Printing machine comprising stripper

A technology of printers and peeling mechanisms, applied in the field of printers, can solve the problems of small space, difficult sensors, increased size and cost, and achieve the effect of avoiding mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] overall structure

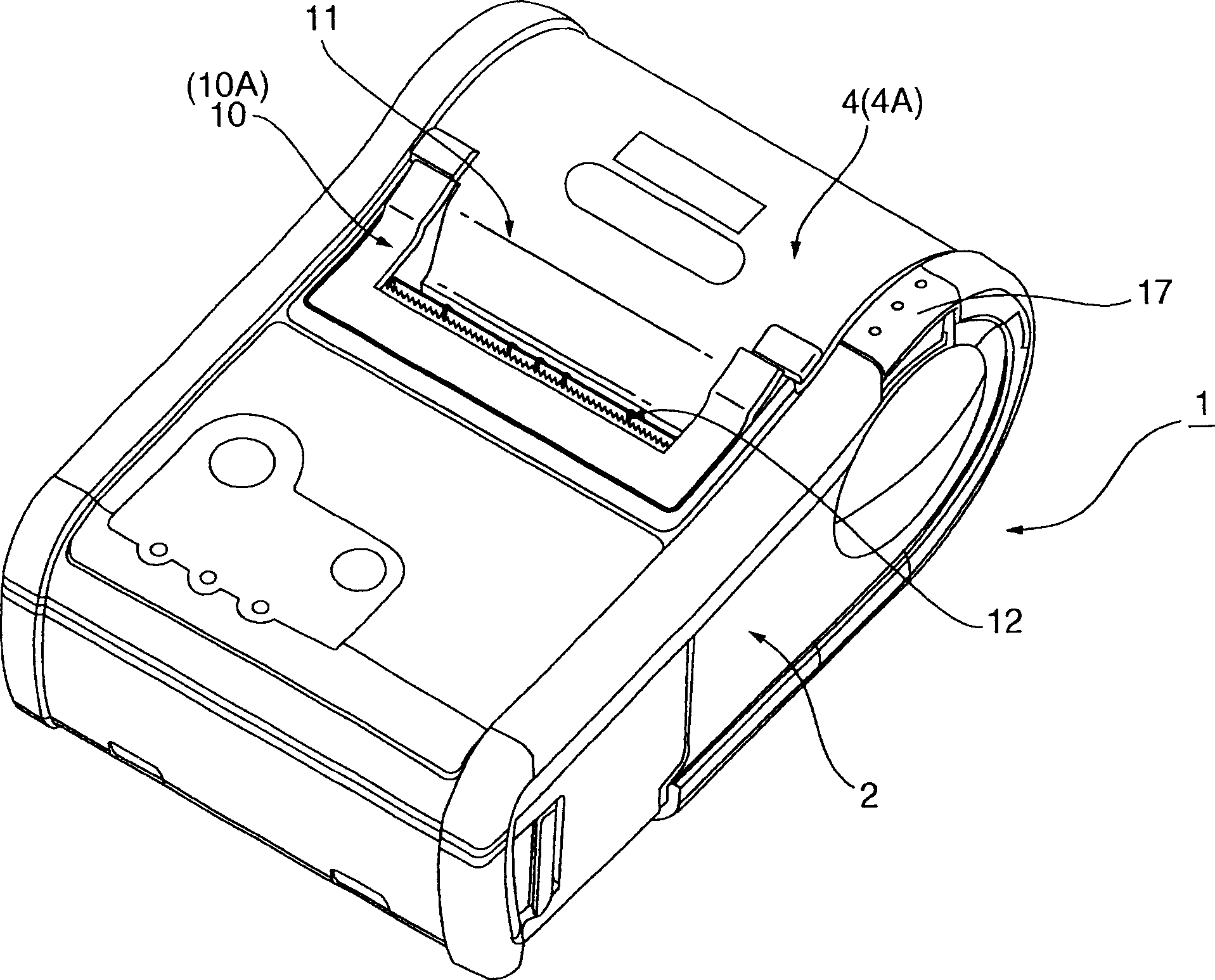

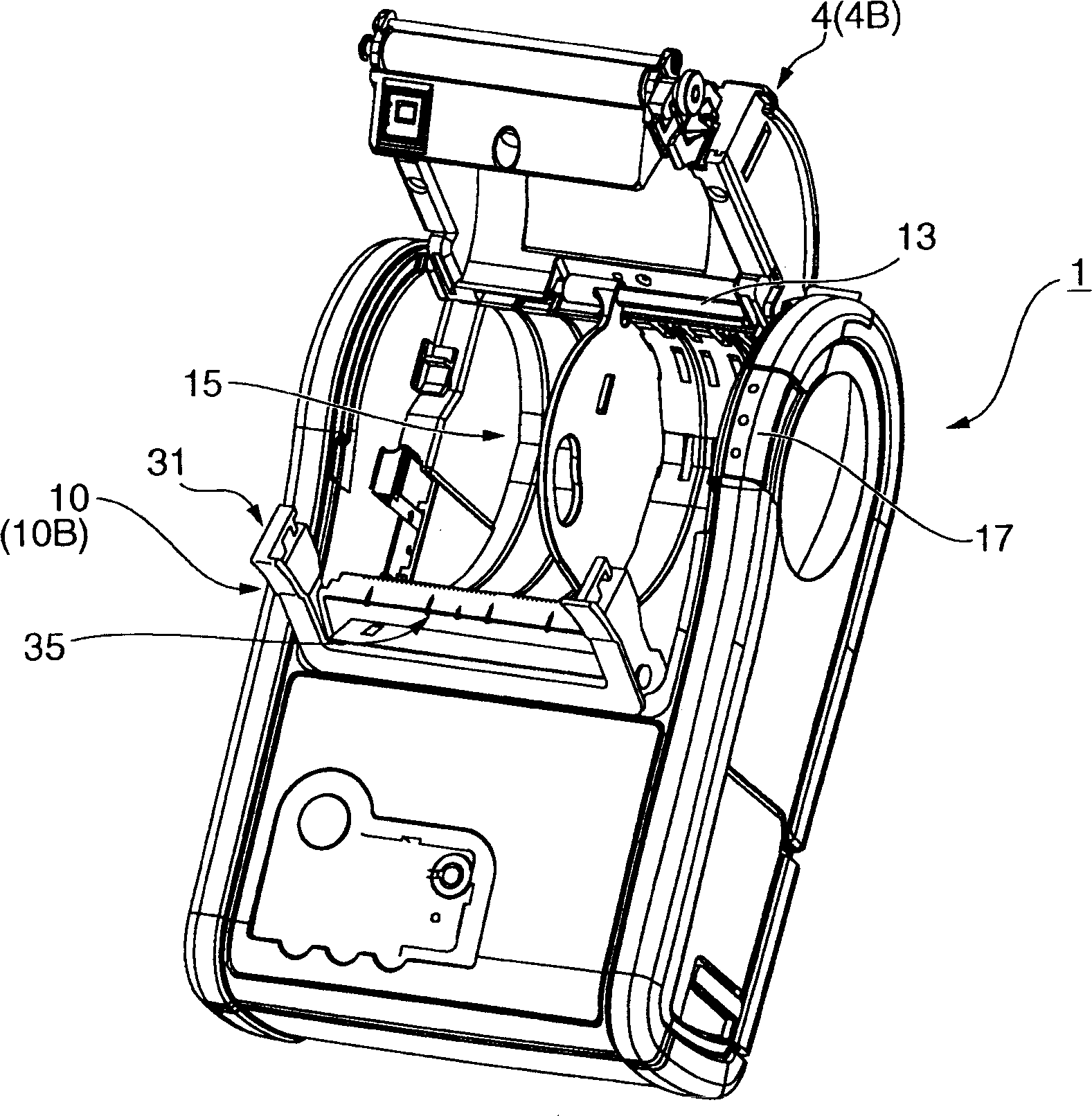

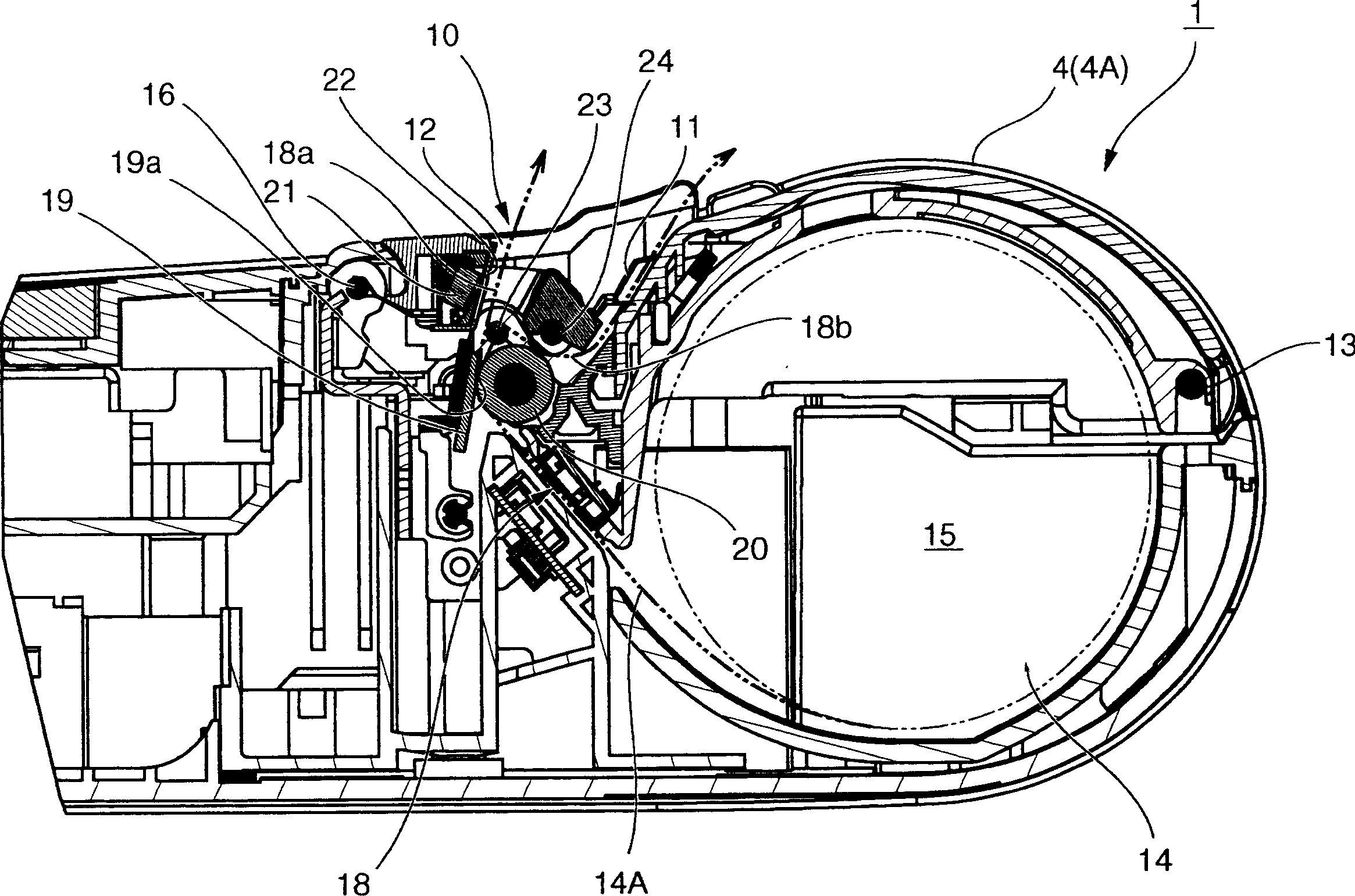

[0052] figure 1 is a perspective view of a printer with a peeling mechanism according to an embodiment of the present invention, figure 2 is showing figure 1 Oblique view of the printer with the middle open / close cover open, image 3 is a sectional view showing a recording medium (roll paper, label, and roll paper) transport path, Figure 4 is a cross-sectional view showing the transport path of the recording medium with the open / close cover opened. The general arrangement of a printer with a peeling mechanism according to the present invention will be described below with reference to these drawings.

[0053] The printer with the peeling mechanism 1 according to this embodiment of the invention has a relatively flat box-like shape, such as figure 1 As shown in, front to back is longer than width. An opening / closing cover 4 and an openable peeling unit 10 are provided on the rear top of the printer casing 2 of the printer with the peeling mech...

Embodiment 2

[0106] See below Figure 10 to Figure 15 A printer with a peeling mechanism according to a second embodiment of the present invention is described.

[0107] *Overall structure

[0108] Figure 10 is an external oblique view of a printer with a peeling mechanism according to this embodiment of the present invention, Figure 11 is a perspective view showing the printer with the open / close cover opened and the bottom of the printer case removed, and Figure 12 is a cross-sectional view showing the transport path of recording media (rolled paper, labels, and rolled paper). The overall arrangement of this embodiment according to the present invention will be described below with reference to these figures.

[0109] The basic arrangement of the printer with the peeling mechanism 100 according to this embodiment of the present invention is the same as that of the printer with the peeling mechanism 1 according to the first embodiment, and as Figure 10 Shown in , has a flatter bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com