Patents

Literature

72results about How to "Change operating mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

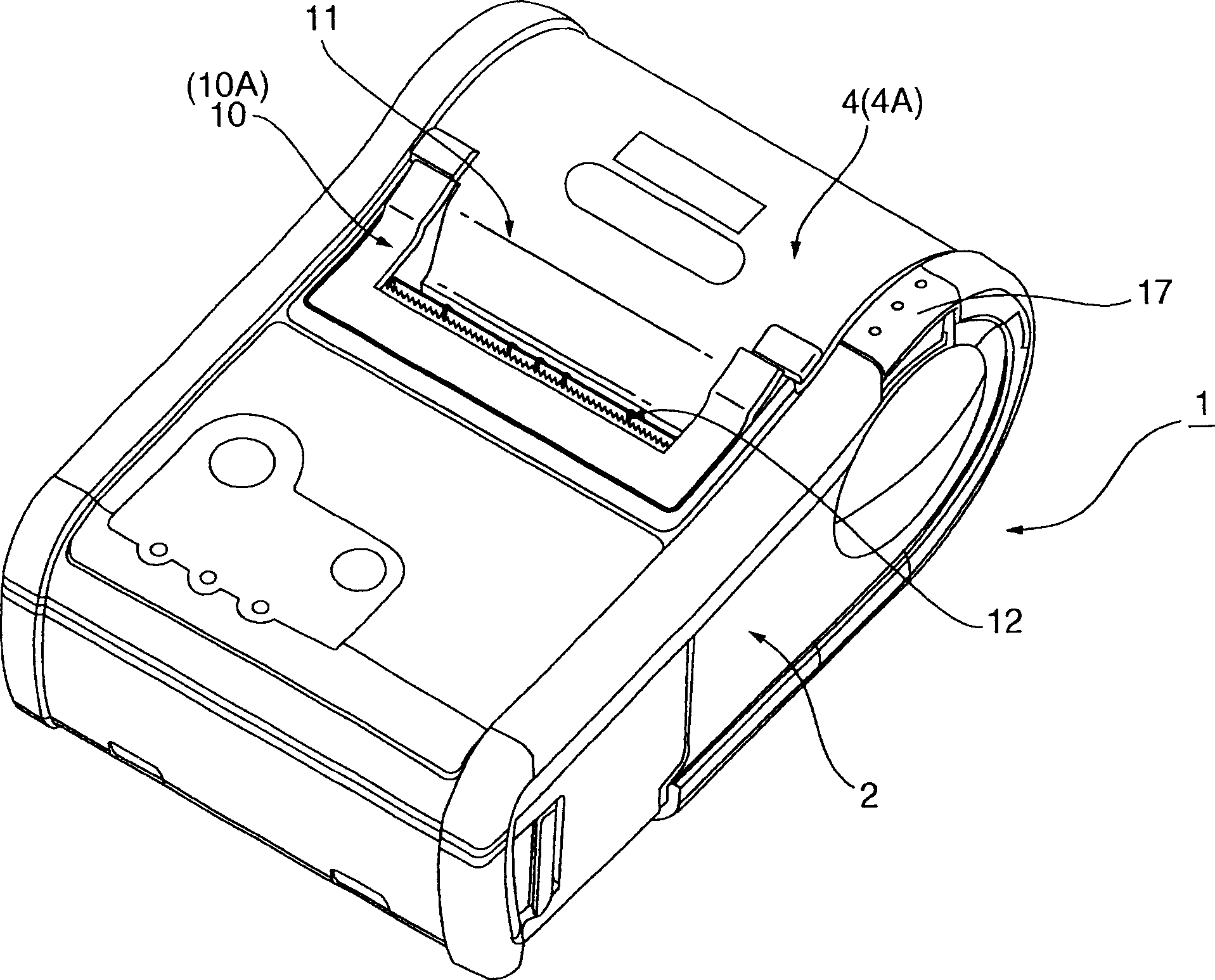

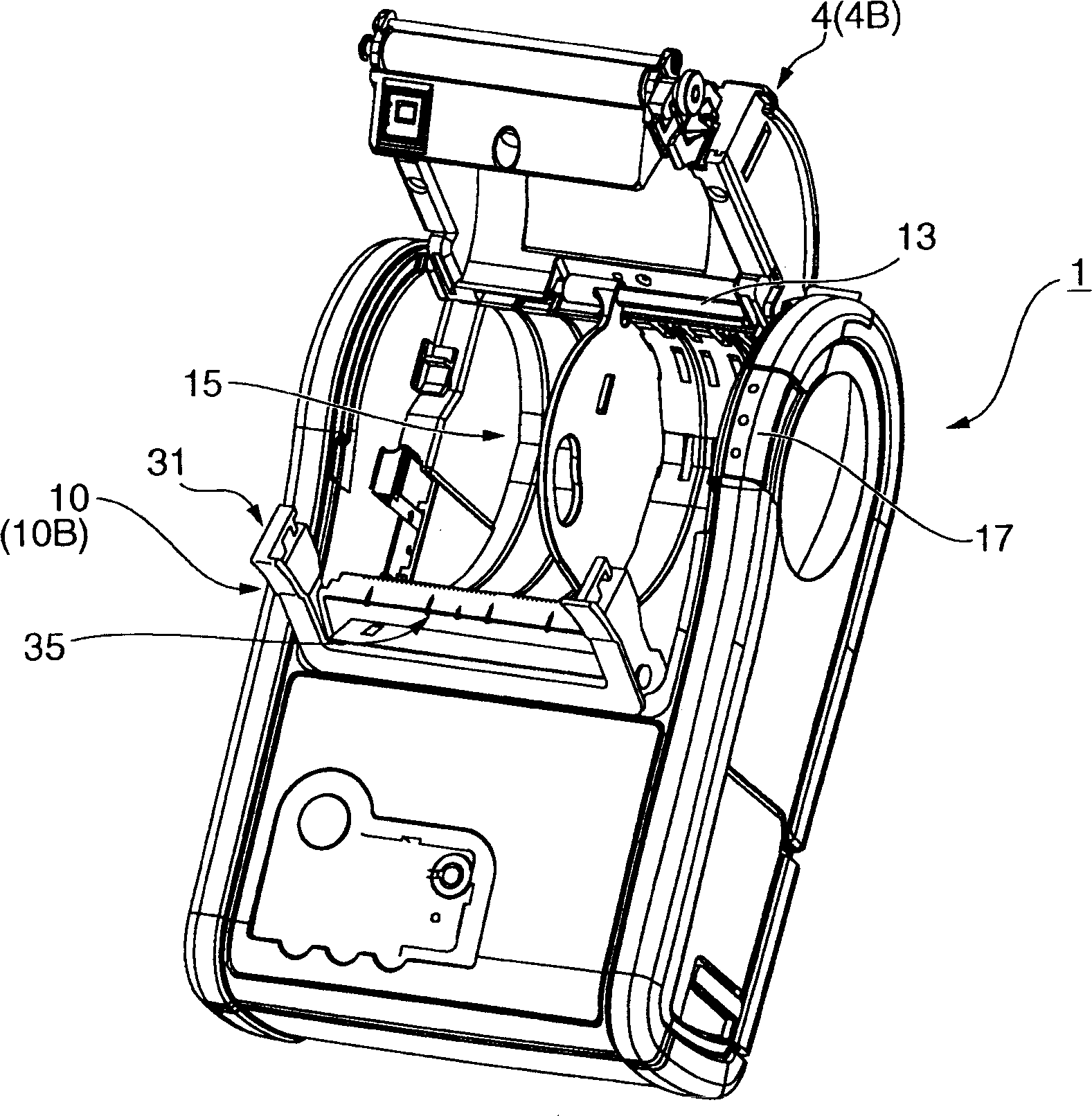

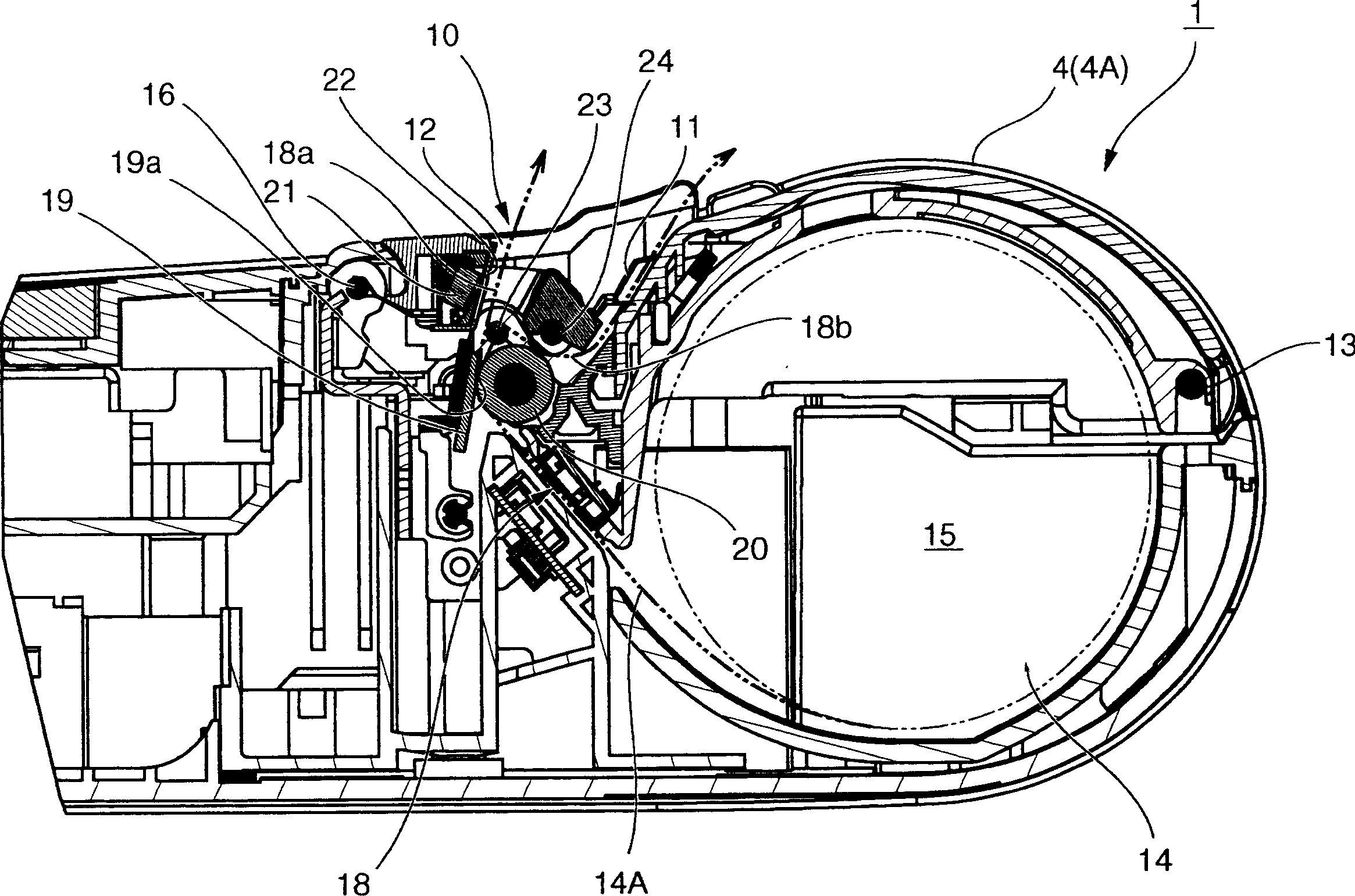

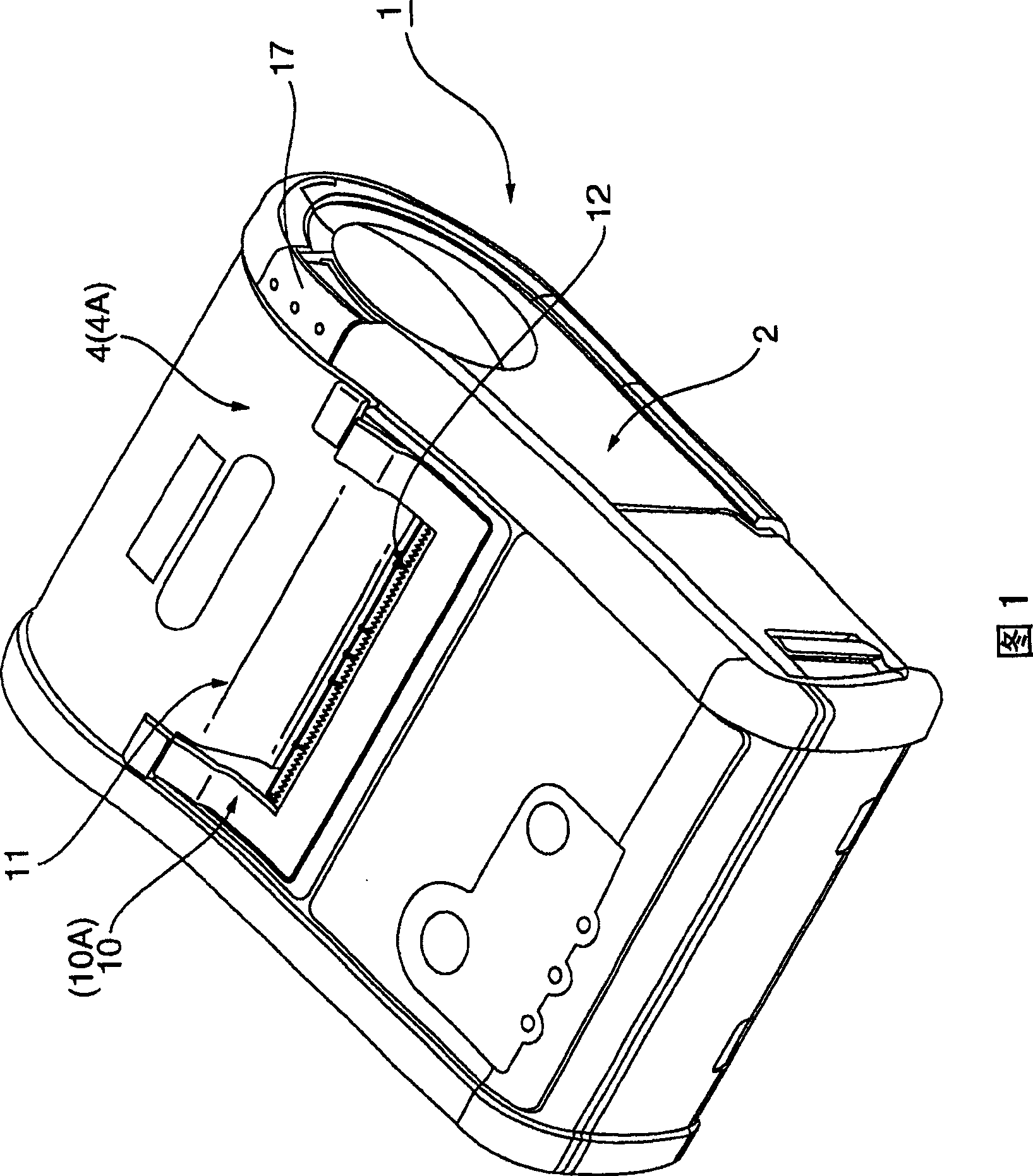

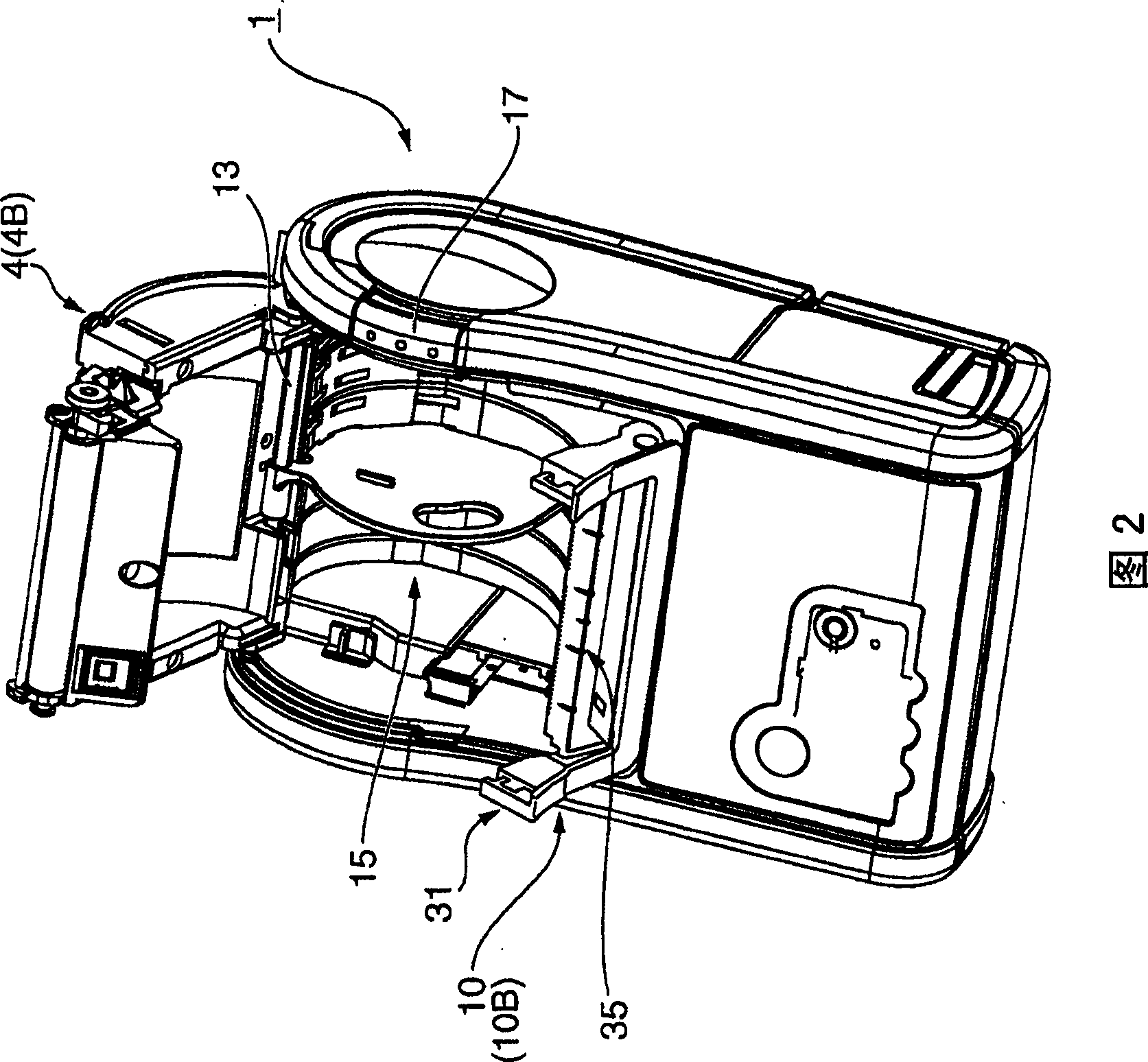

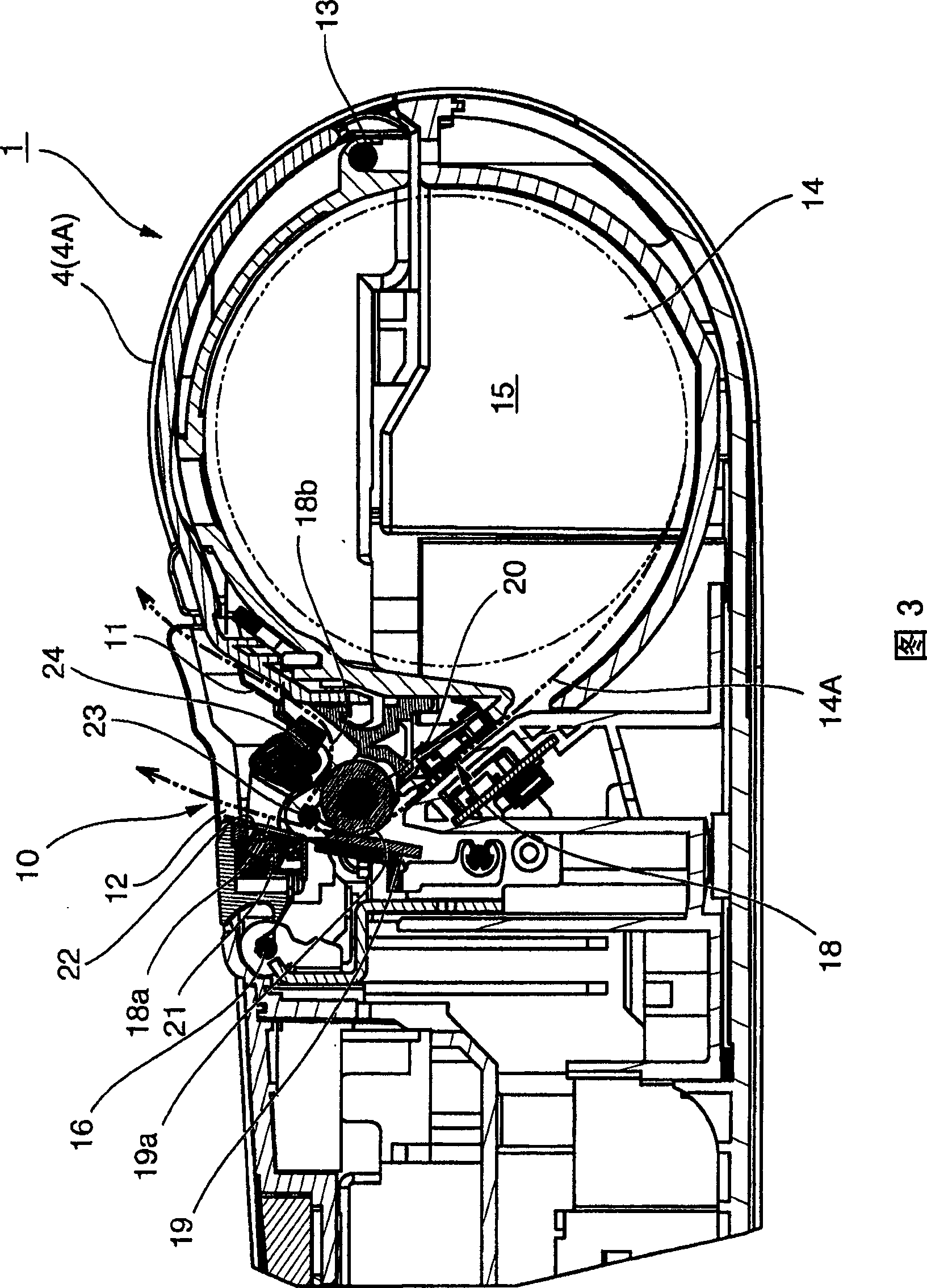

Printing machine comprising stripper

InactiveCN1796238AChange operating modeAvoid problems caused by mismatchesManual label dispensersPrintingEngineeringPaper sheet

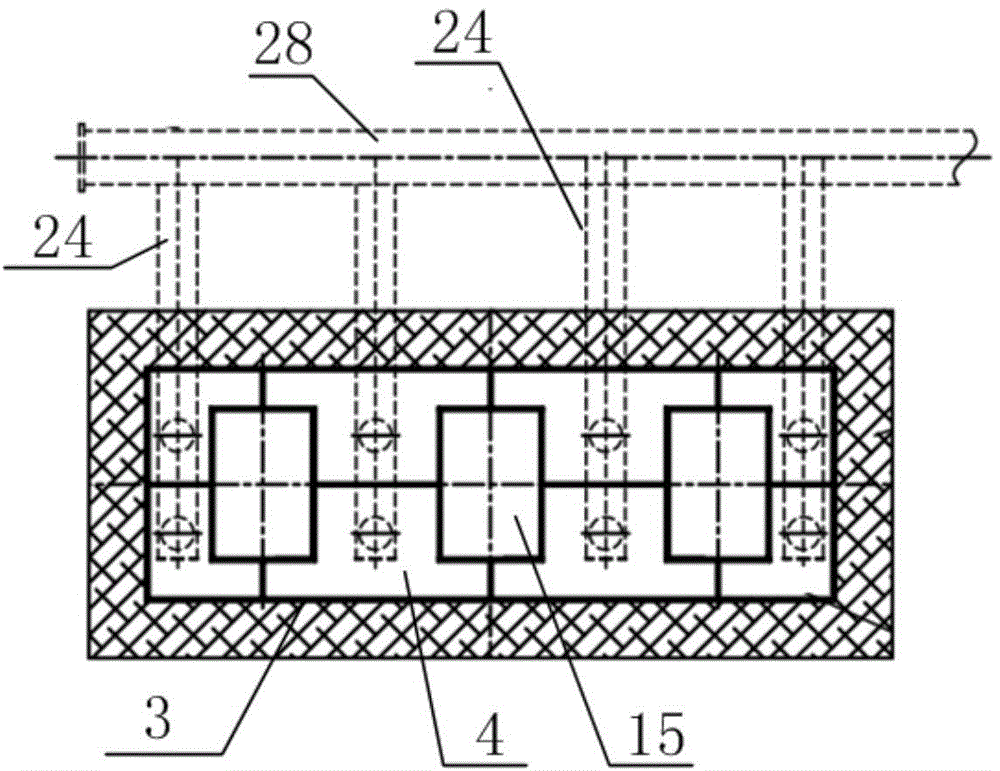

Provided is a printer with a peeling mechanism, when a pasteboard press roller 24 of a peeler 30 is switched from a pasteboard pressing position 24A where the pasteboard press roller 24 can be pressed against a platen roller 20 to a retreat position 24B, the reflector / receiver surface 21a of a photosensor 21 for detecting a label exposed from the opening 22b is covered and the photosensor 21 is at an unlabeled detecting state. Based on the label for detecting the output of the photosensor 21, the peeler 30 whether or not set in a label peeling mode or arranged at a retraction position can be identified, also the label issue mode can be set in the label peeling mode or the label continuous issue mode from the judgment results.

