Multifunctional mechanical jack

A multi-functional machine and jack technology, applied in the direction of lifting devices, etc., can solve the problems of laborious operation, performance not up to the level of the jack, easy damage, etc., and achieve the effects of avoiding potential safety hazards, wide application range, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

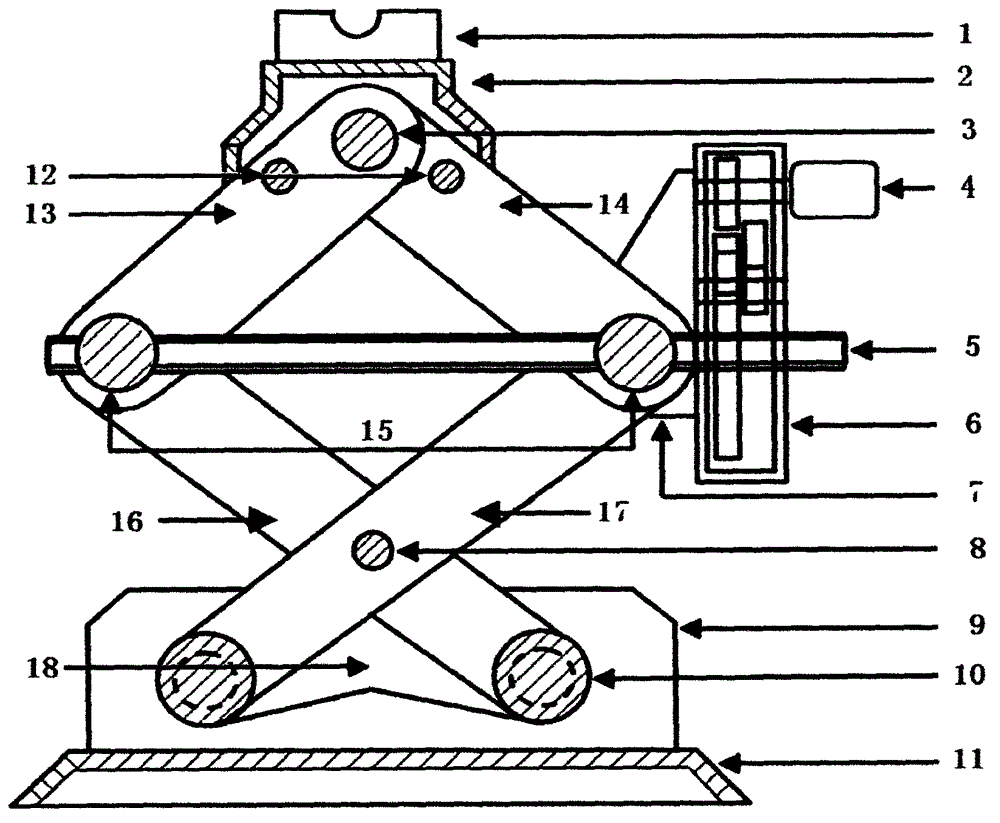

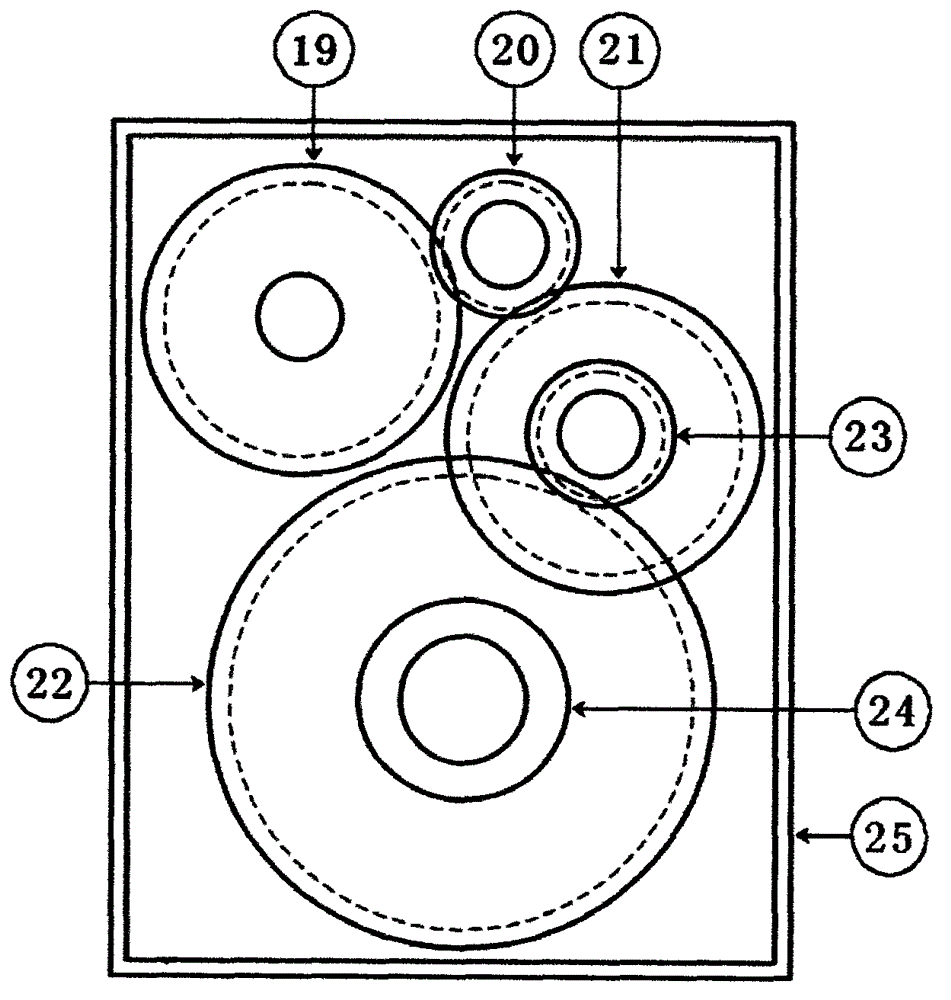

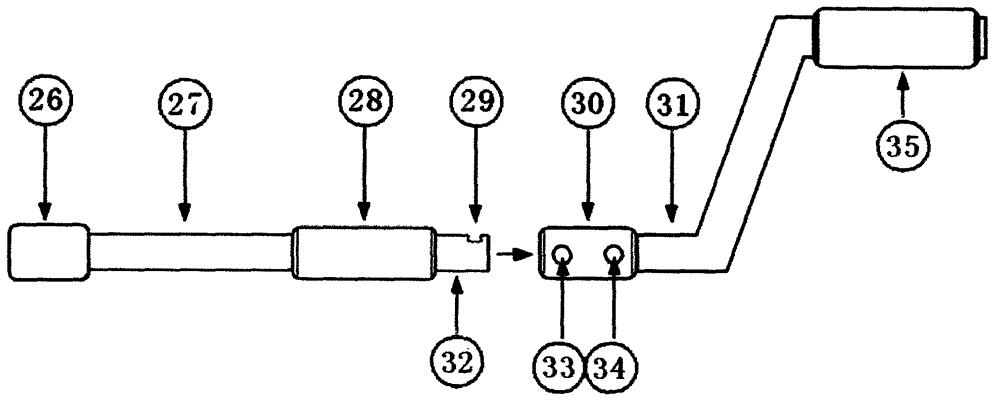

[0022] Below in conjunction with accompanying drawing, the multifunctional mechanical jack of the present invention is further explained

[0023] In this example, if figure 1 The inventive multifunctional mechanical jack shown includes a rubber top cap 1 and a base 11, which are made of high-quality iron plates in the shape of channel steel, divided into upper brackets, left 13, upper brackets, right 14, including lower brackets, left 16, lower brackets The right 17 is cross-hinged to the base 11 through the load-bearing shaft 15, the upper bracket is connected to the top cap 2 to generate automatic positioning support, and the bottom of the lower bracket is designed with 4 pulleys 10 evenly placed on the bottom of the lower bracket, through the chute 18 to achieve automatic alignment and balance As a result, there is a bracket shaft hole in the middle of the connection between the upper and lower brackets to pass through the screw rod 5, the screw rod is fixed on the load-bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com