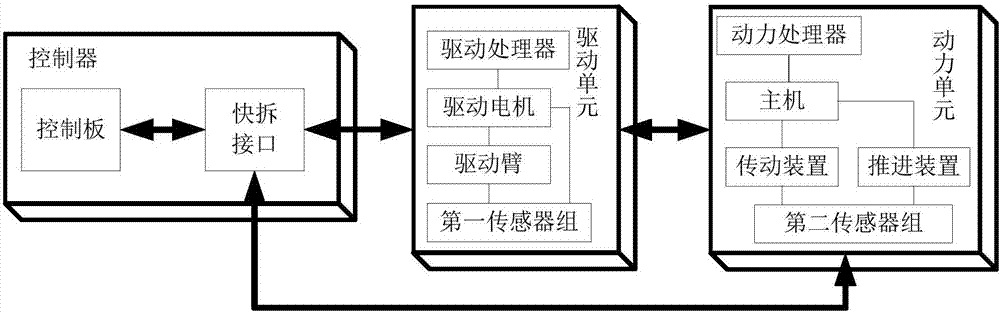

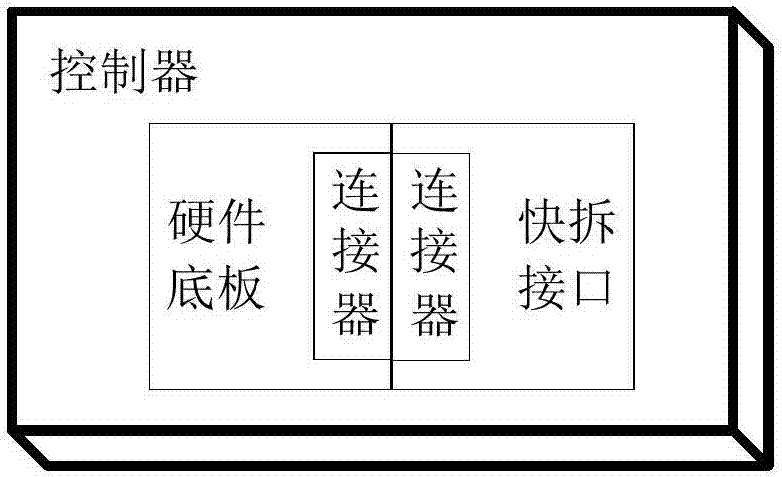

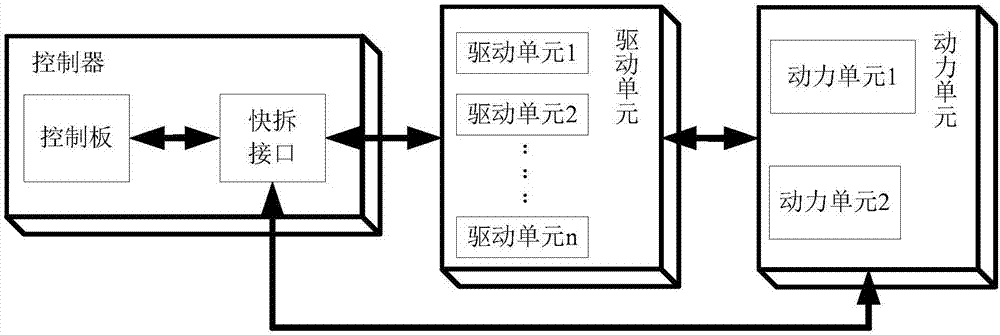

Modularized unmanned ship intelligent power control system

ActiveCN107140169AChange design patternChange processing performancePower plants using propulsion unit combinationsPower plants being motor-drivenOperational systemControl system

The invention relates to the technical field of unmanned ships and provides a modularized unmanned ship intelligent power control system. The method comprises following steps: a control unit obtains parameter information of a driving unit and a power unit after establishing data link connection with the driving unit and the power unit; the control unit analyzes the obtained parameter information of the driving unit and the power unit and updates operating system according to the analyzed results. The embodiment of the invention provides an establishment mode of an intelligent power control system which improves the power control system in the prior art that is fixed for specific ships and is integrated form; the invention provides an intelligent power control system dynamically formed by the control unit, the driving unit and the power unit and changes the intrinsic design mode and processing and manufacturing mode so that the assemblies of the power control system can be dynamically combined and intelligent control is realized.