Owner:SEIKO EPSON CORP

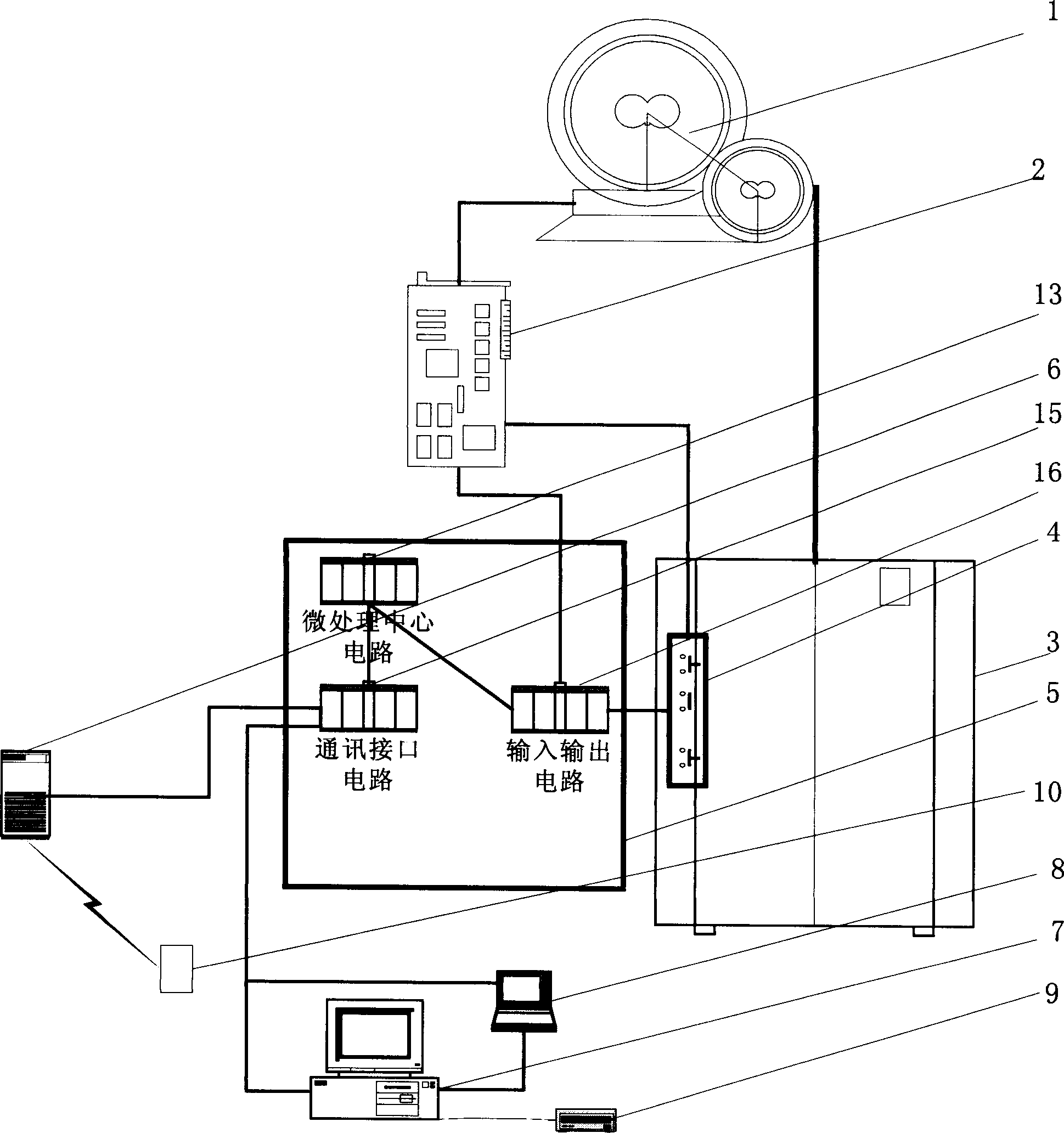

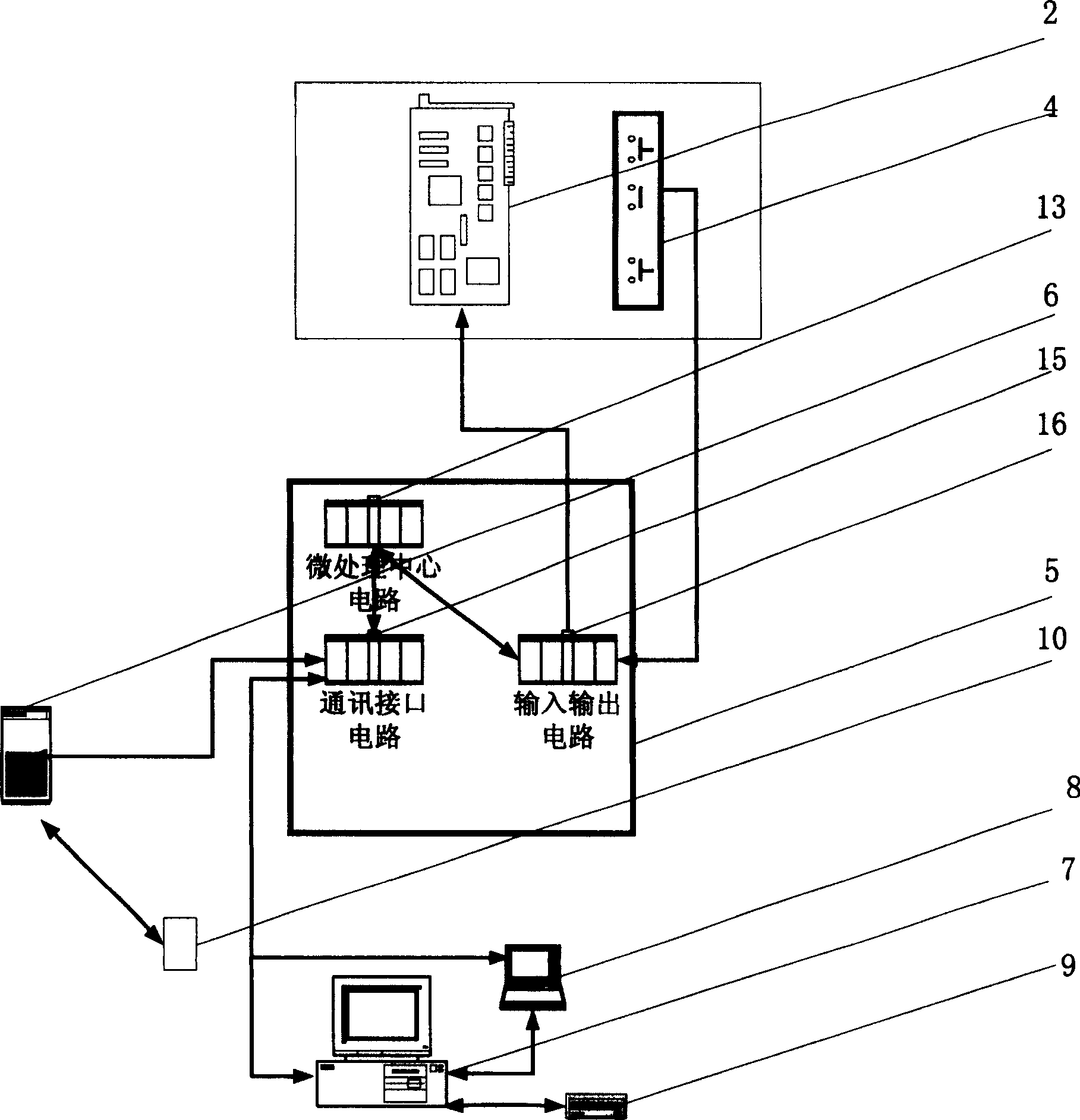

Intelligent control elevator connected with multifunctional device and elevator control method thereof

InactiveCN1439592AChange operating modeImprove securityElevatorsBuilding liftsSpeech identificationSmart card

An intelligent elevator and its control method features that its intelligent management module can be connected with multiple devices, such as interphone, biologic characteristics recognizer (fingerprint or retina recognizer), entrance guard, fire accident alarm, speech recognizer and intelligent card reader As a result, it can only be used by authorized people.

Owner:SHENZHEN WONGLONG INTELLIGENT TECH

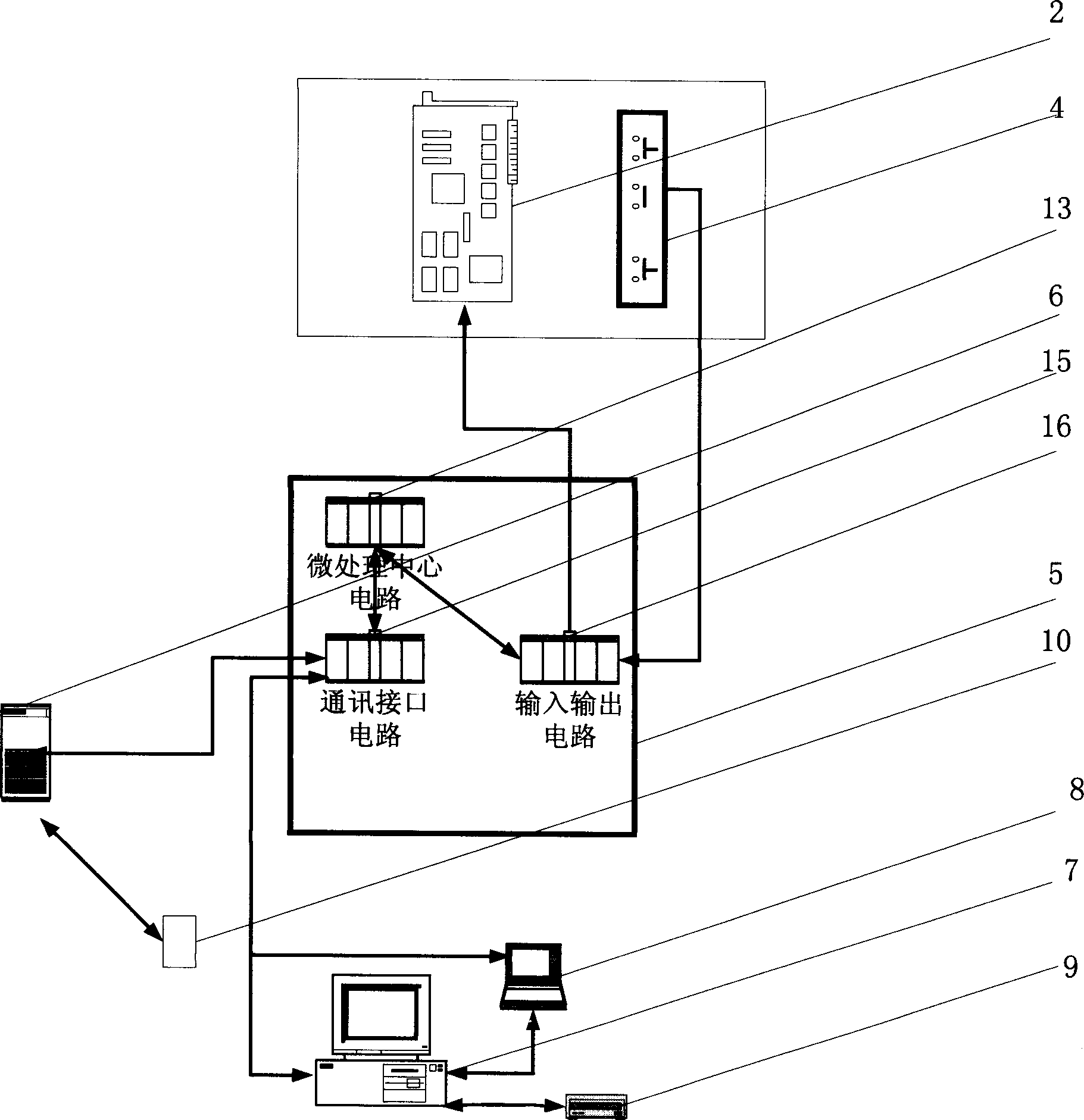

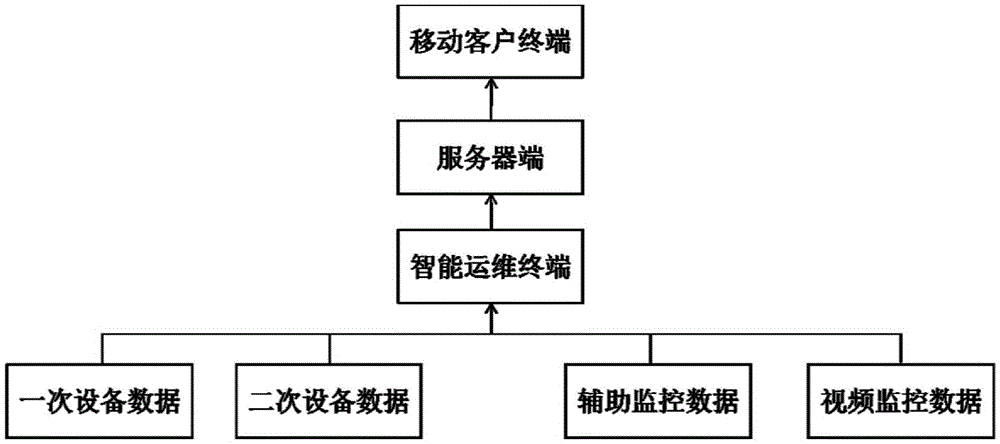

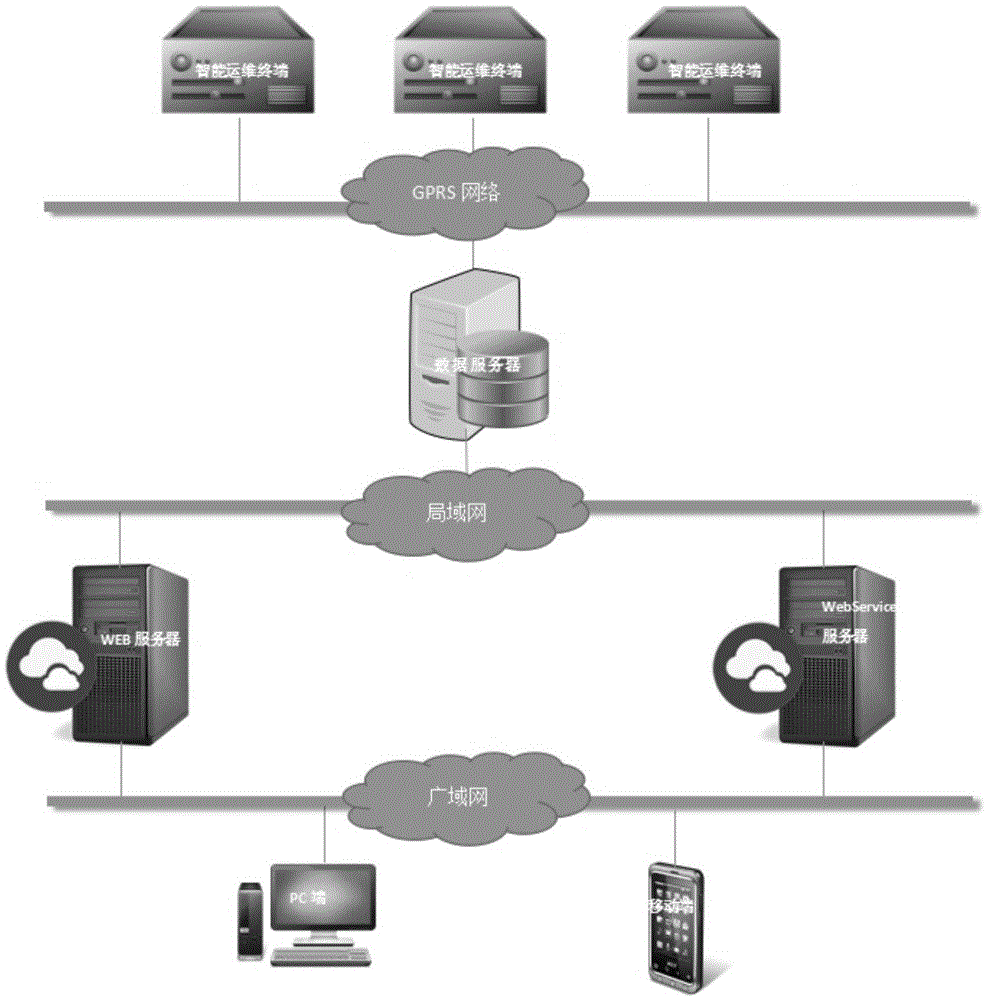

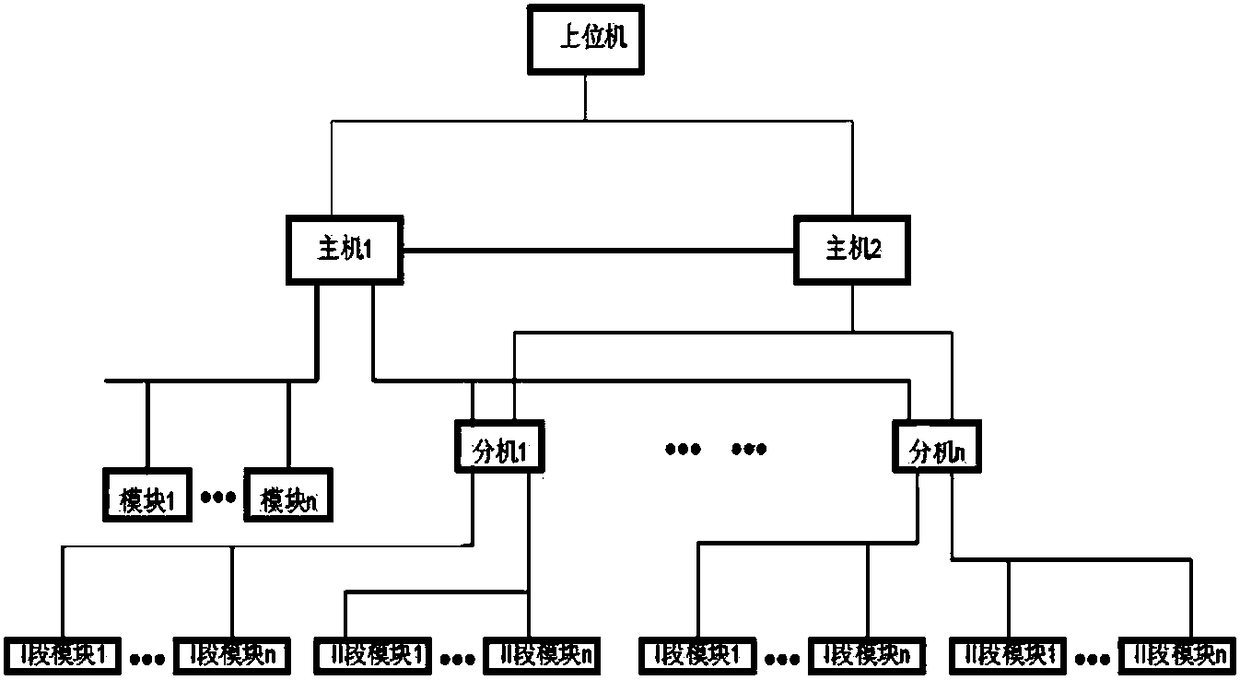

Intelligent monitoring operation and maintenance system for switch cabinets

ActiveCN105656210ARealize online monitoringRealize real-time monitoringCircuit arrangementsSustainable buildingsVideo monitoringElectric power system

The invention relates to a monitoring operation and maintenance system, particularly relates to an intelligent monitoring operation and maintenance system for switch cabinets, and belongs to the technical field of electric power systems. The intelligent monitoring operation and maintenance system for the switch cabinets comprises an intelligent operation and maintenance terminal, a server side and a mobile client terminal. Data acquired by the intelligent operation and maintenance terminal are received by the server side and are pushed to the mobile client terminal. The intelligent monitoring operation and maintenance system has the advantages that the intelligent monitoring operation and maintenance system has functions of monitoring the switch cabinets in an online manner, monitoring auxiliary systems of the switch cabinets, monitoring running states of primary and secondary equipment, analyzing faults, locating the faults, remotely monitoring the switch cabinets by the aid of video, automatically generating reports and the like; the intelligent monitoring operation and maintenance system has complete functions of monitoring the switch cabinets, operation modes of operation and maintenance staffs can be greatly facilitated, operation and maintenance modes for automatic switch cabinets with distribution networks can be completely changed, and all-data real-time monitoring, operation and maintenance can be completely implemented.

