Manufacturing process of optical myopia-preventing paper

A technology of making crafts and myopia paper, which is applied in the field of papermaking, can solve problems such as environmental pollution, and achieve the effects of reducing costs, protecting the environment, and reducing light irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

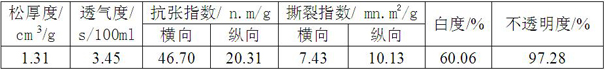

Examples

Embodiment 1

[0051] A production process of optical anti-myopia paper, using a mixture of waste paper and straw as raw materials, the specific steps are as follows:

[0052] a. Cut the straw into flakes with a length of 1cm to 2cm, and remove impurities by a grass washer before dehydration;

[0053] b. Put the dehydrated flaky straw into the container, add swelling agent and cooking agent in the container: the swelling agent is sodium hydroxide accounting for 5% of the straw mass fraction and 0.2% of the straw mass fraction The combination of silicon compounds, the cooking agent is a combination of sodium sulfite accounting for 2% of the mass fraction of the straw and anthraquinone accounting for 0.02% of the mass fraction of the straw, adding water and mixing evenly;

[0054] c, heat the container in step b and cook the straw, the cooking temperature is 120°C, the cooking time is 1h, then keep the temperature at 150°C, soak for 0.5h, soften the flaky straw and remove impurities in the slu...

Embodiment 2

[0062] A production process of optical anti-myopia paper, using a mixture of waste paper and straw as raw materials, the specific steps are as follows:

[0063] a. Cut the straw into flakes with a length of 1cm to 2cm, and remove impurities by a grass washer before dehydration;

[0064] b. Put the dehydrated flaky straw into the container, add swelling agent and cooking agent in the container: the swelling agent is sodium hydroxide accounting for 15% of the straw mass fraction and 0.5% of the straw mass fraction The combination of silicon compounds, the cooking agent is a combination of sodium sulfite accounting for 6% of the mass fraction of the straw and anthraquinone accounting for 0.05% of the mass fraction of the straw, adding water and mixing evenly;

[0065] c. Heat the container in step b and cook the straw. The cooking temperature is 180° C. and the cooking time is 2 hours. Then keep the temperature at 180° C. and soak for 1.5 hours to soften the flaky straw and remov...

Embodiment 3

[0073] A production process of optical anti-myopia paper, using a mixture of waste paper and straw as raw materials, the specific steps are as follows:

[0074] a. Cut the straw into flakes with a length of 1cm to 2cm, and remove impurities by a grass washer before dehydration;

[0075] b. Put the dehydrated flaky straw into the container, add swelling agent and cooking agent in the container: the swelling agent is sodium hydroxide accounting for 10% of the straw mass fraction and 0.3% of the straw mass fraction The combination of silicon compounds, the cooking agent is a combination of sodium sulfite accounting for 4% of the mass fraction of the straw and anthraquinone accounting for 0.03% of the mass fraction of the straw, adding water and mixing evenly;

[0076] c. heat the container in step b and cook the straw, the cooking temperature is 150°C, the cooking time is 1.5h, then keep the temperature at 160°C, soak for 1h, soften the flaky straw and remove impurities in the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com