Owner:DAPENG GAOKE WUHAN INTELLIGENT EQUIP CO LTD

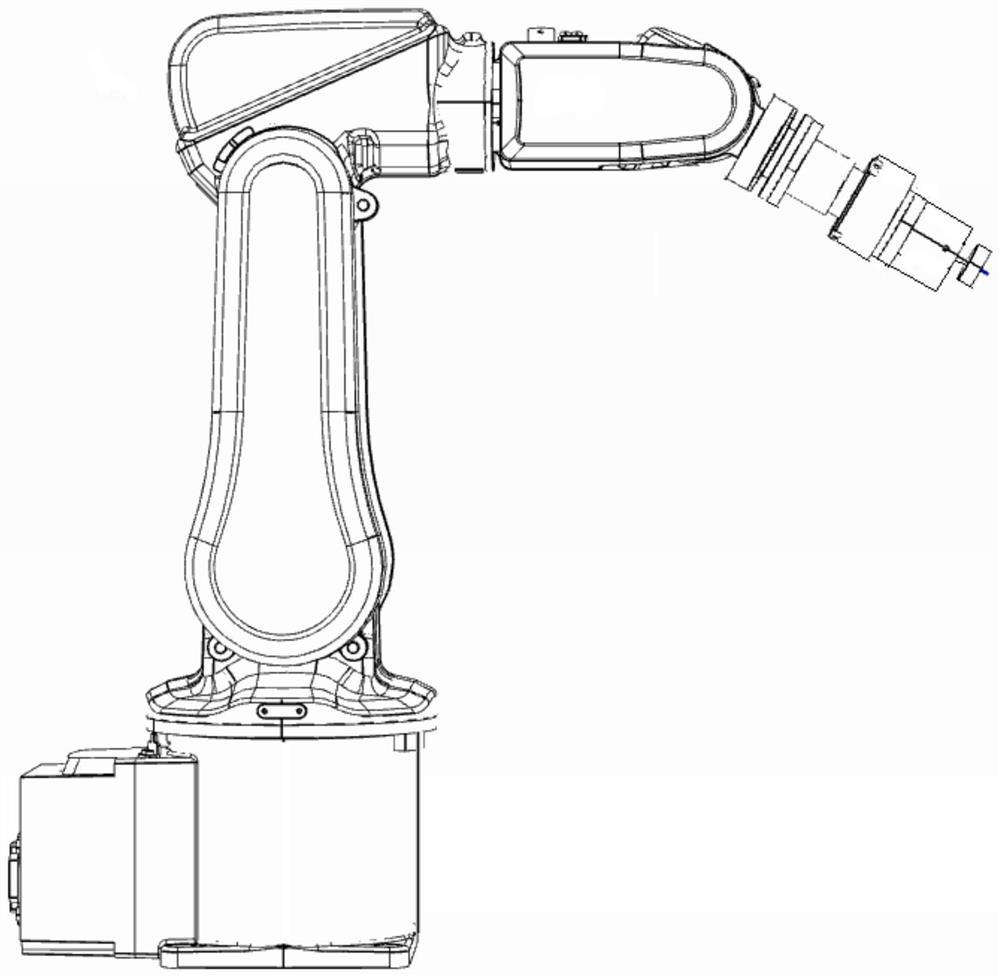

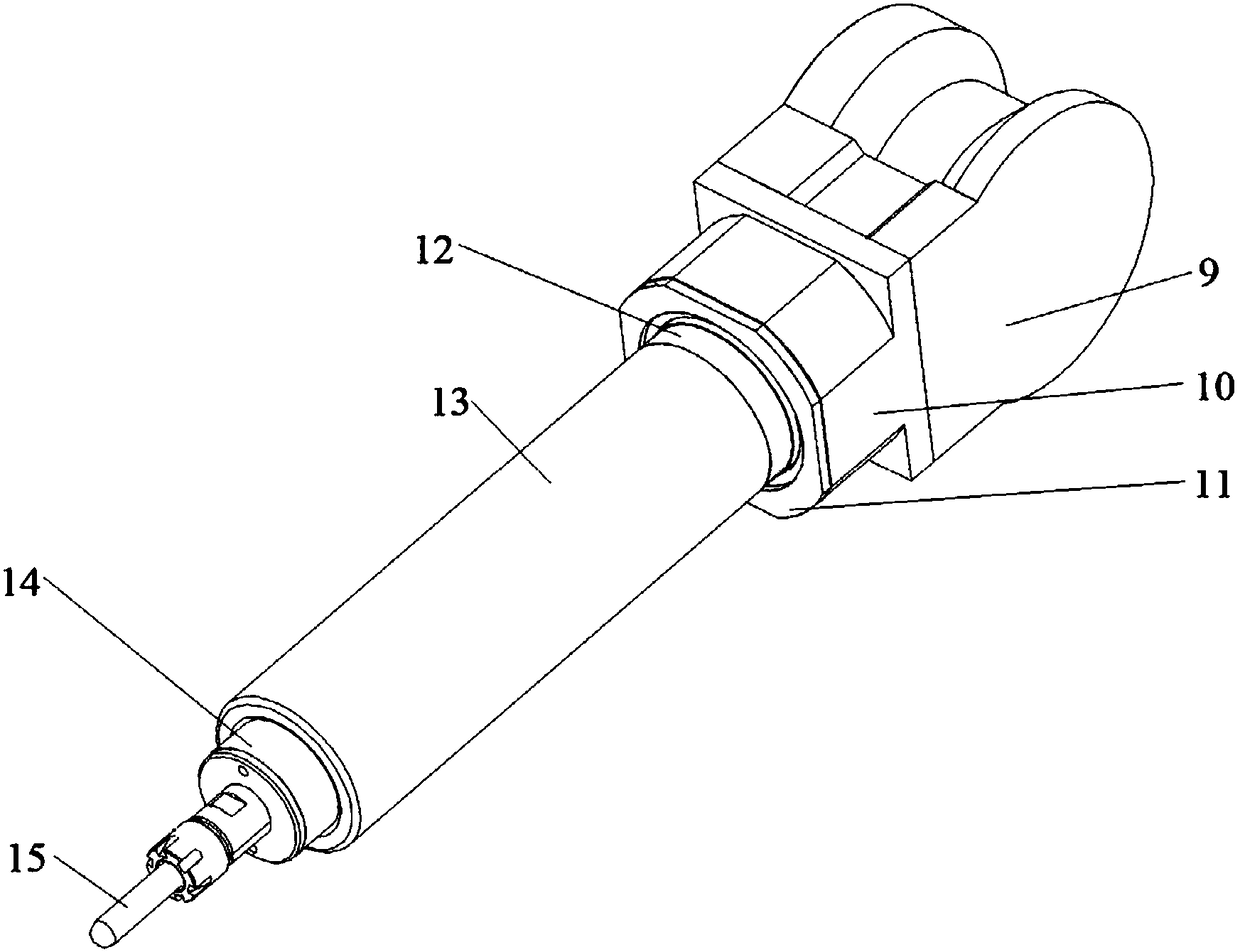

Robot force control end effector and control method thereof

ActiveCN113400143AMeet the force control processReduce sports shockGrinding drivesGrinding feed controlControl engineeringElectric machinery

The invention discloses a robot force control end effector and a control method thereof. The robot force control end effector comprises a connecting flange, a voice coil motor module and a grinding module. The voice coil motor module comprises a voice coil motor, a support, a linear guide rail and a displacement sensor, the linear guide rail and a stator of the voice coil motor are both fixedly mounted on the support, a rotor of the voice coil motor and a sliding block on the linear guide rail are fixedly mounted, and the connecting flange and the support are fixedly mounted. One end of a force sensor and the rotor of the voice coil motor are fixedly mounted, the grinding module is mounted at the other end of the force sensor, the displacement sensor is mounted on the linear guide rail, and the grinding module comprises an electric spindle and a grinding head fixedly mounted at one end of the electric spindle. The controller reads signals of