Owner:NANJING DAQO ELECTRIC CO LTD

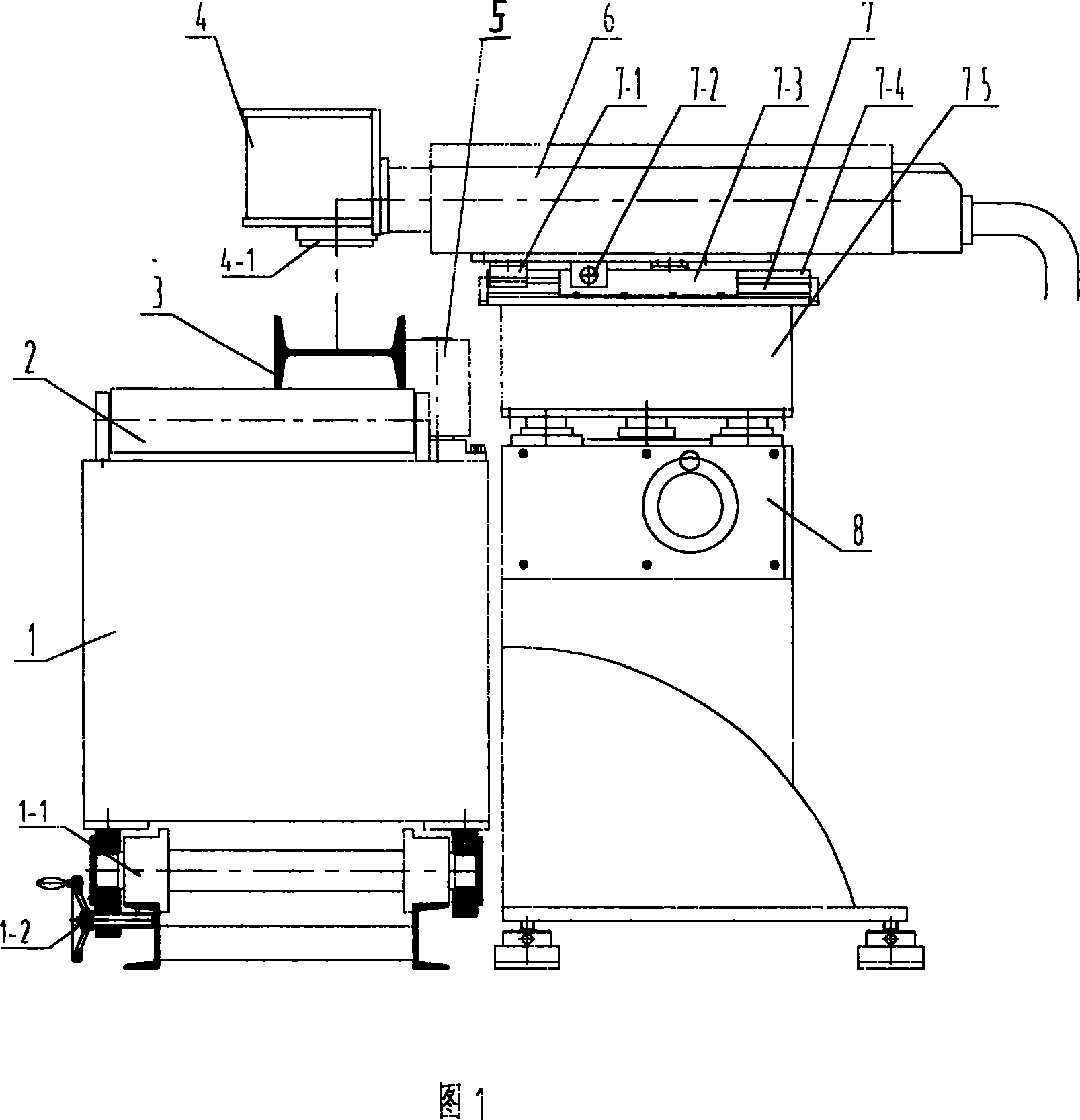

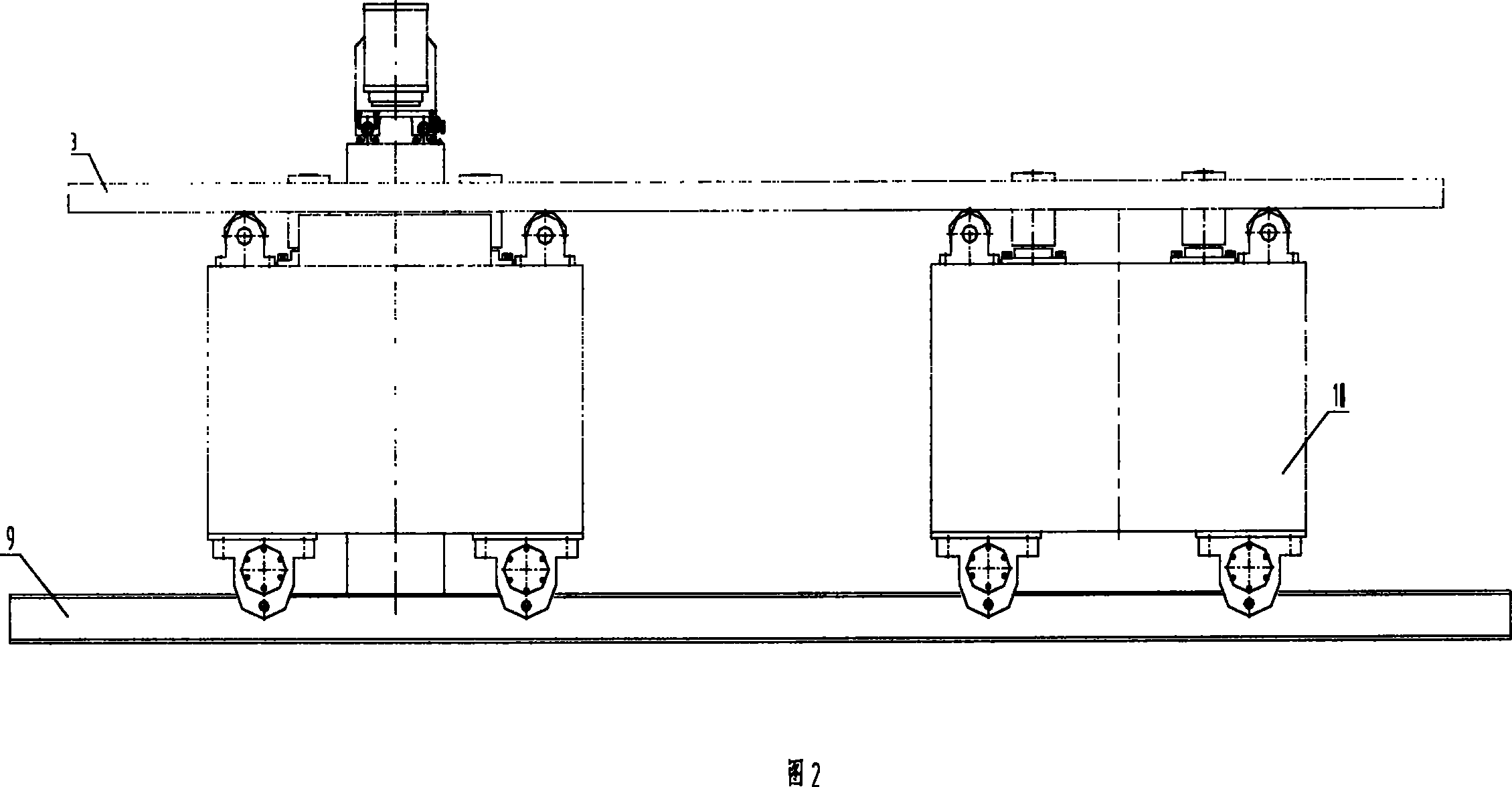

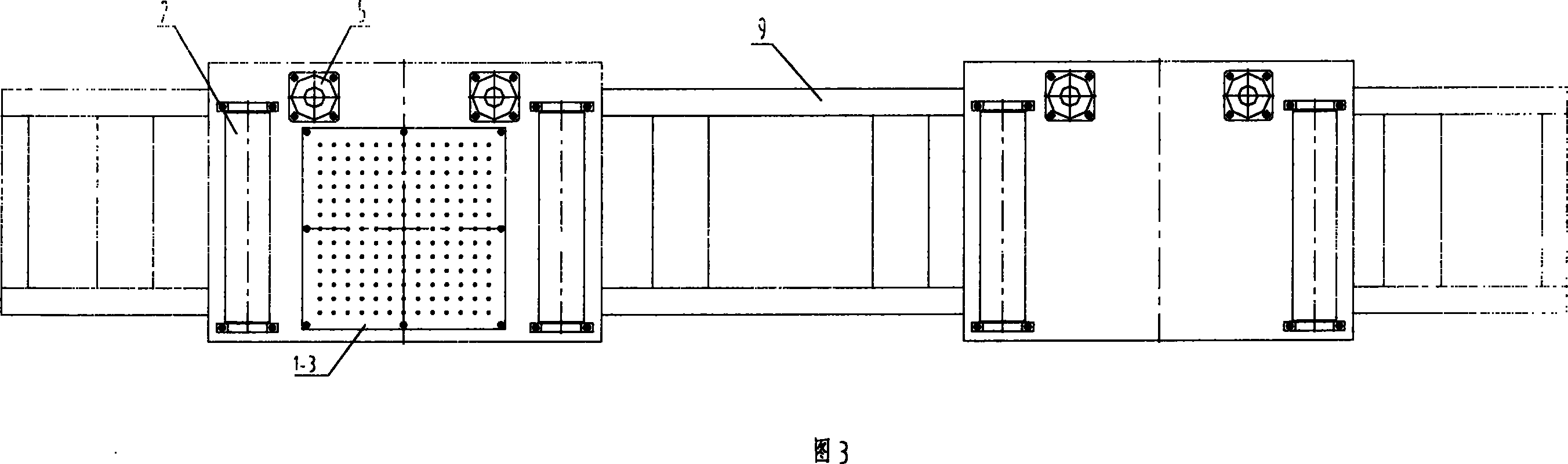

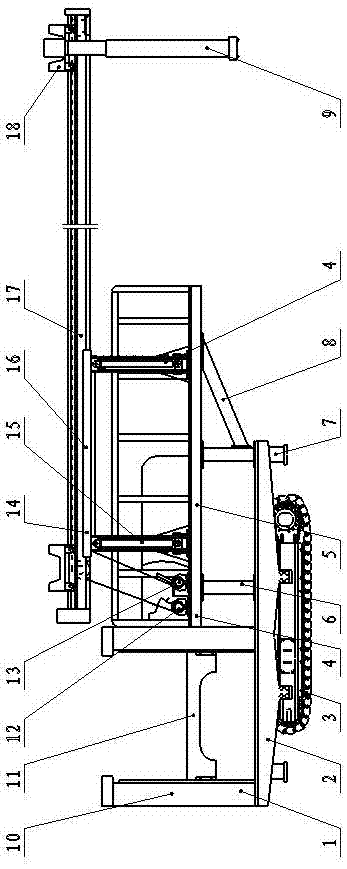

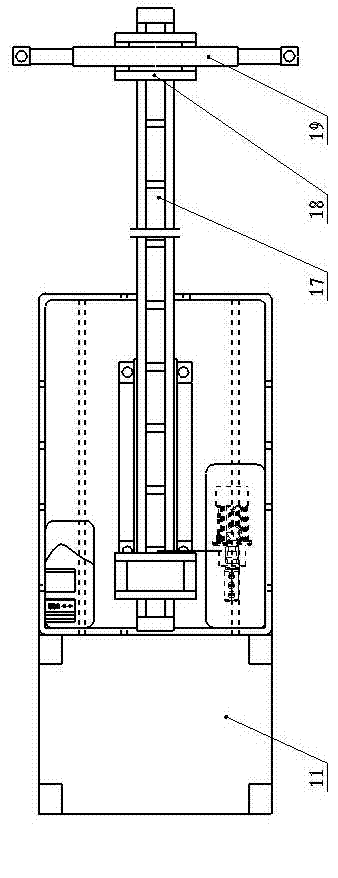

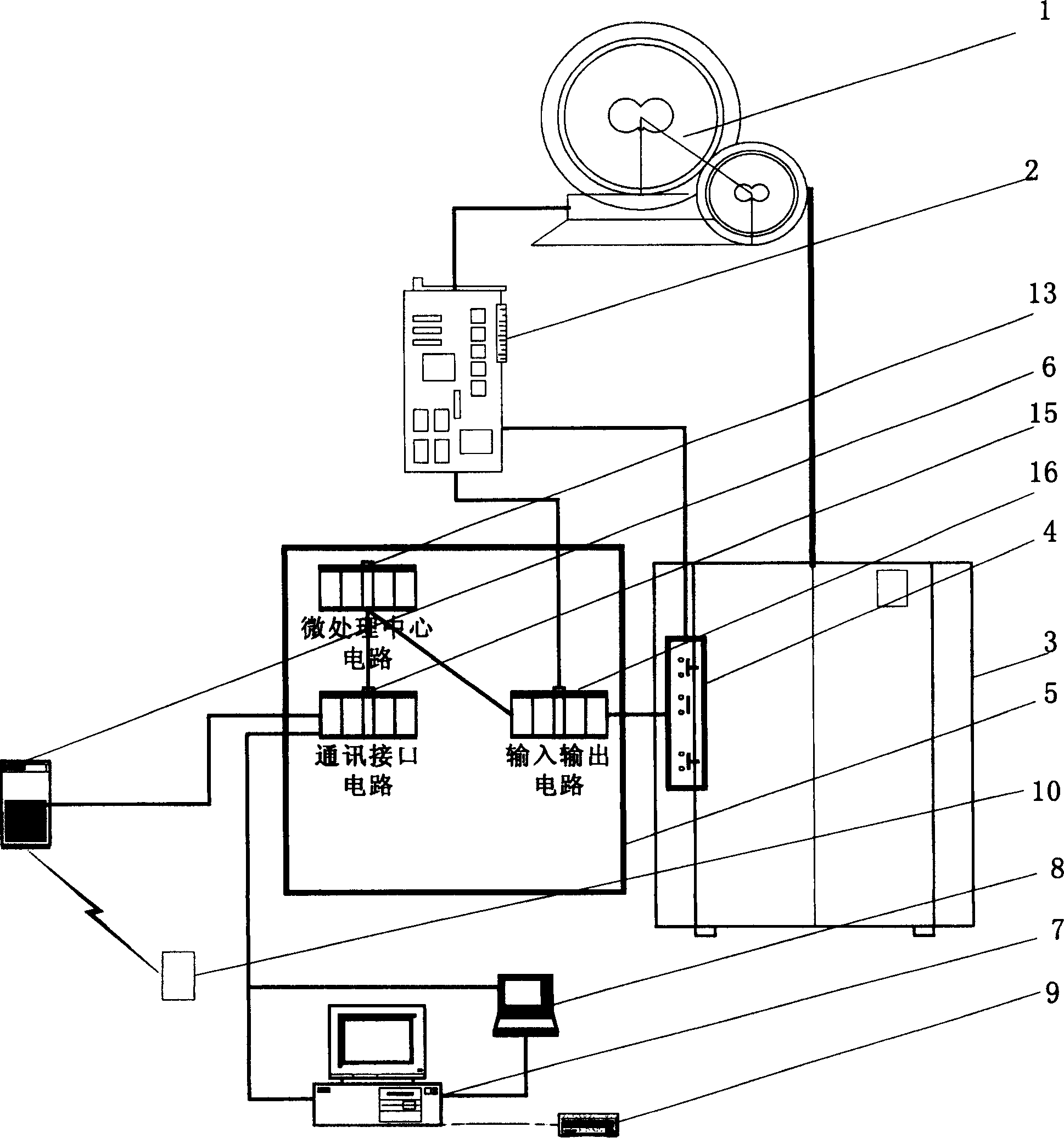

Laser mark printing device for section steel

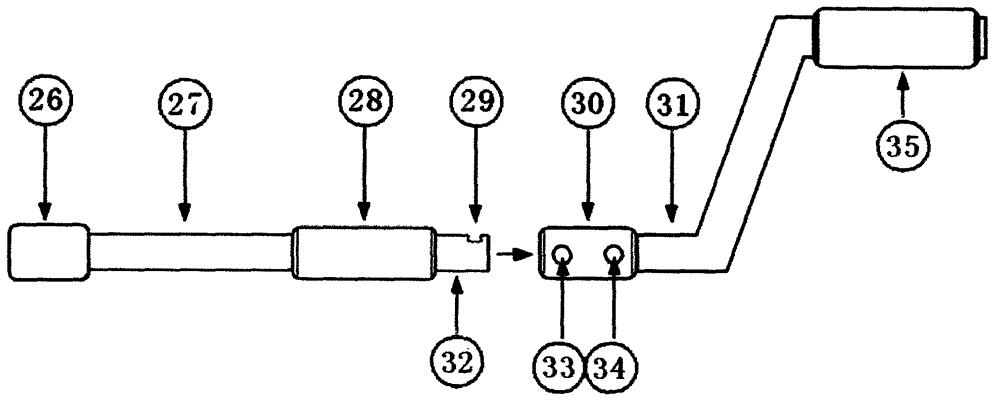

InactiveCN101121349ADoes not change mechanical propertiesCausing mechanical deformationAblative recordingLaser beam welding apparatusGraphicsOptical flat

The invention relates to the field of laser marking. The invention discloses a laser marking device for section steel, which includes a computer system, a laser, and an optical flat-field mirror located below the light-emitting part of the laser. It is characterized in that it also includes a main workbench trolley , workpiece, laser X-direction precision sliding table, laser Y-direction precision lifting mechanism, guide rail, driven work trolley, among which, the main workbench trolley and the slave work trolley are on the guide rail, and the workpiece is placed on the main workbench trolley and the slave work trolley The upper surface of the trolley is located below the optical flat field mirror. The invention has high efficiency, does not affect the performance of workpieces, can realize laser marking on large workpieces, changes the operation mode of manual painting on section steel for model marking, and can mark permanent pictures and texts on section steel.

Owner:武汉楚天激光(集团)股份有限公司

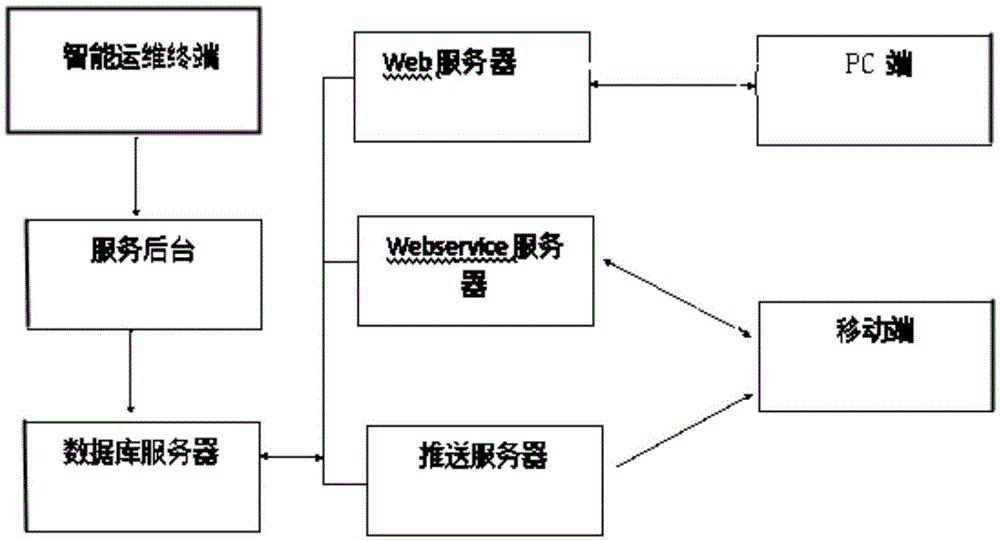

Intelligent operation and maintenance system for electric power line

PendingCN108206586ASimple operation modeChange operating modeCircuit arrangementsVideo monitoringElectric power system

The invention discloses an intelligent operation and maintenance system for an electric power line. The intelligent operation and maintenance system comprises an intelligent operation and maintenanceterminal, a server terminal and a mobile client terminal, wherein the server terminal is used for receiving data collected by the intelligent operation and maintenance terminal and pushing the data tothe mobile client terminal; the intelligent operation and maintenance terminal is arranged in a switchgear; and the collected data include primary equipment data, namely operation parameters of a circuit breaker, secondary equipment data, namely operation data, equipment self-inspection data, an equipment constant value and soft strap data, auxiliary monitoring data, namely data of an environmentsubsystem, a security subsystem, a fire control subsystem and a power subsystem, and video monitoring data, namely real-time field operation state video data. The intelligent operation and maintenance system has a complete monitoring function, the operation mode of operation and maintenance staff is also greatly facilitated, the operation and maintenance mode of the automatic switchgear of a distribution network is completely changed and real-time monitoring, operation and maintenance of all data are completely achieved.

Owner:XIANGYANG POWER SUPPLY COMPANY OF STATE GRID HUBEI ELECTRIC POWER +2

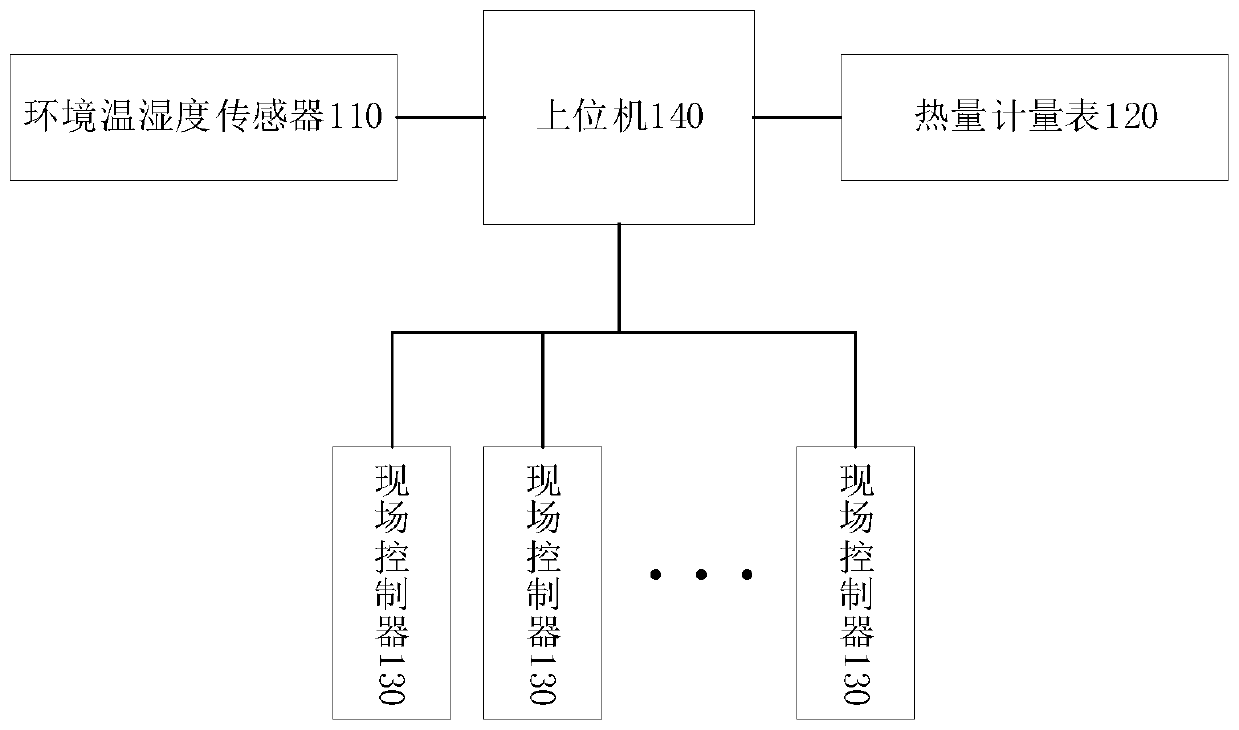

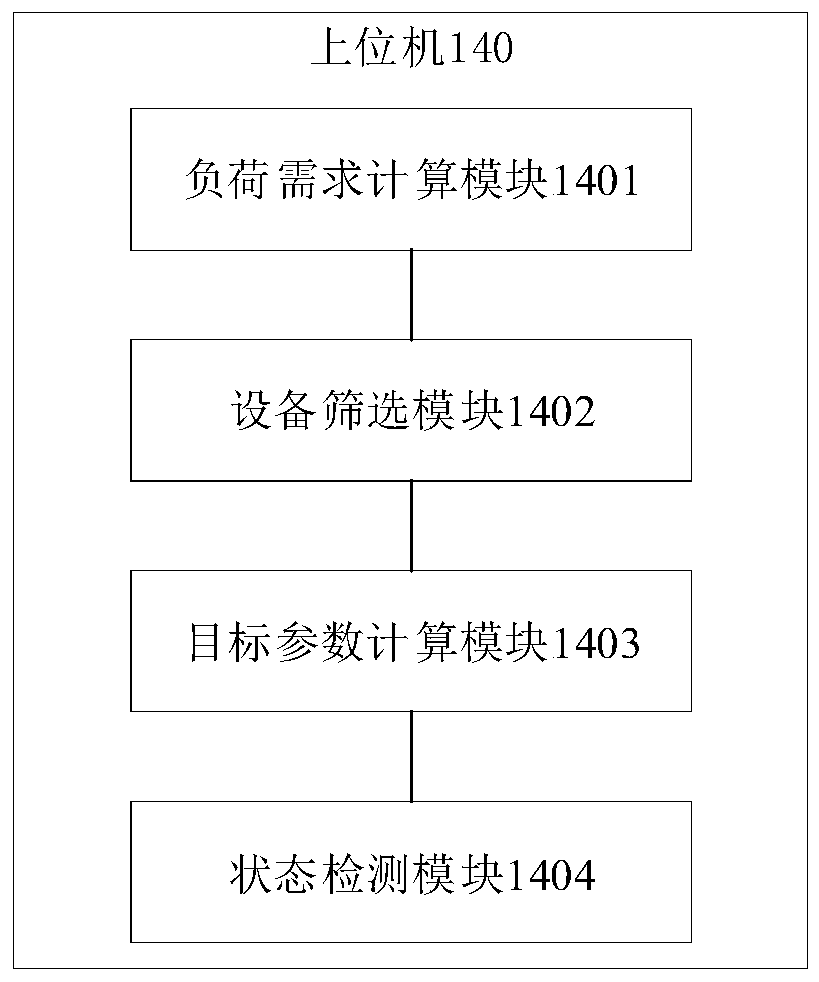

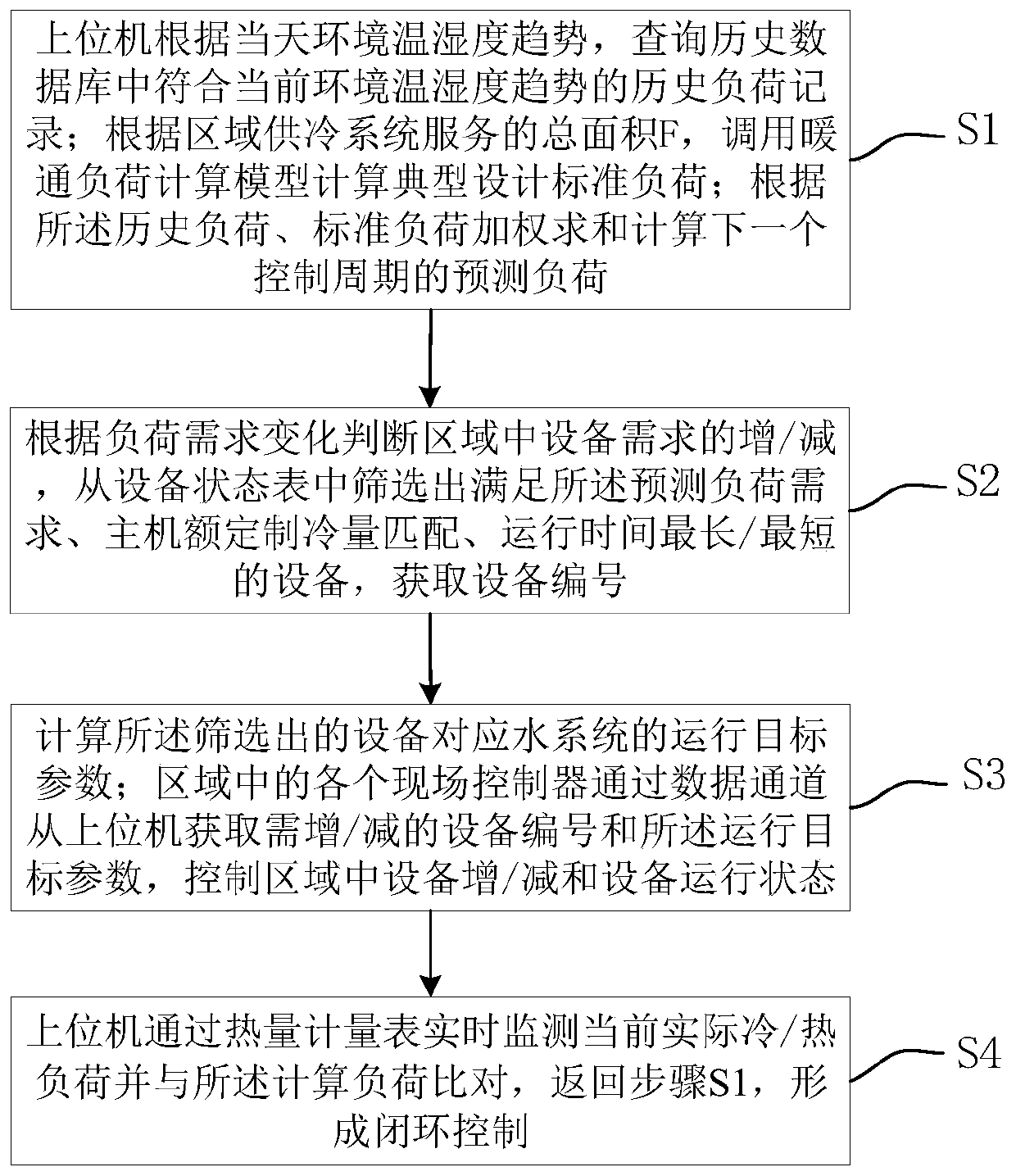

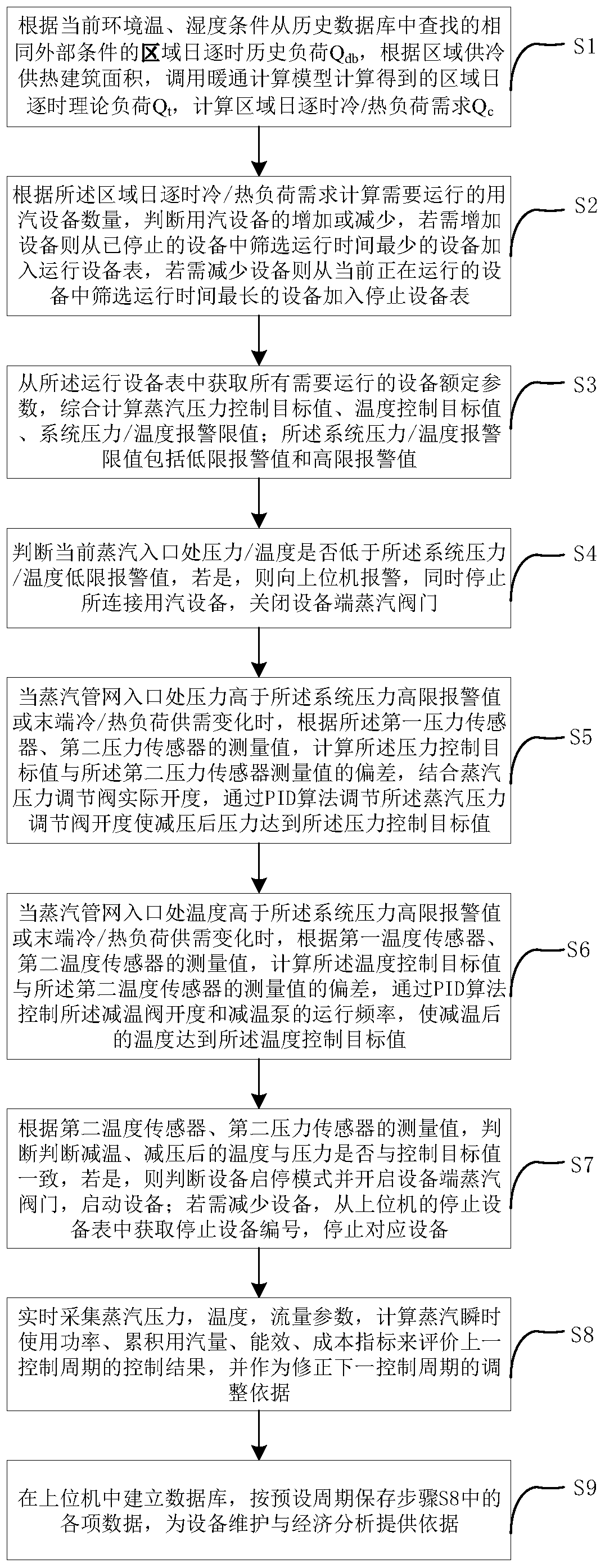

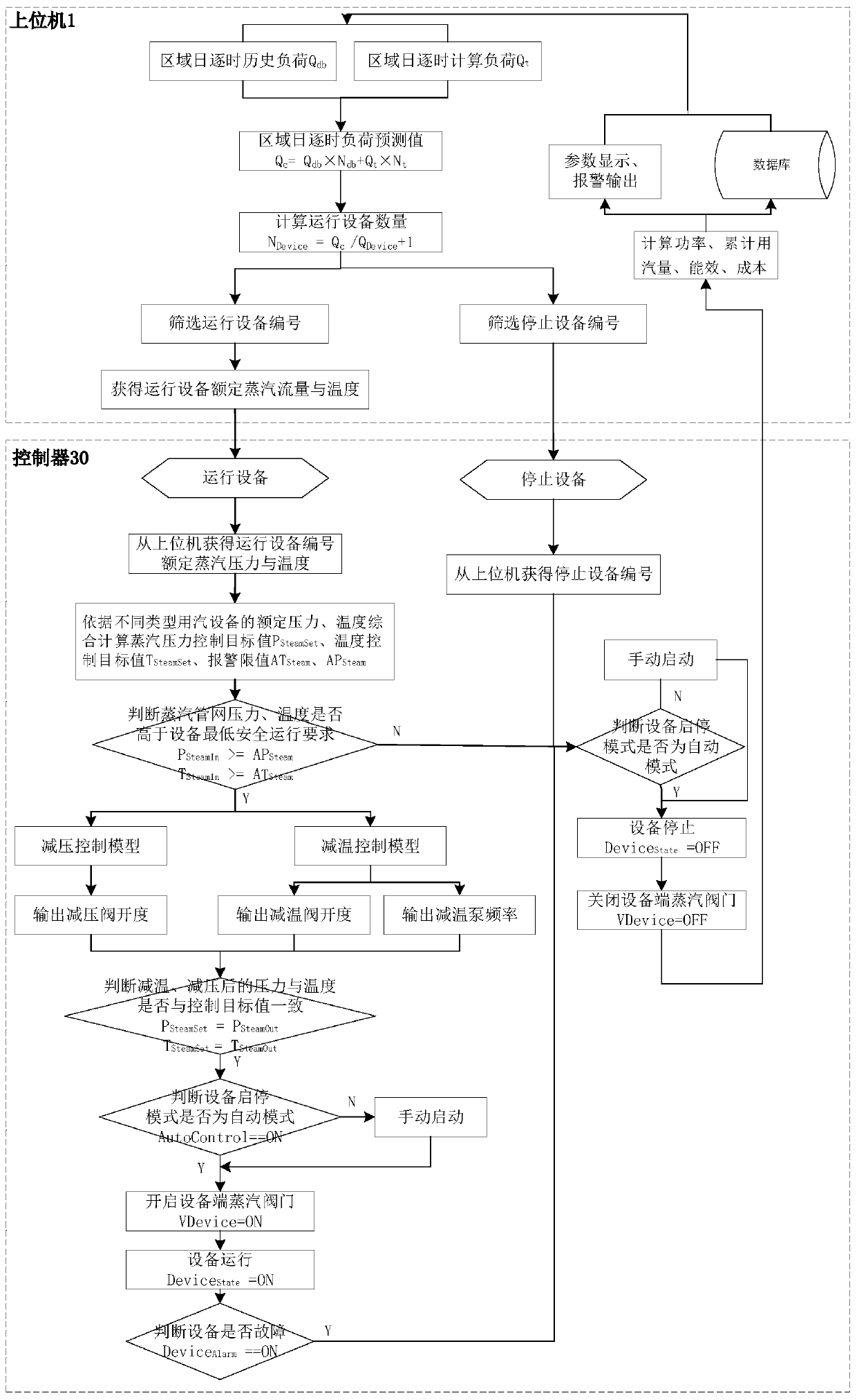

System and method for optimizing operation of cooling and heating devices in area

The invention provides a system and method for optimizing the operation of cooling and heating devices in an area. The method comprises the following steps that: S1, an upper computer queries historical load records, conforming to a current environmental temperature and humidity trend, in a historical database according to the according to a current environment temperature and humidity trend; a heating and ventilation load calculation model is invoked to calculate a typical design standard load; and weighted summation is carried out based on the historical load and the standard load, and a predicted load of a next cycle is calculated; S2, devices that meet the load need, have the matched host rated cooling capacities, and having the longest / shortest operation time are screened and serial numbers of the devices are obtained; S3, operation target parameters of the corresponding systems of the devices are calculated; and a field controller acquires a serial number of a device needing to be added or removed as well as the operation target parameters through a data channel and controls device increasing / decreasing and device operation states in the area; and S4, the S1 is performed again and closed loop control is formed. Therefore, the equipment operation efficiency is improved; the cost is lowered; and the energy consumption is reduced.

