Floor scrubber dry sweep apparatus

A technology for scrubbers and floors, applied in the field of surface devices, can solve problems such as debris clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

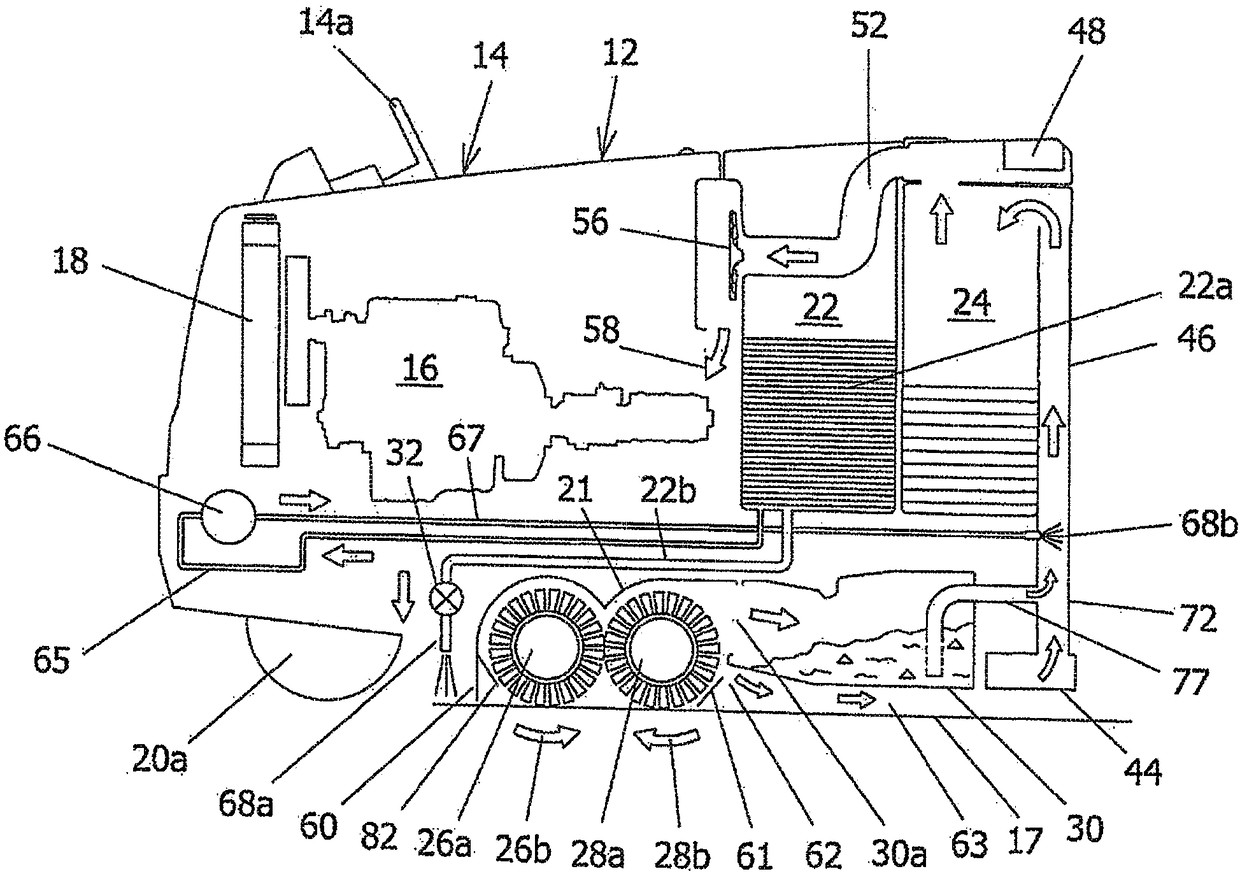

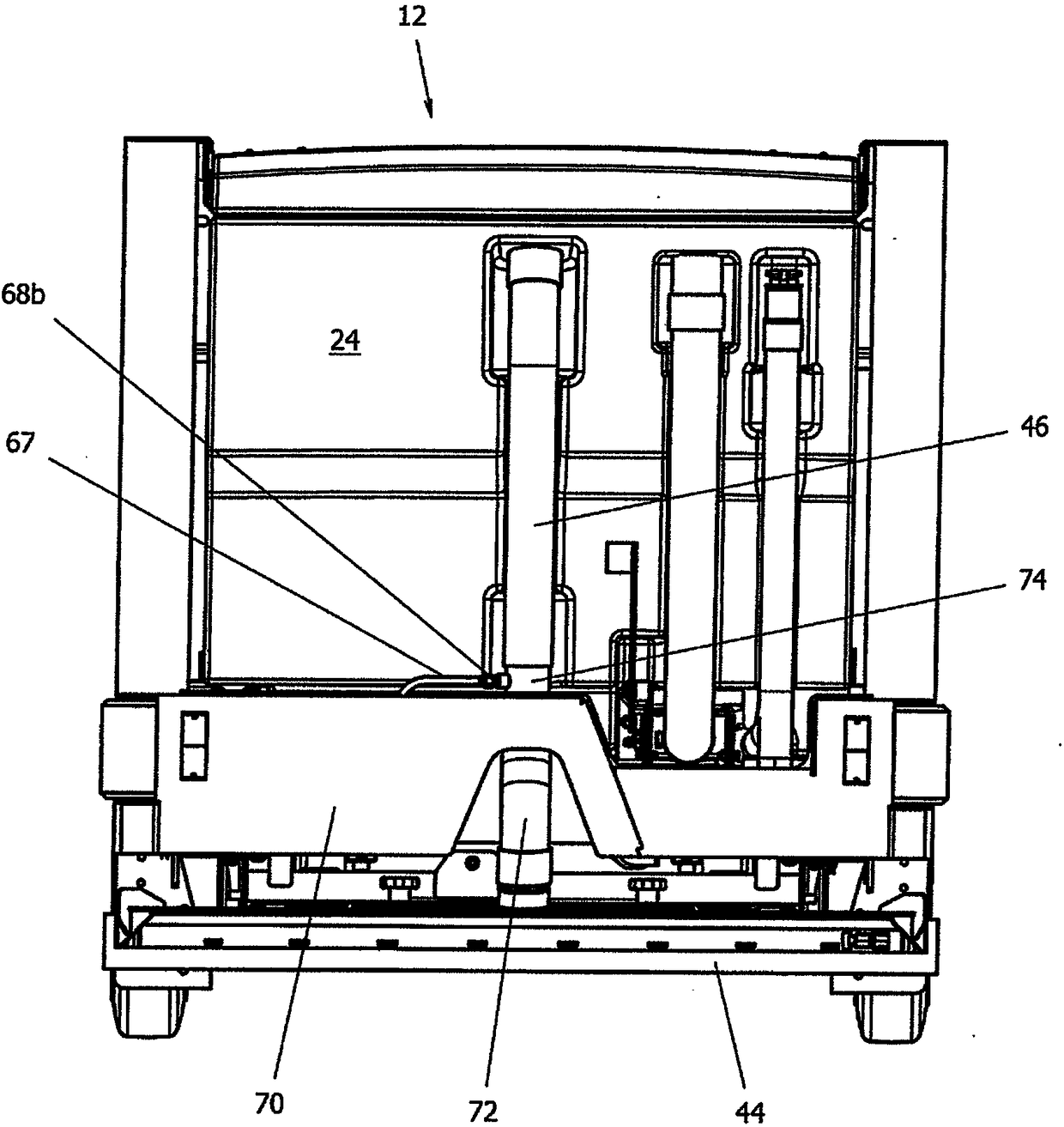

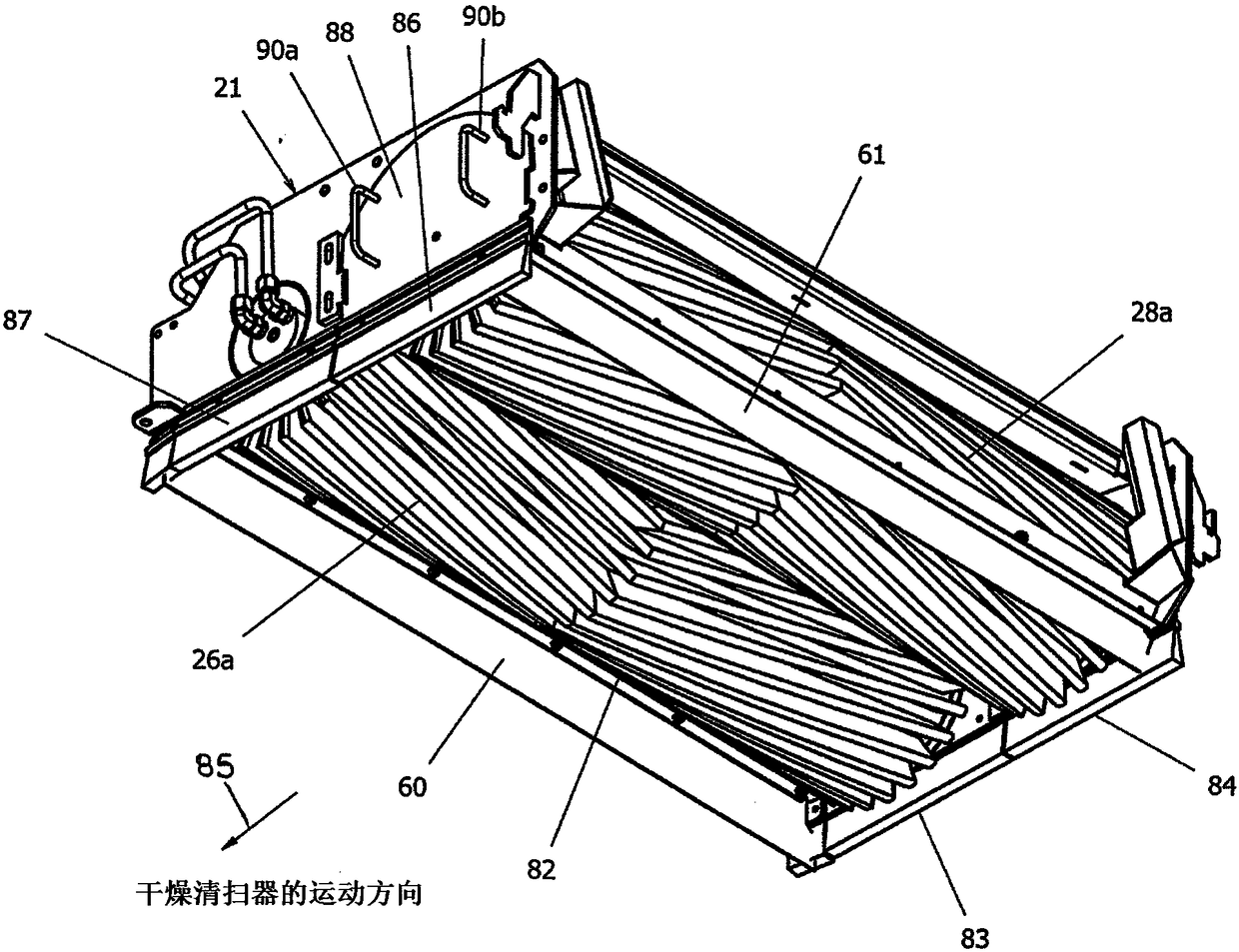

[0017] refer to figure 1 , shows a vertical cross-sectional view of a combined floor sweeper and scrubber unit 12 according to the present invention taken along the length of the unit. figure 2 is the overall plan view of the tail of the creative floor scrubber drying and sweeping device 12, and image 3 is a perspective view of the bottom of the device showing the wash head 21 comprising first front and second rear rotating wash brushes 26a and 28a. The combined floor sweeper and scrubber unit 12 includes a chassis 14 that includes the various components and systems described in the following paragraphs. For example, the device includes a steering wheel 14a, a plurality of wheels, of which one of the front wheels is shown as an element 20a deployed on and engaged with the floor 17 . In addition, the combined floor sweeper and scrubber unit 12 also includes: an engine 16 for moving the position of the sweeper and scrubber unit on the floor 17; and a radiator 18 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com