the force sensor and the displacement sensor and controls the voice coil motor and the electric spindle. The controller is adopted for processing the signals of the displacement sensor and the signals of the force sensor, and constant-force grinding control over the end effector is achieved through real-time adjustment of the grinding and polishing force and the posture of the robot force control end effector.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

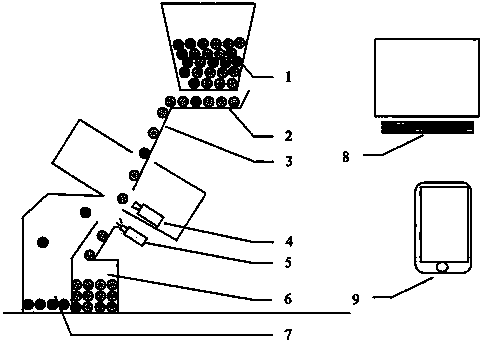

Efficient intelligent grain removing and sorting machine

The invention relates to an efficient intelligent grain removing and sorting machine, and belongs to the field of agricultural machinery and intelligent manufacturing. The equipment can be applied tograin raw material processing, grain seed processing, and recognition and defective product removal of nut, plastic particle, small industrial spare and accessory part and granular food industries. According to the efficient intelligent grain removing and sorting machine, the image recognition technology is adopted, grains, seeds and other granular objects passing through a recognition channel arephotographed, and when defective products are recognized, a pneumatic device can be started to remove the defective products.