Owner:武汉中电节能有限公司

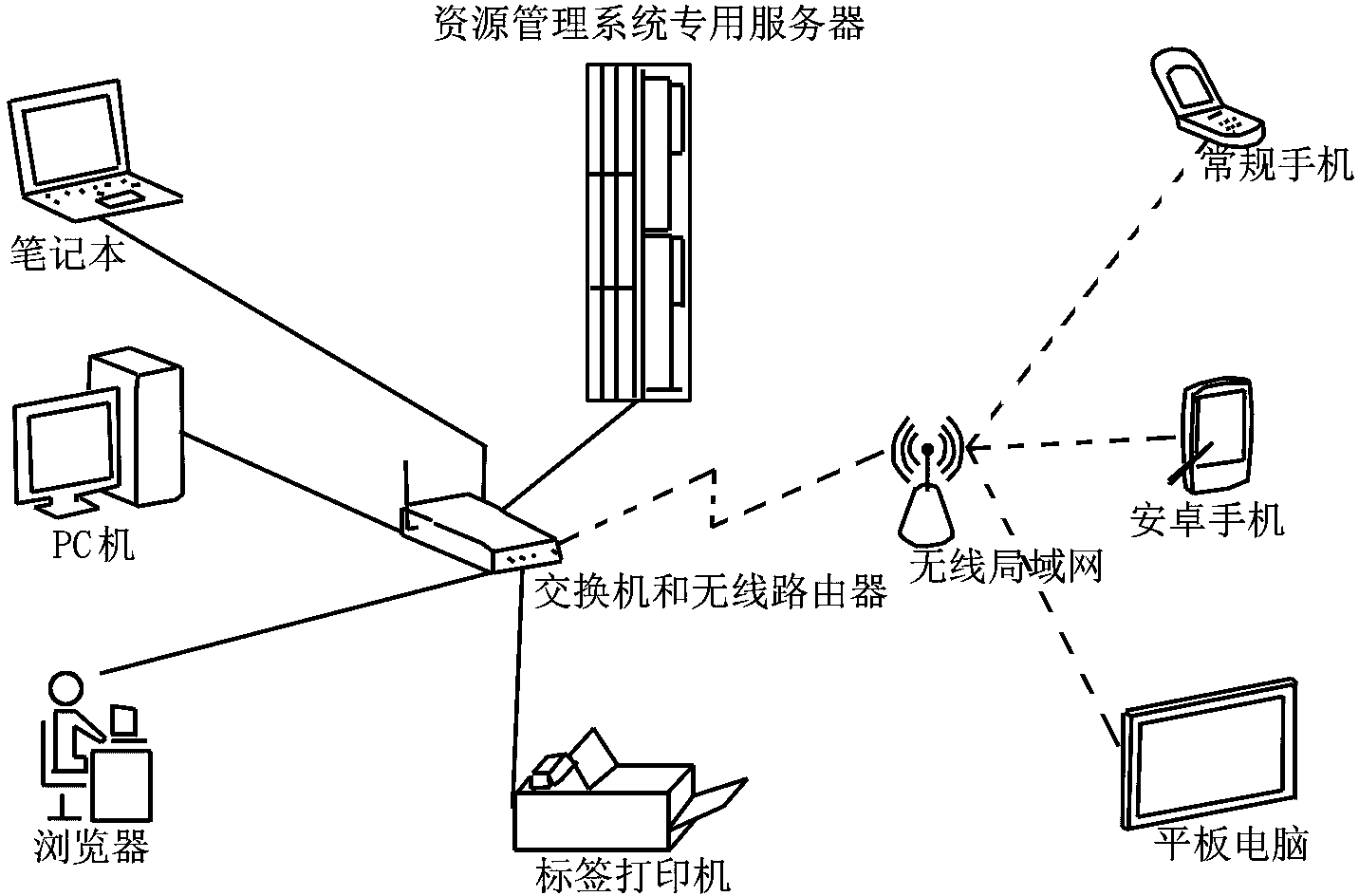

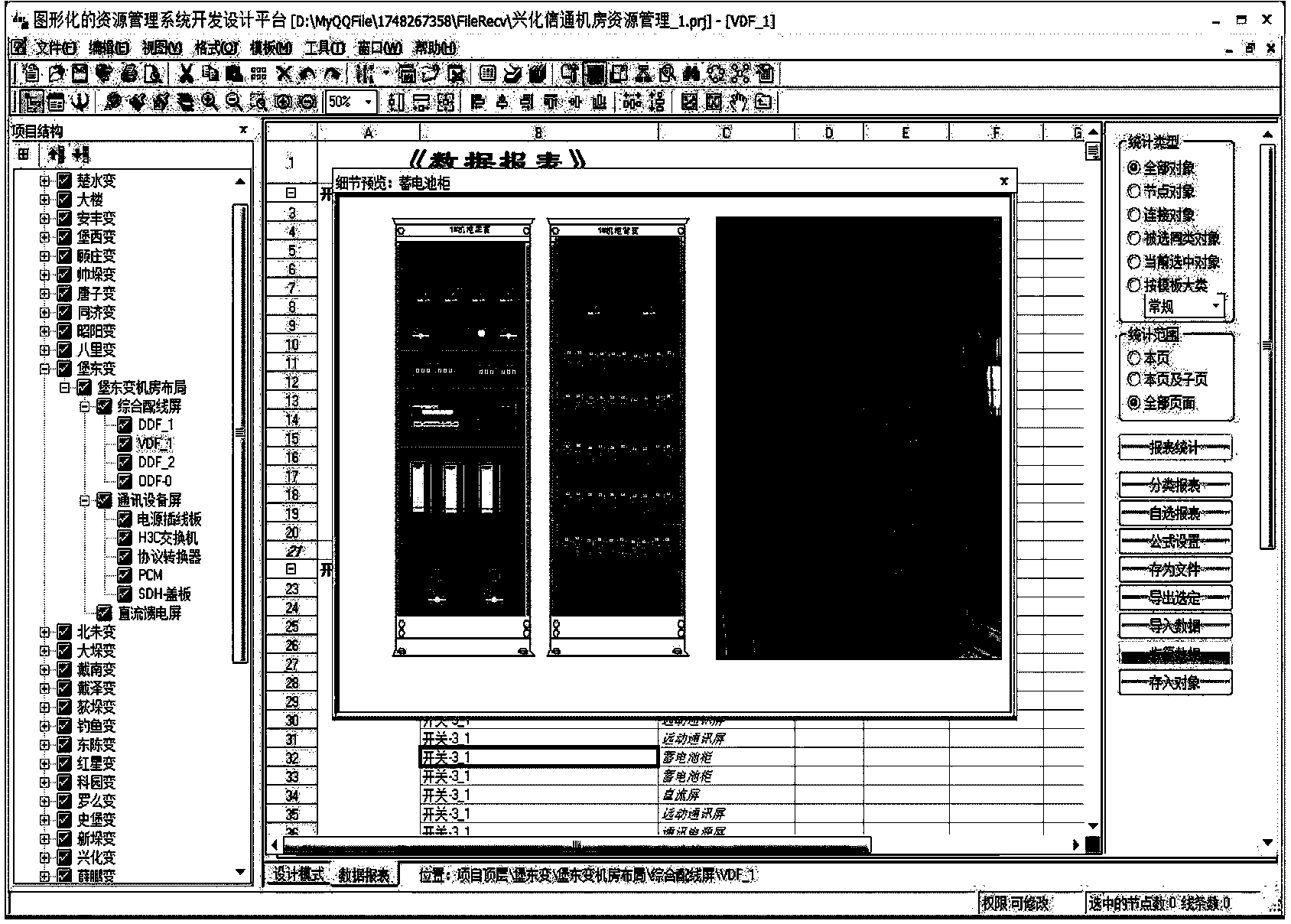

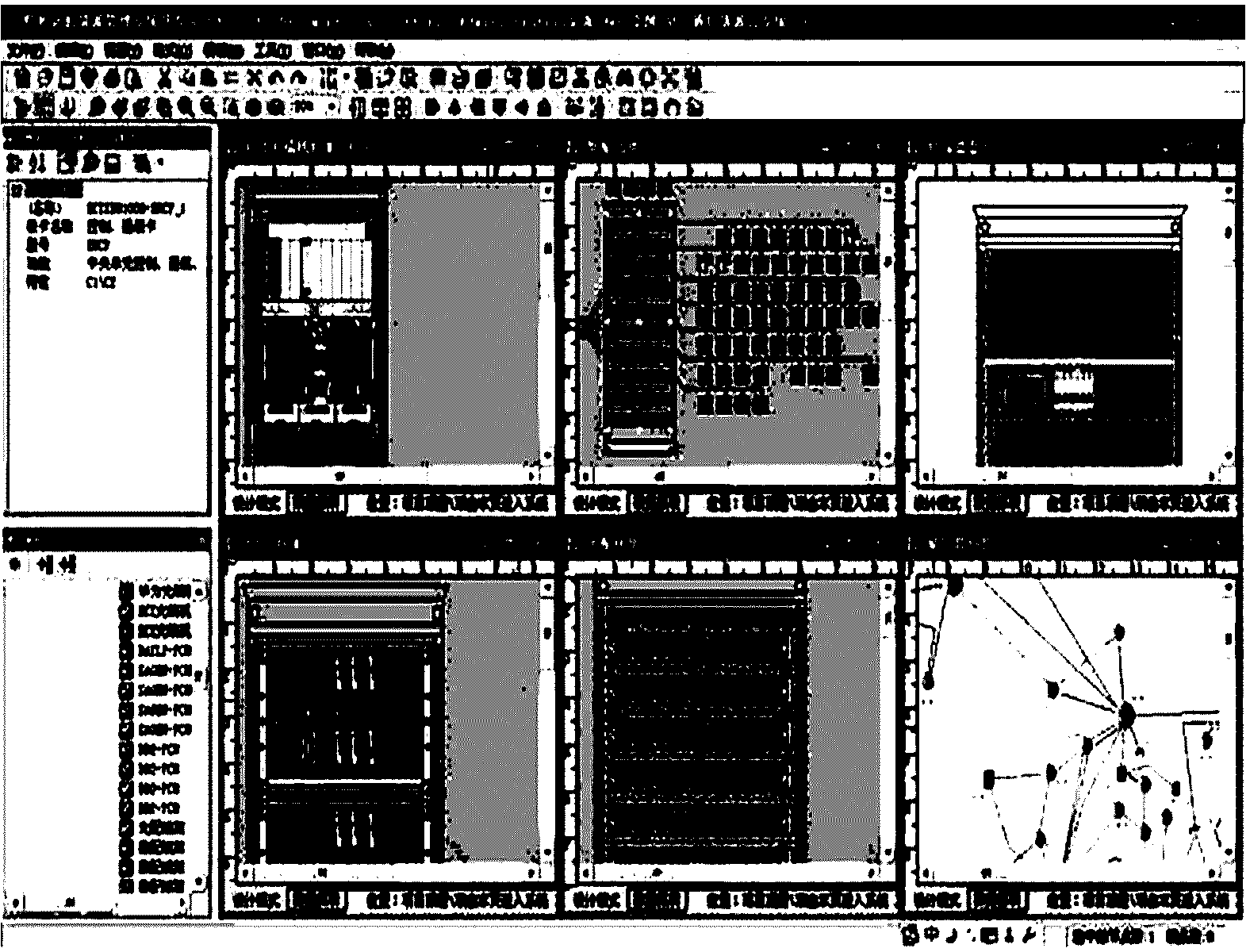

Information communication machine room device and line resource management system

InactiveCN103888286ASave operation and maintenance timeAvoid travel fatigueData switching networksWireless routerTablet computer

The invention discloses an information communication machine room device and line resource management system comprising a resource management system dedicated server, a switch, a wireless router, a laptop computer, a PC, a browser, a tag printer, a regular mobile phone, an Android mobile phone and a tablet computer. The output end of the resource management system dedicated server is connected with the receiving ports of the switch and the wireless router. Emission ports of the switch and the wireless router are respectively connected with the laptop computer, the PC, the browser and the tag printer in a wireless way. Besides, the emission ports of the switch and the wireless router are connected with the regular mobile phone, the Android mobile phone and the tablet computer via a wireless local area network in the wireless way.

Owner:STATE GRID CORP OF CHINA +3

Printing machine comprising stripper

InactiveCN100469658CChange operating modeAvoid problems caused by mismatchesManual label dispensersPrintingEngineeringPaper sheet

Provided is a printer with a peeling mechanism, when a pasteboard press roller 24 of a peeler 30 is switched from a pasteboard pressing position 24A where the pasteboard press roller 24 can be pressed against a platen roller 20 to a retreat position 24B, the reflector / receiver surface 21a of a photosensor 21 for detecting a label exposed from the opening 22b is covered and the photosensor 21 is at an unlabeled detecting state. Based on the label for detecting the output of the photosensor 21, the peeler 30 whether or not set in a label peeling mode or arranged at a retraction position can be identified, also the label issue mode can be set in the label peeling mode or the label continuous issue mode from the judgment results.

Owner:SEIKO EPSON CORP

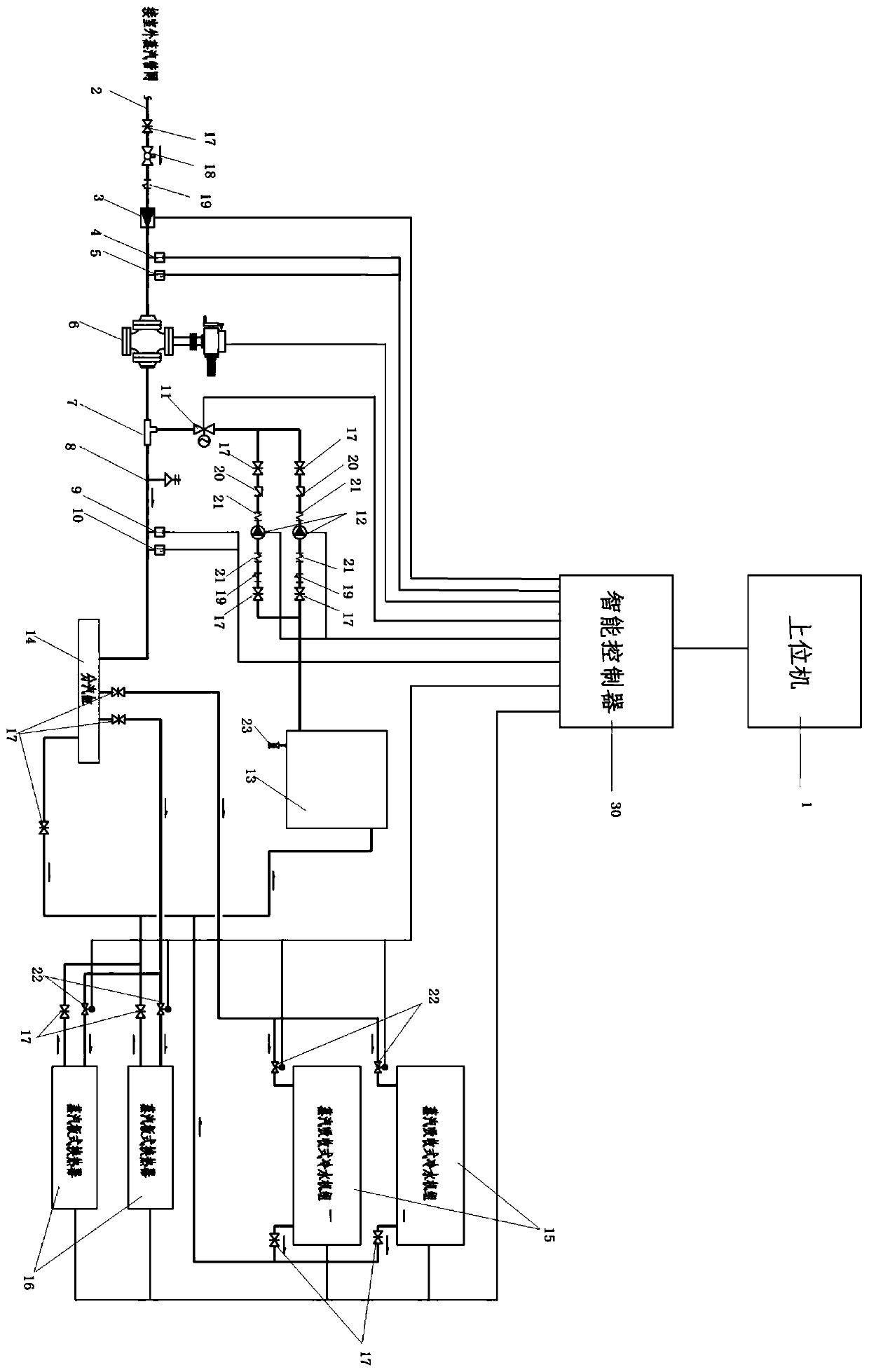

Automatic control system and method for regional cooling and heating steam desuperheating and decompression

ActiveCN109976419AImprove securityImprove work efficiencySimultaneous control of multiple variablesSteam pressureAutomatic control

The invention provides an automatic control system and method for regional cooling and heating steam desuperheating and decompression. The method comprises the steps that a regional cold / heat load demand is calculated; the number of steam devices to be operated is calculated, and the increase or decrease of the steam devices is judged to screen the devices; the steam pressure control target value,the temperature control target value, and the system pressure / temperature alarm limit are comprehensive calculated; whether the pressure / temperature of the current steam inlet is lower than the pressure / temperature low limit alarm value of the system is judged, and if so, an alarm is sent to an upper computer; when the pressure at the inlet of a steam pipe network is higher than the pressure of the system, automatic adjusting of the opening degree of a steam pressure regulating valve is realized through a PID algorithm for decompression control; when the temperature at the inlet of the steampipe network is higher than the temperature limit of the system, automatic control of the opening degree of a desuperheating valve and the operating frequency of a desuperheating pump is realized through the PID algorithm to perform desuperheating control; and if the temperature meets a requirement after desuperheating and decompression, the device is started. According to the invention, the working efficiency is improved; the operating cost is reduced; and energy is saved.

Owner:武汉中电节能有限公司

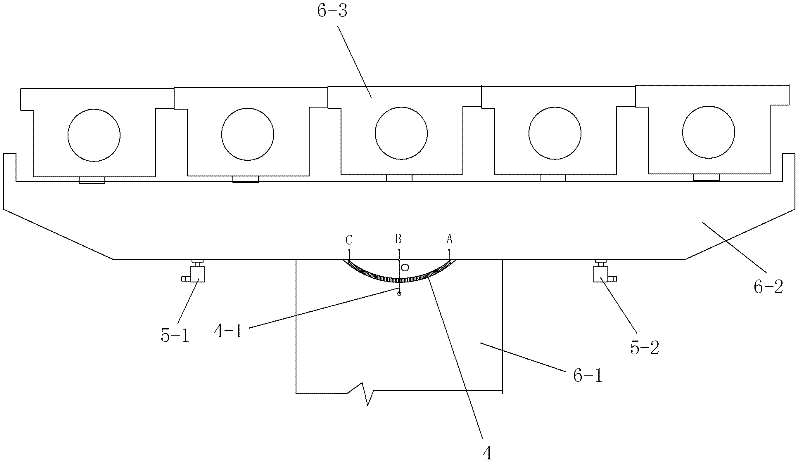

Control system for integrated synchronous jacking of cut pier and control method

ActiveCN102505642AReasonable designLow input costBridge erection/assemblyBridge strengtheningAutomatic controlControl system

The invention discloses a control system for integrated synchronous jacking of a cut pier and a control method. The control system comprises two hydraulic jacking devices for providing jacking power, two hydraulic circuits connected with the two hydraulic jacking devices respectively, two oil feeding amount adjusting devices and a jacking balancing state monitoring device, wherein the two oil feeding amount adjusting devices are installed on the two hydraulic circuits respectively, and the jacking balancing state monitoring device performs real-time monitoring to a balancing state of a structure needing to be jacked in the jacking process and controls the two oil feeding amount adjusting devices according to monitoring results. The control method comprises the steps of jacking preparation and jacking, upward jacking is performed to the structure through the two hydraulic jacking devices in actual jacking until the structure is jacked to a preset height, and timely dynamic deviation rectification is carried out to the structure. The control system for integrated synchronous jacking of the cut pier and the control method are reasonable in design, high in automation, good in coordinating performance and safety performance and simple and convenient to control, enables the jacking process to be smooth and efficient, and can effectively solve the construction problem that unbalanced elevation discrepancy limitation in the pier cutting integration jacking process cannot be automatically controlled.

Owner:CHINA RAILWAY FIRST GRP CO LTD

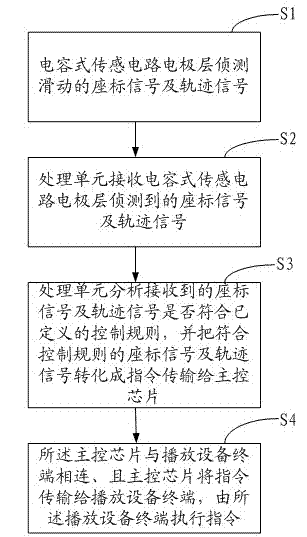

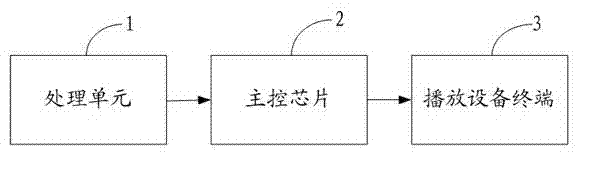

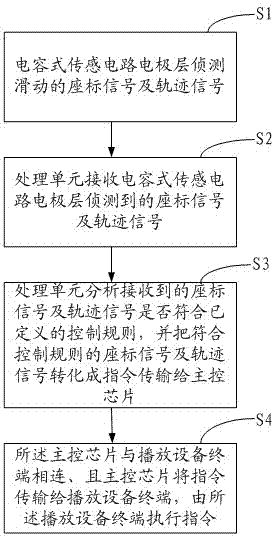

Headset control method and headset

ActiveCN102547511AEasy to controlImprove convenienceEarpiece/earphone mechanical/electrical switchesEngineeringCapacitive sensing

The invention provides a headset control method. The headset control method includes the following steps: (A) the electrode layer of a capacitive sensing circuit detects sliding coordinate signals and track signals; (B) a processing unit receives the coordinate signals and the track signals detected by the electrode layer of the capacitive sensing circuit; (C) the processing unit analyzes whether the received sliding coordinate signals and track signals meet a defined control rule, converts the coordinate signals and the track signals meeting the control rule into instructions, and transmits the instructions to a main control chip; (D) the main control chip is connected with a player terminal, and transmits the instructions to the player terminal, and the player terminal executes the instructions.

