Vertical pipe production line

A vertical pipeline and production line technology, applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of multiple production sites, uneven force on fibers, stress concentration, etc., to improve product quality and processing stability, Change the processing sequence and concept to achieve the effect of mechanized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

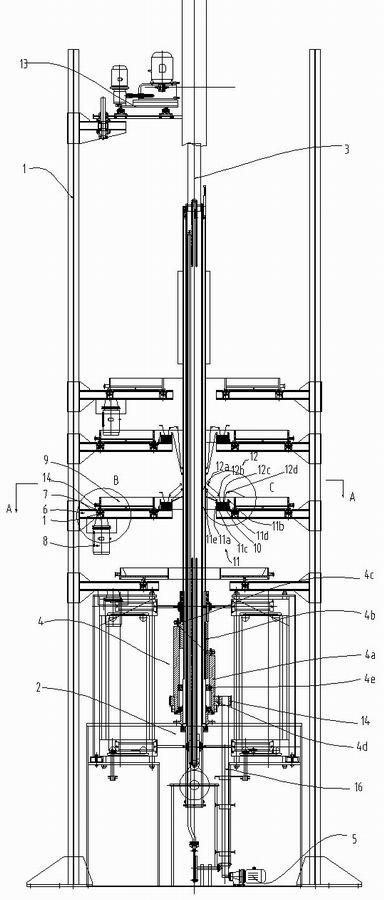

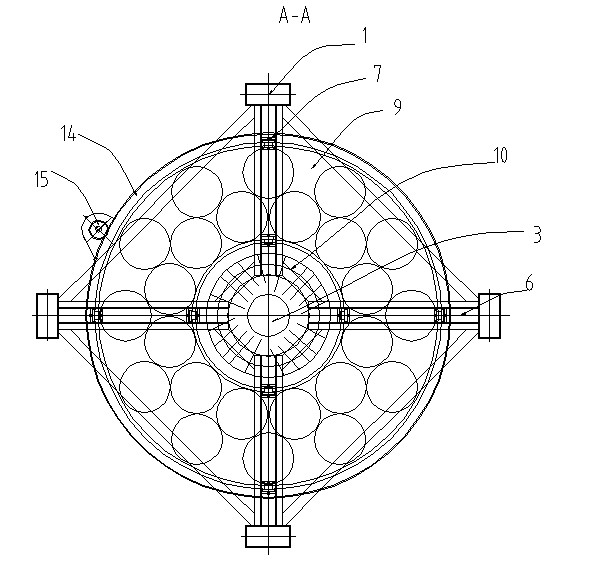

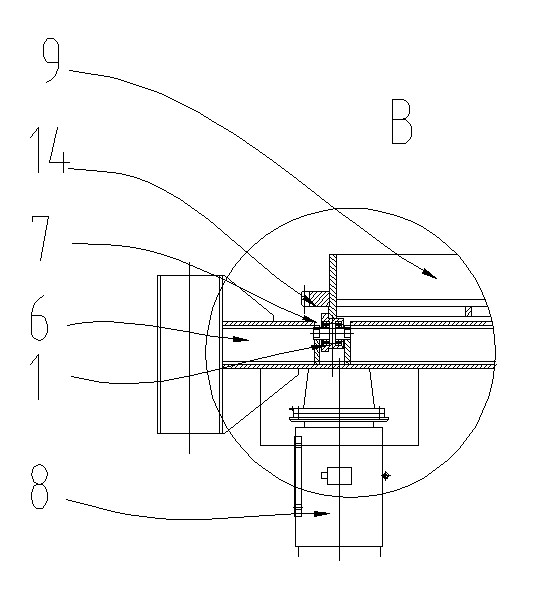

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4 A vertical pipeline production line shown is composed of a frame 1, a mandrel support 2, a mold mandrel 3, a propulsion device 4, a support frame 6, a circular yarn disc 9, a dipping tank 10, and an axial fiber positioning frame 11 and a ring fiber positioning frame 12 etc., a mandrel support 2 is installed at the bottom of the frame 1, and a mold mandrel 3 is fixed upright on the mandrel support 2, that is, a flange is provided at the lower end of the mold mandrel 3 , the flange is fixed on the mandrel support 2 via screws, a propulsion device 4 is installed at the bottom of the mold mandrel 3, and the propulsion device 4 is connected with the first power motor 5; at least fixed on the frame 1 One layer of support frame 6, the support frame 6 is located above the mandrel support 2, an annular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com