Owner:董艳红

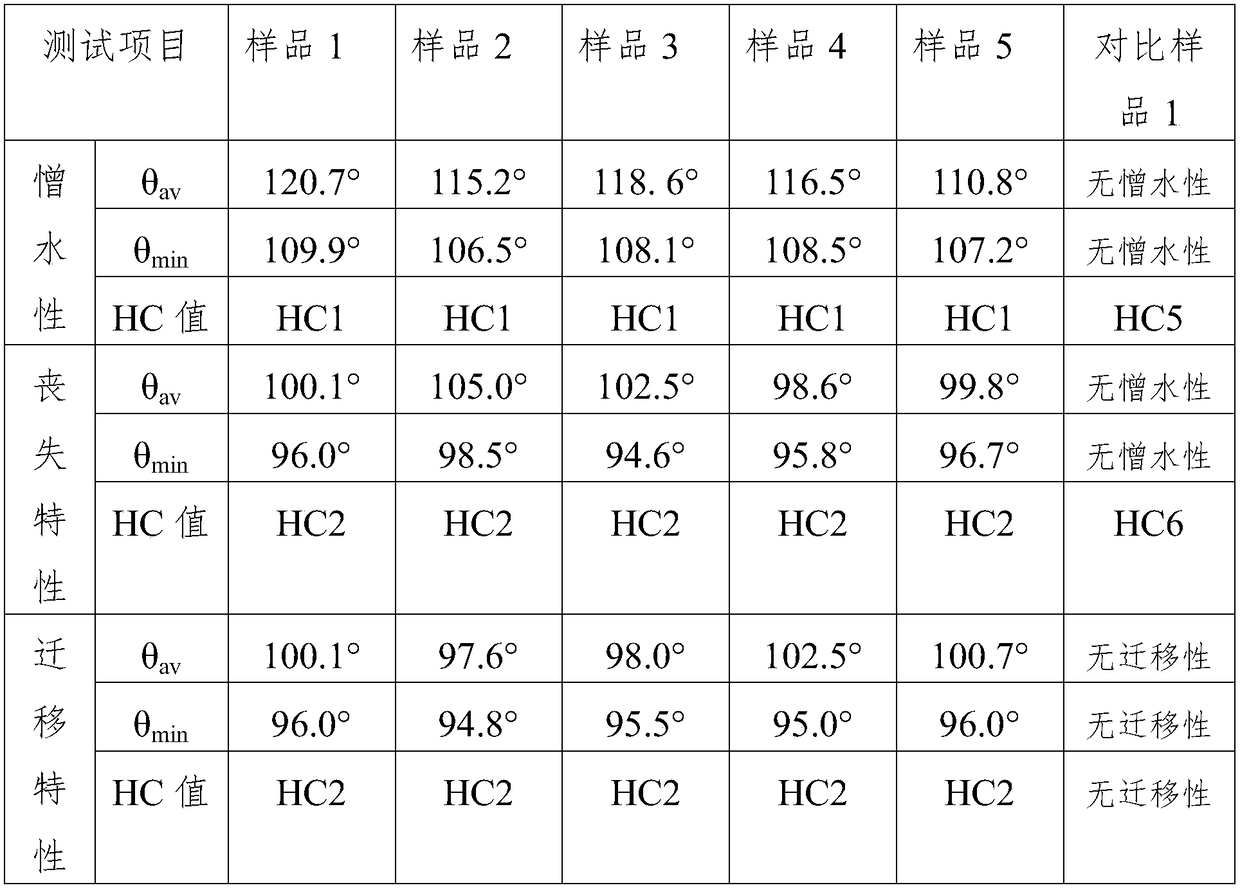

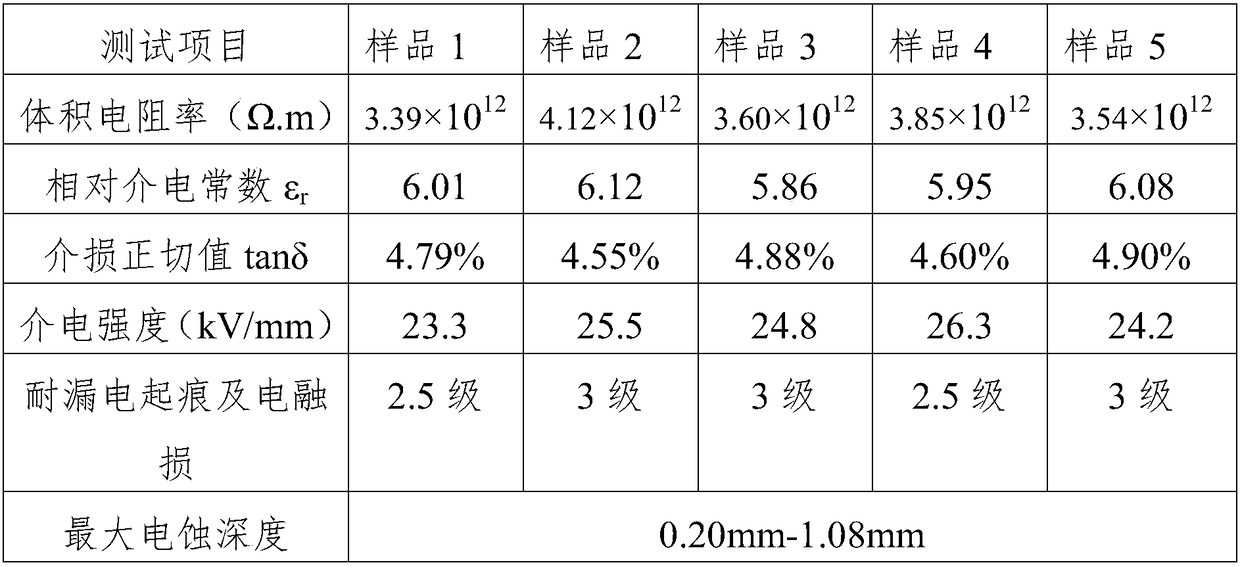

Novel fluoro-silicone coating preventing pollution flashover and a preparing method thereof