Owner:SHENZHEN LEZUN ELECTRONICS

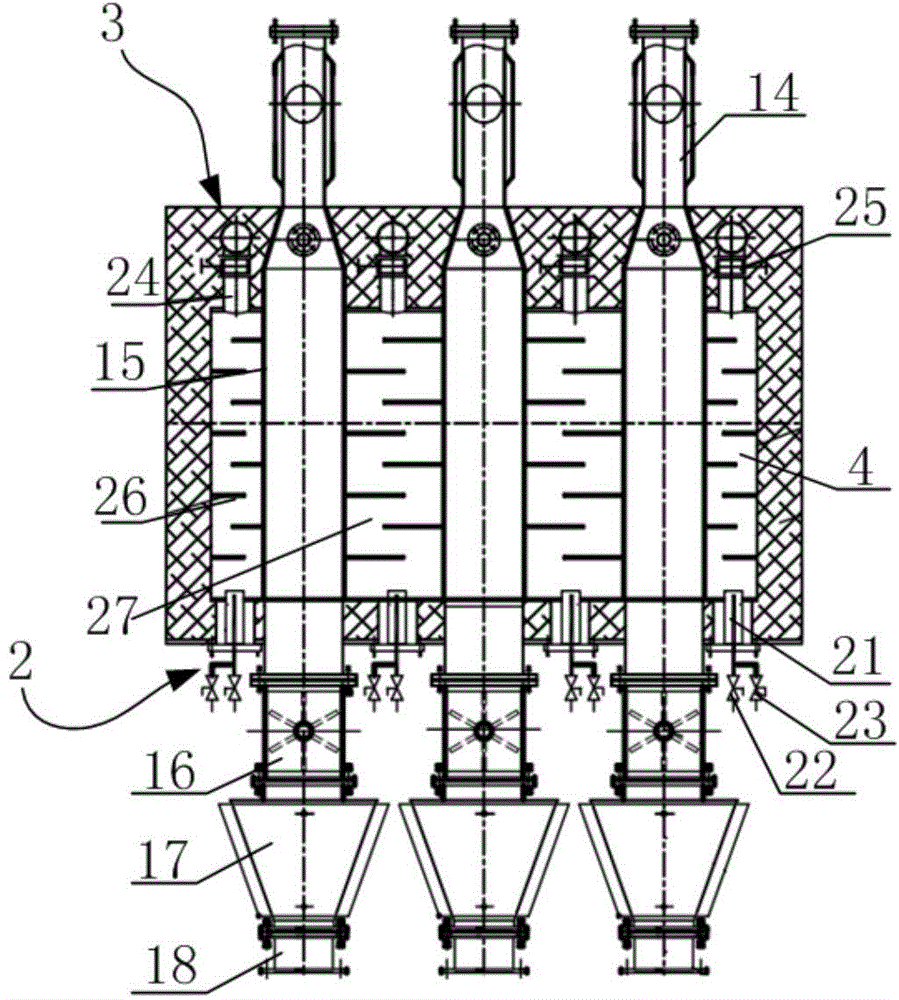

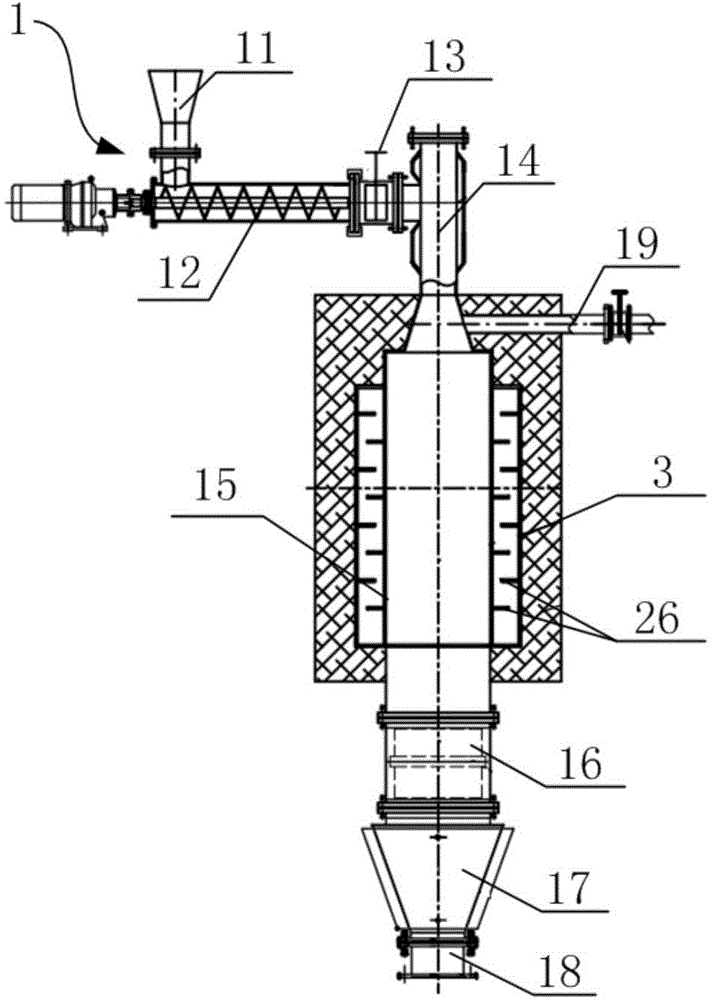

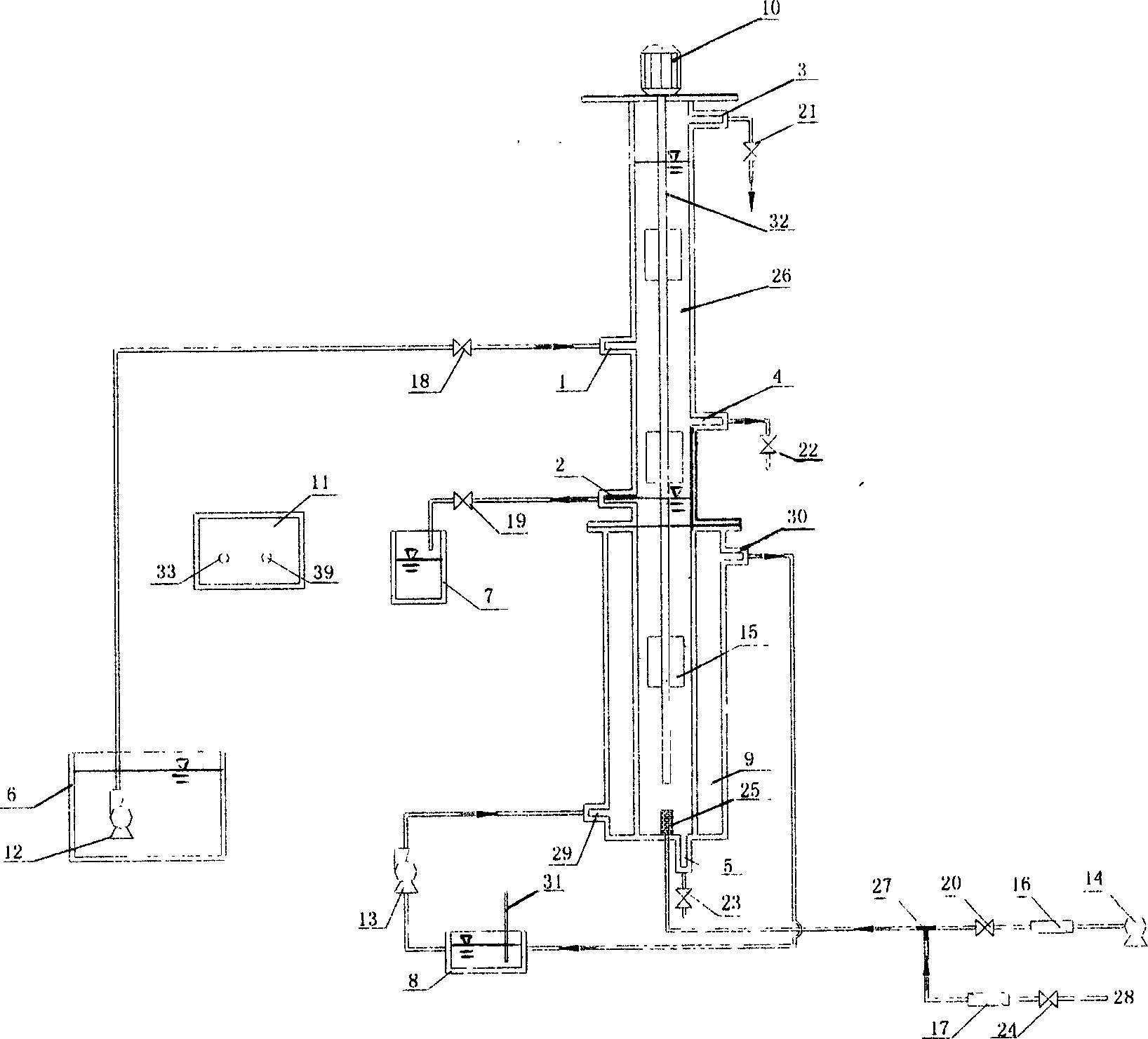

Waste tire cracking furnace

InactiveCN104059684ALarge amount of processingAvoid the disadvantages of intermittent operationPigmenting treatmentPlastic recyclingEnergy consumptionPetroleum engineering

The invention relates to a waste tire cracking furnace which comprises a cracking furnace body, a cracking system, and a heating system for heating the heating chamber, and the inside of the cracking furnace body is a heating chamber. The cracking system comprises cracking chambers, a feeding conduit, a spiral feeder and a star-like discharging valve, wherein the cracking chambers are vertically arranged in the heating chamber of the cracking furnace body and both ends of the cracking chambers extend out of the cracking furnace body, the feeding conduit is vertically installed at the top end of the cracking chamber, the spiral feeder is communicated with the feeding conduit and the star-like discharging valve is vertically installed at the bottom end of the cracking furnace. The cracking chambers of the waste tire cracking furnace provided by the invention are vertical and are alternately arranged in the heating chamber, and feed and slag discharge are continuously and hermetically operated, so that the operating mode of the rotary kiln type cracking furnace is changed, the energy loss caused by intermittent operation is reduced, and the environmental pollution caused by leakage of cracking gases in loading and unloading and overflow of carbon black is avoided. Therefore, the waste tire cracking furnace is simple in process equipment, great in handling capacity, low in production cost and low in energy consumption and can realize zero emission.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

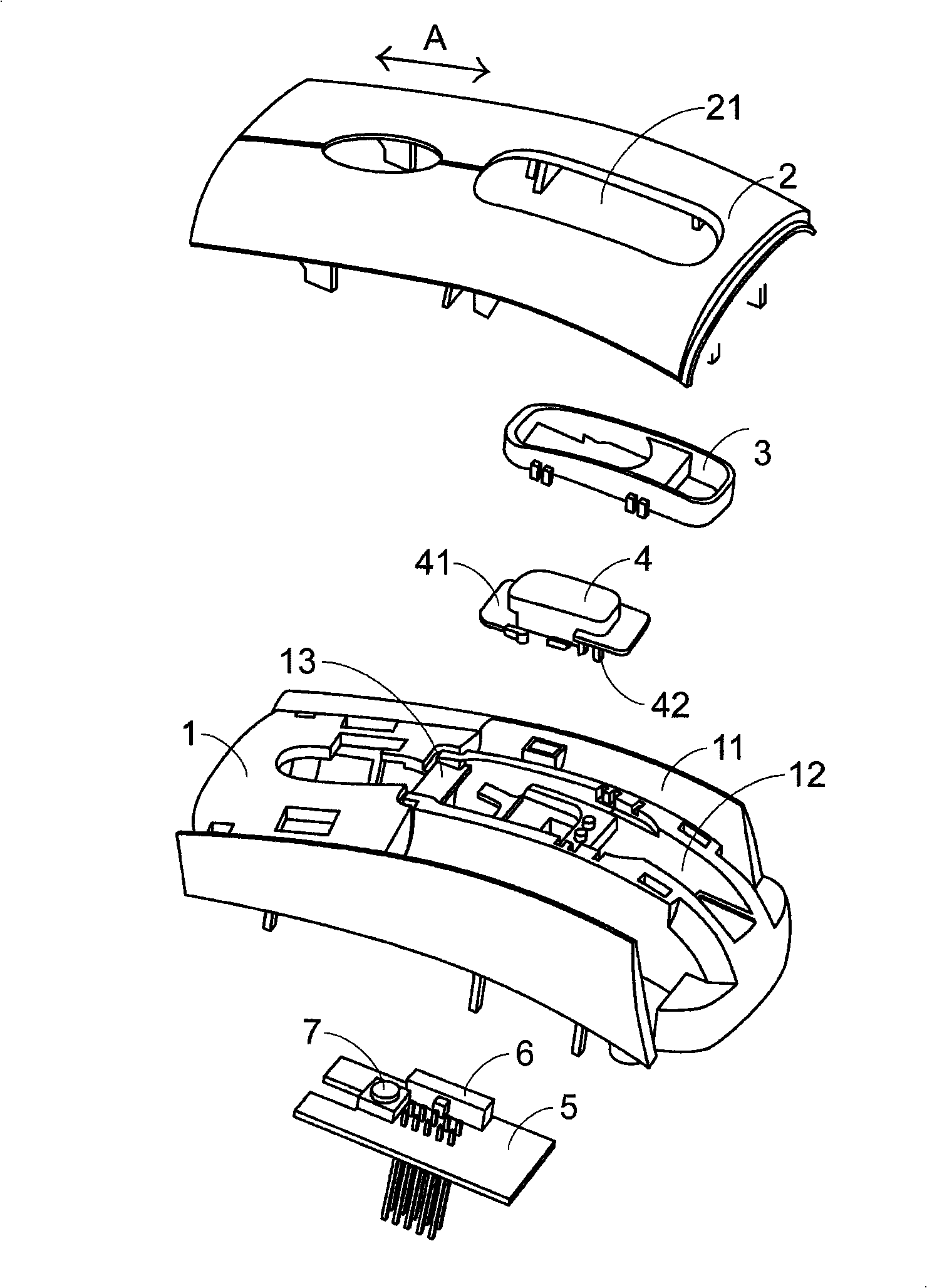

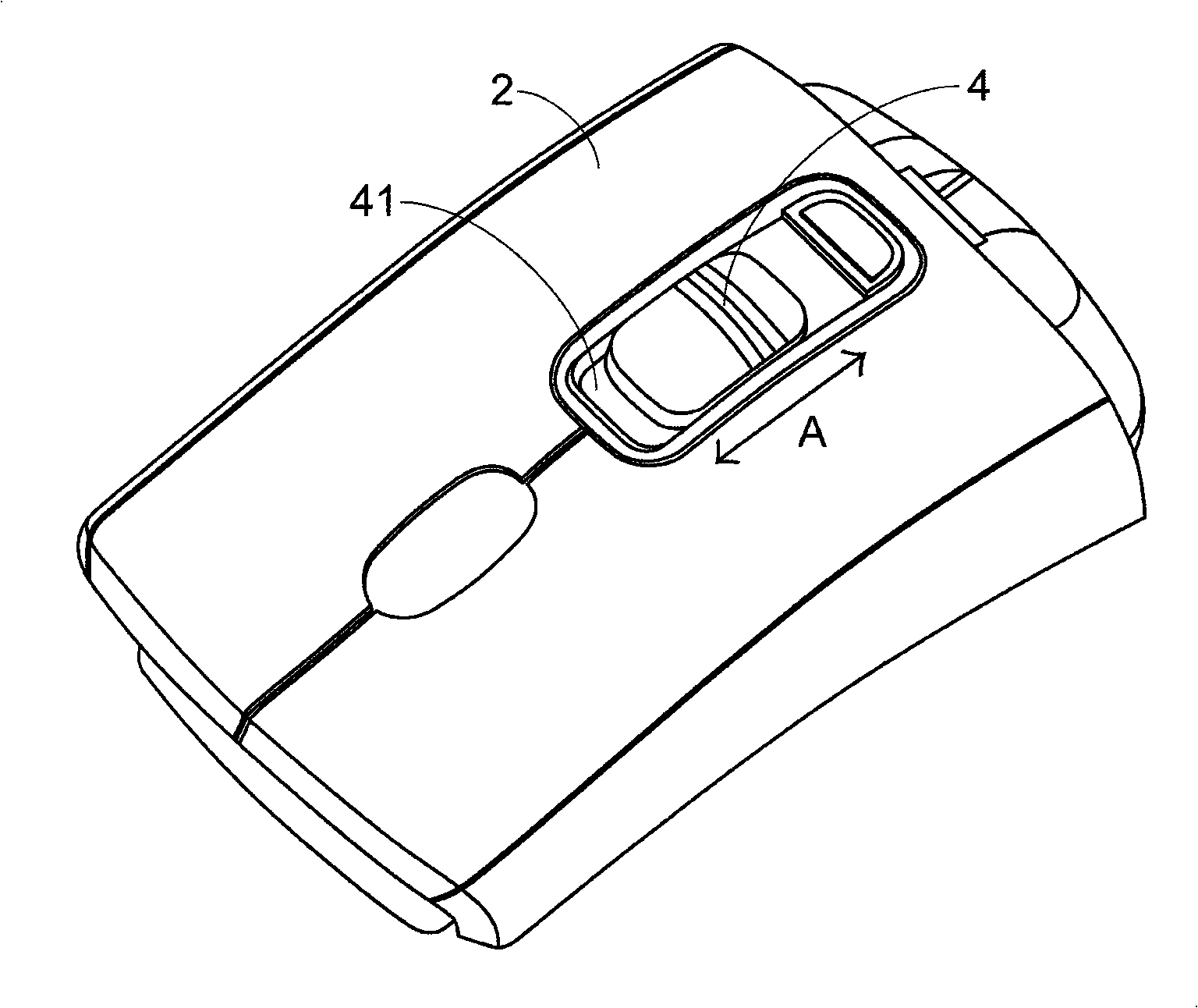

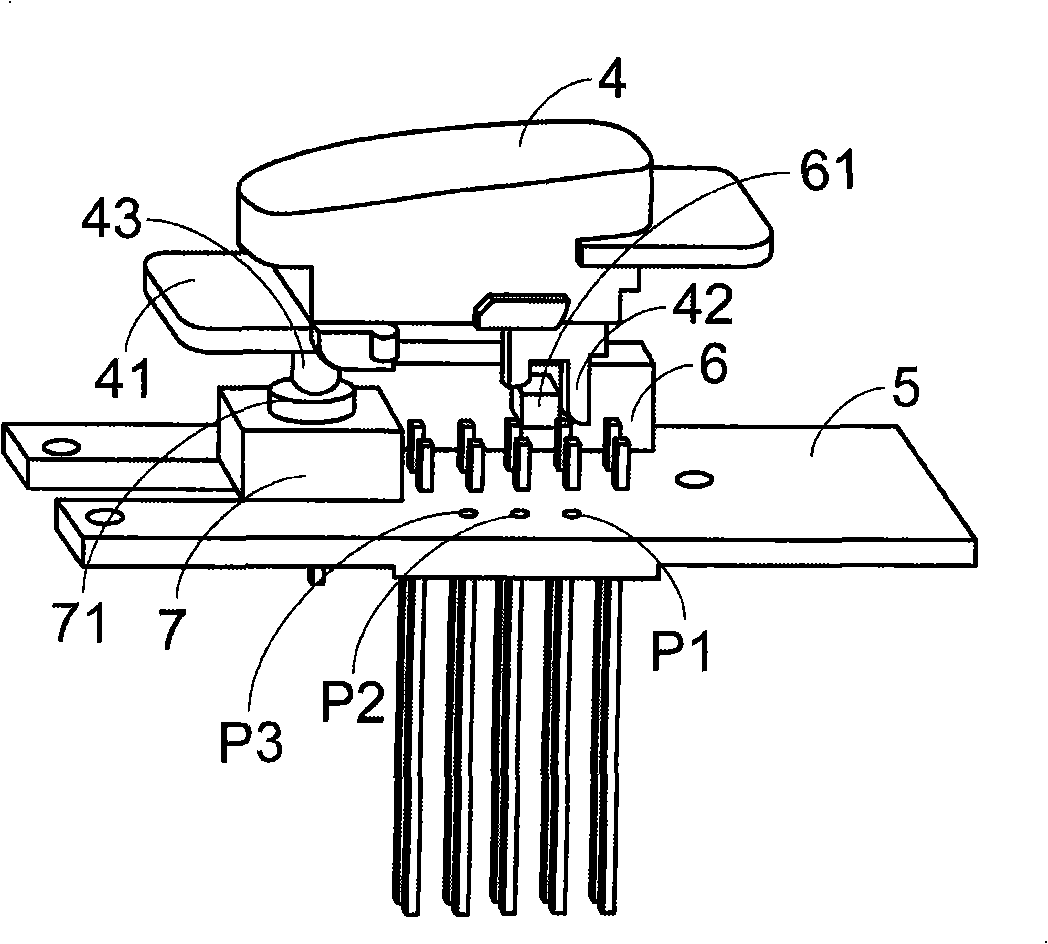

Mouse possessing combined switch

InactiveCN101308410AChange operating modeElectric switchesInput/output processes for data processingElectricityOperation mode

The invention discloses a mouse with a compound switch and comprises a main shell body, a cover piece and a button; the button comprises a tongue piece, a gripping part and a contact part; the mouse also comprises a circuit board, a multi-section slide switch and a contact switch. The multi-section slide switch is electrically connected to the circuit board and has a first mode and a second mode; the multi-section slide switch comprises a slide arm gripped in the gripping part of the button; the slide arm is moved to a first position or a second position along with the movement of the button; when the slide arm is moved to the first position, the multi-section slide switch is in the first mode; when the slide arm is moved to the second position, the multi-section slide switch is in the second mode. The state of the multi-section slide switch can be changed through the movement of the button so as to switch the operation mode of the mouse of the invention.

Owner:PRIMAX ELECTRONICS LTD

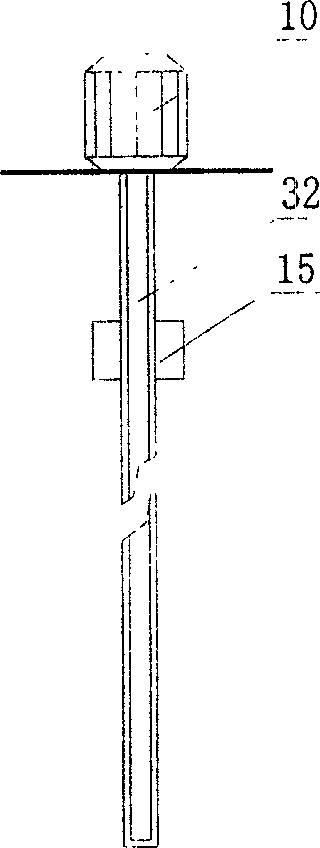

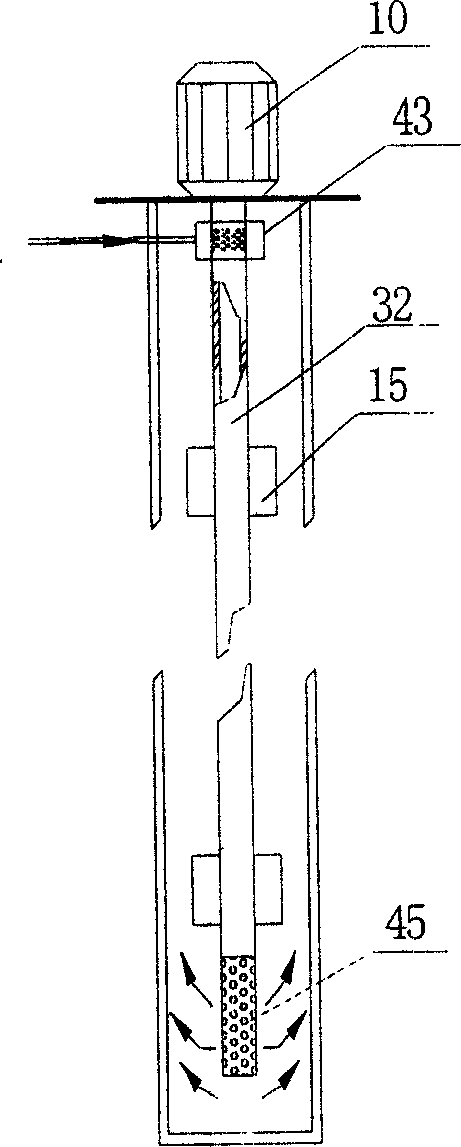

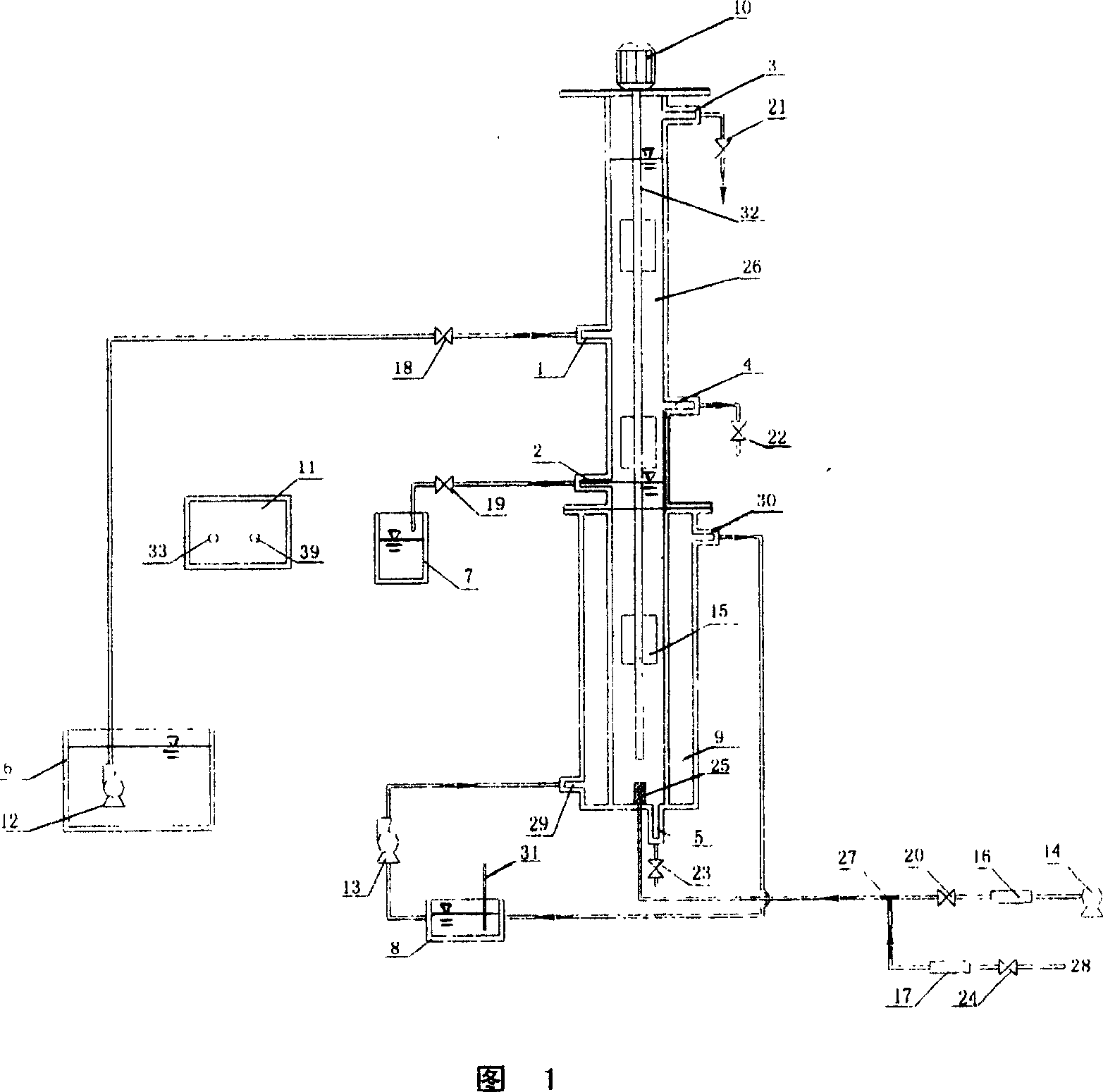

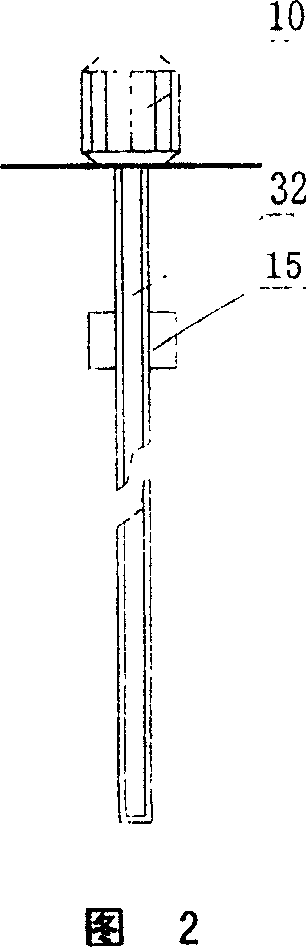

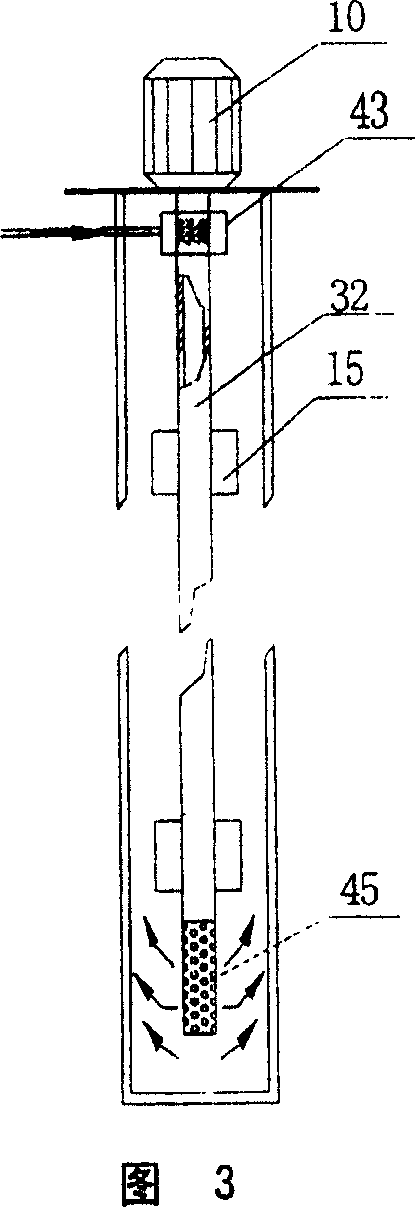

Automatized sequential reaction unit for aerobic particle sludge culture and research

InactiveCN1579958APromote formationEasy dischargeSustainable biological treatmentBiological water/sewage treatmentAeration systemWater source

The invention relates to automatic batch reaction equipment for research and development of aerobic grain sludge. It includes main body of reactor, mixing system, aeration system and control system. The length-diameter ratio of reactor is over 10. In the main body or the reactor, there are infalls, sample connection, outfalls and sludge outlet whose make and break can be controlled by system. The mixing system is set in lumen of reactor's main body. Connecting with fan and nitrogen system controlled by control system through air conduit, micro pores of aeration system are set at the bottom. At the middle-down of main body of reactor, there is a heating system which includes a heating jacket. In the heating jacket there are infall and outfall connecting with water pump and homothermal hot water source. Using the invention, grain sludge can be formed quickly, at the same time, it can realize research, development nitration, denitrify and dephosphorization using denitrify of grain sludge. Its operation is simple and feasible.