InactiveCN108948937AImprove hydrophobicityExcellent hydrophobic migrationFireproof paintsAntifouling/underwater paintsElectric power systemDip-coating

Novel fluoro-silicone coating preventing pollution flashover is disclosed. The coating includes, by weight, 10-80 parts of a fluorinated acrylate monomer, 9-60 parts of an acrylate monomer, 7-43 partsof a silane coupling agent, 2-23 parts of polysiloxane, 0.2-1.8 parts of an initiator and 1-80 parts of a solvent. The coating has excellent hydrophobicity, hydrophobic mobility, weather fastness, chemical resistance, ageing resistance, self-cleaning performance, electric performance, tear strength, shearing strength, and flame retardant performance, and is suitable for an electrical power system. A preparing method disclosed is high in manufacturability, and material and object surfaces can be coated with the coating prepared by the method in dip-coating, spread-coating and spraying mannersand the like. The coating prepared is easy to dry, easy to shape, easy to clean and capable of repeated coating, and the drying time at room temperature is not longer than 10 min. The coating has advantages of simple construction process and easy operation and is safe and environmentally friendly.

Owner:赵永锋

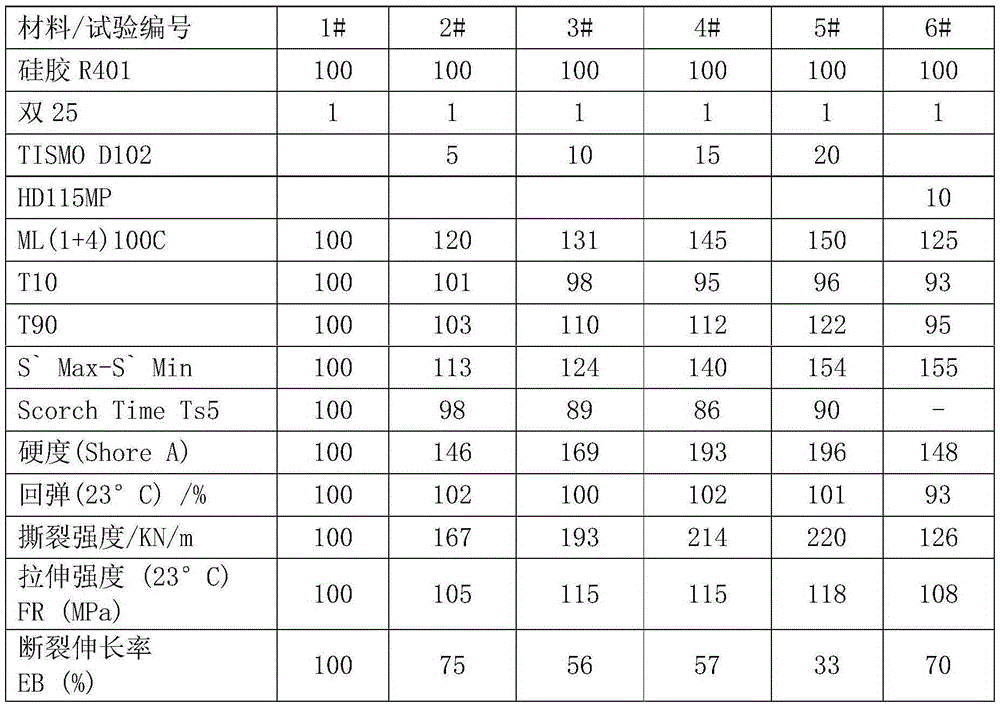

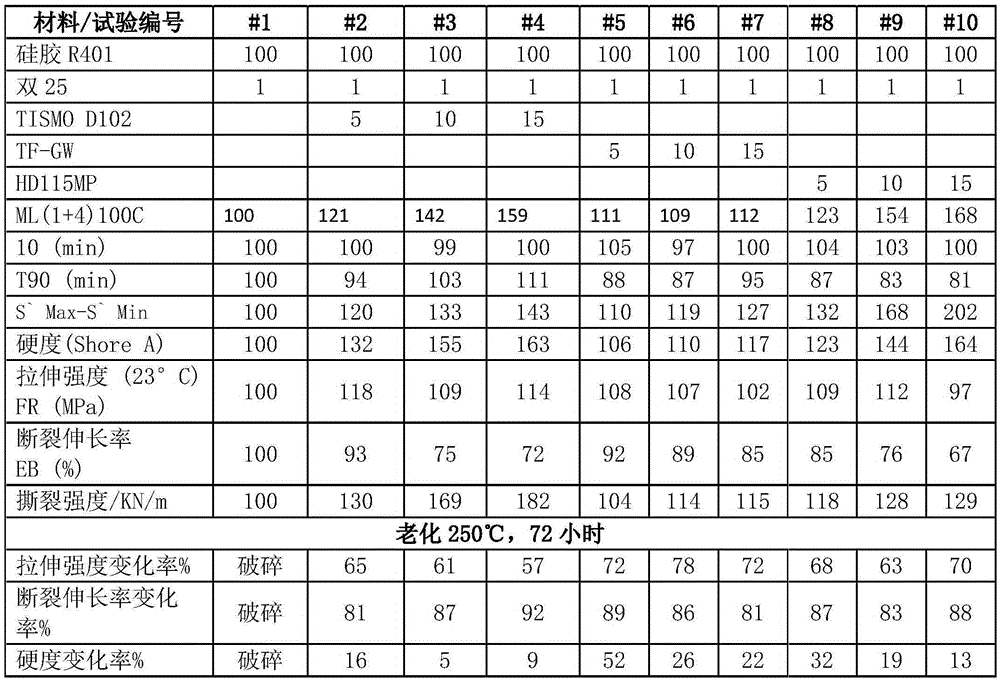

Silicon rubber material containing titanate component

The invention discloses a silicon rubber material containing a titanate component. The silicon rubber material containing the titanate component is prepared from, by weight, 100 parts of silicon rubber and 1-50 parts of titanate, wherein titanate is fiber potassium titanate or flake potassium titanate. The silicon rubber material is reasonable in design and easy to prepare, the processing performance of a silicon rubber compound is not changed, a silicon rubber system is filled with a certain quantity of potassium titanate fibers subjected to surface treatment or potassium titanate fibers without surface treatment, the tensile strength of a silicon rubber product is increased by 10%, and the splitting and tearing strength of the silicon rubber product is increased by 30%-100%; meanwhile, the high-temperature resistance of the rubber material can be obviously improved, the elongation of the silicon rubber can also be reduced, and the rigidness of the extruded silicon rubber product can be improved.

Owner:OTSUKA MATERIAL SCI & TECH SHANGHAICO LTD +1

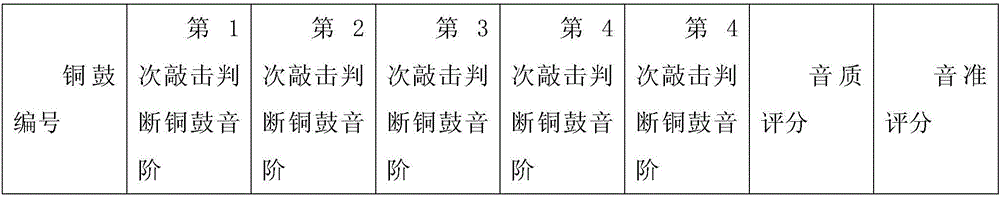

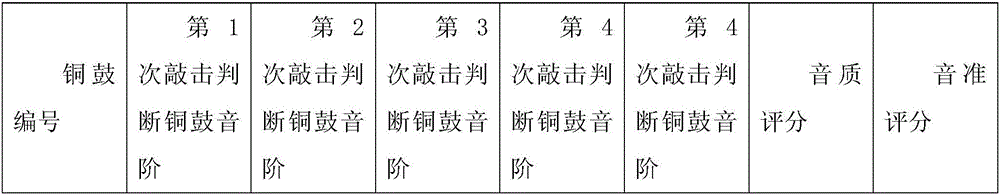

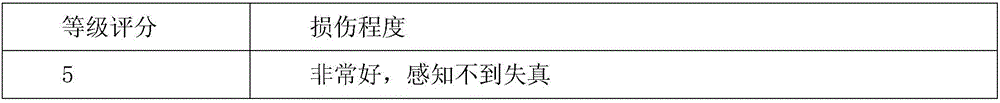

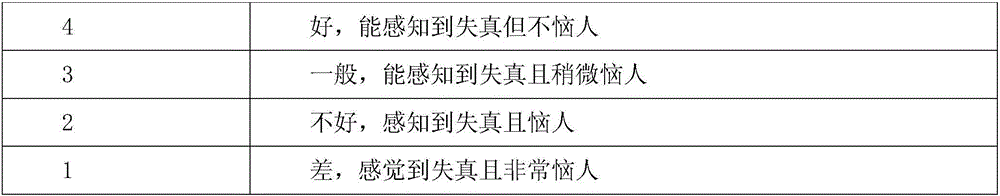

Manufacturing method for high scale music bronze drum

InactiveCN106531135AGuaranteed delicateFully removePercussion musical instrumentsFoundry mouldsWaxManufacturing technology