Owner:HUNAN UNIV

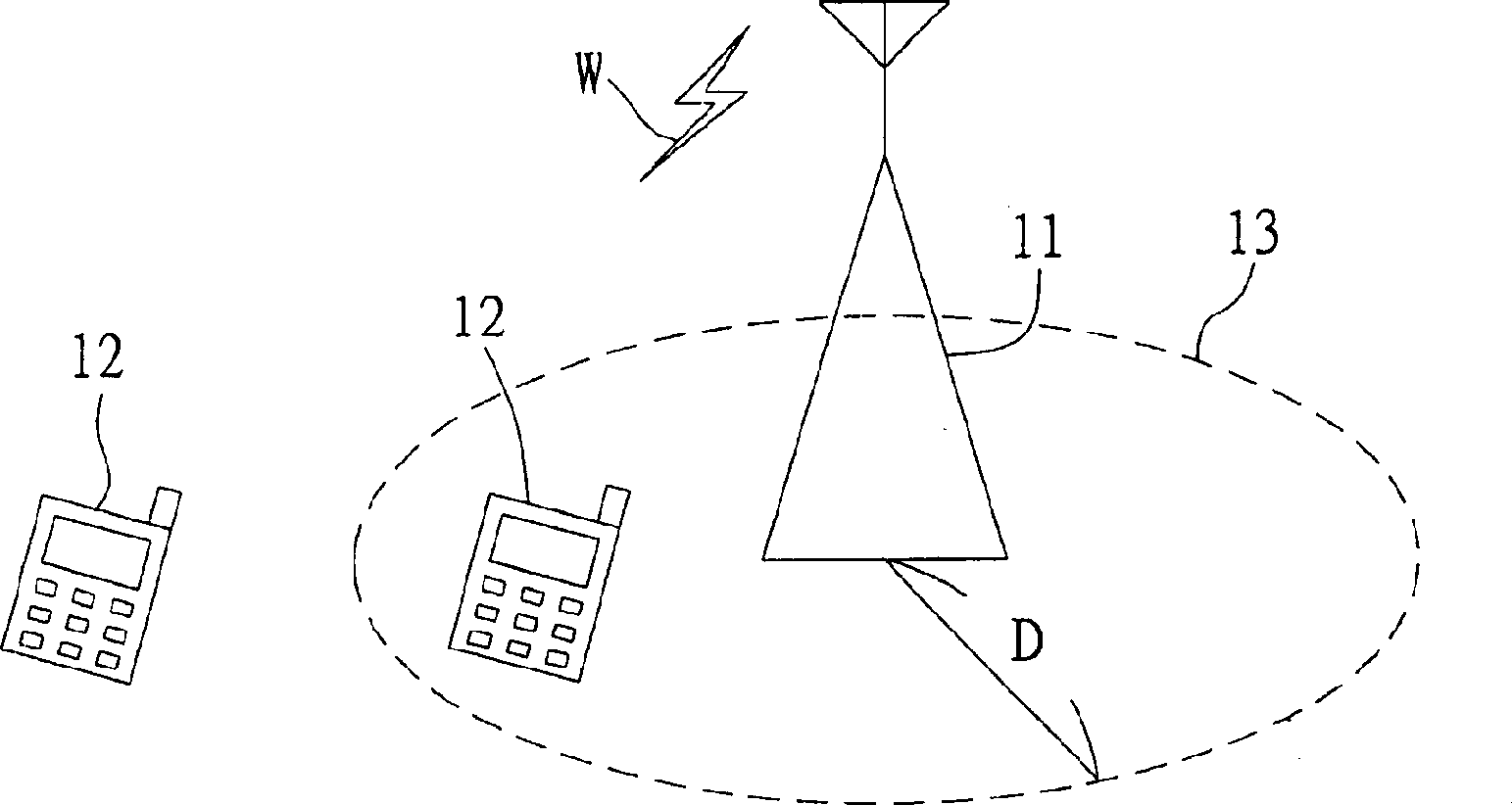

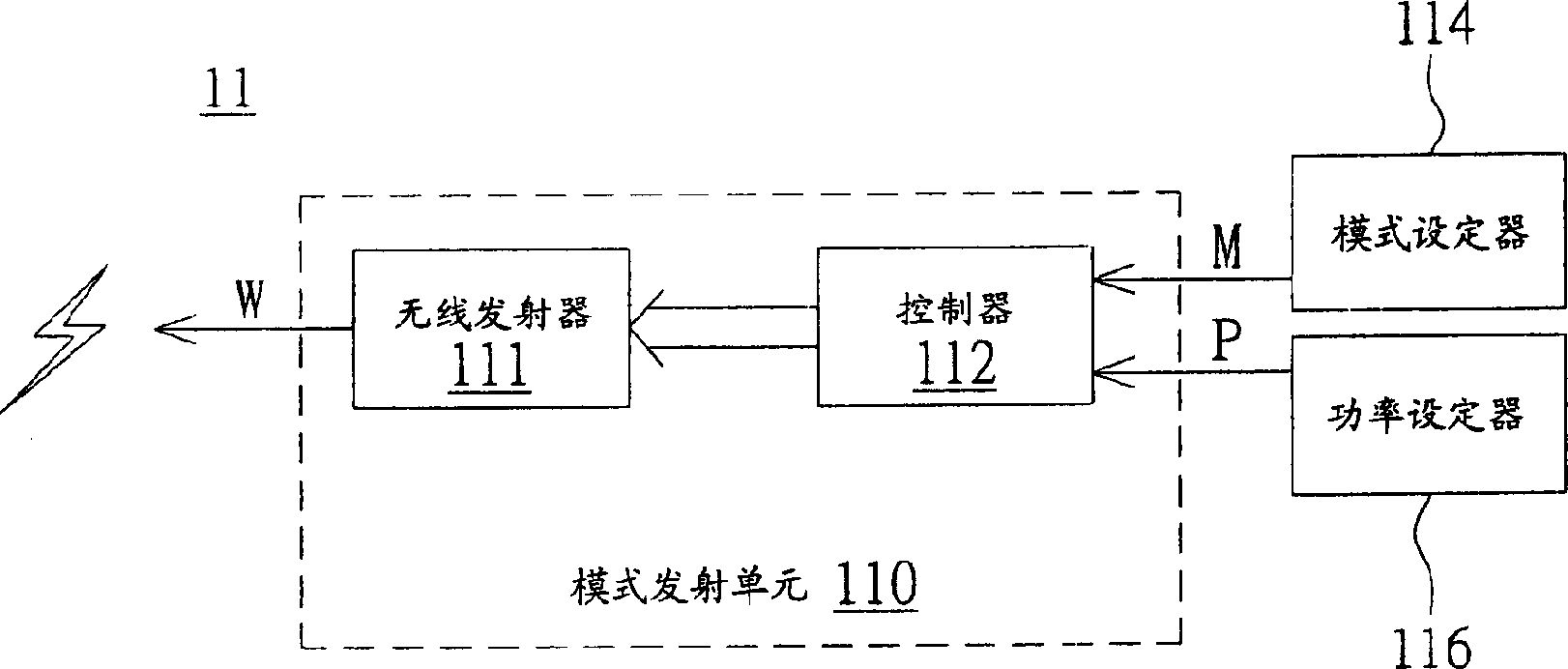

Operation mode control system and method for mobile phone

InactiveCN1665164AChange operating modeRadio/inductive link selection arrangementsSubstation equipmentMobile phoneOperation mode

The invention discloses an operating mode setting and controlling system, comprising operation control platform and mobile phone, where the operation control platform comprises a mode setter and a mode transmitting unit, the mode setter is used to determine a mode signal and the mode transmitting unit receives the mode signal and transmits a wireless signal according to the mode signal. As the mobile phone receives the wireless signal, the system translates it into a corresponding mode signal and changes the operating mode of the mobile phone according to the mode signal.

Owner:BENQ CORP

Synchronous pre-support and anchorage device for follow-up heading machines

InactiveCN103206232AImprove work efficiencyEasy to adapt to aisle heightProps/chocksAnchoring boltsMachineWinch

The invention relates to a synchronous pre-support and anchorage device for follow-up heading machines, belongs to the technical field of fully-mechanized coal mining equipment for coal mines and particularly relates to a device for pre-support and anchorage of a working surface. The pre-support and anchorage device is high in operating efficiency, effective in support and high in safety. According to the technical scheme, a framework is fixedly mounted on two symmetrically arranged travelling mechanisms identical in structure. A lifting anchorage platform and a pre-support platform are fixed on the framework, a lifting frame is arranged on the pre-support platform, beam transport guide rails are mounted on the lifting frame, a cart moving winch and a rail moving winch are mounted on a mounting panel of the pre-support platform, the cart moving winch is connected with a beam transport cart through a steel wire to control the beam transport cart to move on the beam transport guide rails, and the rail moving winch is connected with the beam transport guide rails through a steel wire to control the beam transport guide rails to move on the lifting frame. The synchronous pre-support and anchorage device is applicable to anchorage and pre-support of working surfaces of coal mine tunnels.

Owner:SHANXI DONGHUA MACHINERY

Separated type touch display system and operation method thereof

InactiveCN102495689ASimple structureLow costInput/output processes for data processingTouchscreenTransmitter

The invention discloses a separated type touch display system, which is characterized by comprising a display screen and a touch screen which are completely independent, wherein a signal transmitter is arranged in the touch screen, a signal receiver matched with the signal transmitter is arranged in the display screen, and the touch screen is in wired or wireless connection with the display screen. The separated type touch display system disclosed by the invention not only is simple in structure, but also is low in cost; the display screen is operated and controlled at long distance by the touch screen, and the experience feeling of long-distance touch operation and control on the display screen is satisfied; and therefore, the separated type touch display system is suitable for popularization and application.

Owner:沈河

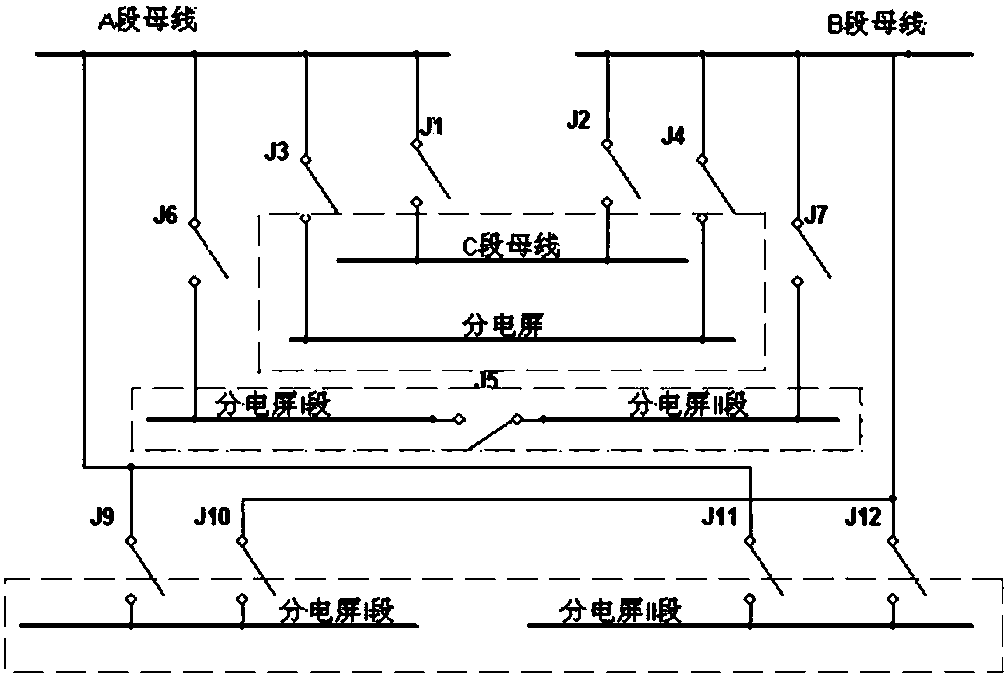

DC bus multi-segment parallel operation switching method and system

ActiveCN108318787AChange operating modeNo human intervention requiredTesting dielectric strengthEmbedded systemDC-BUS

The invention discloses a DC bus multi-segment parallel operation switching method and system. The method comprises the steps that: two or more segments of DC buses run in parallel, when a DC power supply in a segment of DC bus is subjected to storage battery check discharge or equipment maintenance, and a DC insulation monitoring host in the segment of DC bus automatically exits an operation andautomatically cuts off balance bridge resistance; at the same time, a grounding line selection device of all feeders in the segment of DC bus is automatically switched to a normal DC bus such that thegrounding line selection function of the segment of the DC bus is automatically switched to DC insulation monitoring host of the normal DC bus to be achieved. The method and the system have the advantages that a DC insulation monitoring extension can automatically adapt to various different distribution screen configuration modes, the DC insulation monitoring extension can automatically change anoperation mode when a distribution screen changes an operation mode, and manual intervention is not needed.

Owner:SHANDONG LUNENG SOFTWARE TECH

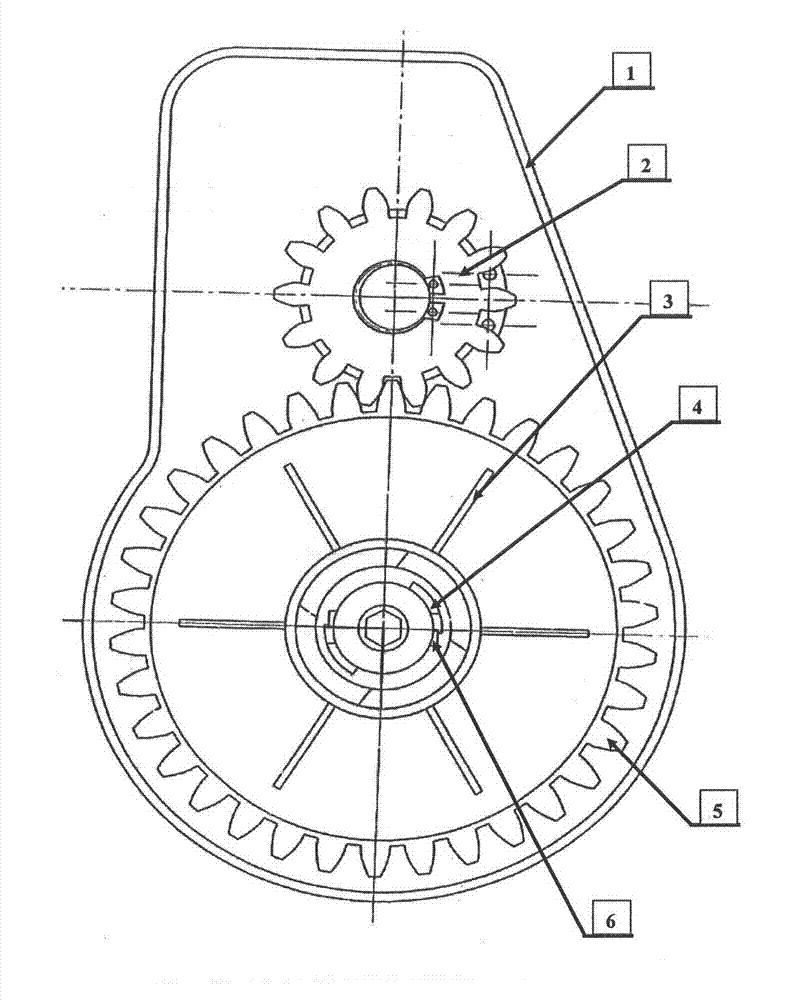

Torsion stored energy release starting mechanism

InactiveCN102954169AChange operating modeOptimizing and caring for working postureGearingFuel oilCold weather

The invention discloses a torsion stored energy release starting mechanism which is used for starting various small-sized fuel oil power machines reliably and easily, using potential energy for torsion energy storage and enabling the torsion potential energy accumulated by a main torsion energy storage spring to release kinetic energy so as to transfer torsion to the machines. Manual cord pulling start mechanisms of existing small-sized fuel oil power machines are generally assembled. When the machines are started by manually pulling a cord, effect is poor due to the fact that start conditions of the small-sized fuel oil power machines can be affected by cold weather, rainy days and strength. The torsion stored energy release starting mechanism has the advantages that change of an operating mode of the manual cord pulling start mechanisms enables doubled torsion stored energy to be transferred easily and rapidly; and by the aid of change of the operating mode of the manual cord pulling start mechanisms, working body positions of operators are optimized and cared, and reasonable product design is perfected more effectively.

Owner:王盘龙

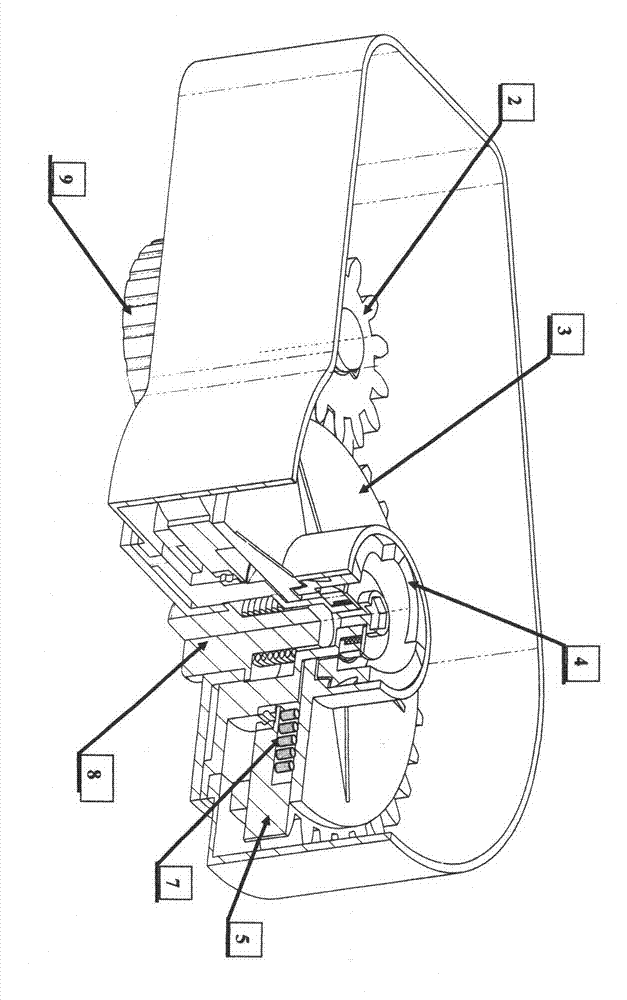

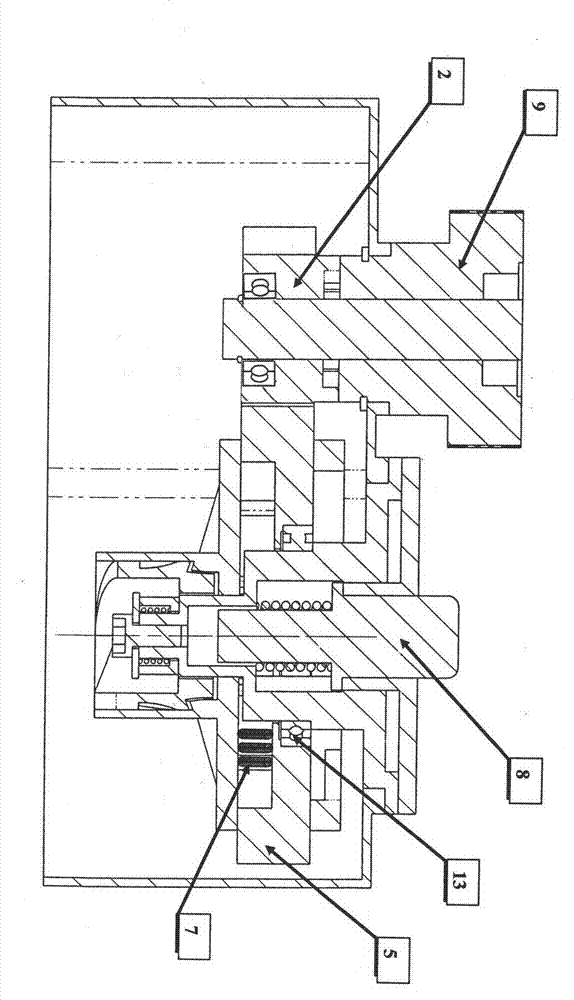

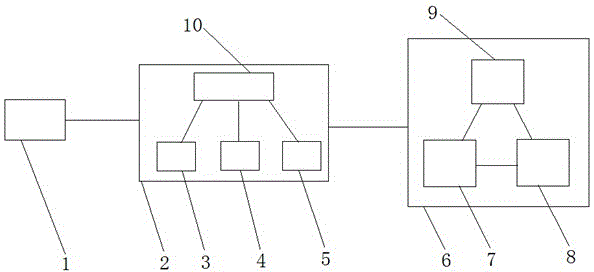

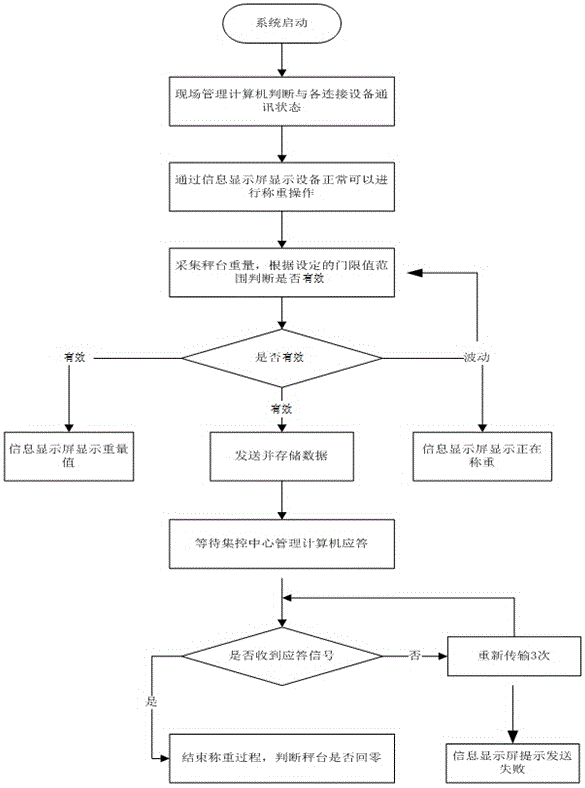

Remote automatic metering system for finished aluminum ingots and method thereof

InactiveCN105092005ARealize automatic meteringReduce labor intensitySpecial purpose weighing apparatusWork periodIngot

The invention discloses a remote automatic metering system for finished aluminum ingots and a method thereof. The remote automatic metering system for the finished aluminum ingots comprises a digital buffer electronic platform scale, a field management computer and a centralized control center management computer. The digital buffer electronic platform scale is electrically connected with the field management computer. The field management computer is in signal connection with the centralized control center management computer. The field management computer is composed of an information display screen, a state indicating lamp, a storage module and a field management module. The centralized control center management computer is composed of a monitoring image camera, a memory and a processing module; wherein the monitoring image camera, the memory and the processing module are interconnected. The remote automatic metering system for the finished aluminum ingots and the method have advantages of realizing automatic metering for the finished aluminum ingots in aluminum electrolysis, realizing no requirement for tedious and repeated operations such as data statistics, calculation and checking manually, greatly reducing labor intensity of workers, greatly improving labor productivity, greatly reducing error probability in a metering process, ensuring good continuous operation of the system, greatly simplifying a working flow, and reducing working time.

Owner:YUNNAN RUNXIN ALUMINUM

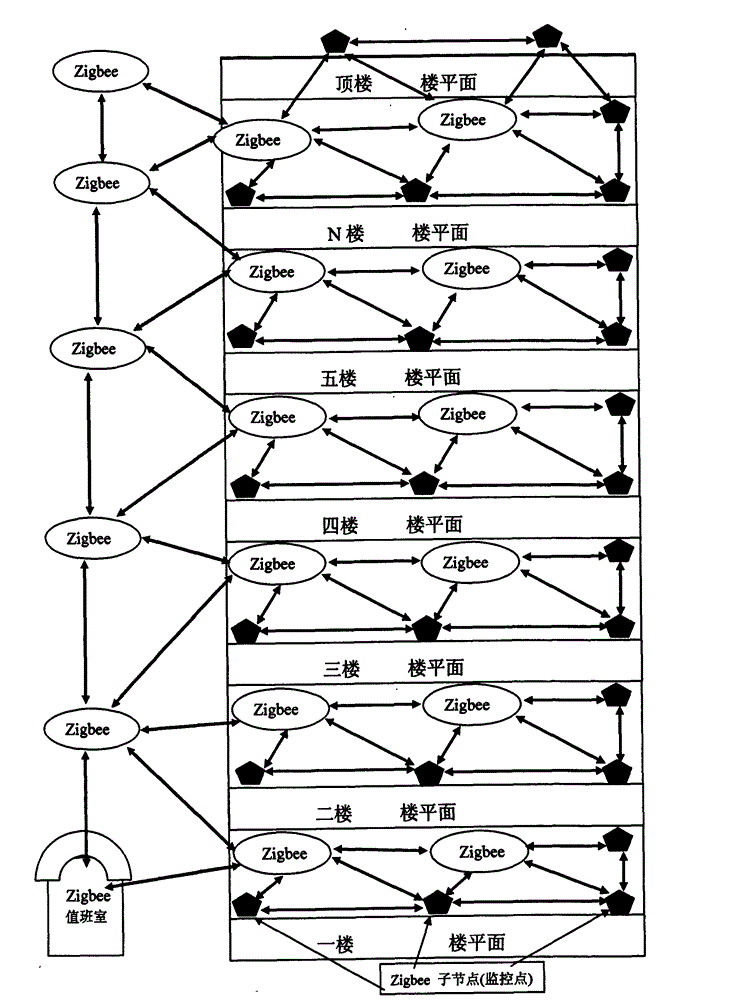

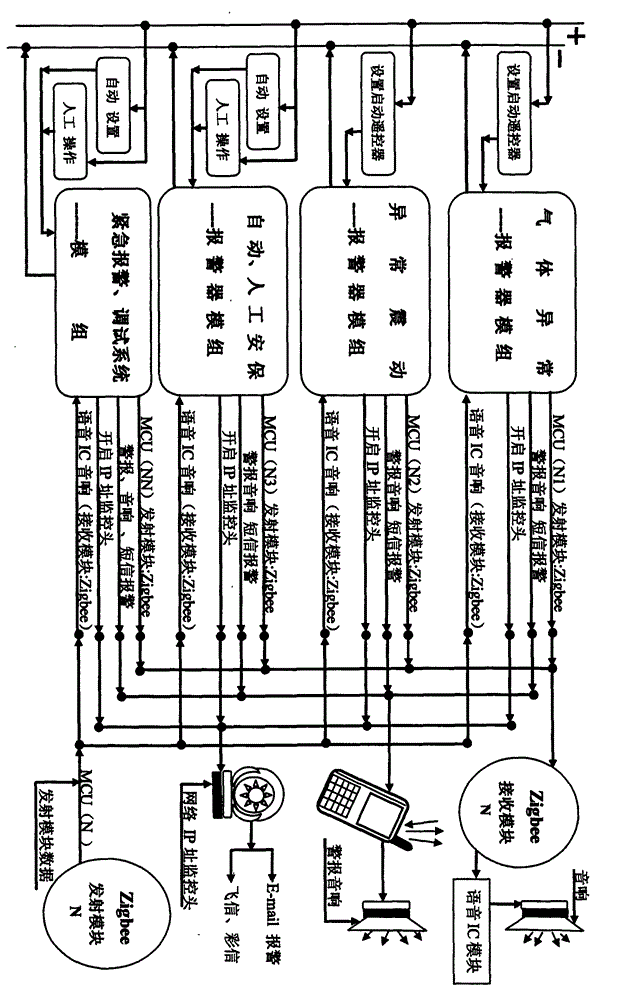

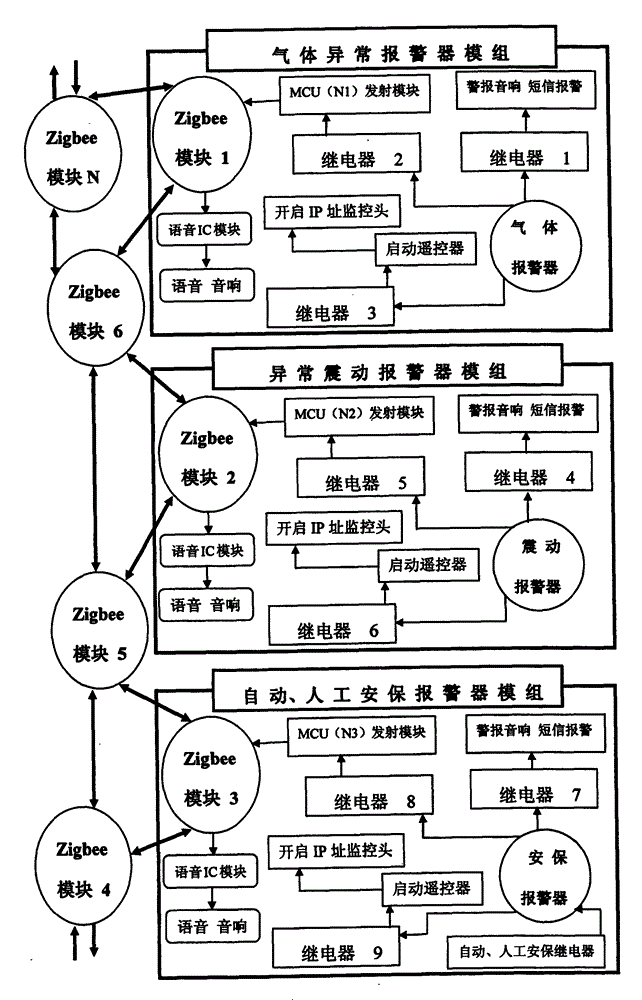

Method for transmitting abnormal data in Zigbee network and alarming apparatus system

ActiveCN102752337AAchieve restraintChange operating modeNetwork topologiesTelephonic communicationReal-time dataNatural disaster

The embodiment of the invention provides a method for transmitting abnormal data in a Zigbee network and an alarming apparatus system, which are used for realizing the accuracy of automatic monitoring and timely broadcasting of gas anomaly, first-time informing performance of natural calamities, the reliability of comprehensive upgrade of public safety and the unitarity of regional information broadcasting. A user sets a gas anomaly alarm module, an abnormal shake alarm module, an automatic manual security alarm module and an urgent alarming debugging system module; and the data are wirelessly transmitted and received through Zigbees, and real-time automatic monitoring of complex environments and regions is completed by utilizing the Zigbee ad-hoc network. The controllability of a uniterm alarming system and a multiterm alarming system can be increased, and the initiative and the accuracy of real-time data monitoring are improved.