The invention relates to the manufacturing technology field for bronze drums and more particularly, to a manufacturing method for high scale music bronze drum. The manufacturing method for music bronze drum comprises the following steps: a) preparing bronze drum casting model: the drum surface of the bronze drum casting model is 0.5 to 1.2mm thick; the diameter of the drum surface ranges from 21 to 23.5 cm and the bronze drum wax model is 15 to 17.8 cm high; b) fusing the bronze drum materials: the raw materials for the bronze drum are made up of the following metal elements with their shares in the bronze drum as follows: zinc 14-15.5%, tin 4.2-4.8%, aluminum 5.6-6.3%, beryllium 2.1-2.6 %, iron 3.2-4.5%, nickel 5.0-5.6%, phosphor 0.3-0.45%, and the remaining being copper; and c) casting to take shape. According to the manufacturing method for the high scale music bronze drum, the bronze drum prepared by the method can produce the scale of si and strikes the sound accurately, therefore, enriching and carrying forward bronze drum culture.

Owner:DONGLAN MUSIC TONGGU CULTURAL COMM

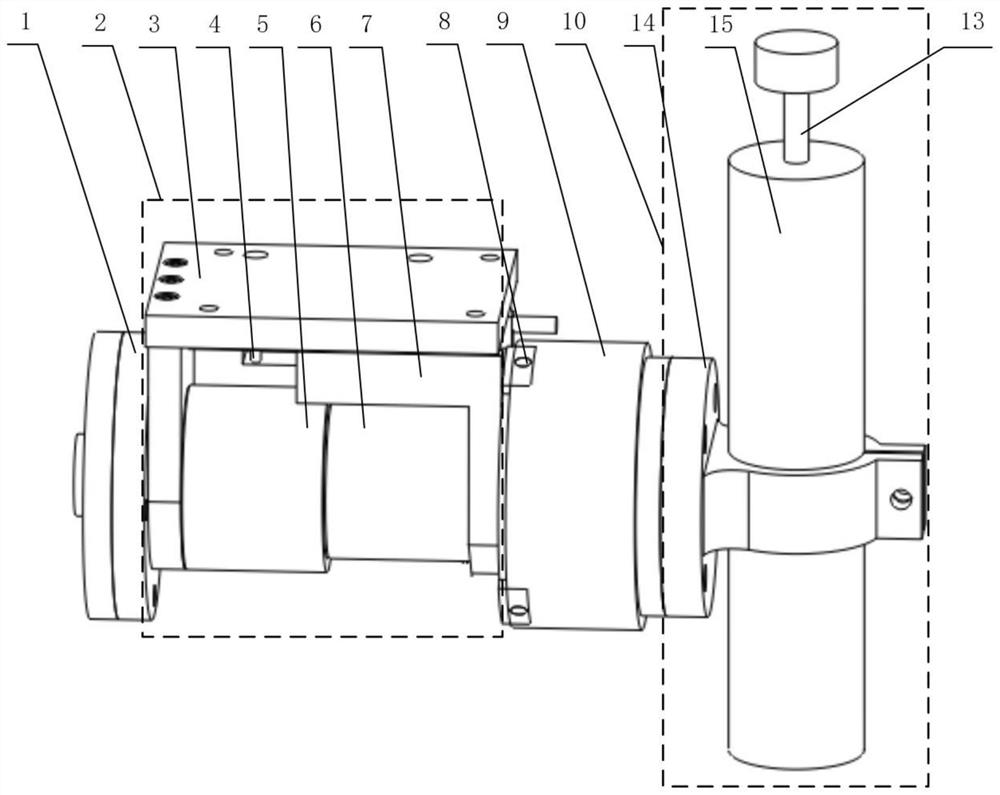

Cabin body inner wall robot automatic milling processing device

PendingCN108515215AChange processing performanceChange depthProgramme-controlled manipulatorMilling equipment detailsControl systemEngineering

The invention provides a cabin body inner wall robot automatic milling processing device. The device includes a mechanical arm control system, a wrist body system and a main shaft system. The mechanical arm control system comprises a base, a rotating disk, a rotating disk motor, a large arm, a large arm motor, a box body, a small arm and a small arm motor; the wrist body system mainly comprises awrist body, a wrist body support, a wrist body end cover and a wrist body connection flange; and the main shaft system mainly comprises an air-operated main shaft, a fixture and a cutting tool. The device controls cutting tool operation through mechanical arms, achieves cabin body inner wall robot automatic milling processing, and has the advantages of simple structure and convenient installation.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

Pressure control strategies to provide uniform treatment streams in the manufacture of microelectronic devices

ActiveUS11241720B2Easy to controlWay accurateSemiconductor/solid-state device manufacturingCleaning using liquidsProcess engineeringIndustrial engineering

The present invention provides techniques to more accurately control the process performance of treatments in which microelectronic substrates are treated by pressurized fluids that are sprayed onto the substrates in a vacuum process chamber. control strategies are used that adjust mass flow rate responsive to pressure readings in order to hold the pressure of a pressurized feed constant. In these embodiments, the mass flow rate will tend to vary in order to maintain pressure uniformity.