Owner:王盘龙

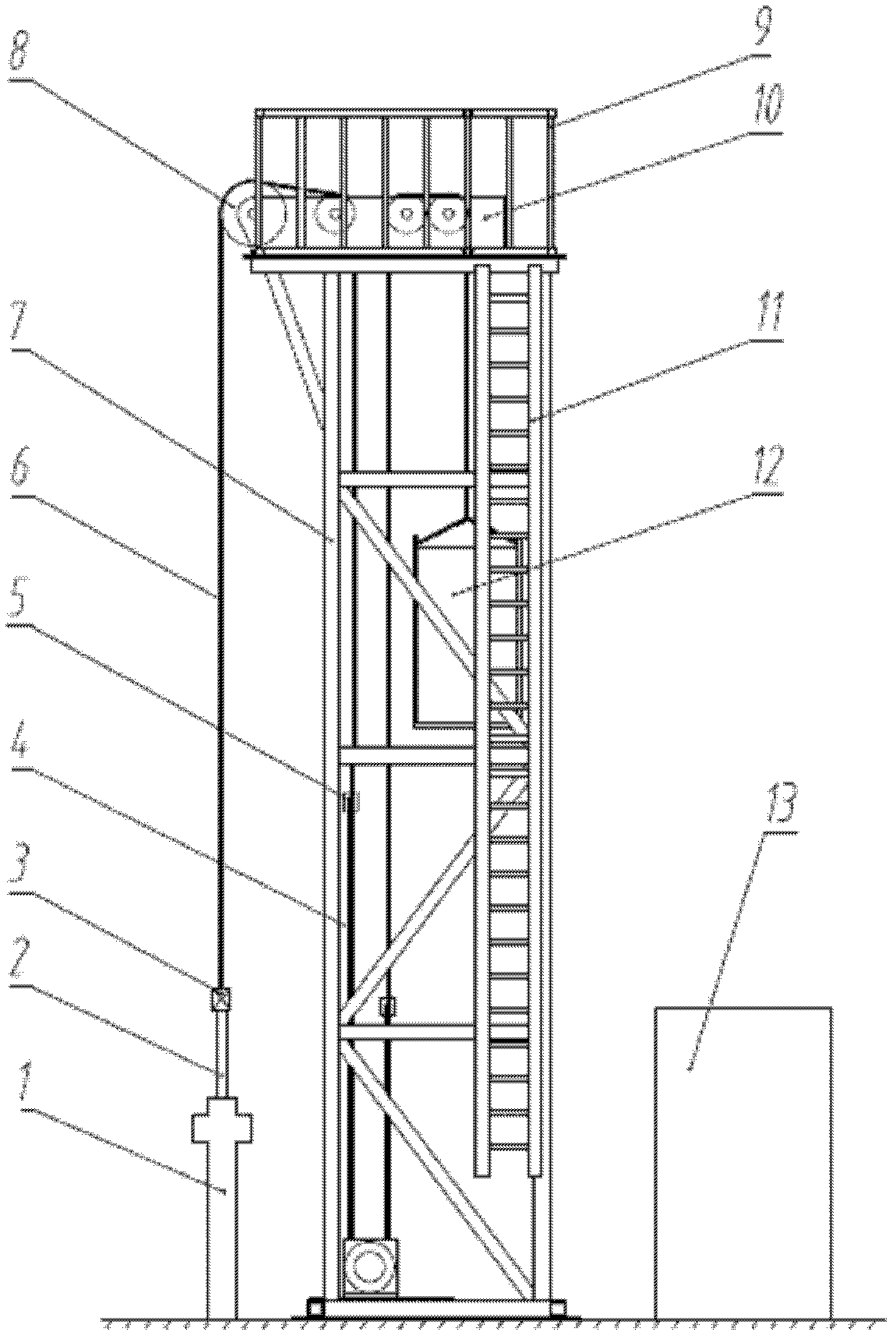

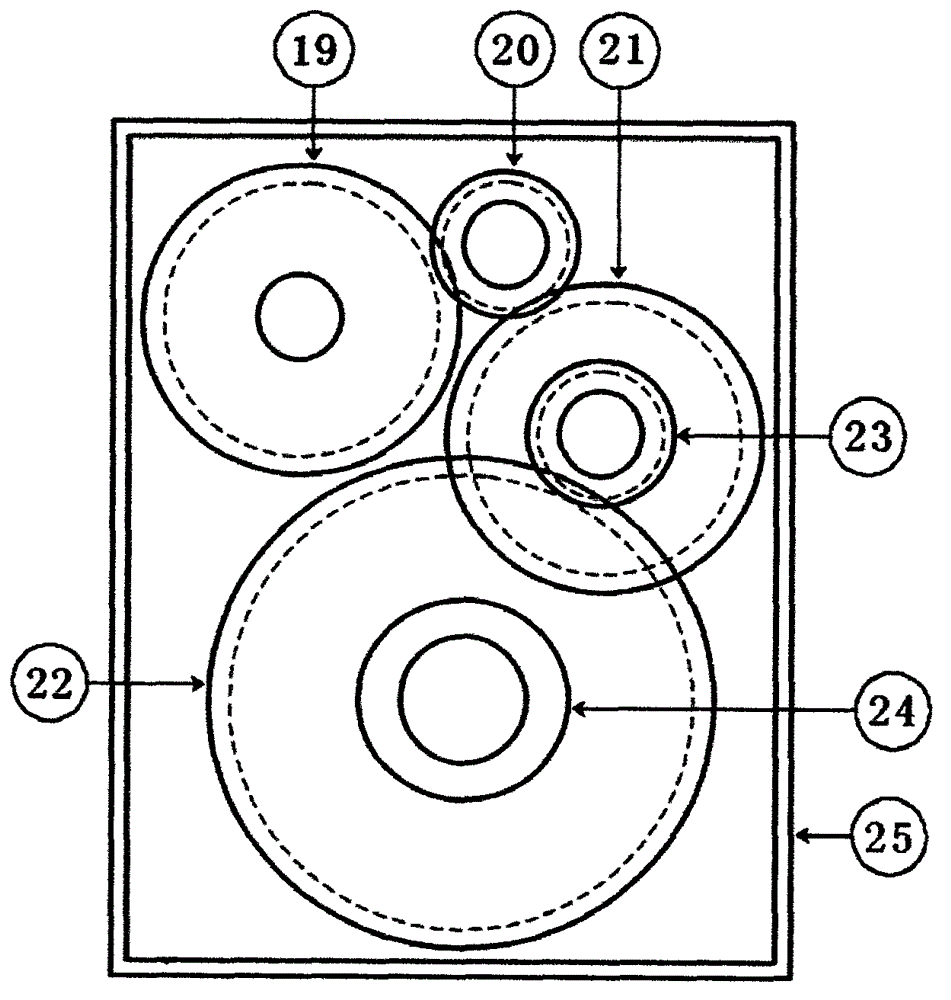

Direct-drive pumping unit of permanent-magnet disk-type motor

InactiveCN102562002AImprove transmission efficiencyHigh transmission reliabilityFluid removalDrive wheelSpeed control system

The invention discloses a direct-drive pumping unit of a permanent-magnet disk-type motor. The direct-drive pumping unit comprises a frame, a permanent-magnet disk-type servo motor, a brake, a synchronous pulley, a drive shaft, a drive wheel base, a guide pulley, a pulley base, an opening synchronous belt and the like. The permanent-magnet disk-type servo motor is adopted as a power source; a motor output shaft is the drive shaft and directly drives the synchronous pulley in key connection with the motor output shaft to rotate positively and reversely; the synchronous pulley also pulls the opening synchronous belt meshed with the synchronous pulley to move in a reciprocating manner, and the two ends of the opening synchronous belt are connected with a plurality of steel wire ropes. The direct-drive pumping unit of the permanent-magnet disk-type motor, disclosed by the invention, has the beneficial effects that: a transmission system is very simple without a middle retarding mechanism; the direct-drive pumping unit is directly driven and reversed by the permanent-magnet disk-type servo motor with excellent governing performance and is matched with a servo speed control system, in addition, a weight box is adopted for performing direct balancing, so that the pumping unit has the advantages of long stroke, low jig frequency, high efficiency, low power consumption, easy adjustment of parameters, simple structure, convenience in operation and the like.

Owner:XI AN JIAOTONG UNIV

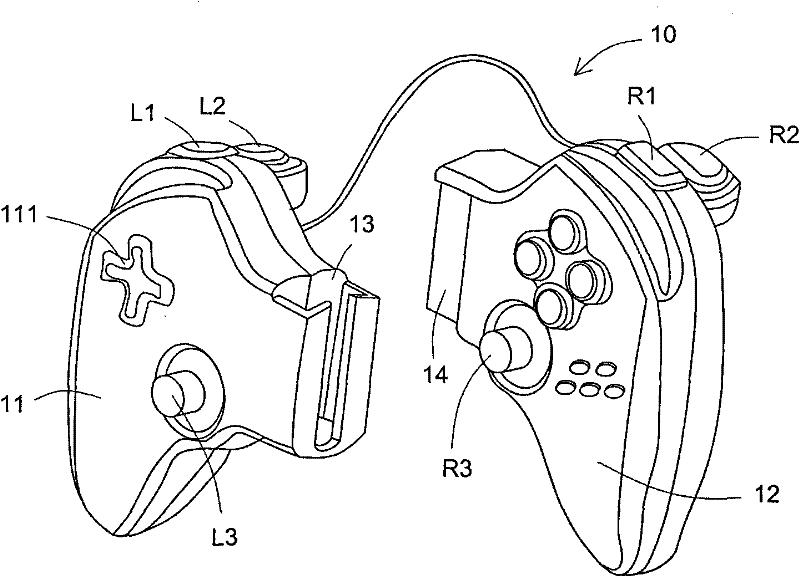

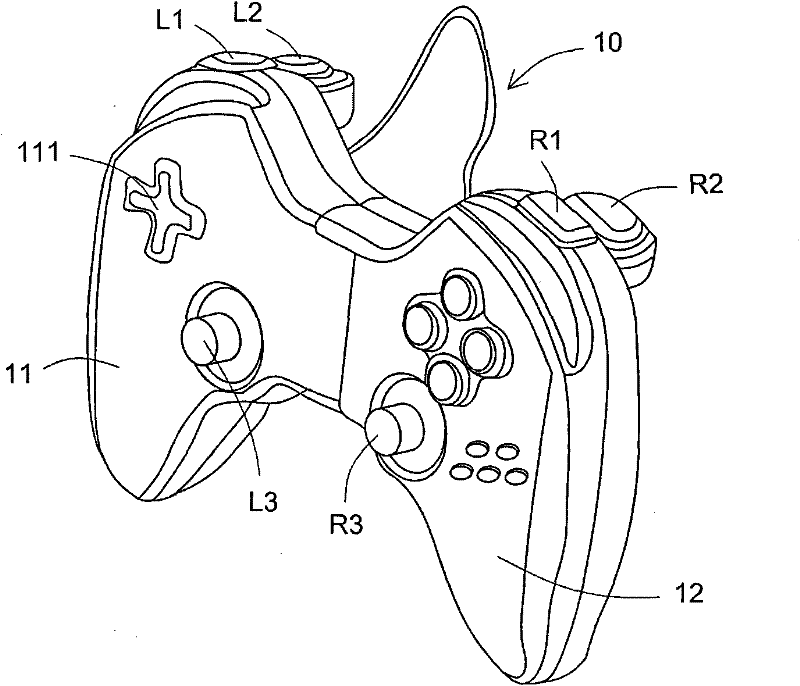

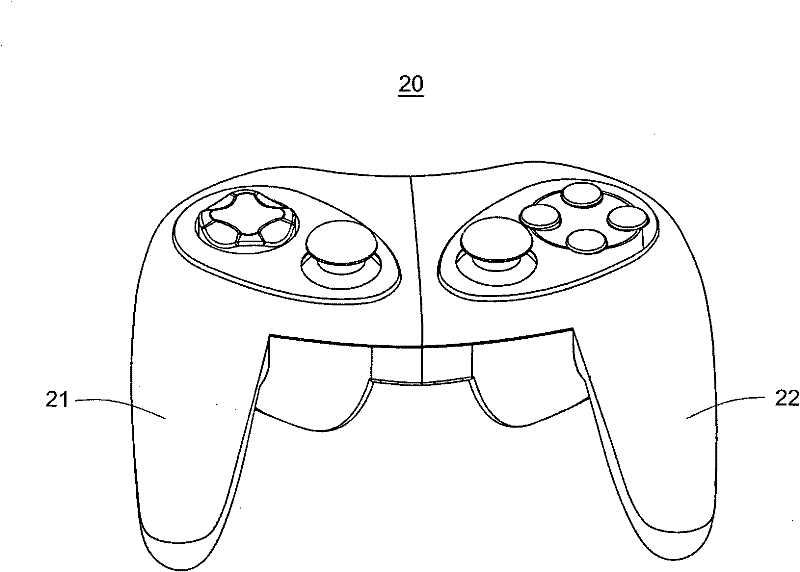

Detachable game controller

The invention discloses a detachable game controller, comprising a first holding part, a second holding part and a fixing unit. The second holding part comprises a first sensor, a second sensor and a first controller, wherein the first controller is electrically connected to the first sensor and the second sensor. The first sensor is used for sensing whether the first holding part and the second holding part are separated; if yes, the first sensor generates a first signal to the first controller. When the first controller receives the first signal, the second sensor is started by the first controller to generate a second signal and is used for sensing displacement of the second holding part. The detachable game controller disclosed by the invention can be used for changing operation modes, simplifying game operations and reducing harm of the game controller to hands of a user.

Owner:PRIMAX ELECTRONICS LTD

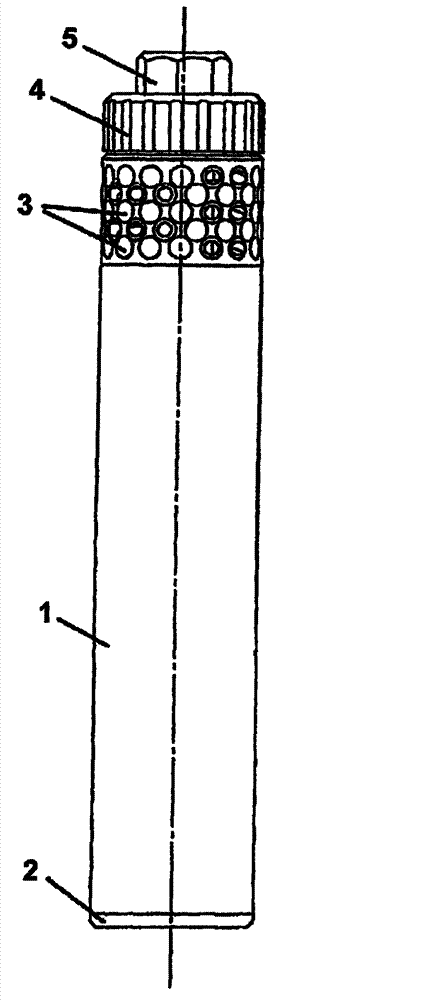

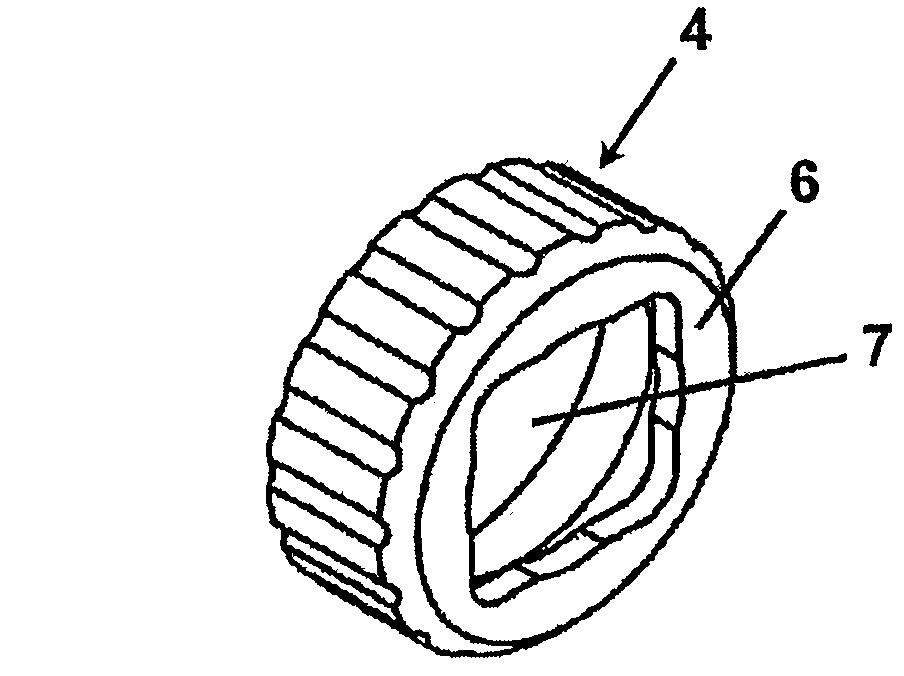

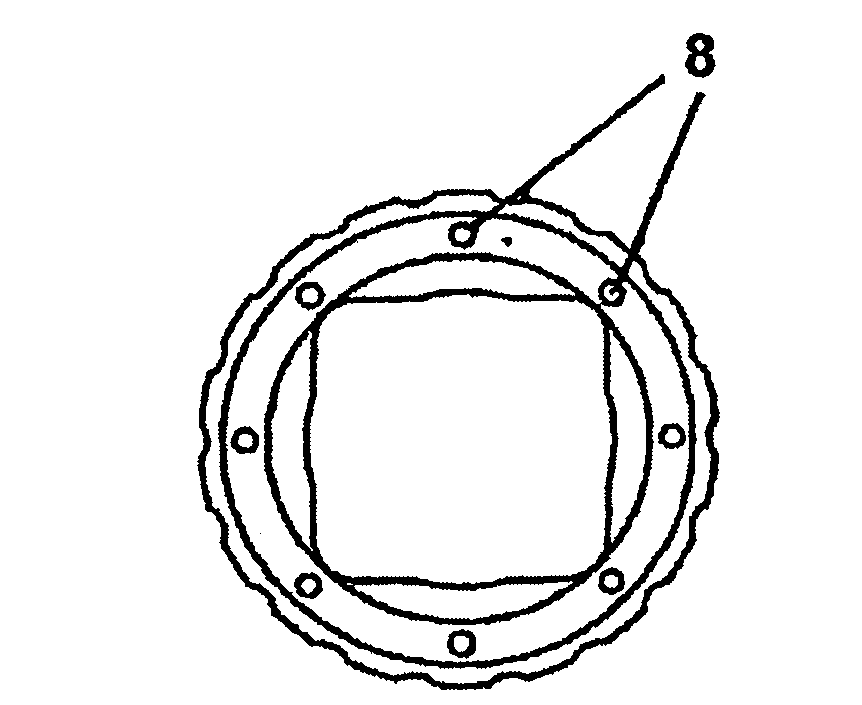

Locking device for movable momentum connection in suppressors for semiautomatic and fully automatic weapons

The devices and assemblies of the invention allow the design and use of suppressors with at least two modes of operation and the suppressor can be reset significantly faster and more simply from a locked position into an unlocked position. The suppressors of the invention comprise a mounting ring (4) and a momentum part or assembly (5) that can be shifted axially, or along the axis of the barrel of the weapon. A pressure spring (23) is positioned between the momentum part or assembly (5) and a column sleeve (1) of the silencer, which on the one hand presses the momentum part (5) against a projection (25) of the column sleeve (1) and on the other hand against the index disk (18). Interlocking cams (16) are positioned on the momentum part (5), which are blocked in a first position of the mounting ring (4), and in a second position of the mounting ring (4) they can be shifted so that the momentum part is unlocked and can move axially in response to firing. Rotating the mounting ring (4) allows the operator to switch from the first position into the second position, and lock or unlock the momentum part and the recoil booster function of the devices.

Owner:SPHINX SYST

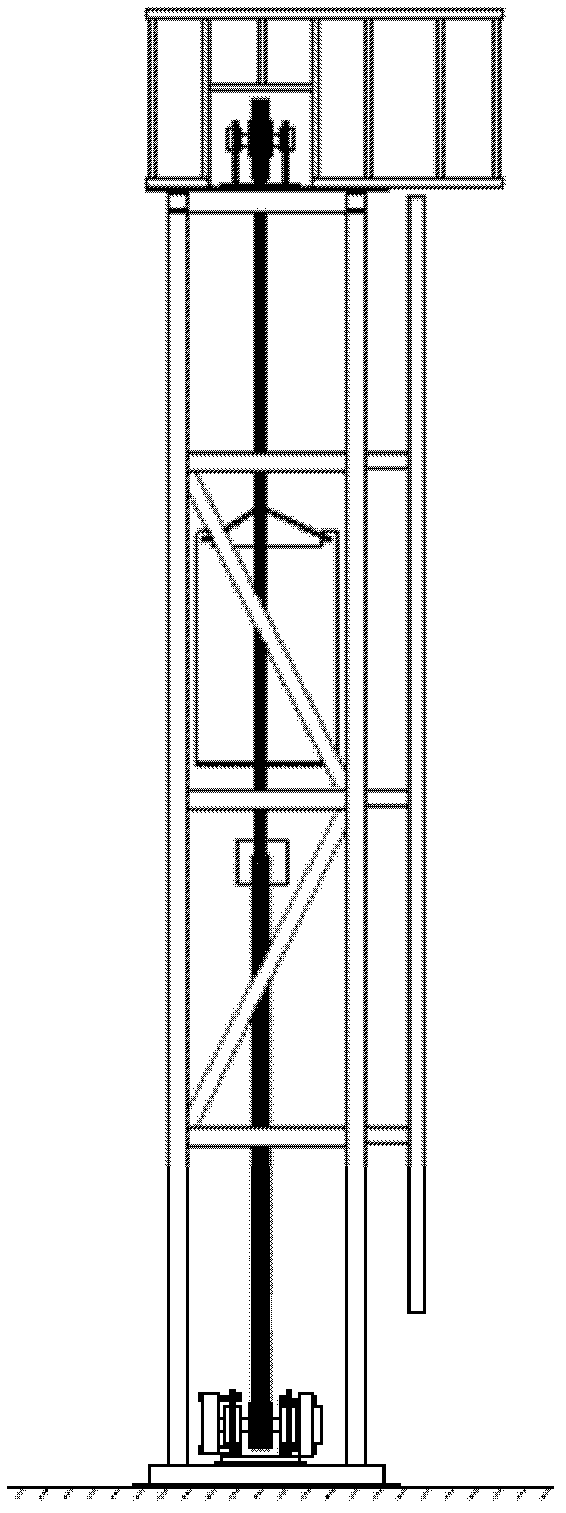

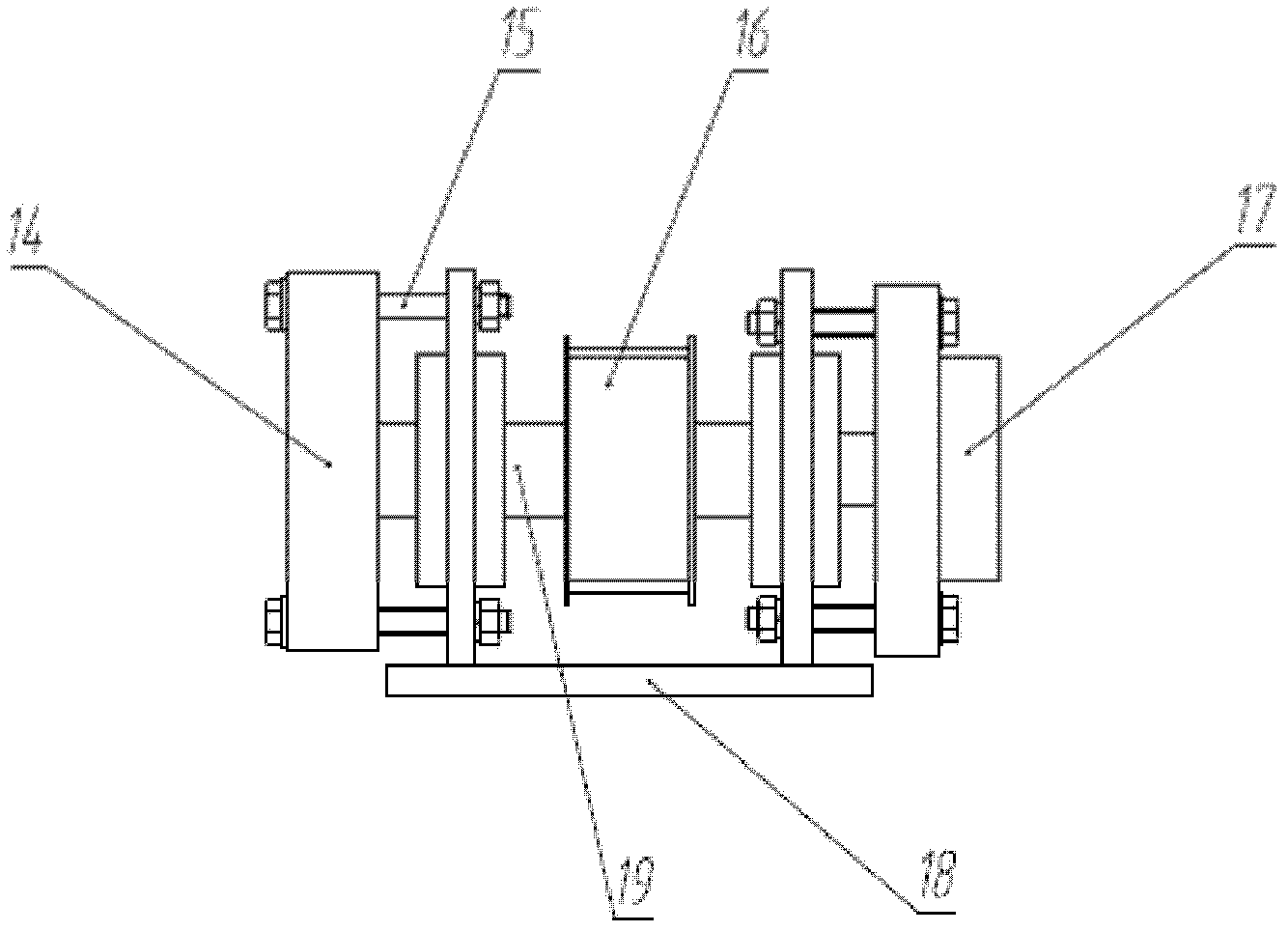

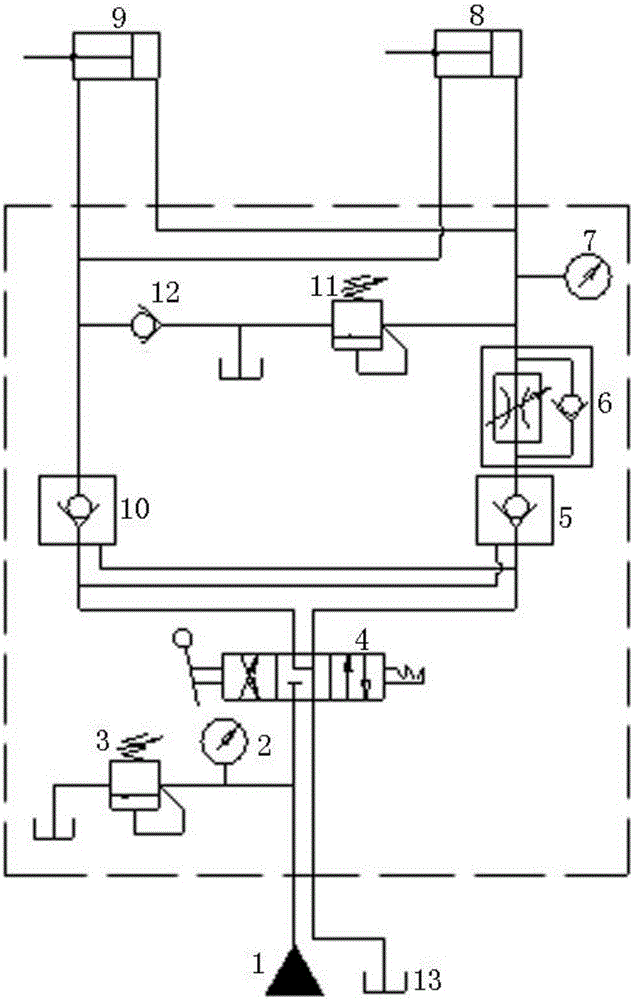

Lifting and lowering buffer control device for derrick of drilling machine and use method thereof

The invention relates to a lifting and lowering buffer control device for a derrick of a drilling machine and a use method thereof. The device comprises two buffer hydraulic cylinders fixed on a propeller strut, wherein a control handle for controlling the buffer hydraulic cylinders is connected with the two buffer hydraulic cylinders through a hydraulic system; and the hydraulic system comprises an oil pump, an oil tank, a three-position four-way directional control valve, a system overflow valve, a buffer overflow valve, a speed regulating valve and a hydraulic balance lock composed of two hydraulic control one-way valves. According to the invention, one control handle is used for controlling the coordination action of the two buffer hydraulic cylinders, so that the device provided by the invention has a buffering function, a balancing function and a speed regulating function; the system response is rapid, the adjustment is convenient, and the buffer cylinders at the two sides have uniform stress, so that the accident rate is greatly reduced, and the stability and reliability of the device are improved; and the device is also suitable for the lifting and lowering processes of a base of the drilling machine.

Owner:HAICHENG CITY GASOLINEEUM MACHINERY MFG

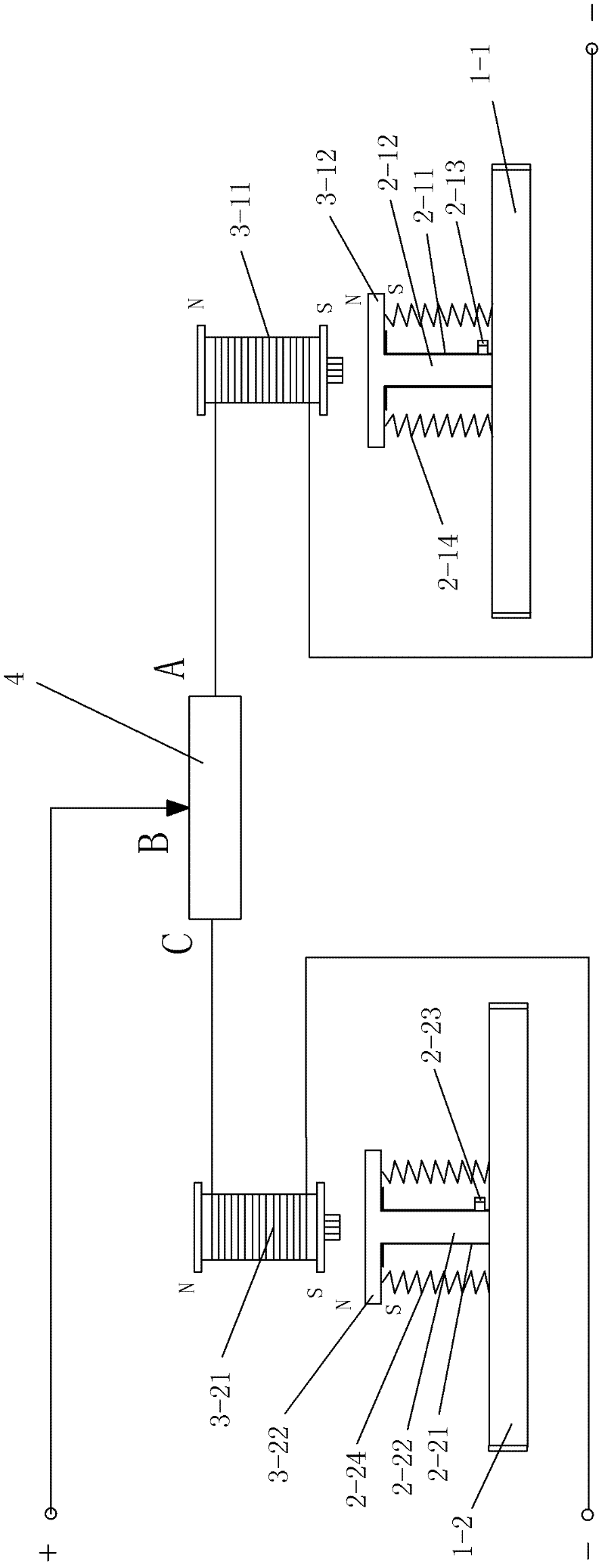

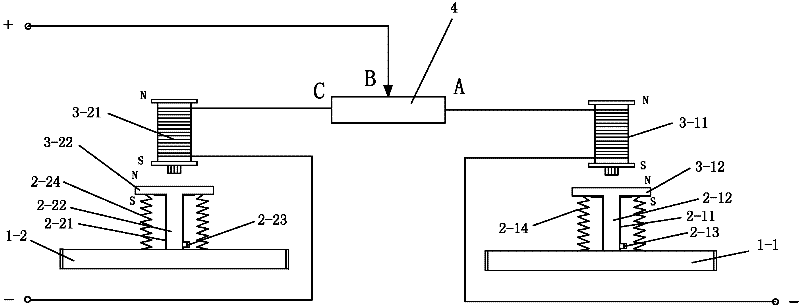

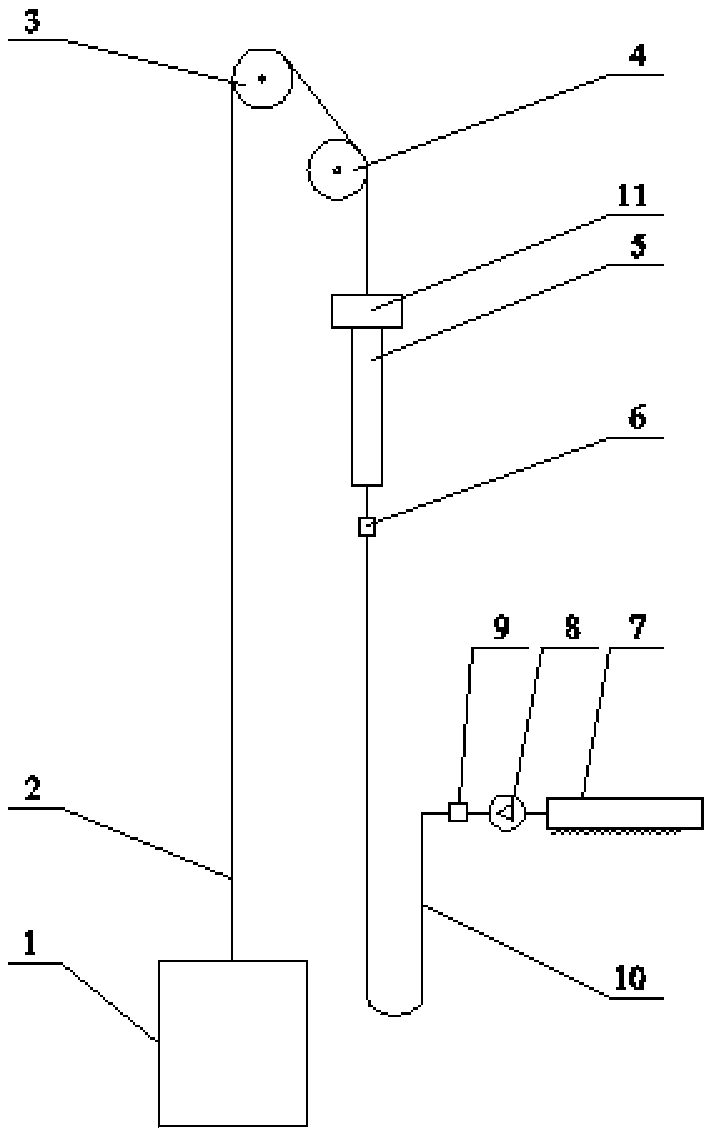

Dynamic change balance compensation device for traction elevator and dynamic change balance compensation method

The invention discloses a dynamic change balance compensation device for a traction elevator and a dynamic change balance compensation method. The dynamic change balance compensation device comprisesa lift car; a hoist rope is connected to the lift car, wound on a traction wheel and a beam pulley and then is connected to a counterweight device; the traction wheel and the beam pulley are fixed ina machine room of the top layer of the elevator room; a first liquid tank is arranged at the bottom of the counterweight device and is connected to a conveying pump through a connecting pipe; the conveying pump is further communicated with a second liquid tank, and the second liquid tank is fixed to the side shaft wall of the counterweight device; a first directional control valve and a second directional control valve are arranged at the end, close to the first liquid tank, of the connecting pipe and the end, close to the conveying pump, of the connecting pipe correspondingly; and the conveying pump, the first directional control valve and the second directional control valve are electrically connected to a controller respectively. According to the dynamic change balance compensation device and the dynamic change balance compensation method, a dynamic change compensation balance technology is utilized, so that the daily operation mode of the elevator is a favorable operation mode, thestarting current and the running current of the elevator are greatly decreased, so that the operation of the elevator can be more stable and energy-saving, and therefore the practicability is good, and the device and the method are worthy of popularization.

Owner:张洪学

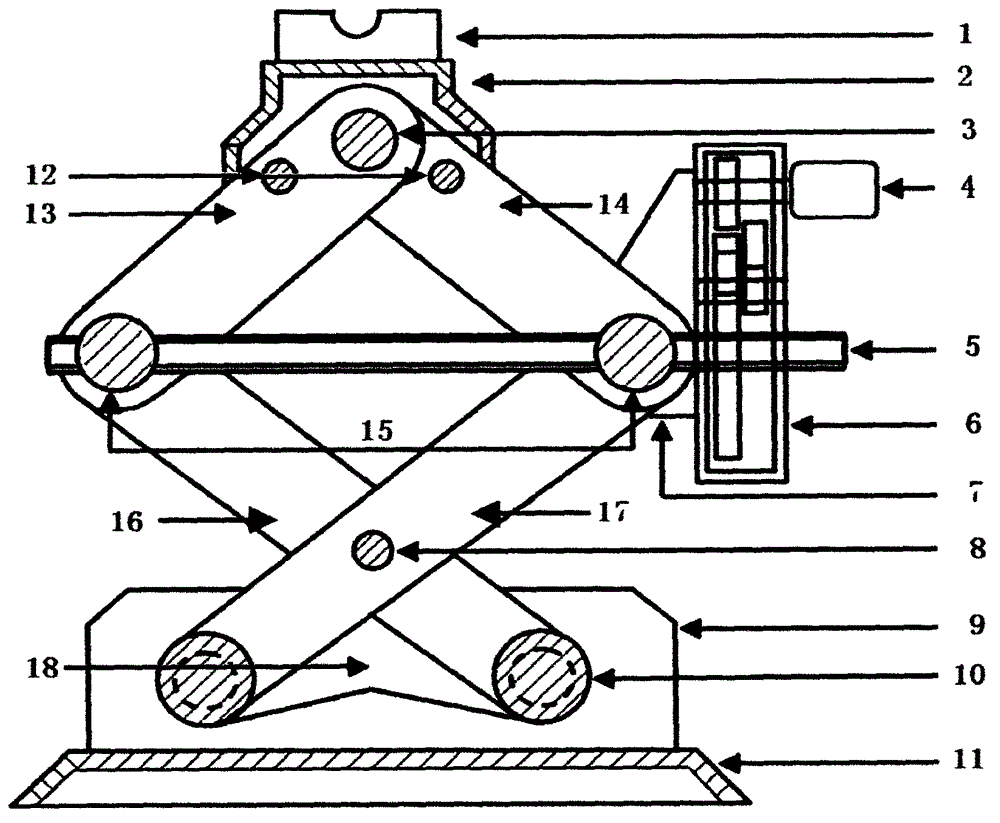

Multifunctional mechanical jack

A multifunctional mechanical jack has multiple functions and has the strong power, the design in all aspects is perfect, the structure of an original jack is thoroughly changed, the design concept of the jack is as follows: the support supporting principle is perfected by virtue of scientific and technological mechanics, the jack is simple to operate, time-saving and effort-saving and comprises an automatic aligning device, a support can be hidden, the storage space can be reduced, the jack is convenient to carry, the operation modes can be selected at will during operation, the jack is very time-saving, effort-saving, safe and reliable, and the jack adopting the structure can jack 2.5 tons easily and is most applicable to construction of small and medium-sized vans or buildings and equipment mounting.

Owner:张丽娟

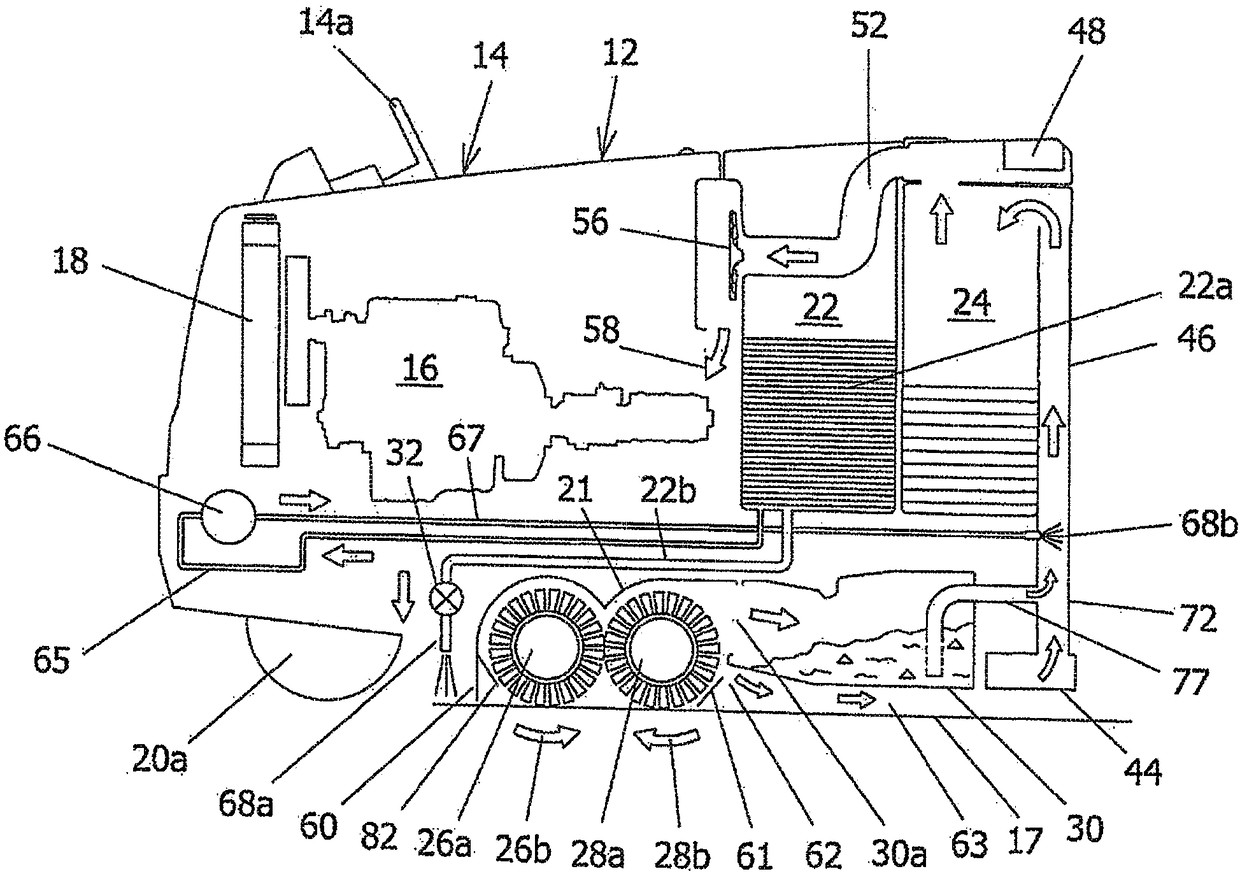

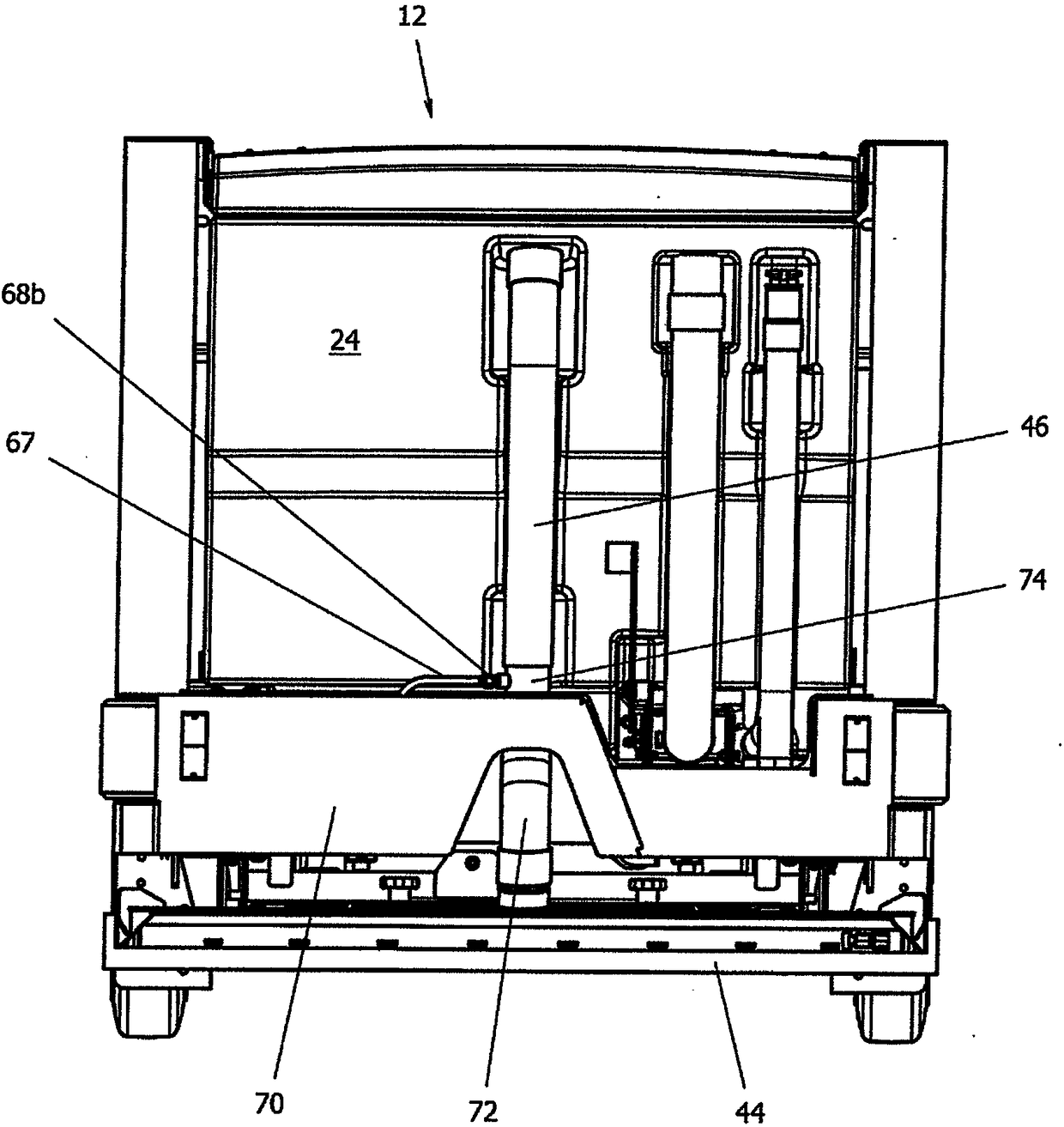

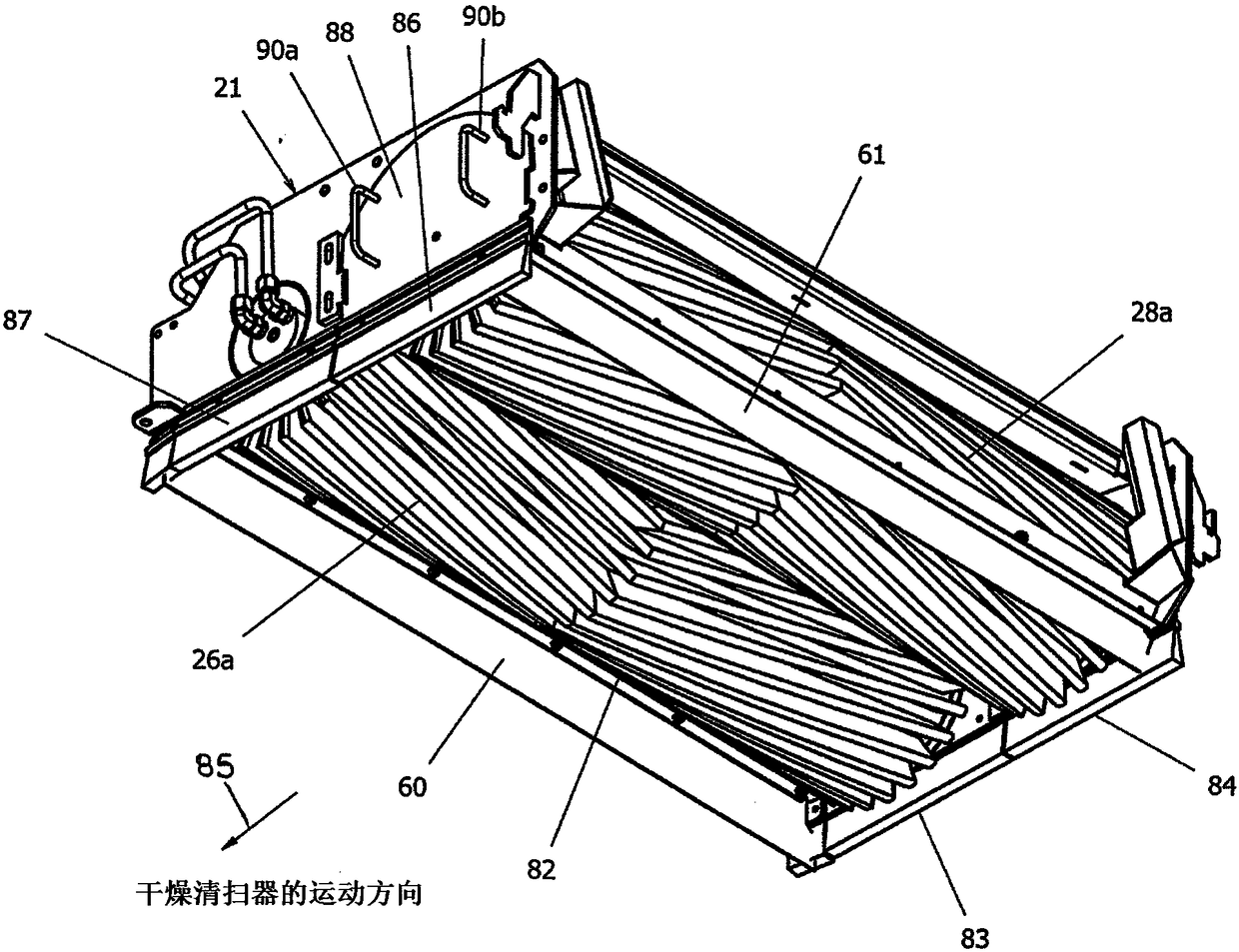

Floor scrubber dry sweep apparatus

Owner:MINUTEMAN INT

Automatized sequential reaction unit for aerobic particle sludge culture and research

InactiveCN1317208CPromote formationEasy dischargeSustainable biological treatmentBiological water/sewage treatmentAeration systemWater source

The invention relates to automatic batch reaction equipment for research and development of aerobic grain sludge. It includes main body of reactor, mixing system, aeration system and control system. The length-diameter ratio of reactor is over 10. In the main body or the reactor, there are infalls, sample connection, outfalls and sludge outlet whose make and break can be controlled by system. The mixing system is set in lumen of reactor's main body. Connecting with fan and nitrogen system controlled by control system through air conduit, micro pores of aeration system are set at the bottom. At the middle-down of main body of reactor, there is a heating system which includes a heating jacket. In the heating jacket there are infall and outfall connecting with water pump and homothermal hot water source. Using the invention, grain sludge can be formed quickly, at the same time, it can realize research, development nitration, denitrify and dephosphorization using denitrify of grain sludge. Its operation is simple and feasible.

Owner:HUNAN UNIV

Intelligent control elevator connected with multifunctional device and elevator control method thereof

InactiveCN1207180CChange operating modeImprove securityElevatorsBuilding liftsSmart cardWalkie-talkie

Owner:SHENZHEN WONGLONG INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com