Owner:TEL EPION

Method for producing winter jujube multienzyme complex probiotic through winter jujube pomace

InactiveCN104366488ARealize eating dry and squeezing cleanSolve employment problemsFood preparationPhosphateMonopotassium phosphate

The invention discloses a method for producing winter jujube multienzyme complex probiotic through winter jujube pomace and belongs to winter jujube multienzyme complex probiotic production. The method includes 1, winter jujube pomace enzymatic hydrolysis; 2, centrifugal, concentration and sterilization, namely utilizing a centrifuge to separate mixed jujube paste after enzymatic hydrolysis, and obtaining original water jujube juice for standby and partial pomace; performing pressure reduction and concentration on the centrifuged original water jujube juice until the soluble solid content is of 20%, adding 0.2% of yeast extract, 1.9% of ammonium sulfate, 0.1% of zinc chloride, 0.1% of magnesium sulfate and 0.6% of potassium dihydrogen phosphate, and sterilizing; 3, inoculation and ventilation fermentation; 4, spray drying. By the aid of the method, resource is saved, the jujube pomace waste is converted into treasures for reuse, pollution and enterprise cost are reduced, load is reduced for enterprises, environment is protected, the advantage of 'eating and extracting winter jujube completely' is realized actually, and high promotion and application value is provided.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Self-reinforced polymer composite and preparation method thereof

InactiveCN105524334AWill not destroy the aggregate structureInvariant structureRadioactive element fibre treatmentFiberPolymer science

The invention provides a self-reinforced polymer composite and a preparation method thereof and belongs to the technical field of composites. The technical problem that the existing self-reinforced polymer composite preparation process has strict requirements is solved. The method includes: firstly, putting polyethylene fibers into a Co-60 source or electron beam, and subjecting polyethylene fibers to irradiation crosslinking in an atmosphere of vacuum or nitrogen to obtain crosslinked polyethylene; secondly, mixing the crosslinked polyethylene with polyethylene to obtain the self-reinforced polymer composite. The preparation method is simple and not limited to the preparation process, reinforced fibers can keep the own aggregation structure and physical properties basically unchanged during hot processing due to the characteristics of insolubility and infusibility of the prepared three-dimensional body structure, and the composite finally obtained is macroscopic homogeneous and microscopic split without obvious interfaces.

Owner:JILIN UNIV

Method for manufacturing mean tone scale music bronze drum

ActiveCN106345971AControl hardnessControl characteristicsPercussion musical instrumentsFoundry mouldsZincMetallic Nickel

The invention relates to the technical field of bronze drum manufacturing, and in particular to a method for manufacturing a mean tone scale music bronze drum. The method for manufacturing the mean tone scale music bronze drum specifically comprises the following steps: a, manufacturing a bronze drum cast mold, wherein the surface of the bronze drum cast mold is 1.5-2.0mm in thickness, and the diameter of the surface is 20-22cm; b, melting a bronze drum raw material, wherein the bronze drum raw material contains the following metal elements in percentage: 8.3-10.2% of zinc, 3.2-3.6% of tin, 5.3-5.4% of aluminum, 1.7-1.84% of beryllium, 5.0-6.2% of iron, 3.5-3.9% of nickel and the balance of copper; and c, performing casting molding. By adopting the method for manufacturing the mean tone scale music bronze drum, a scale 4(fa) can be generated from the bronze drum, accurate toning can be achieved, the scales of the bronze drum can be enriched, and the bronze drum culture can be well carried forward and inherited.

Owner:DONGLAN MUSIC TONGGU CULTURAL COMM

One-step production method of thermoplastic polyurethane waterproof coiled material

The invention discloses an one-step production method of a thermoplastic polyurethane waterproof coiled material. The method comprises the following steps: (1) heating solid raw material to be liquid, weighing liquid raw material according to the mixing ratio, and uniformly mixing; (2) conveying the liquid raw material to a screw extruder to chemically react and melt; (3) preparing through a film forming machine to obtain a Tpu film. Compared with the prior art, the method has the advantages that the fixed processing mode and process of the Tpu film are completely changed, the energy consumption is small, the resource and energy are saved, the carbon discharge is reduced, and the effects on energy saving and consumption reduction are obvious; the method has outstanding characteristics and obvious improvement on either improvement or active effect of energy saving and emission reduction.

Owner:茹家佑

Damping paint

The invention provides damping paint and belongs to the technical field of paint. The damping paint is mainly used for vibration and noise reduction in the fields of automobiles, trains, steamboats, airplanes, engineering machinery and the like. The damping paint is prepared from, by weight, 25-30 parts of acrylic emulsion, 40-45 parts of white mica, 18-28 parts of fire retardant, 20-40 parts of filler, 0.5-1 part of dispersant, 12-18 parts of deionized water and 5-12 parts of auxiliaries. The damping paint has good damping, sound insulation, heat preservation and flame retardation performance.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com